Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

239 results about "Punching shear" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

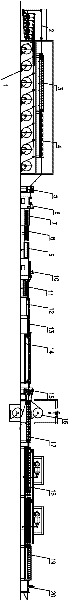

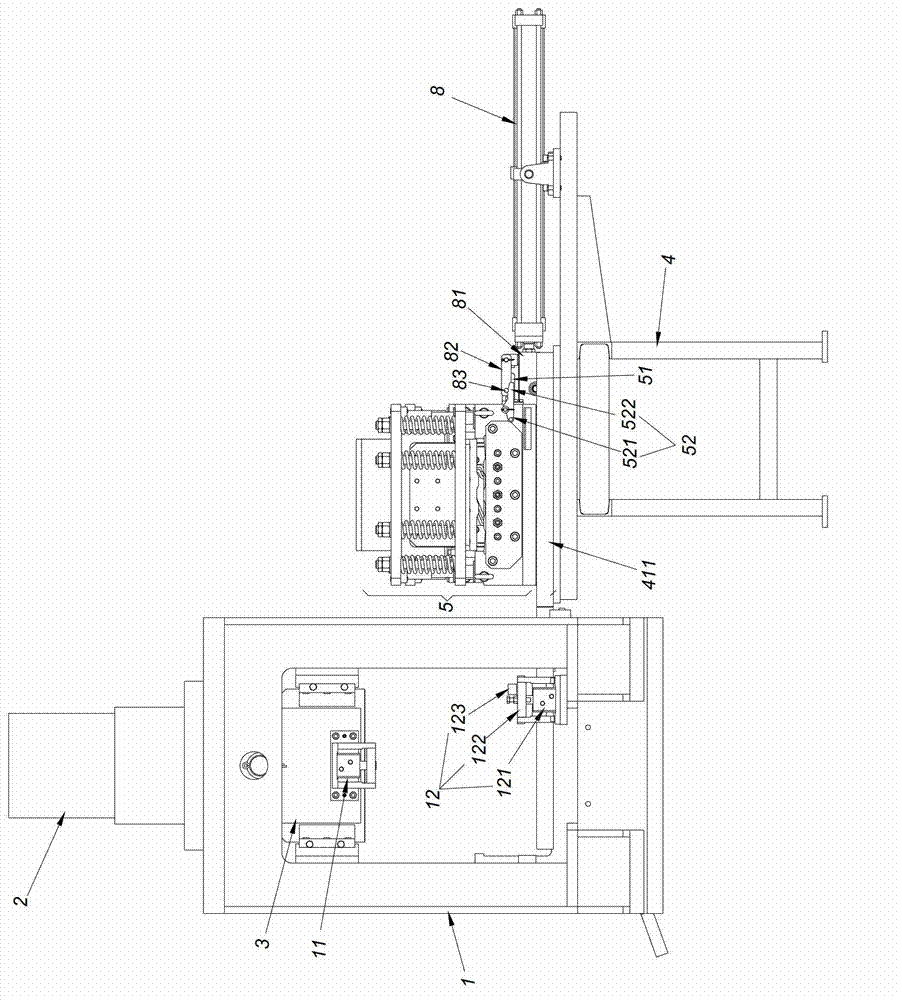

All-in-one machine for vacuum forming, molding and punching

InactiveCN101774273AAvoid lateral displacementAccurate horizontal positionMetal working apparatusTrappingPlastic film

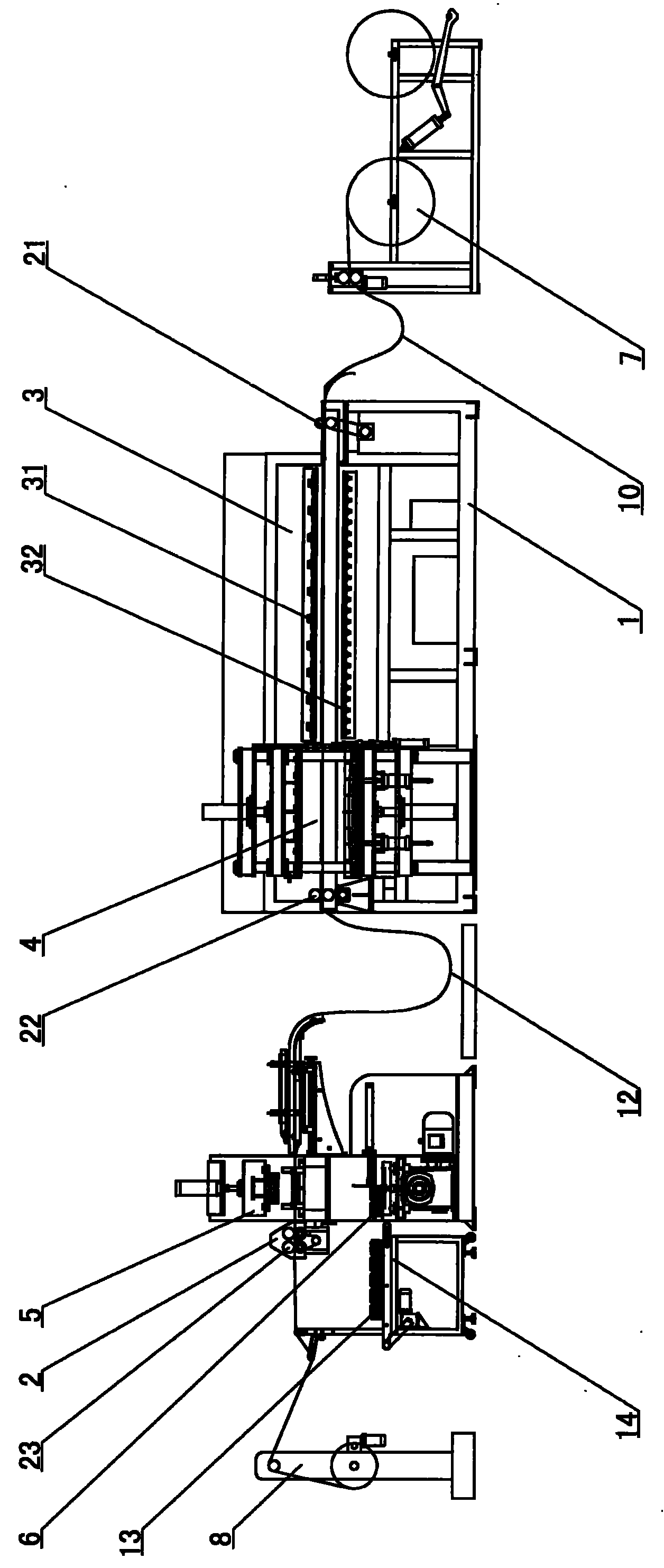

The invention relates to an all-in-one machine for vacuum forming, molding and punching, comprising a rack, a material traction device, a heating device, a forming unit, a punching device and a control device; wherein a top die platform and a bottom die platform of the forming device are provided with moulding moulds which are thereupon provided with a convex part or a concave part for forming a light trapping bump on plastic sheets; the punching device comprises a punching shear mechanism, a guide rail which moves frontwards and backwards and a photocell eye for detecting the light trapping bump; the guide rail is arranged in the front of the punching shear mechanism, the photocell eye is arranged in the front of the punching shear mechanism and is connected with a corresponding input terminal corresponding to the control device.In the invention, when forming is carried out, the light trap bump can be formed on the plastic sheet, the flaky plastic products can be prevented from transversely displacing by the guide of the guide rail, the photocell eye can be used to detect the light trap bump and the control device can be used to lead the material traction device to convey the flaky plastic products to preset distance, so that the longitudinal position of the plastic products is accurate when the plastic products enter the punching shear mechanism and the flaky plastic products can accurately arrive at the preset position of the punching mechanism.

Owner:广东金兴机械股份有限公司

Flashing precise planning and cutting hydropress

The invention relates to a flash precise slicing hydraulic press used for the punching shear of a forging flash. The equipment combines a linear driving mechanism, a blank holding mechanism, a back pressure mechanism and a buffer device into novel special punching shear equipment. By adopting the linear unidirectional driving type of the equipment, a workpiece is only subject to a vertical unidirectional punching shear force, but not subject to a lateral force or an additional torsion in the punching-shear process; owning to the blank holding mechanism, the flash can not be warped in the punching-shear process as the flap edge is subject to a compulsive restraining force; owning to the back pressure mechanism, the forging is supported by a back pressure cylinder in the punching-shear process, and the flexible deformation of the forging is reduced; owning to the buffer device, the impact to the hydraulic system is avoided. The slicing hydraulic press which is provided by the invention can be used for the normal punching shear of the flash of the forging, and is especially suitable for the precise punching shear of the flap edge of the forging; the incision of the forging after punching shear has high precision and good quality. The invention can be suitable for all the enterprises which produce forgings.

