Preparation of crystal grain size controllable bimodal distribution block superfine/nanocrystalline alloy

A nanocrystalline alloy, bimodal distribution technology, applied in the field of metal materials, can solve the problems of difficult control of process parameters, poor reproducibility, complex process, etc., and achieve the effect of easy realization, simple realization and high strength index.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

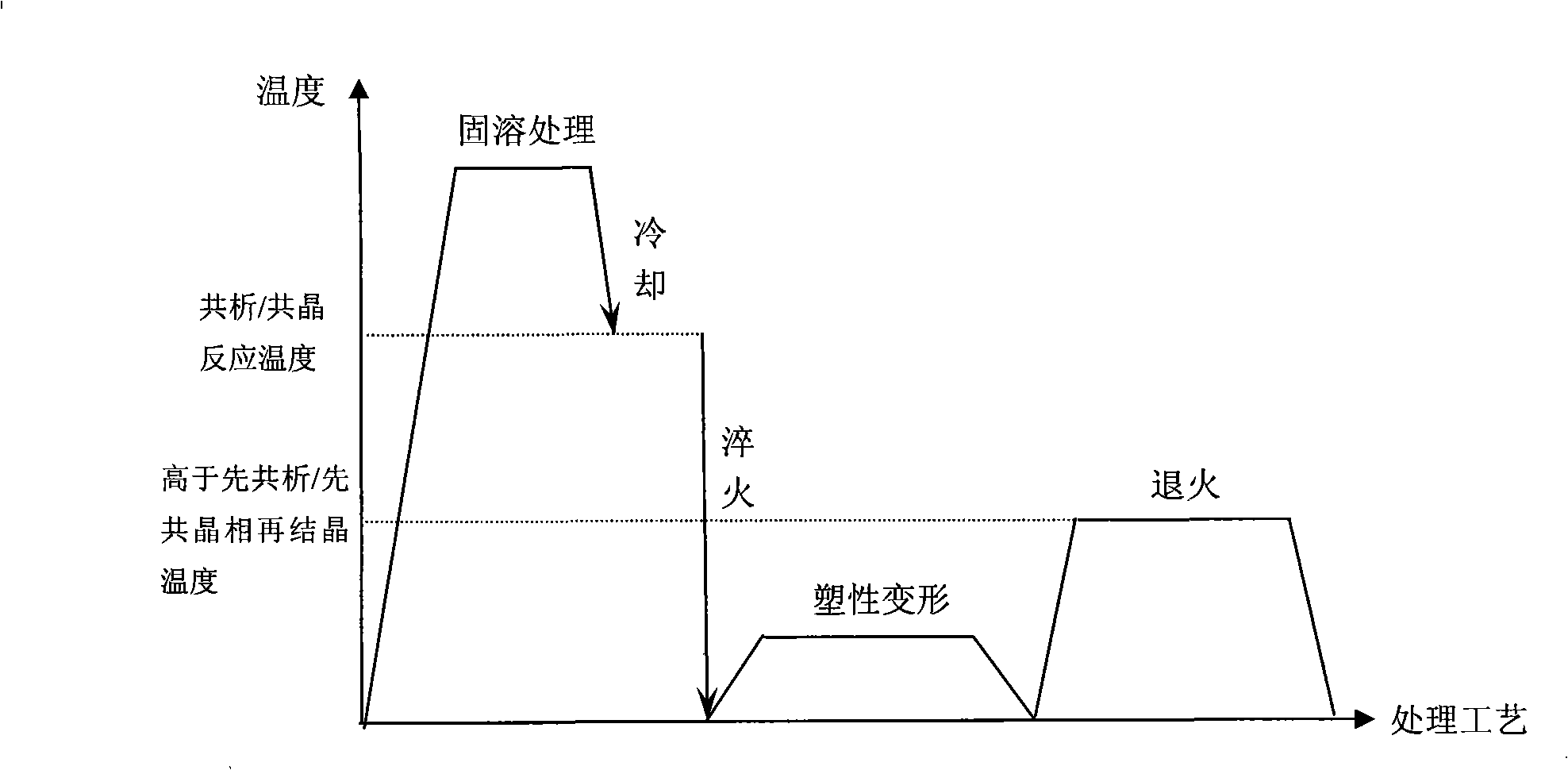

[0021] to combine figure 2 , the preparation method of the bulk ultrafine / nanocrystalline alloy with controllable bimodal distribution of grain size in the present invention utilizes the control and improvement effects of alloying, solid-state phase transformation treatment and plastic deformation on the structure, and obtains a bimodal alloy with grain size Bulk nanocrystalline materials with peak distribution characteristics provide a new way to solve the high-strength and low-plasticity defects of bulk nanocrystalline materials, including the following steps:

