Method for preparing metallurgical coke

A technology for metallurgical coke and dry quenching, which is used in coke ovens, special forms of dry distillation, and petroleum industry. Product index performance and the effect of improving coke quality index

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

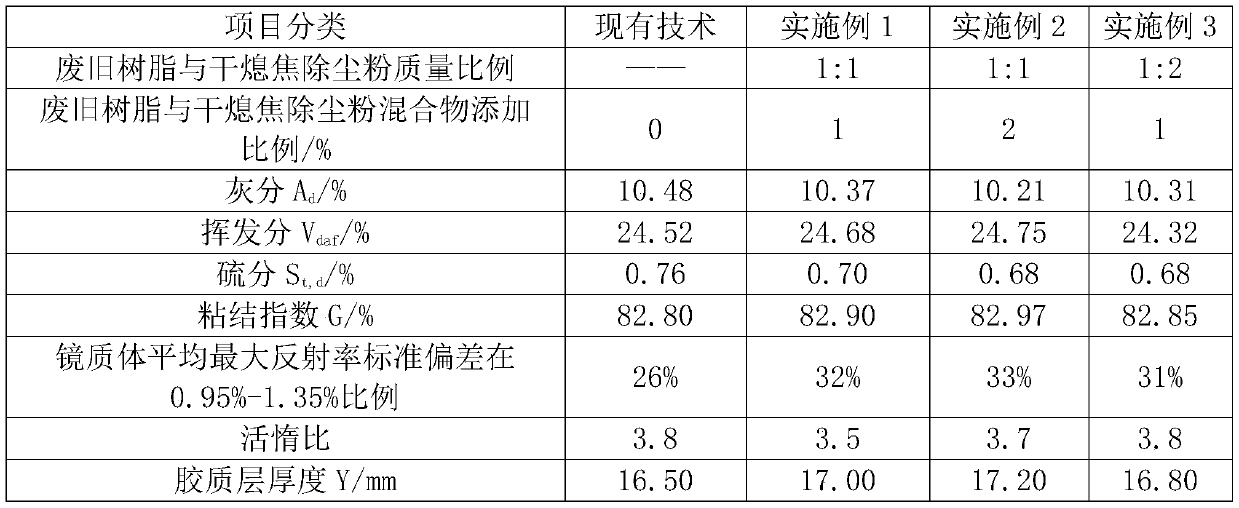

Embodiment 1

[0023] A method of preparing metallurgical coke, comprising:

[0024] 1) Raw materials are mixed coal, waste resin, CDQ dust removal powder; waste resin is filter resin after use, waste resin index requirements: moisture less than 14.5%, ash content 2.5%-5%, volatile content 70%-77% , Sulfur content is 0.2%-0.5%, CDQ dust removal powder index requirements: moisture is less than 1%, ash content is 10%-13%, volatile content is 1%-3%, sulfur content is 0.5-0.9%;

[0025] 2) Centrally recover the waste resin, and carry out grinding treatment through crushing equipment such as a pulverizer or a ball mill, and the pulverization treatment makes the particle size less than 3mm;

[0026] 3) According to the mass ratio of 1:1, fully mix the waste resin and CDQ dust removal powder, formulate and make balls, the diameter of the balls is 1-3cm, the index of the mixed balls is: the water content is less than 8%-11%, A d 4%-7%, V d 20%-22%, S t,d 0.5-0.7%;

[0027] 4) Grinding and mixing...

Embodiment 2

[0030] A method of preparing metallurgical coke, comprising:

[0031] 1) Raw materials are mixed coal, waste resin, CDQ dust removal powder; waste resin refers to petrochemical plastic resin, waste resin index requirements: moisture less than 14.5%, ash content 2.5%-5%, volatile content 70%-77% , Sulfur content is 0.2%-0.5%, CDQ dust removal powder index requirements: moisture is less than 1%, ash content is 10%-13%, volatile content is 1%-3%, sulfur content is 0.5-0.9%;

[0032] 2) Centrally recover the waste resin, and carry out grinding treatment through crushing equipment such as a pulverizer or a ball mill, and the pulverization treatment makes the particle size less than 3mm;

[0033] 3) According to the mass ratio of 1:1, fully mix the waste resin and CDQ dedusting powder, formulate and make balls, the diameter of the balls is 1-3cm, and the indicators of the mixed balls are: the water content is less than 8%-11%, and the ash content is 4 %-7%, volatile content 20%-22%...

Embodiment 3

[0037] A method of preparing metallurgical coke, comprising:

[0038] 1) The raw materials are mixed coal, waste resin, CDQ dust removal powder; the waste resin is chelating resin, and the waste resin index requirements: moisture content is less than 14.5%, ash content is 2.5%-5%, volatile content is 70%-77%, The sulfur content is 0.2%-0.5%, and the index requirements for CDQ dust removal powder: moisture content is less than 1%, ash content is 10%-13%, volatile content is 1%-3%, and sulfur content is 0.5-0.9%;

[0039] 2) Centrally recover the waste resin, and carry out grinding treatment through crushing equipment such as a pulverizer or a ball mill, and the pulverization treatment makes the particle size less than 3mm;

[0040] 3) According to the mass ratio of 1:2, fully mix the waste resin and CDQ dust removal powder, formulate and make balls, the diameter of the ball is 1-3cm, the index of the mixed ball is: the water content is less than 8%-11%, and the ash content is 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com