Owner:BEIJING RES INST OF MECHANICAL&ELECTRICAL TECH

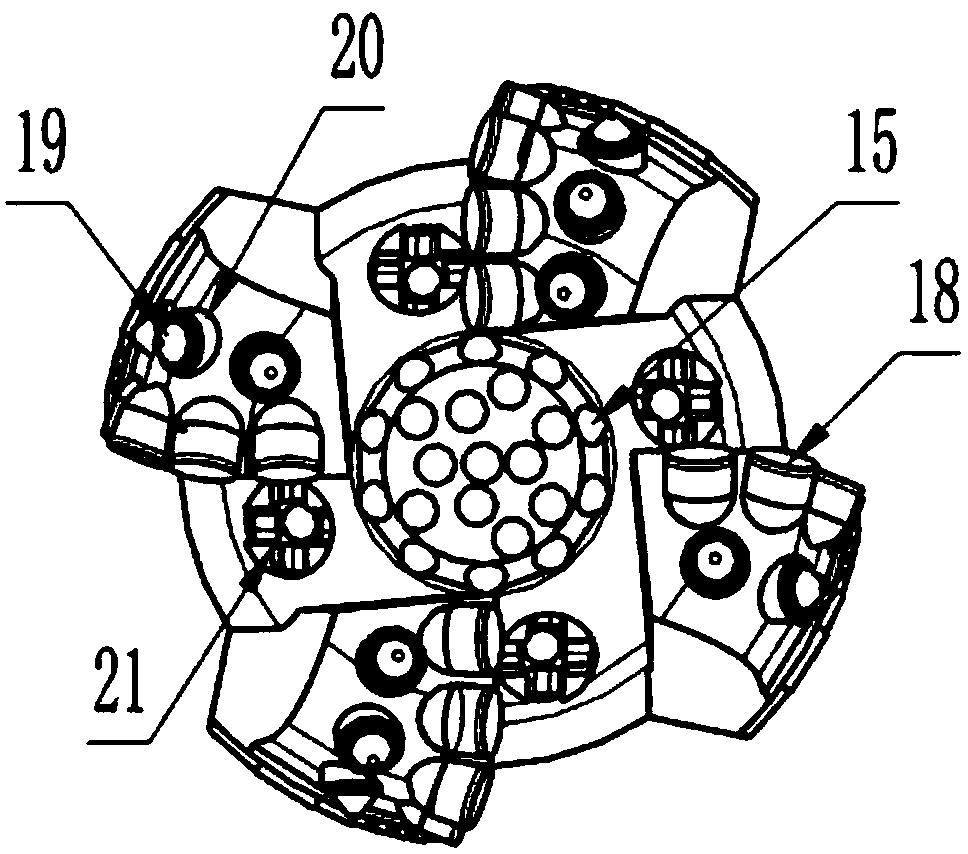

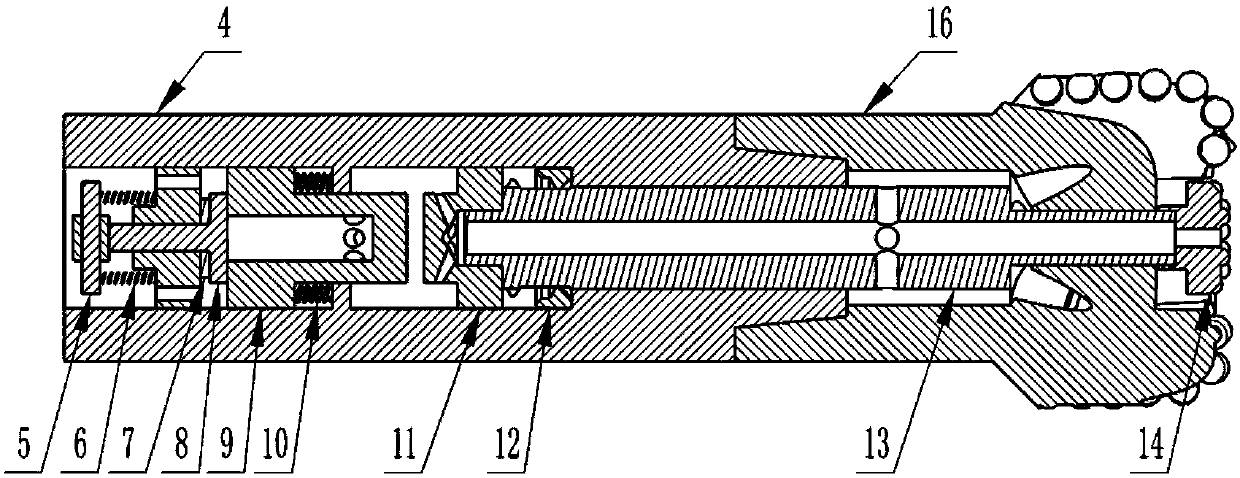

Punching-shear composite drill bit for hard rock drilling

ActiveCN107842317AReduced compressive strengthLow shear strengthDrill bitsTectonic stressPre cracking

The invention discloses a punching-shear composite drill bit for hard rock drilling. The punching-shear composite drill bit comprises three parts of an impactor, an internal punching bore bit and an external cutting drill bit, a lower joint of the impactor can be in threaded connection with the external cutting drill bit, and the upper part of the internal punching bore bit is connected with the impactor in a spline mode; and the lower end face of the internal punching bore bit extends out of the surface of the external cutting drill bit, the central axis of the internal punching bore bit is parallel to or coincident with the central axis of the external cutting drill bit, distributed teeth on the internal punching bore bit and distributed teeth on the external cutting drill bit are combined and can completely cover a downhole, and distributed teeth on the internal punching bore bit and the distributed teeth on the external cutting drill bit are independent of each other. In this way,rock crushing through shearing and rock crushing through impact are creatively combined together, a rock stratum at the hole bottom is pre-cracked first through the internal punching bore bit, the whole tectonic stress of the rock stratum is destroyed, the strength of compression resistance and shearing resistance of rock is reduced so that PDC column teeth and PDC cone teeth can more easily cut / plough-cut the rock, and the rock-breaking efficiency of the super hard rock stratum is greatly improved.

Owner:XIAN RES INST OF CHINA COAL TECH& ENG GROUP CORP

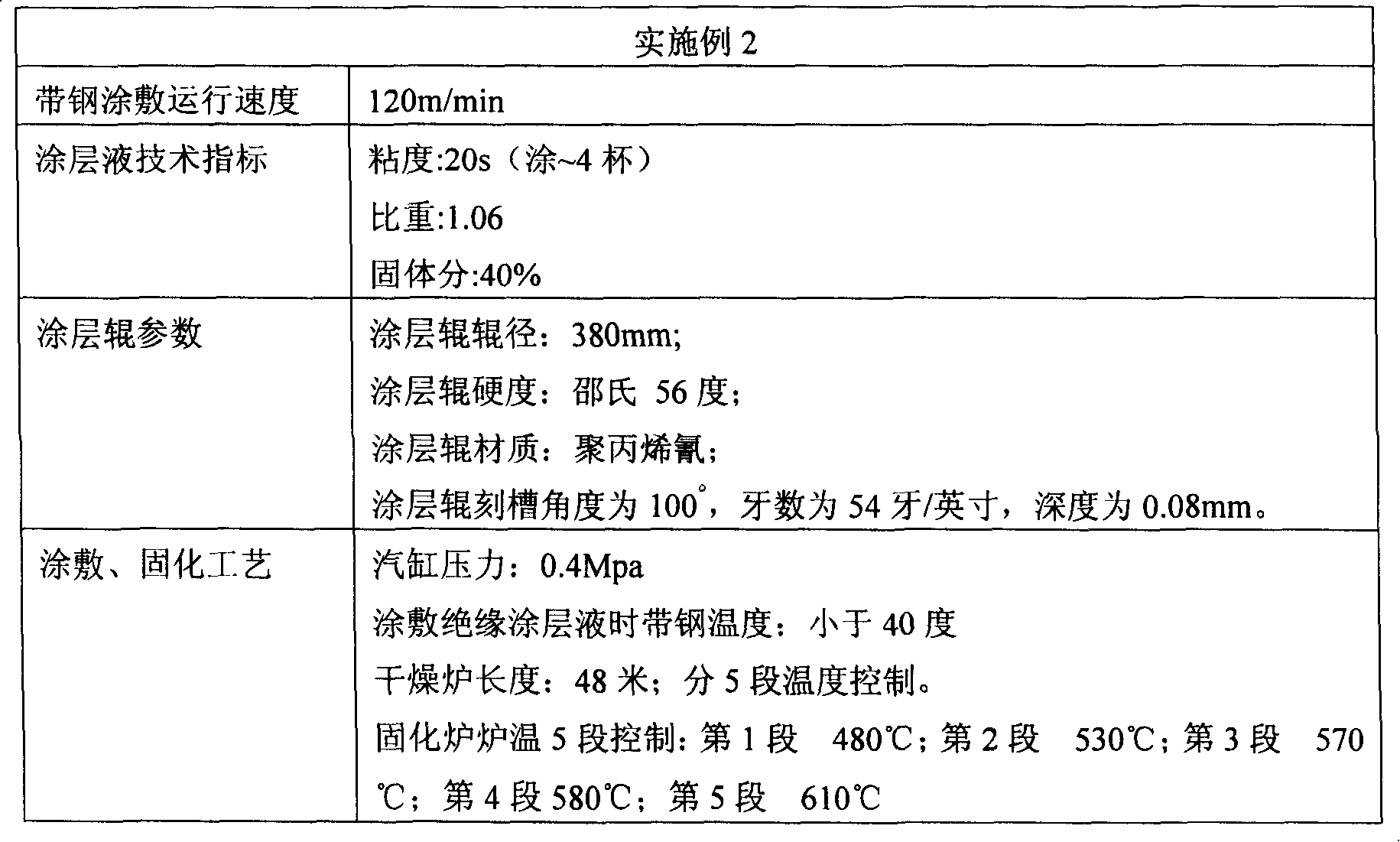

Coating method of cold-rolled silicon steel chromium-free insulating coatings, coating rubber roll and coating liquid

