Cigarette paper with lattice fringes and production method thereof

A production method and technology for cigarette paper, applied in the field of tobacco, can solve the problems affecting the strength index of cigarette paper, single appearance of cigarettes, etc., and achieve the effects of increasing novelty, improving strength index, and optimizing internal stress structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

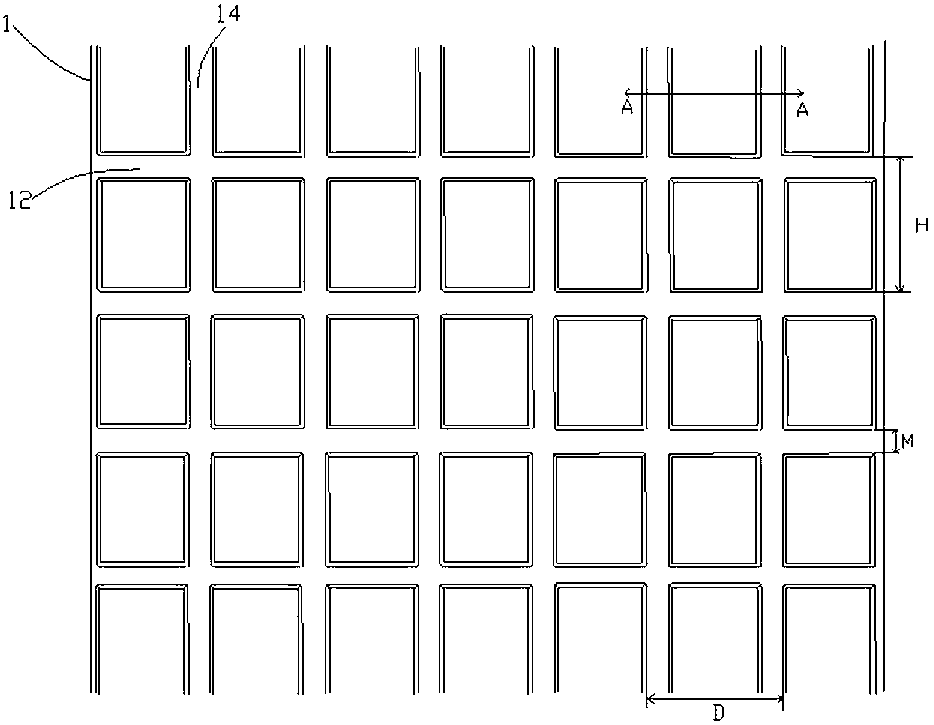

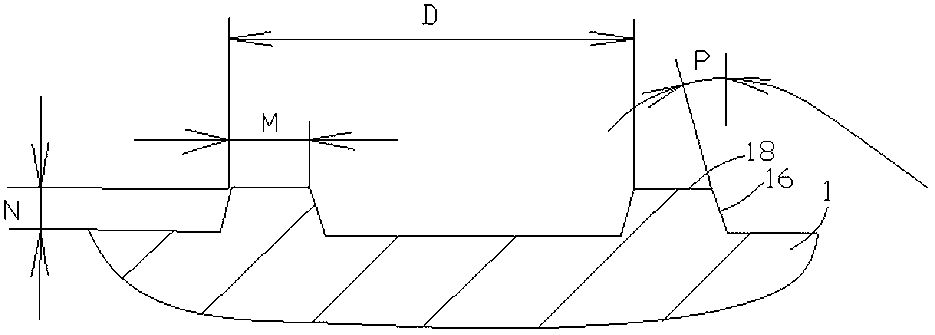

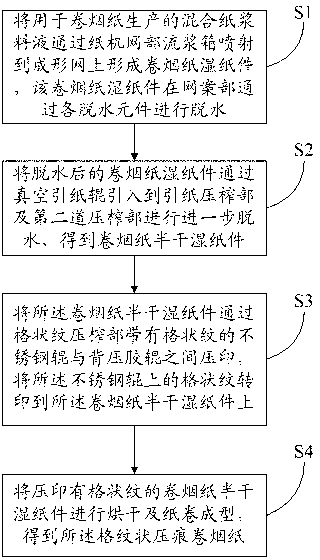

[0028] see figure 1 and figure 2 , the grid pattern cigarette paper of the present invention includes a paper body 1, and the paper body 1 is embossed with a plurality of intersecting first direction indentations 12 and second direction indentations 14 through a grid pattern stainless steel roller and a back pressure rubber roller , the indentation 12 in the first direction is perpendicular to the indentation 14 in the second direction, and the spacing H between the indentations 12 in the adjacent first direction is 1.3 mm, and the indentation 14 in the adjacent second direction The distance D between the first and second direction indentations 12 and 14 is 1.1mm, the indentation width M of the first direction indentation 12 and the second direction indentation 14 is 0.22mm, and the indentation depth of the first direction indentation 12 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com