High specific surface area graphene with well-developed mesopores, and preparation method thereof

A high specific surface, graphene technology, applied in the field of high specific surface graphene and its preparation, can solve the problems of weak reactivity of activator, and achieve the effects of shortening activation time, reducing production cost, and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] A preparation method of high specific surface graphene with well-developed mesopores, comprising the steps of:

[0060] (1) Take graphite oxide prepared by Hummers method, and obtain graphene oxide powder after microwave exfoliation;

[0061] (2) Weigh 500mg of the graphene oxide powder obtained in step (1) and KOH aqueous solution with a concentration of 45wt% at a ratio of 1:9 by weight, fully mix, stir, and dry;

[0062] (3) Place the mixture of graphene oxide and KOH obtained in step (2) in a vacuum tube furnace, after removing the air in the furnace, feed argon gas with a purity of 99.99% into the vacuum tube furnace at a flow rate of 100 sccm, First raise the temperature to 700°C, keep the temperature constant, then pass in saturated water vapor at a flow rate of 80 sccm, and react at 700°C for 60 minutes;

[0063] (4) After the reaction is completed, the temperature is naturally lowered to room temperature, washed, and dried to obtain a high specific surface gra...

Embodiment 2

[0070] A preparation method of high specific surface graphene with well-developed mesopores, comprising the steps of:

[0071] (1) Take graphite oxide prepared by Hummers method, and obtain graphene oxide powder after microwave exfoliation;

[0072] (2) Weigh 500mg of the graphene oxide powder obtained in step (1);

[0073] (3) Place the graphene oxide obtained in step (2) in a vacuum tube furnace, and after removing the air in the furnace, feed argon gas with a purity of 99.99% into the vacuum tube furnace at a flow rate of 100 sccm, and first raise the temperature to 600 ℃, keep the temperature constant, then feed saturated water vapor at a flow rate of 50 sccm, and react at a high temperature of 600 ℃ for 30 minutes;

[0074] (4) After the reaction is completed, the temperature is naturally lowered to room temperature, washed, and dried to obtain a high specific surface graphene material with well-developed mesopores.

[0075] Performance Testing:

