Method for producing 500 Mpa high strengh threaded reinforced bar

A threaded steel bar and production method technology, applied in temperature control, workpiece surface treatment equipment, metal rolling, etc., can solve problems such as increased production costs and complex smelting production processes, so as to save steel, shorten project construction period, and increase benefits Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

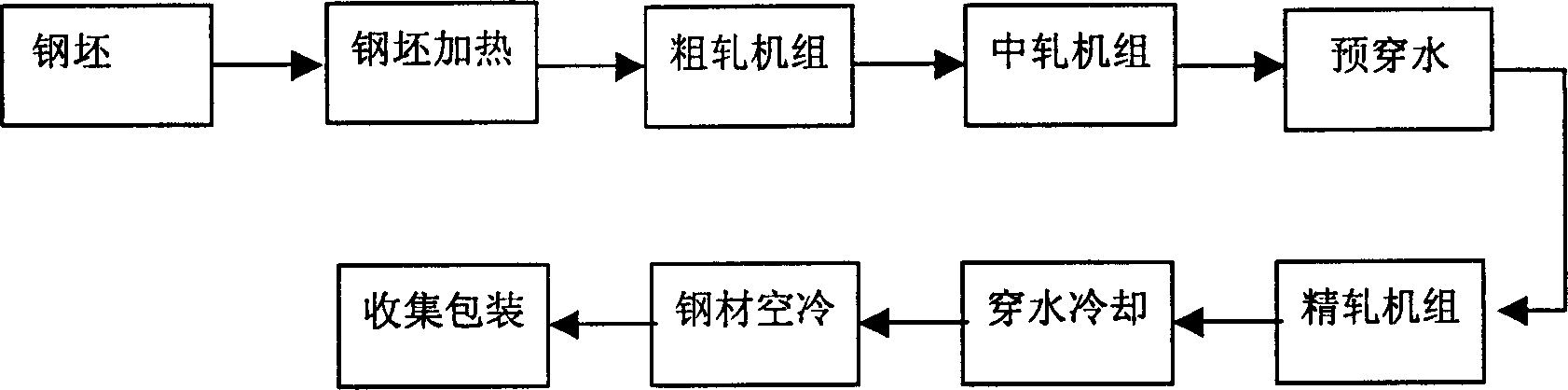

[0017] figure 1 Shown is the embodiment of the production method of 500Mpa high-strength threaded steel bar of the present invention, comprises the following steps:

[0018] a. Use ordinary 20MnSi steel billet, whose chemical composition is shown in Table 1, and keep the starting rolling temperature at 880-950°C in an ultra-low temperature method. Cooling through water cooling, the number of pre-piercing water sections can be 1-3, the water pressure is normal pressure, and the temperature after pre-piercing water is 850-950°C;

[0019] b. After the steel passes through the water-piercing section, it enters the finish rolling unit, and the power of the main motor is 1350KW; then it enters the water-piercing cooling section to rapidly reduce the surface temperature of the rolled piece. The number of sections in the water-piercing cooling section is 1 to 5 sections, The water pressure is 0.8-1.2Mpa, so that the surface temperature of the steel upper cooling bed is controlled at ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| crystal size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com