InactiveCN101209440ASmooth and even colorUniform colorPretreated surfacesCoatingsChromium freeStrip steel

The invention discloses a coating method of chrome-free insulation coatings of cold rolling silicon steels, a coating rubber roller and coating solution, which is characterized in that technique parameters of the coating rubber roller, operation speed of a unit, composition of the insulation coating solution, specific gravity of the coating solution, temperature of a curing furnace, coating, drying, curing, etc. are selected to carry out optimization for coating band steels. The invention has the advantages and effects lie in that water is employed to disperse the insulation coating solution of chrome-free one-component silicon steels; two rubber rollers with carving grooves are used; in a certain speed and pressure, through curing in a certain temperature, a cold rolled silicon steel plate coating is produced and has the thickness of 1-3 mm, smooth and uniform surface, adhesive force of coating (O grade), insulation property (more than 600 Omega / mm<2>), good rust-proof capability, refrigerant resistance and good punching shear property and has uniform color, luster, no packing, good appearance and environmental production process and products, thus fully meeting the requirements of ROHS Instructions of European Union and national environmental protection policy of the insulation coating of the cold rolling silicon steels.

Owner:ANGANG STEEL CO LTD

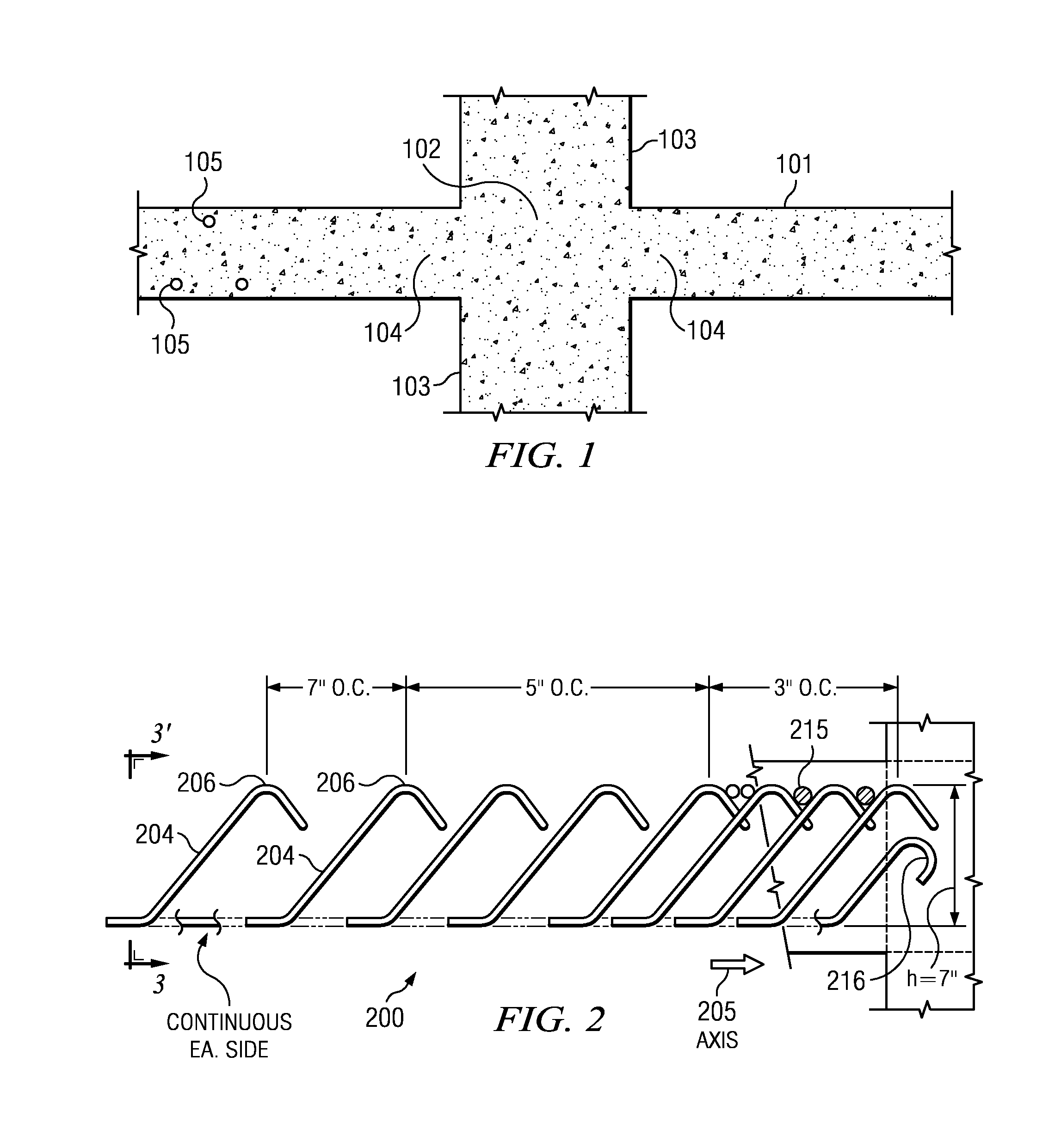

Reinforcing Assemblies and Reinforced Concrete Structures

InactiveUS20080263978A1Easy to anchorIncrease heightBuilding repairsBuilding reinforcementsRebarRetaining Pin

Reinforcing assemblies for use in structural concrete members, as well as reinforced concrete structures, are provided that are uniquely suited to deal with punching shear failure in structural concrete members such as slabs, beams footings and flat foundations. The reinforcing assemblies include a support base, comprising two elongate rebar members disposed substantially parallel to each other, and several shear-resisting rebar elements having two opposing ends and cast, or bent, in hairpin shape on a common plane in generally parallel orientation to each other and secured to the base. The reinforced concrete structures include a concrete member, having a first face and a generally opposed second face, and at least four reinforcing assemblies that are embedded and retained at prescribed locations within the concrete member by their base and by the opposed faces of the concrete member, and which comprise a support base and multiple hairpin-shaped rebar elements secured to the support base.

Owner:P T E STRAND CO

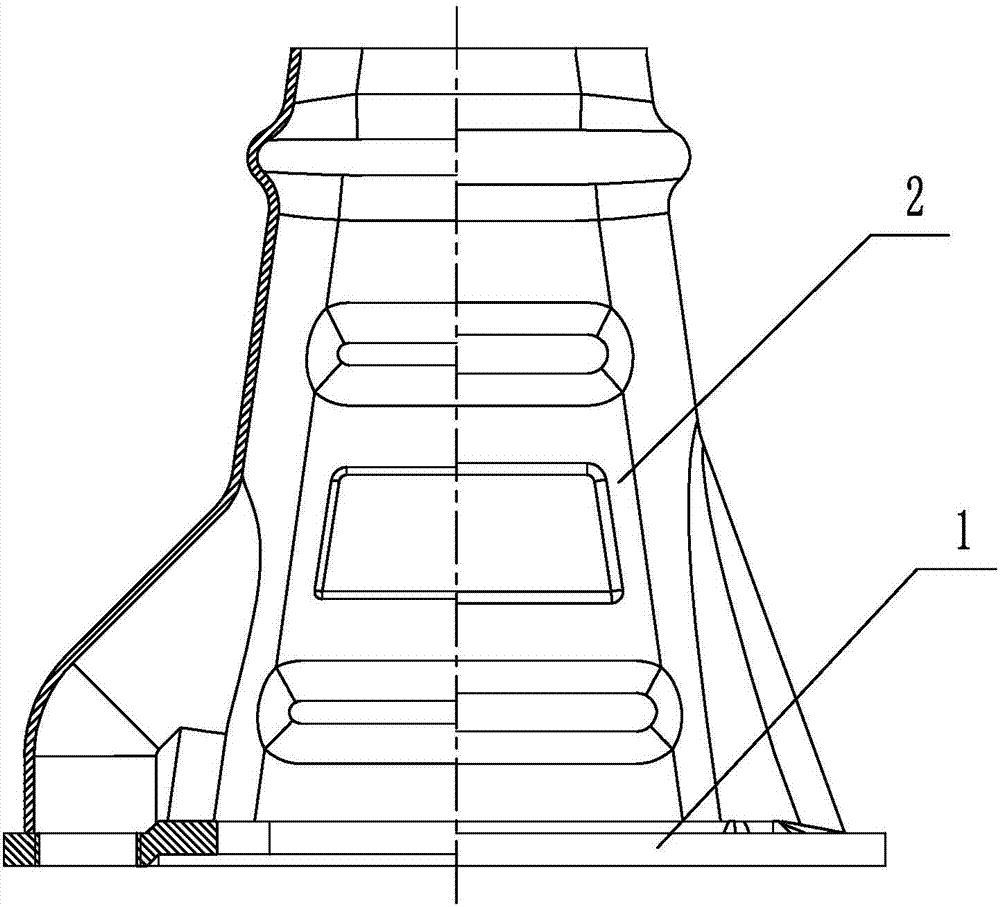

Production technology of guide wheel body

ActiveCN104118486ALow costImprove mechanical propertiesEndless track vehiclesStress conditionsEngineering

The invention relates to a production technology of caterpillar band parts, in particular to a production technology of a guide wheel body for a caterpillar band. The production technology of the guide wheel body comprises the steps of rim manufacturing, hub manufacturing, spoke manufacturing, rib manufacturing, wheel body welding, hot processing, finish machining and the like. By means of the production technology of the guide wheel body, the traditional integrally-cast guide wheel body is divided into a rim, a hub, a spoke and ribs, and the parts are manufactured separately and connected together in a welding mode. Therefore, the parts of the guide wheel body can be made of corresponding materials according to actual stress conditions and have no need to be made of high-cost alloy steel, so that cost of the whole guide wheel body is low. Forging and punching shear replace traditional casting, so that non-uniformity of the wall thicknesses is avoided, and the formed material is larger in density and better in abrasion resistance.

