Method for preparing activated carbon material with humic acid as raw material and application of activated carbon material

A technology for preparing activated carbon and humic acid, applied in chemical instruments and methods, other chemical processes, inorganic chemistry, etc., can solve problems such as difficulty in ensuring the reproducibility of activated carbon, shrinkage of wood and charcoal sources, and limitation of activated carbon raw materials, etc. The effect of low cost, large reserves and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Mix the humic acid and the activator potassium hydroxide uniformly in a mass ratio of 1:3, then transfer to a high-temperature furnace, and react at a temperature of 800°C for 1 hour under the protection of an inert atmosphere of nitrogen;

[0029] Then cool, wash with 2M dilute hydrochloric acid solution until the pH value is 6-7, and dry to obtain humic acid porous activated carbon material;

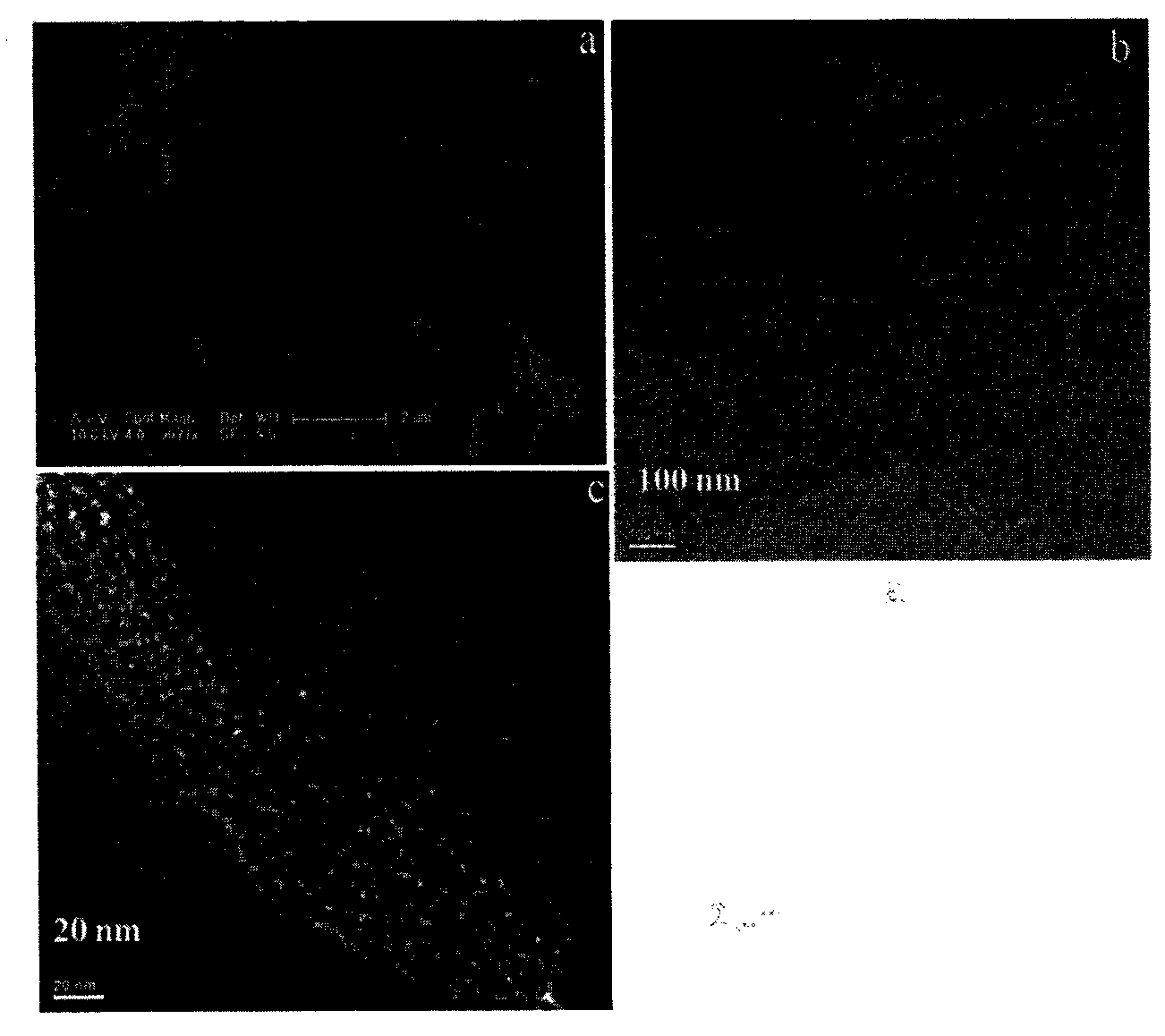

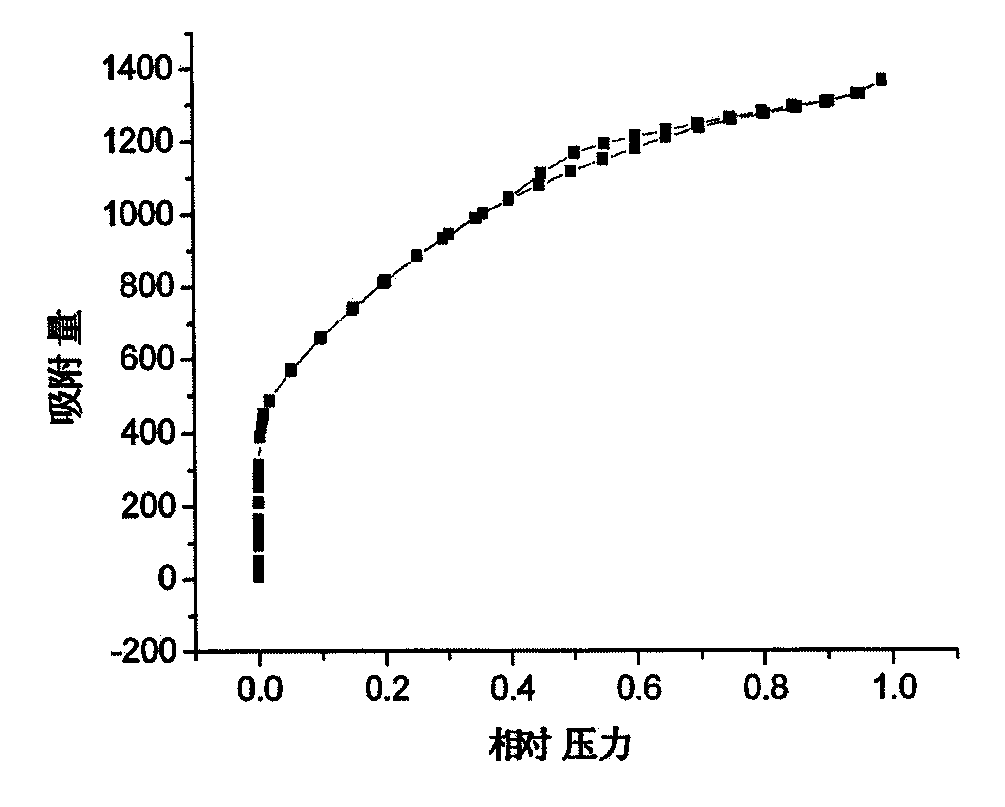

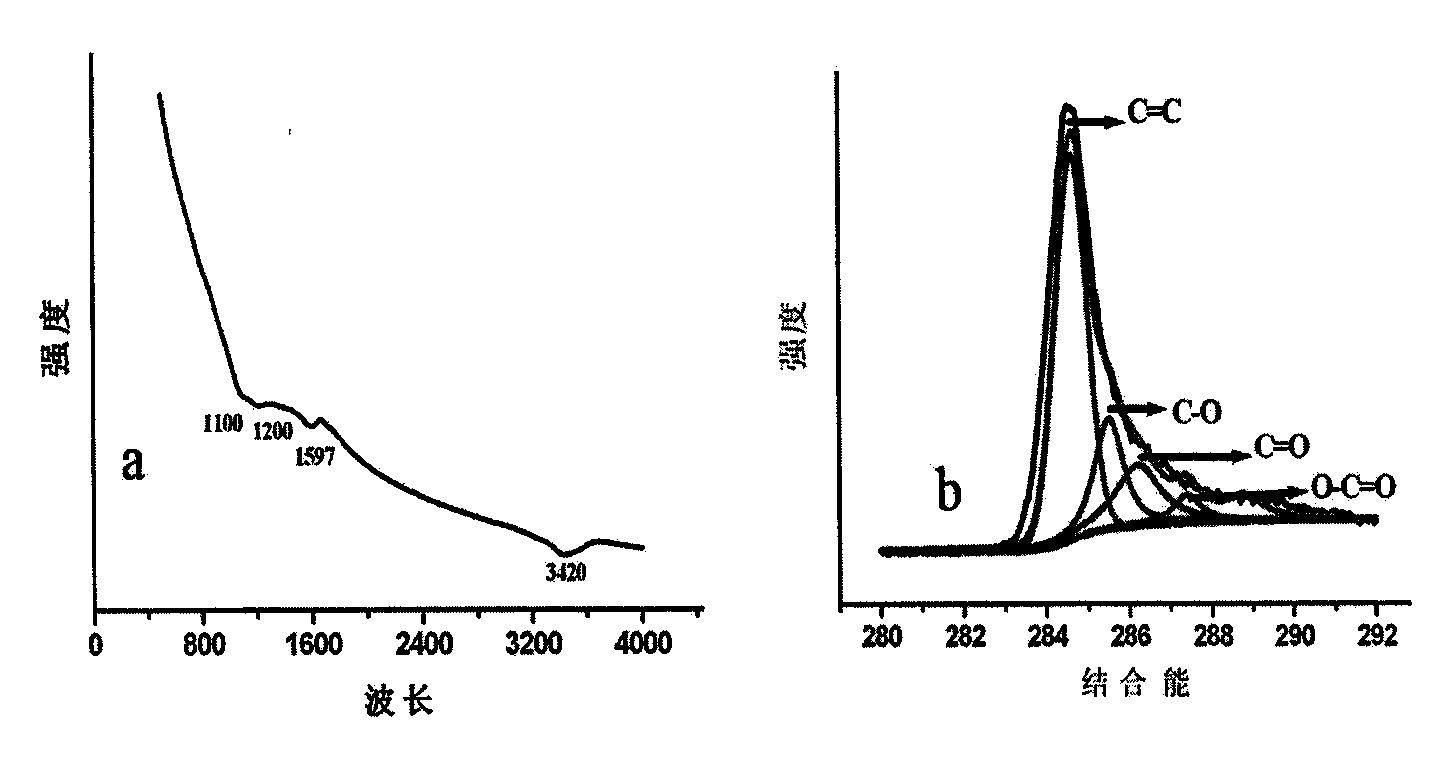

