Method for controllably preparing three-dimensional graphene carbon nano-tube composite material

A technology of carbon nanotubes and composite materials, which is applied in the field of controllable synthesis of three-dimensional graphene/carbon nanotube composite materials, can solve the problems of unmentioned pressure influence, large number of layers, and low graphene porosity, etc. Realize the effects of controllable preparation, high degree of crystallization and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

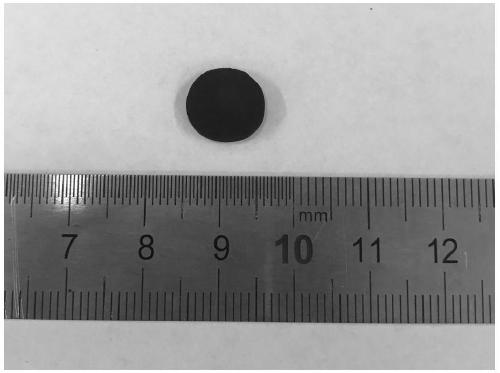

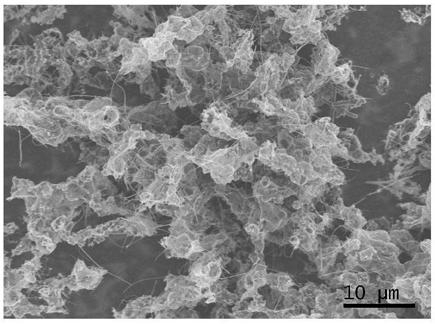

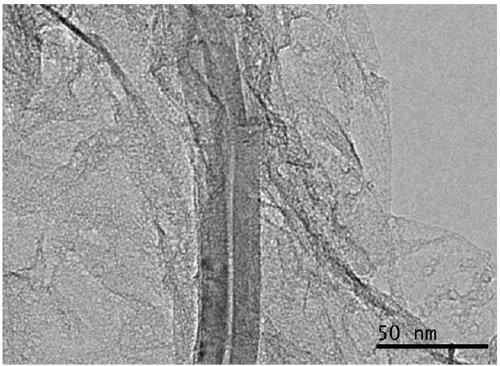

[0023] Add 3g of nickel powder and 0.4g of sucrose into 150mL of distilled water, and at the same time, ultrasonically treat the multi-walled carbon nanotubes and the surfactant at a ratio of 1:1 to obtain a carbon nanotube dispersion, and then add the mixed solution of nickel powder and sucrose In the process, the beaker was placed on a flat heating table, mechanically stirred at 90°C until evaporated to dryness, then placed in a vacuum oven at 80°C, dried for 12 hours, and then ground into powder. Place the powder in a quartz boat, shake it to make the powder flat, and then 2 Under the atmosphere, the temperature was raised to 1000°C at a heating rate of 10°C / min, and then kept at a temperature of 30 minutes. Purified with distilled water, and finally dried to obtain a three-dimensional graphene / carbon nanotube composite.

Embodiment 2

[0025] Add 3g of nickel powder and 1g of sucrose into 150mL of distilled water, and at the same time, ultrasonically treat the multi-walled carbon nanotubes and the surfactant in a ratio of 1:2 to obtain a carbon nanotube dispersion, and then add the mixed solution of nickel powder and sucrose , put the beaker on a flat heating table, mechanically stir at 80°C until it evaporates to dryness, then put it in a vacuum oven at 100°C, dry it for 12h, and then grind it into powder. The prefabricated powder was compacted using a pressure of 500MPa, the bulk material was placed in a quartz boat, and then heated under 10sccmAr and 500sccmH 2 Under the atmosphere, the temperature was raised to 600°C at a heating rate of 10°C / min, and then kept for 2 hours, and then the quartz boat was quickly pulled out to the low temperature area for rapid cooling, and then it was etched until the color of the etching solution no longer changed, and then used Purified with distilled water, and finally ...

Embodiment 3

[0027] Add 3g of nickel powder and 3g of sucrose into 150mL of distilled water, while ultrasonically treating the multi-walled carbon nanotubes and the surfactant at a ratio of 1:4 to obtain a carbon nanotube dispersion, and then add the mixed solution of nickel powder and sucrose , put the beaker on a flat heating platform, mechanically stir at 50°C until it evaporates to dryness, then put it into a vacuum oven at 50°C, dry it for 12h, and then grind it into powder. The prefabricated powder was compacted using a pressure of 1120MPa, the bulk material was placed in a quartz boat, and then heated under 200sccmAr and 10sccmH 2 Under the atmosphere, the temperature was raised to 800°C at a heating rate of 10°C / min, and then kept at a temperature of 5 hours. Purified with distilled water, and finally dried to obtain a three-dimensional graphene / carbon nanotube composite.

[0028] Compared with CN106629668A and CN106185879A, self-supporting three-dimensional graphene / carbon nanotube...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com