Owner:FUJIAN XIAHUA HEAVY MACHINERY CO LTD

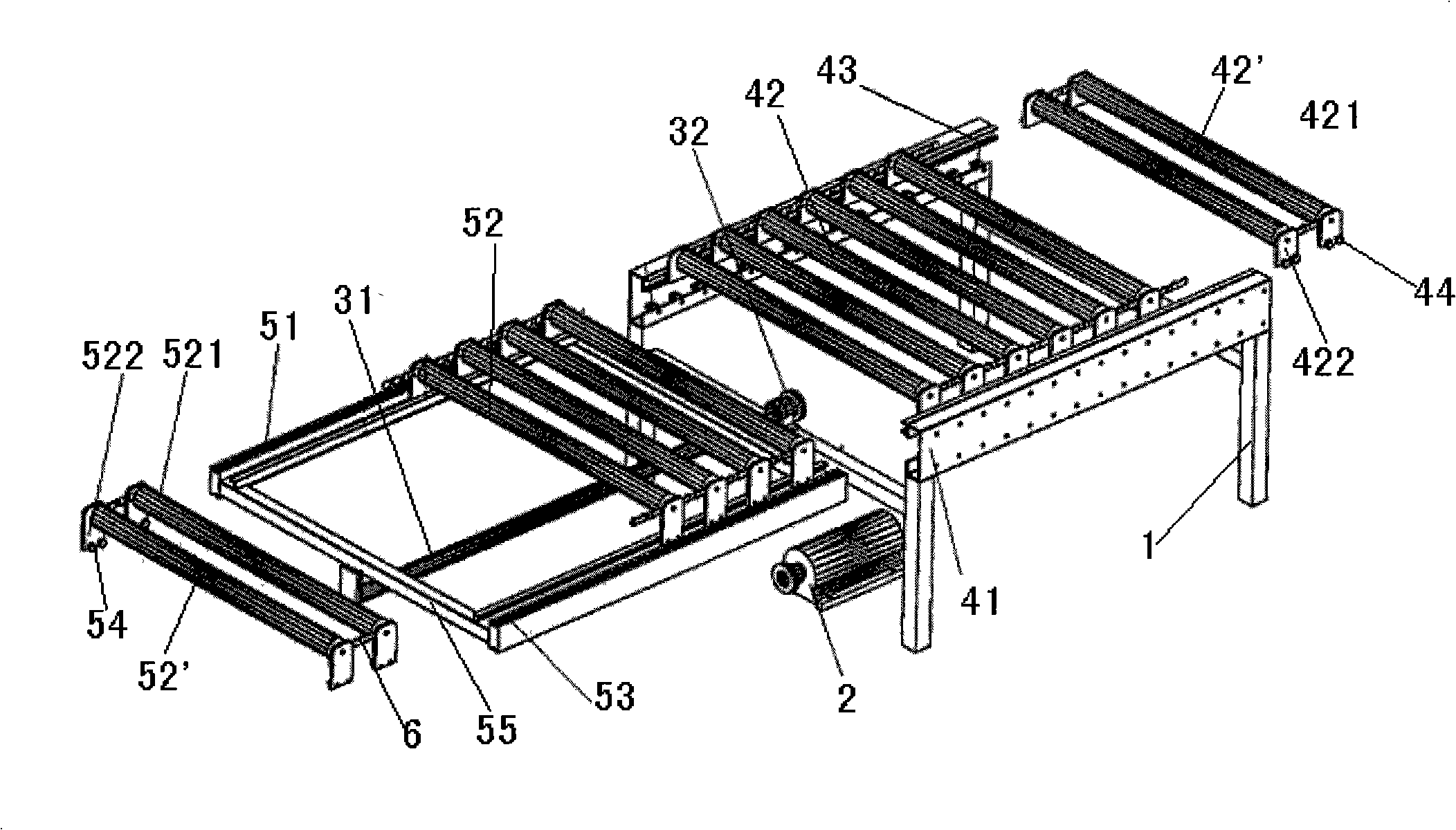

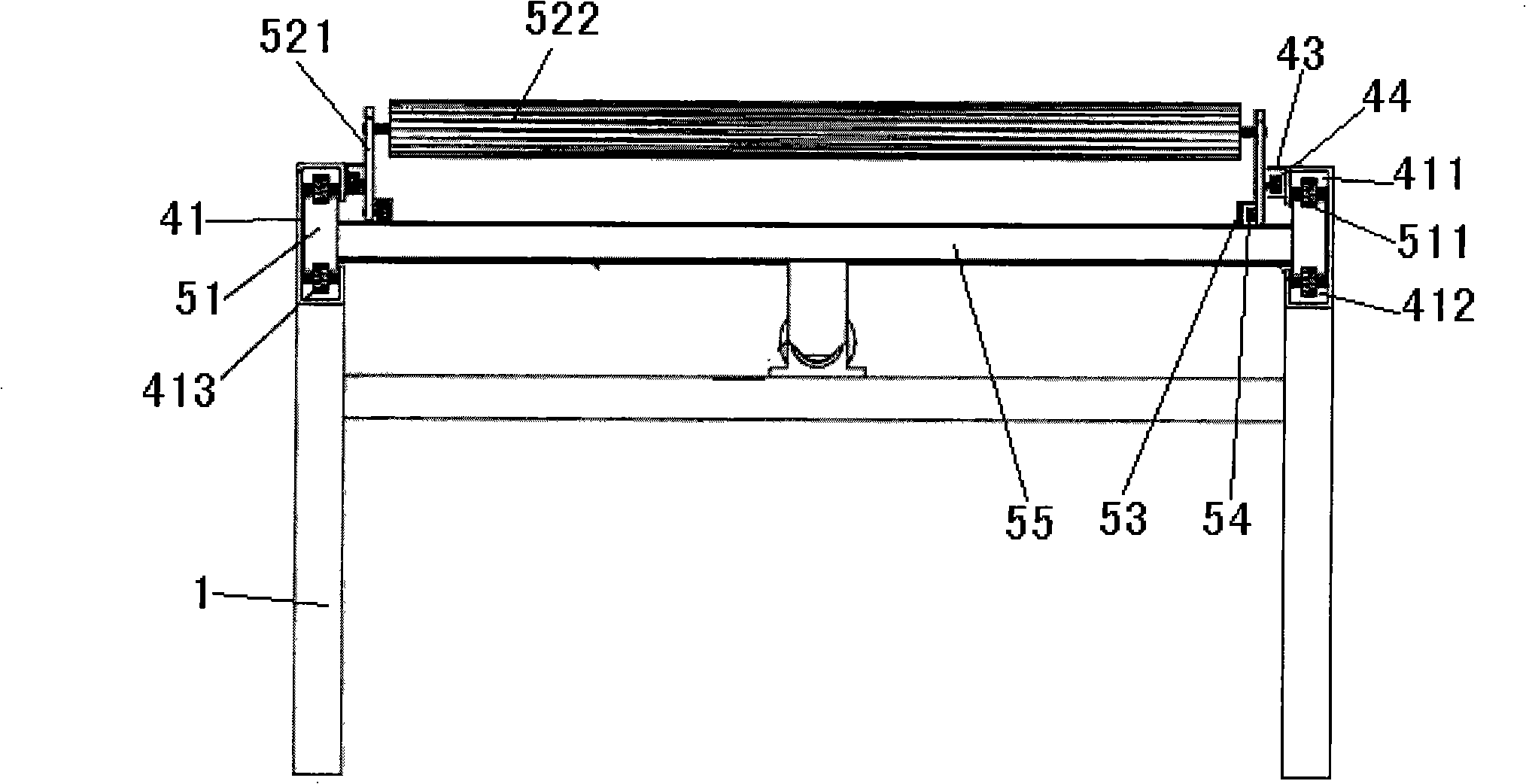

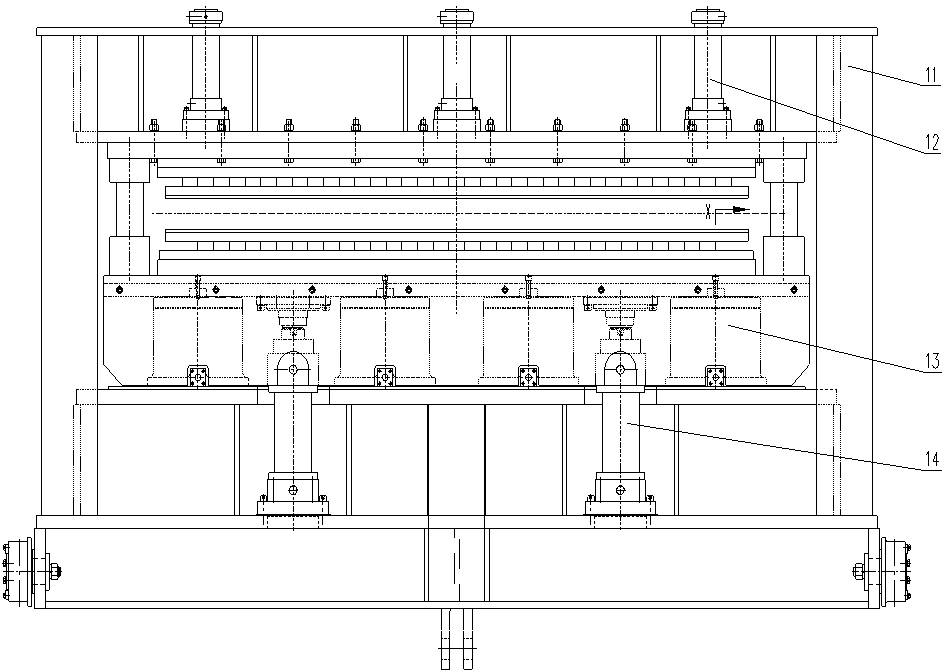

Telescopic horizontal transmission bench

InactiveCN101342988AMeet the needs of useStable structureMetal working apparatusRoller-waysHorizontal transmissionEngineering

The invention discloses a telescopic horizontal conveying platform which comprises a main body support, a conveying platform, a drive motor and a telescopic part; the conveying platform includes a fixed conveying platform and a telescopic conveying platform; the fixed conveying platform includes a slide groove, a plurality of back conveying components and back guide grooves; the telescopic conveying platform includes a telescopic rod, a plurality of front conveying components and front guide grooves; the telescopic rod is arranged in the slide groove and is able to slide relative to the slide groove; the adjacent conveying components, the adjacent front conveying component and the adjacent back conveying components are connected through flexible connecting pieces respectively; the upper conveying planes of the front conveying component and the back conveying component are in the same horizontal plane; one end of the telescopic part is connected with the drive motor and fixed on the fixed conveying platform; the other end is fixedly connected with the telescopic conveying platform. The telescopic horizontal conveying platform has the advantages of stable structure, reliability, convenient application, satisfying the application requirement of telescopic platform, being applicable to vehicle sheet punching shears and the conveying in other product production process.

Owner:上海赛科利汽车模具技术应用有限公司

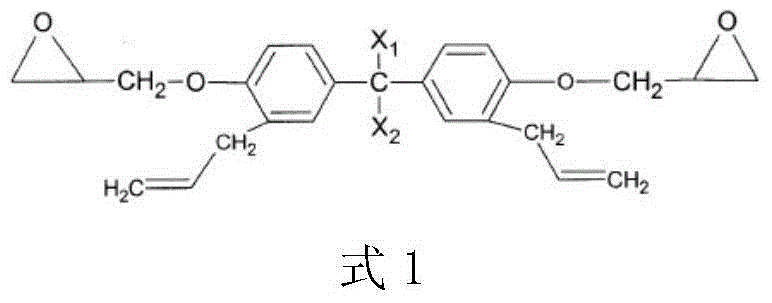

Epoxy adhesive for repairing and reinforcing hinge joint and application of epoxy adhesive

InactiveCN103555245ASlow curingGuaranteed impact resistanceBridge structural detailsBridge erection/assemblyCationic polymerizationCohesive strength

The invention discloses an epoxy adhesive for repairing and reinforcing a hinge joint and an application of the epoxy adhesive. The epoxy adhesive is composed of a component A and a component B, wherein the component A is composed of bisphenol-A epoxy resin, modified epoxy resin containing double bonds, a diluent, a toughening agent and the like, the component B is composed