[0030] Utilize scanning electron microscope, transmission electron microscope, infrared, elemental analyzer, carry out the characterization result of physicochemical property to obtained humic acid porous activated carbon material see figure 1 , figure 2 and image 3 , carried out adsorption test and supercapacitor test on the obtained humic acid porous activated carbon material, the results are shown in Figure 4 and Figure 5 ;

[0031] figure 1 , figure 2 and image 3 The results show that the obtained humic acid porous activated carbon material has a specific surfac...

Embodiment 2

[0033] Mix humic acid and zinc chloride uniformly in a mass ratio of 1:4, transfer to a high-temperature furnace, and react at a temperature of 500°C for 2 hours under the protection of an inert atmosphere of nitrogen;

[0034] Then cool, wash with 2M dilute hydrochloric acid solution until the pH value is 6-7, and dry to obtain humic acid porous activated carbon material;

[0035] The specific surface area of humic acid porous activated carbon material obtained by nitrogen adsorption and desorption analysis and elemental analyzer detection is 1020m 2 g -1 , the pore size is mainly micro-mesopores smaller than 2-6nm; the mass percentage of elemental analysis is carbon 78.1%, oxygen 13%, nitrogen 0.9%. The adsorption iodine value is 800mg / g, the adsorption methylene blue value is 300mg / g, and the supercapacitor test result is 110Fg -1 .

Embodiment 3

[0037] Mix humic acid and sodium hydroxide evenly in a mass ratio of 1:4, transfer to a high-temperature furnace, and react at 600°C for 3 hours under the protection of an inert atmosphere of nitrogen;

[0038] Then cool, wash with 2M dilute nitric acid solution until the pH value is 6-7, and dry to obtain humic acid porous activated carbon material;

[0039] The specific surface area of humic acid porous activated carbon material obtained by nitrogen adsorption and desorption analysis and elemental analyzer detection is 2000m 2g -1 , the pore size is mainly micro-mesoporous; the mass percentage of elemental analysis is carbon 90.3%, oxygen 4.7%, nitrogen 0.4%; the adsorption iodine value is 1300mg / g, the adsorption methylene blue value is 400mg / g, and the supercapacitor test result is 210Fg -1 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com