Pulp, pulp manufacturing method, body paper and papermaking method

A technology of pulp and pulp, which is applied in the field of pulp, base paper and papermaking, and can solve the problems of low filler retention rate, inability to fully exert the short fiber adsorption force, and inability to exert the strength of long fiber paper, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

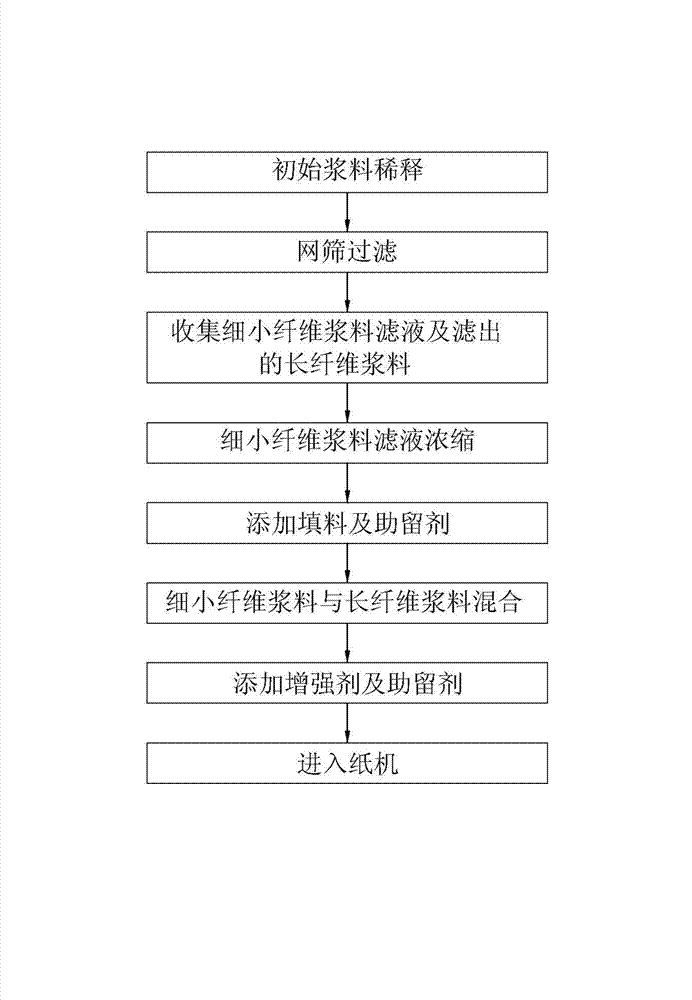

[0029] The technical solution also provides a pulp preparation method comprising the above steps (1) to (7). Of course, those skilled in the art can understand that the above step (7) is not a necessary step.

[0030] The technical solution also provides a kind of pulp prepared by the pulp preparation method above, the pulp includes fillers, short fibers with a length less than or equal to 180 microns and long fibers with a length greater than 180 microns, and the fillers with a mass content of more than 60% are adsorbed on Short fiber surface.

no. 1 example

[0032] The first embodiment: 100g dry weight of hardwood chemical pulp through beating is diluted to 0.5% mass concentration, filtered through an 80 mesh screen, the filtrate is collected in a bucket, and the supernatant is poured out after the filtrate is precipitated, and concentrated Finally, get short fiber slurry with a mass concentration of 5%, add filler light calcium carbonate, the absolute dry weight is 10g, stir evenly, then add 2g of retention aid, the retention aid is 0.2% cationic polyacrylamide , stir well, and mix for 45 minutes. Mix the short-fiber slurry with the long-fiber slurry sieved out of the sieve, and then add 25g of a reinforcing agent, which is cationic starch with a mass concentration of 4%, mix evenly, and then add 8g of cationic polyacrylamide with a concentration of 0.2%, Stir evenly and make slices. For comparison, a blank sample was carried out at the same time, that is, according to the existing papermaking method, 10 g of light calcium carbo...

no. 2 example

[0034] The second embodiment: the mass ratio of softwood chemical pulp: hardwood chemical pulp=30:70 mixed slurry dry weight 80g through beating is diluted to 0.5% mass concentration, filtered by 80 mesh screens, and the filtrate Collect it in a bucket, pour off the supernatant after the filtrate is precipitated, and after concentrating, obtain a short fiber slurry with a mass concentration of 4.5%, add 10g of filler light calcium carbonate dry weight, stir evenly, and then add retention aid 1.6g, the retention aid is a cationic polyacrylamide with a mass concentration of 0.2%, stir evenly, and mix for 30 minutes. Mix the treated short-fiber pulp with the sieved long-fiber pulp, then add 20 g of reinforcing agent, which is cationic starch with a mass concentration of 4%, stir evenly, and then add cationic polypropylene with a mass concentration of 0.2% Amide 6.4g, stir evenly, make tablets. For contrast, carry out a blank sample simultaneously, promptly according to existing ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mesh | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com