of a modified polyamine curing agent, a cationic polymerization curing agent, a free radical initiator and the like; before curing, the epoxy adhesive is long in working life and low in viscosity, and has proper thixotropic property, the curing time is extremely short and the cohesive strength and the adhesion strength are not influenced by punching shear effect and humid environment; the cured epoxy adhesive is small in shrinkage, good in flexibility, impact resistant, and fatigue resistant; the epoxy adhesive applied to the repairing and the reinforcing of the hinge joint entirely satisfies the demands of repairing and reinforcing the hinge joint of a plate girder bridge without interrupting the traffic.

Owner:湖南固特邦土木技术发展有限公司

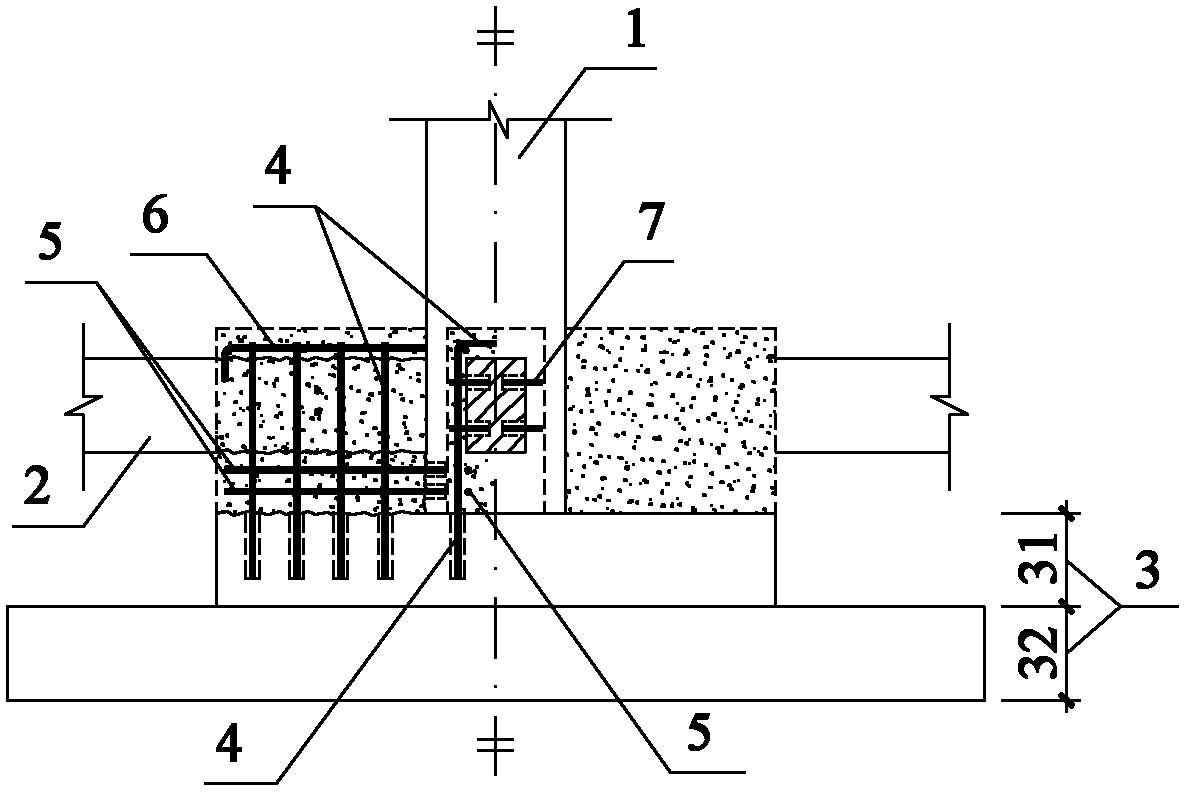

Reinforcing method for improving bend and shear bearing capacity of independent foundation

The invention discloses a reinforcing method for improving a bend and shear bearing capacity of an independent foundation, belonging to the technical field of structural reinforcement. The reinforcing method comprises the main steps of: scabbling the surface of concrete of a connection beam and the independent foundation; forming holes on the upper surface of the independent foundation and planting reversed-U-shaped reinforcing steel bars which enclose the connection beam; forming holes on the surface of a column, planting horizontal shear reinforcing steel bars and binding the reinforcing steel bars; coating an interface agent on the scabbled concrete surface, supporting a mould and casting the concrete so as to finish the reinforcement of the independent foundation. The reinforcing method provided by the invention utilizes less reinforced concrete to integrally connect the previous independent foundation with the connection beam to form a new independent foundation, so that the punching shear capacity of the independent foundation is improved and the distance from a plate bottom reinforcing steel bar to the center of a resultant force point of the concrete is enlarged; and furthermore, the bend bearing capacity of the independent foundation is improved. The reinforcing method provided by the invention has the advantages of simplicity in construction and material saving, and can be widely applied to the reinforcement and reconstruction of the independent foundation with the connection beam under the column.