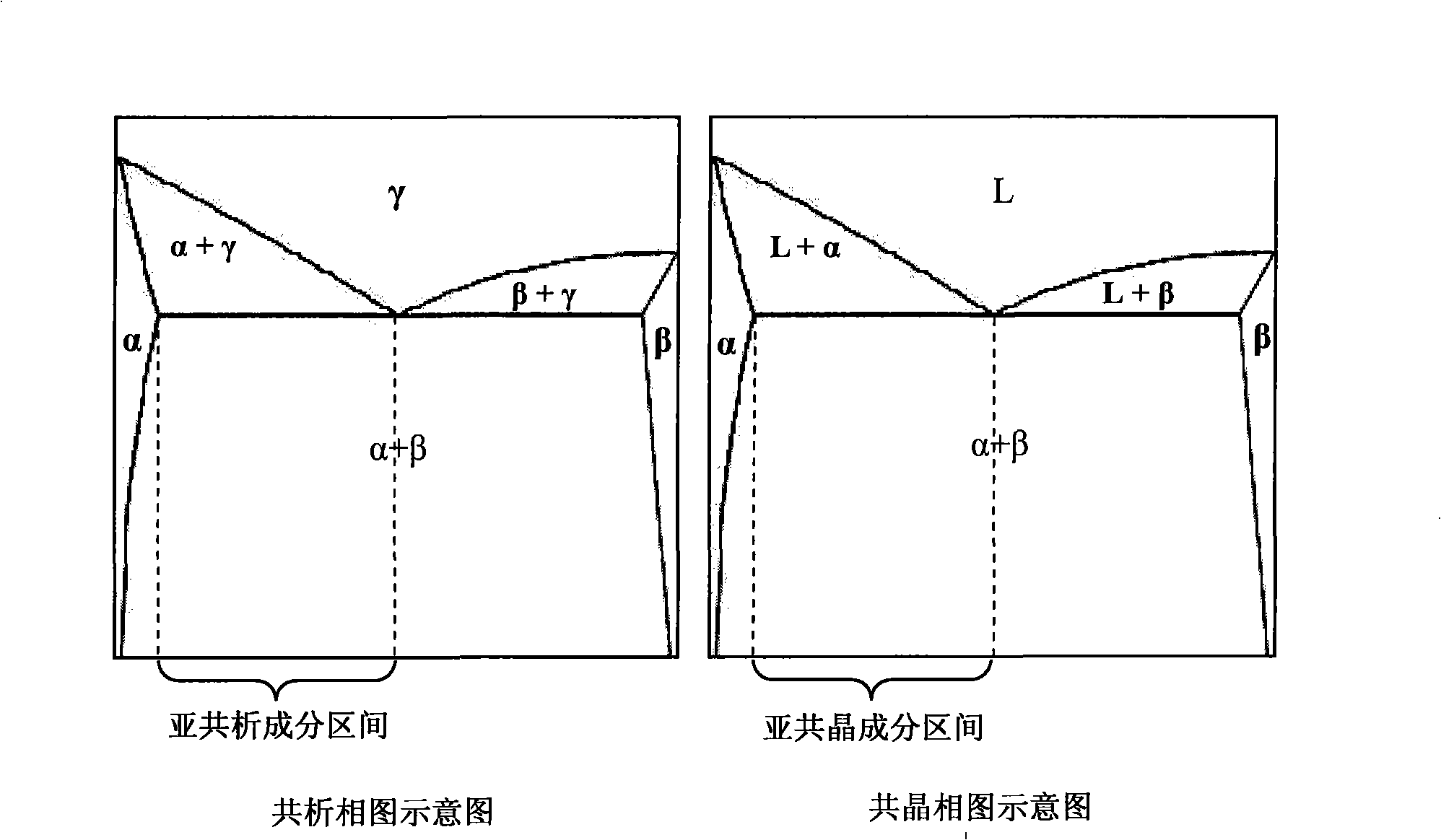

[0022] (1) Select a two-phase eutectoid or eutectic system, by figure 1 The phase diagram shown is calculated in combination with the lever law, and in the hypoeutectoid / hypoeutectic composition range (according to the characteristics of the proeutectoid / proutectic phase, the alloy composition can also be selected in the hypereutectoid / hypereutectic region) through a reasonable Select the alloy composition and quan...

Embodiment 1

[0027] Example 1: Preparation of Cu-10.8%Al hypo-eutectoid alloy.

[0028] Alloy composition (percentage by weight): 10.8% Al, impurity elements less than 0.02%, and the rest being Cu. The pro-eutectoid phase proportion of the hypo-eutectoid alloy calculated by the lever law is 40%.