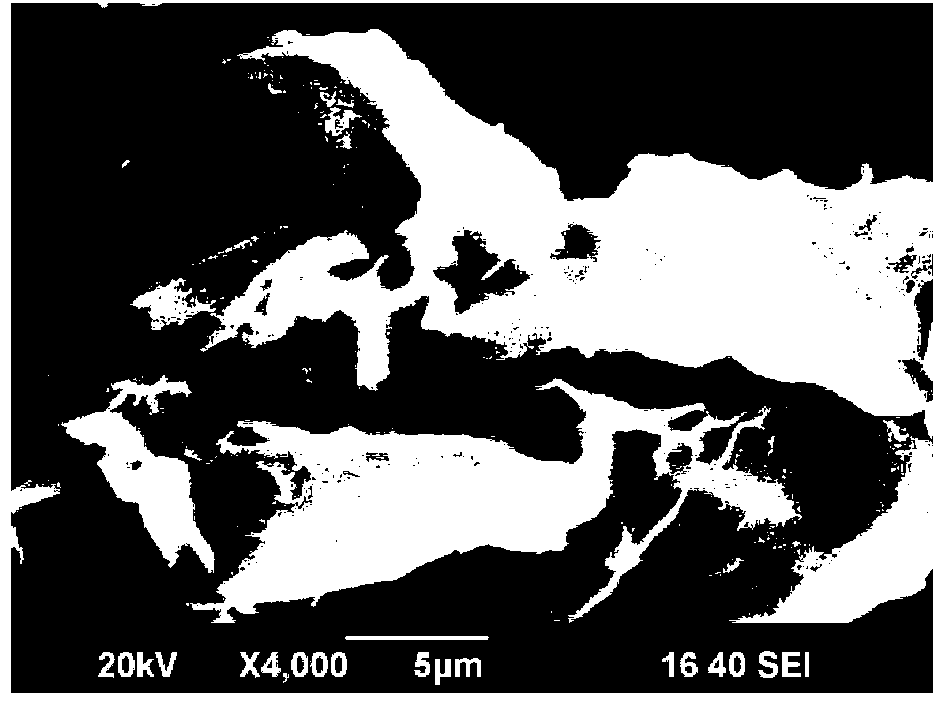

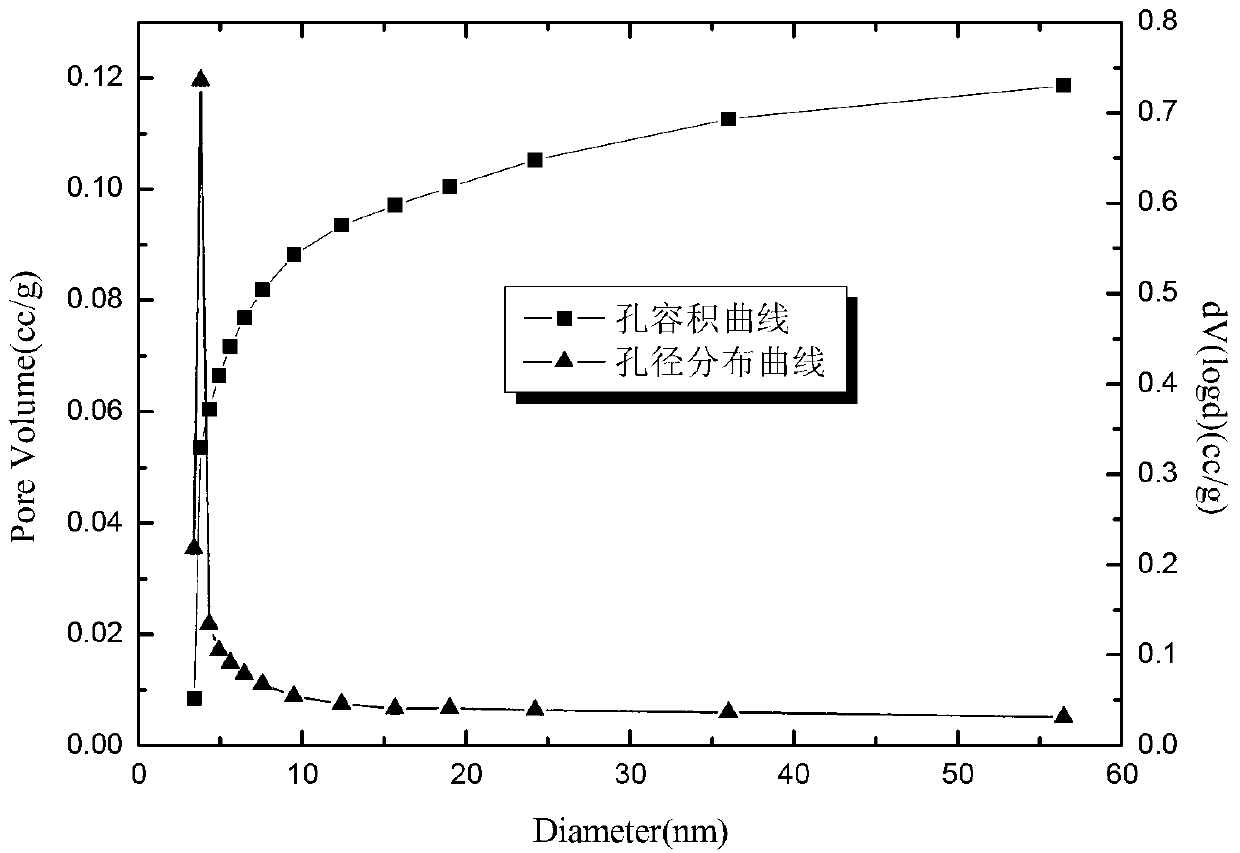

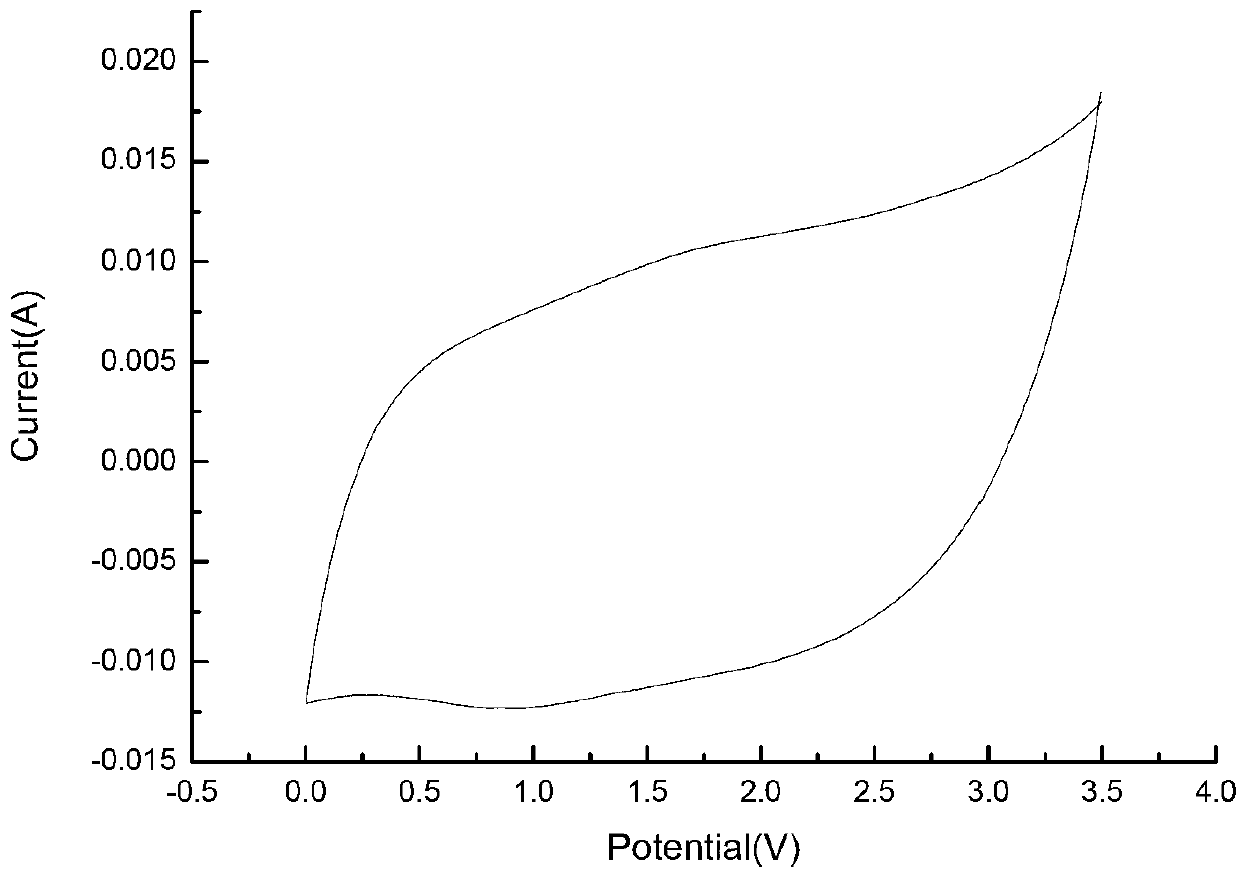

[0076] (1) For the SE...

Embodiment 3

[0081] A preparation method of high specific surface graphene with well-developed mesopores, comprising the steps of:

[0082] (1) Take graphite oxide prepared by Brodie method, and obtain graphene oxide powder after microwave exfoliation;

[0083] (2) Weigh 500mg of the graphene oxide powder obtained in step (1) and KOH aqueous solution with a concentration of 45wt% at a ratio of 1:1 by weight, fully mix, stir, and dry;

[0084] (3) Place the mixture of graphene oxide and KOH obtained in step (2) in a vacuum tube furnace. After removing the air in the furnace, 3 The flow rate per minute is to feed helium gas with a purity of 99.99% into the vacuum tube furnace, first raise the temperature to 500°C, keep the temperature constant, and then increase 3 Inject carbon dioxide gas at a flow rate of / min, then raise the temperature to 1800°C, and react at a high temperature of 1800°C for 30 minutes;

[0085] (4) After the reaction is completed, the temperature is naturally lowered ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com