Owner:郭猛

Automatic feeding device for die punching

ActiveCN101745588AReduce labor intensityReasonable structural designShaping toolsPerforating toolsPunch pressPropeller

The present invention relates to an automatic feeding device for die punching, comprising an upper die holder and a lower die holder. Punching shear blades and an iron wedge are fixed on the upper die holder. A lower die is fixed in the middle of the lower die holder, an extending plate is fixed on the front part, and a fixing plate is arranged on the rear. A spring is arranged on the fixing plate, a slider is connected to the front end of the spring, and a baffle and a rack plate are arranged at the front end of the slider. The front end of a support rod is fixed on the extending plate, the rear end is fixedly provided with a core die, and a sizing plate is fixed at the front end of the support rod. A propeller is sheathed on the support rod, a motor lock rod is arranged on the propeller, and the head of the motor lock rod is clamped in the tooth socket of the rack plate. The device of reasonable structure design can be mounted on a punch for punching steel pipes. The efficiency is high, and the work intensity of operators is largely reduced.

Owner:鞍钢房地产开发集团有限公司

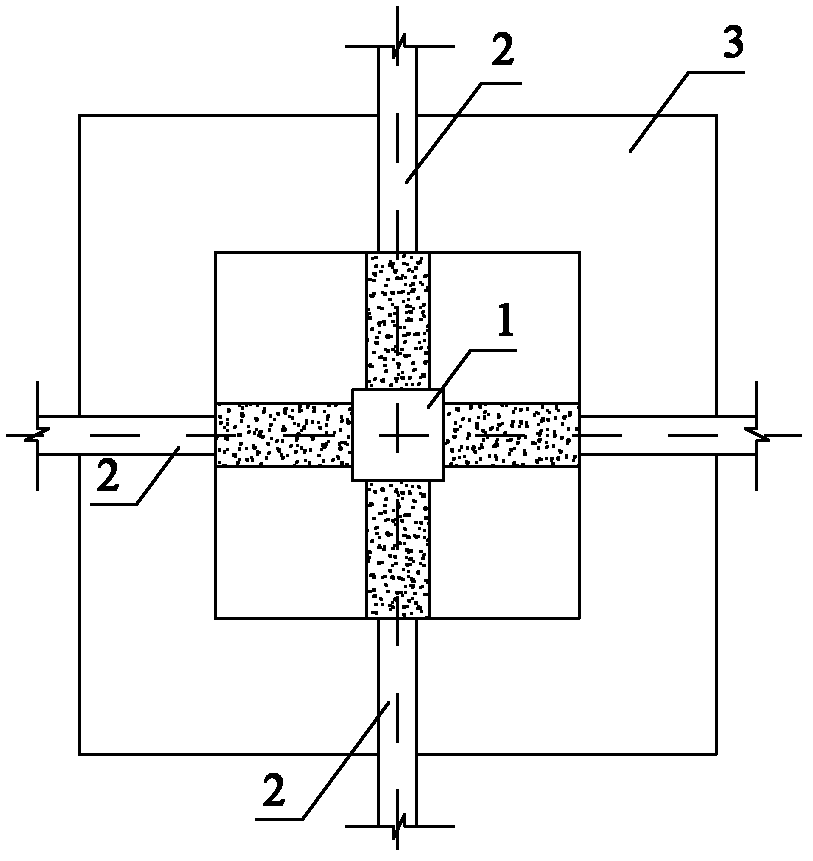

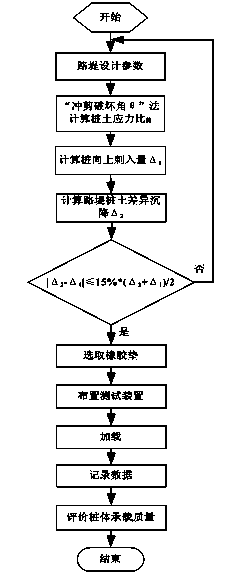

CFG pile composite roadbed rubber spacer static load testing device and method

InactiveCN104196060AQuick calculationAvoid complex iterative calculationsFoundation testingSoil stressEngineering

The invention provides a CFG pile composite roadbed rubber spacer static load testing device and method. The method comprises the steps that according to the embankment design condition, the punching shear failure angle method is adopted to calculate loads of embankment filling acting on piles and soil between the piles respectively, and pile soil bearing loads and the pile soil stress ratio are obtained; differential settlement of the piles upwards piercing into the spacer amount and differential settlement of the piles upwards piercing into composite foundation pile soil are respectively calculated, the pile piercing amount is comprehensively determined, and according to the table 1, rubber spacers are selected. Arranging is carried out according to the CFG pile composite roadbed rubber spacer static load testing device, and the steps of gradation loading, steady judgment, final load control, data recording and the like are carried out reference to existing specifications and design. According to the device and method, rubber spacers are determined in a mode that load-bearing compression deformation of the rubber spacers is close to the loads, borne by pile bodies, in the actual station, of the upward piercing amount of the spacer amount, a load transfer mechanism of the actual working condition can be simulated, the aim that embankment loads are distributed by the rubber spacers is achieved, and the pile soil stress ratio conforming to the reality can be achieved.

Owner:HOHAI UNIV +1

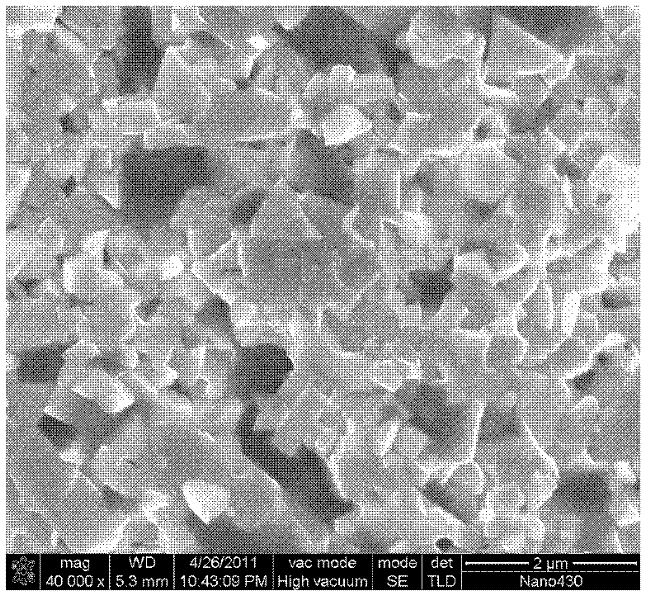

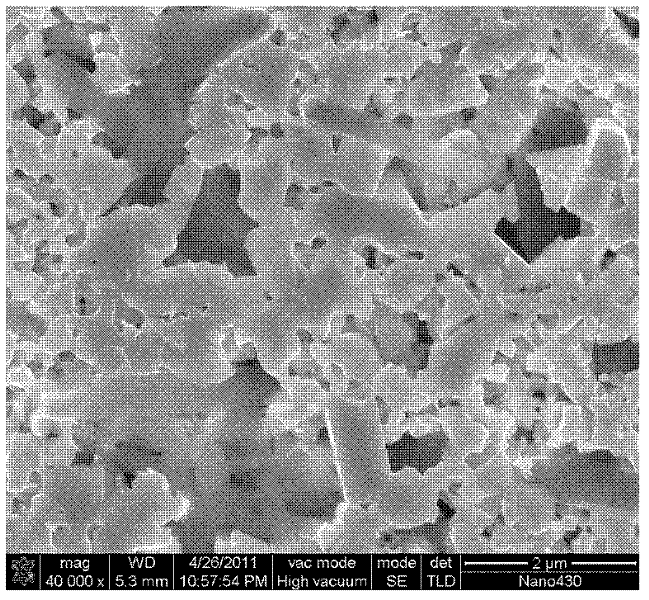

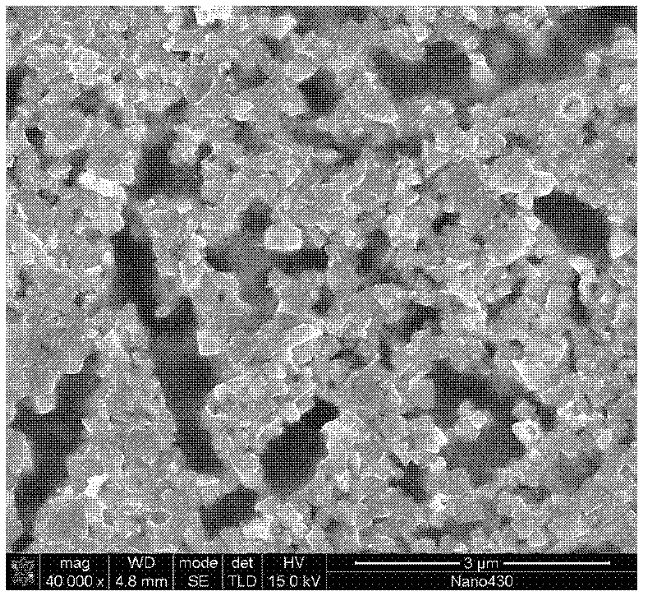

Tungsten carbide composite material containing aluminum oxide particles and silicon nitride whiskers, and preparation method thereof

The invention discloses a tungsten carbide composite material containing aluminum oxide particles and silicon nitride whiskers, and a preparation method thereof. The tungsten carbide composite material contains components of, by mass: 0.5 to 3% of aluminum oxide particles, 0.4 to 10% of silicon nitride whiskers, and balance of tungsten carbide and inevitable impurity phases. The silicon nitride whiskers are in-situ synthesized beta-Si3N4 whiskers. The WC composite material provided by the invention contains no metallic binding phase, and has excellent hardness, excellent wear resistance, excellent high-temperature mechanical properties, and medium toughness. With the material and the method provided by the invention, preparation cost of the WC composite material can be reduced, and the application range of the material is widened. The material is suitable to be produced into cutting tools such as indexable inserts, plastic working tools such as wire drawing dies, and shearing tools such as punching shear dies.