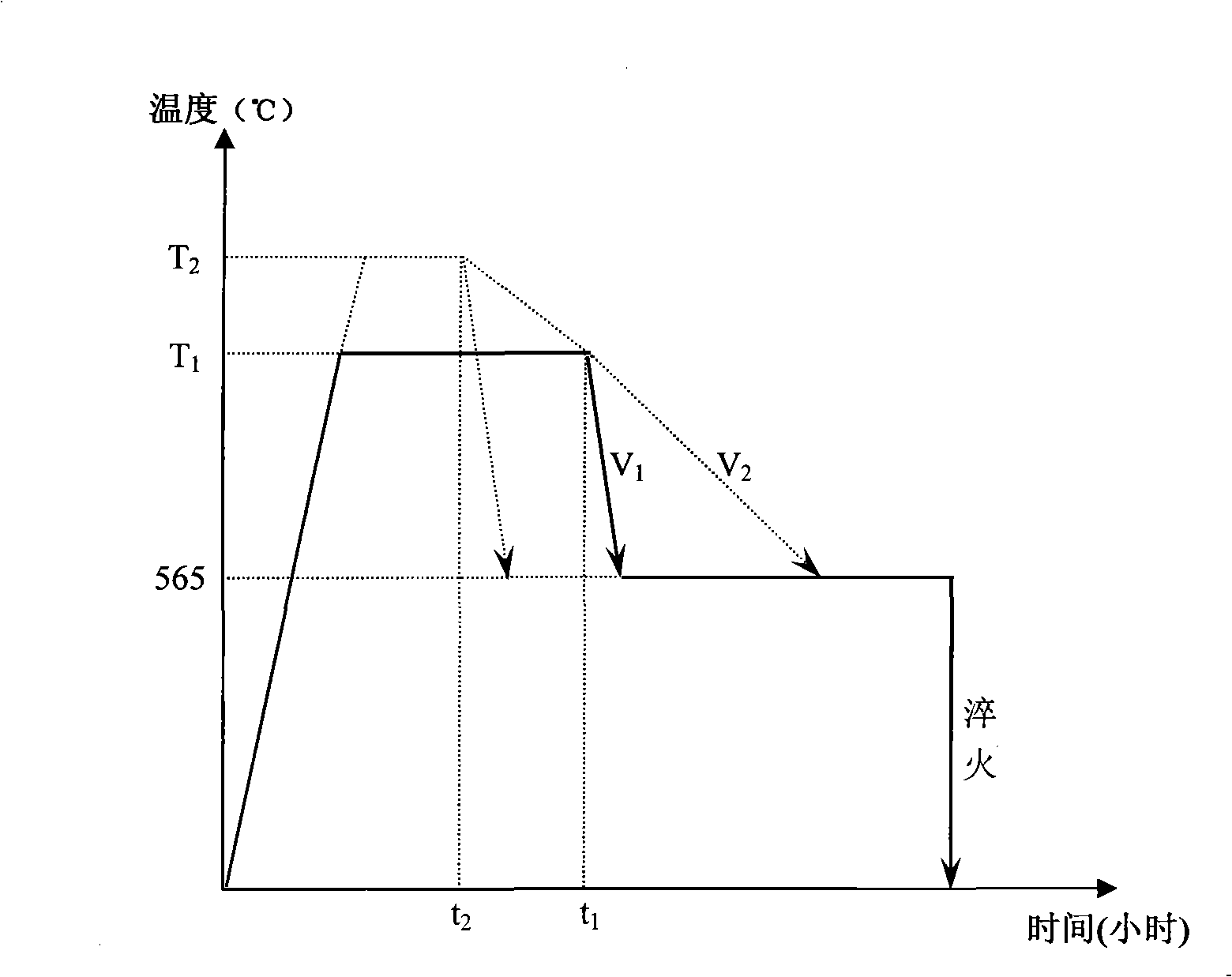

[0029] The specific steps of the preparation process of copper-aluminum alloy with bimodal distribution structure of controllable grain size are as follows: (1) After determining and selecting the above-mentioned components, a melting method is used to obtain an alloy ingot with uniform composition and structure. (2) Perform phase change treatment: place the sample in a heating furnace at 850°C for 2 hours to make the alloy uniformly solid solution, then cool (cooling rate V 1 =2~3°C / min) to eutectoid reaction temperature 565°C, water quenching immediately (process route such as image 3shown by the solid line). To change the distribution of the proeutectoid phase, you can pass (eg image 3 d...

Embodiment 2

[0031] Example 2: Preparation of Zn-41%Al hypoeutectoid alloy.

[0032] Alloy composition (percentage by weight): 41% Al, impurity elements less than 0.01%, and the rest being Zn. The pro-eutectoid phase proportion of the hypo-eutectoid alloy calculated by the lever law is 40%.

[0033] The specific steps of the preparation process of zinc-aluminum alloy with bimodal distribution structure of controllable grain size are as follows: (1) After determining and selecting the above-mentioned components, adopt a melting method to obtain an alloy ingot with uniform composition and structure. (2) Perform phase change treatment: place the sample in a heating furnace at 360°C for 24 hours to make the alloy uniformly solid solution, and then cool (the cooling rate is respectively selected V 1 =2~3℃ / min, V 2 =20~30°C / min) to the eutectoid reaction temperature of 275°C, immediately water quenched. (3) After the eutectoid phase transformation treatment, the grains of the sample were refi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| recrystallization temperature | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com