Production process of ABS valve body material for cars

A production process and valve body technology, which is applied in the production process field of ABS valve body materials for automobiles. Intense shear deformation of the surface of the ingot, etc., to save energy and time, high uniformity, and optimize the alloy composition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

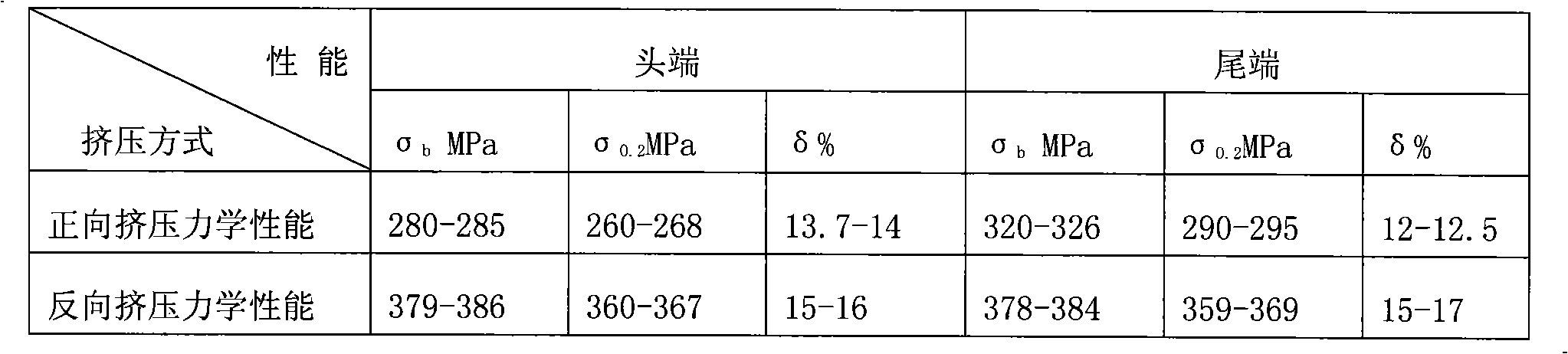

[0039] The complete set of technology of the present invention has been implemented on a complete production line consisting of 45MN double-action reverse extruder, 200T tension leveler and other auxiliary equipment.

[0040] Taking the production of ABS valve body material for automobiles with a specification of 101×43.6mm as an example, the specific steps are as follows:

[0041] The production calculates the amount of aluminum ingots, intermediate alloys, pure metals and aluminum scrap according to the proportioning plan of the chemical composition, and then carries out furnace smelting. The smelting temperature is about 740°C and the smelting time is about 7 hours;

[0042] 6061 alloy chemical composition optimization adjustment data are: Si 0.45~0.50%, Fe 0.30~0.40%, Cu 0.35~0.40%, Mn≤0.15%, Mg 0.95~1.05%, Cr 0.20~0.25%, Zn≤0.20%, Ti ≤0.10%, other impurities are not more than 0.05% individually, and the total is not more than 0.10%, aluminum is the balance; when preparing...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com