Owner:SOUTH CHINA UNIV OF TECH

Equipment for producing full-automatic high-speed cellular board

The invention relates to a production line for a cellular board, in particular to equipment for producing a full-automatic high-speed cellular board. The cellular boards made of various materials can be produced on the production line. The production line consists of a comprehensive coater, a material rolling machine, a conveying compaction machine, a slab core dryer, a secondary coater, a transverse cutting machine, a laminating machine, a compaction machine, a self-lifting hoistable platform, a core cutting machine, a multilayer butt joint machine, a slab core conveyor, a conveying platform, a slab core stretching dryer, a compound coater, a compound panel material rolling machine, a compound machine, a primary dryer, a secondary dryer, a cooler and a cellular board punching shear machine, wherein the material rolling machine and the compound panel material rolling machine have a structure of two volumes or a plurality of volumes of equipment to fulfill the aim that the materials can be subjected to butt joint automatically without machine halt when replaced and realize full-automatic high-speed running; and by the comprehensive coater, single-layer two-sided dislocation coating and interlayer coating in the coating process can be realized, the glue amount is controlled in a dripped glue injection mode to prevent glue from overflowing and reduce glue waste, so that environment friendliness and resource conservation are realized.

Owner:罗建华

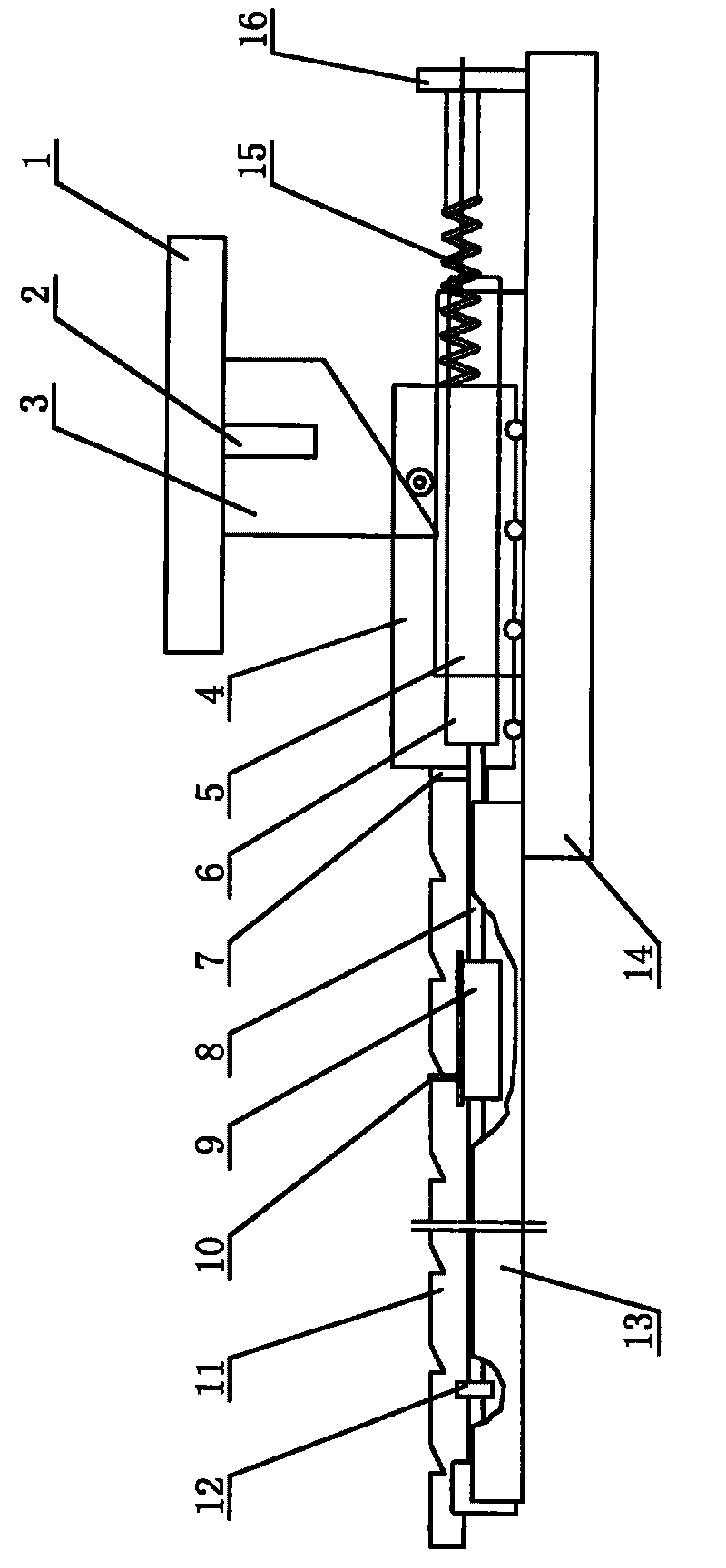

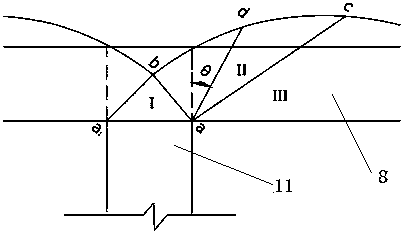

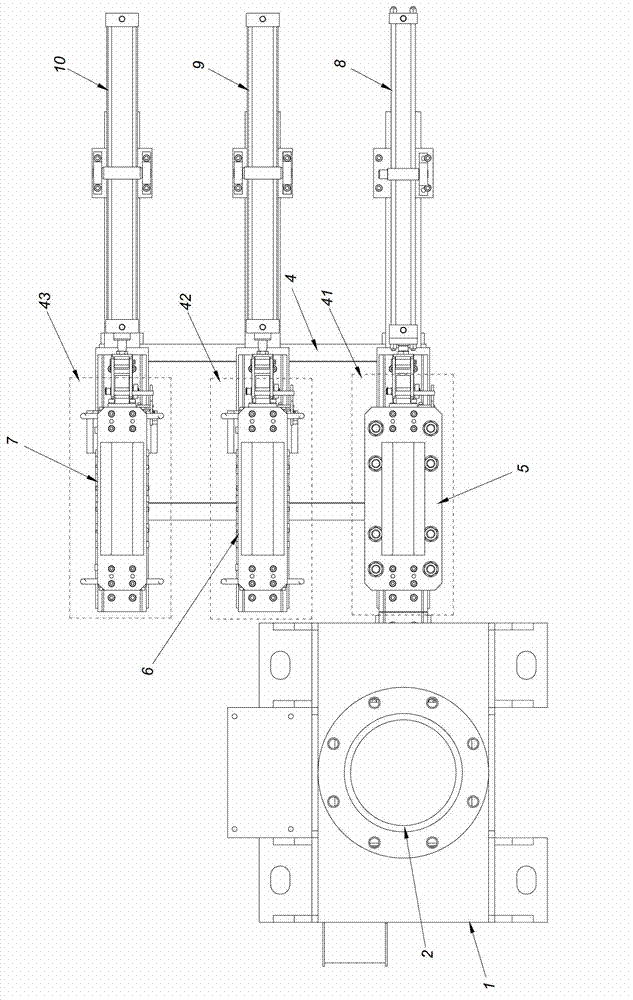

Test device for simulating continuous punching shear loading

InactiveCN103728191ARealize the function of direct shear testEasy to measure intensity changesMaterial strength using steady shearing forcesMaterial strength using repeated/pulsating forcesPositive pressureAxial force

The invention discloses a test device for simulating continuous punching shear loading. An impact loading mechanism comprises a central post, a drop hammer, a rope and a cover plate, wherein the drop hammer comprises a group of lantern rings which are nested at the top of the central post, the radiuses of the lantern rings gradually increase, the lantern rings are suspended by the rope, and the cover plate is fixed in such a way that the central post penetrates through the center of the cover plate. A sample punching shear mechanism is a pressure chamber which is arranged at the lower part of the impact loading mechanism, a sample cavity which is coated with a rubber film cover is arranged in the pressure chamber, and an upper shear box and a lower shear box are respectively arranged at the upper part and the lower part of the sample cavity in the rubber film cover. Axial force is converted to shear force by a difference between the rigidity of a shear block and the rigidity of a deformation block in the shear device, and a test function of directly shearing a sample vertically is realized. A shear plane is determined, and convenience in shear loading and positive pressure application is instrumental to the measurement of the variation of the strength of the sample under punching shear action. All the solid rings in the device are equal in mass. Impact energy can be effectively controlled through the control of drop heights, so that the mechanical parameters, such as shear, of the sample under dynamically loaded action can be accurately determined.

Owner:HOHAI UNIV

Sewing machine for sewing ultra-wide thick plate belt materials

InactiveCN102601249ASatisfy the sewing requirementsMaintain good propertiesShaping toolsHydraulic cylinderThick plate

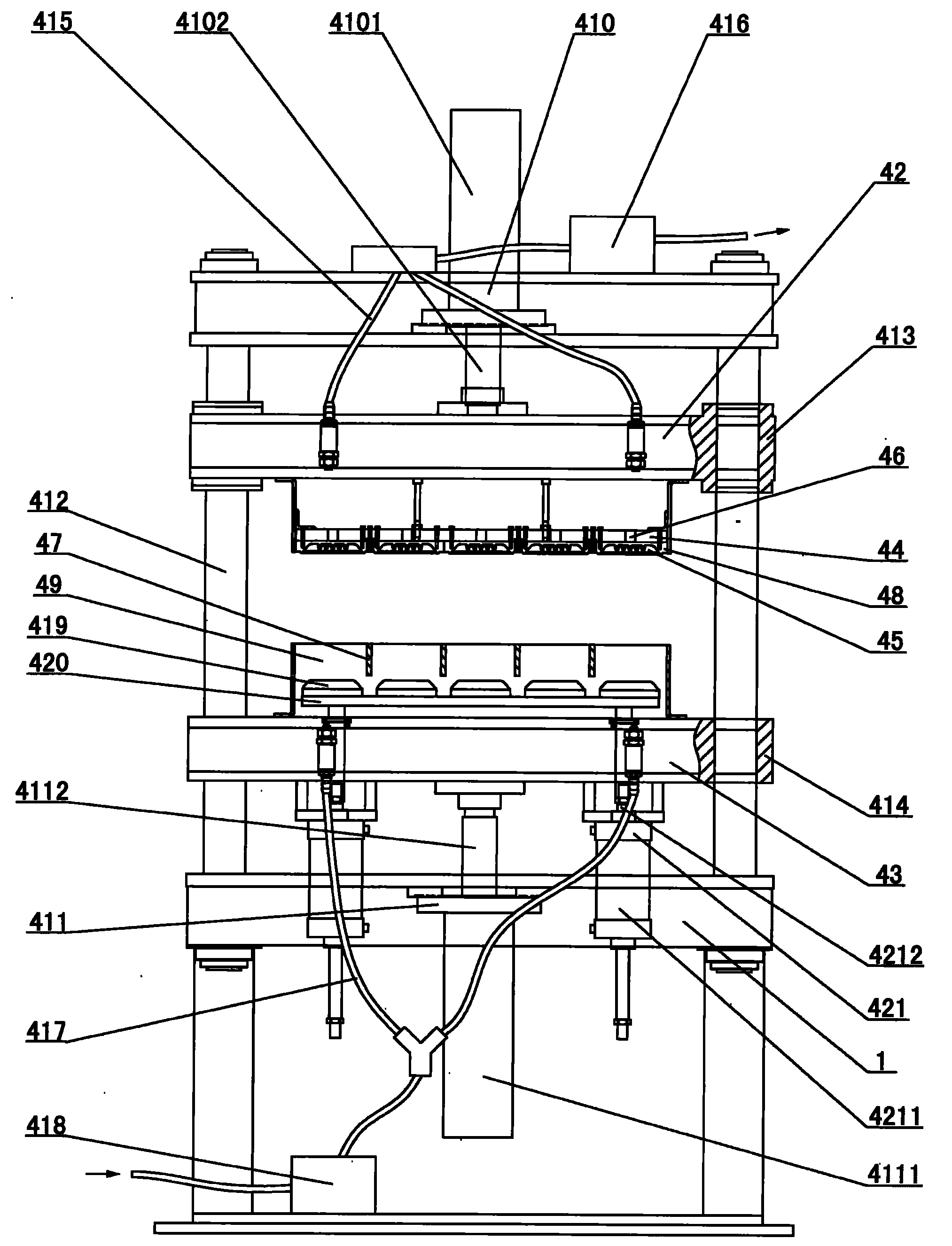

A sewing machine for sewing ultra-wide thick plate belt materials comprises a frame, an upper punching shear device and a lower punching shear device mounted on the frame, the upper punching shear device comprises an upper bottom plate, an upper mould clamp plate fixedly mounted on the upper bottom plate, an upper pressure plate connected with the upper mould clamp plate by an upper elastic device, and an upper punch fixedly mounted on the upper mould clamp plate, the top of the upper punch is arranged into an upper guide hole aranged on the upper pressure plate; the lower punching shear device comprises a lower bottom plate, a lower mould clamp plate fixedly mounted on the lower bottom plate, a lower pressure plate connected with the lower mould clamp plate by a lower elastic device, and a lower punch fixedly mounted on s the lower mould clamp plate; a punching shear hydraulic cylinder is arranged between the lower bottom plate and the frame, the upper bottom plate is connected by the lower bottom plate by a guide shaft, the punching shear cutting edge curves of the upper punch and the lower punch are approximately circular curves fit by multiple points. The sewing machine for sewing ultra-wide thick plate belt materials of the invention can be suitable for punching and sewing thin and narrow belt materials and ultra-wide thick plate belt materials.

Owner:CISDI ENG CO LTD

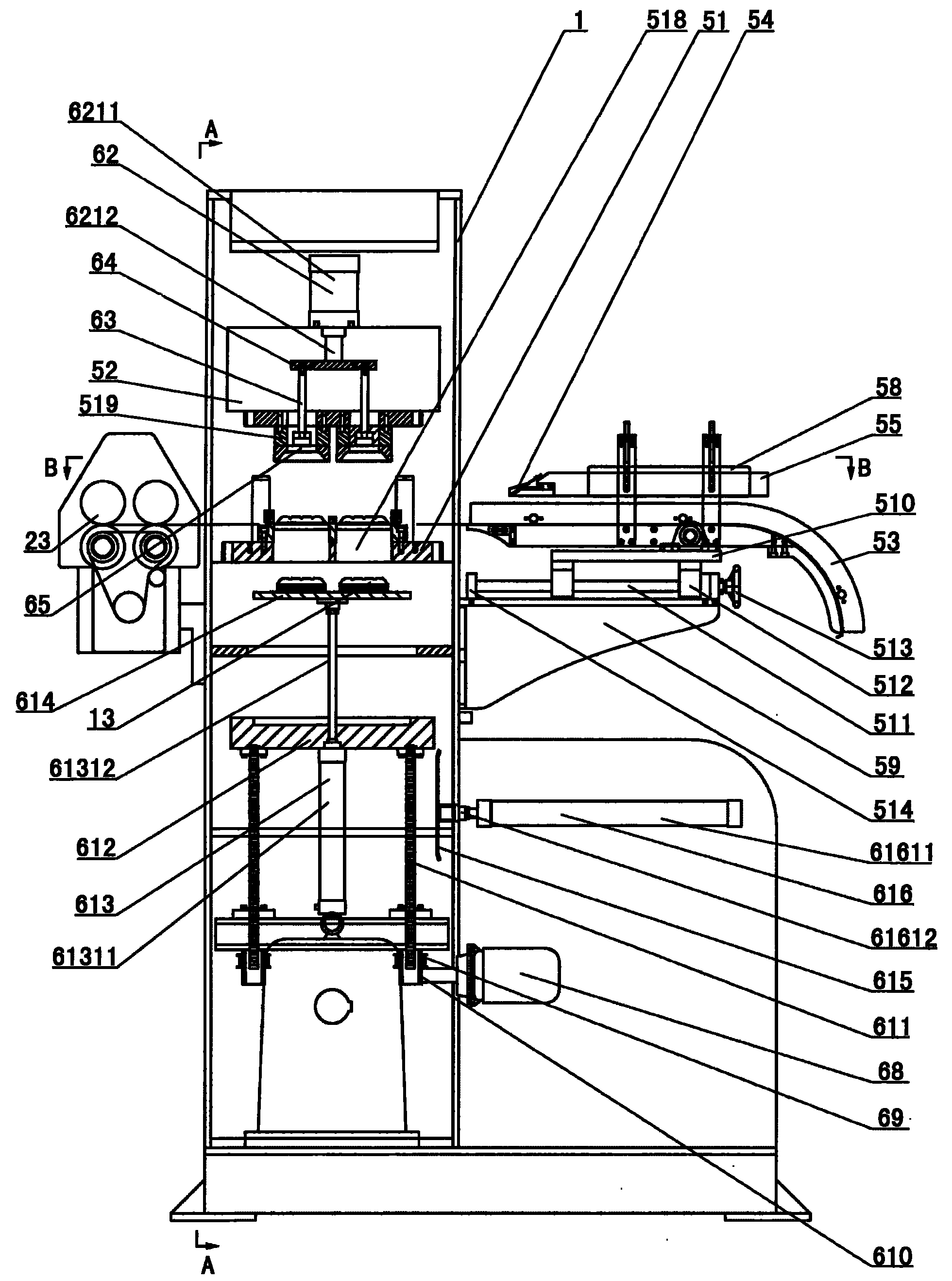

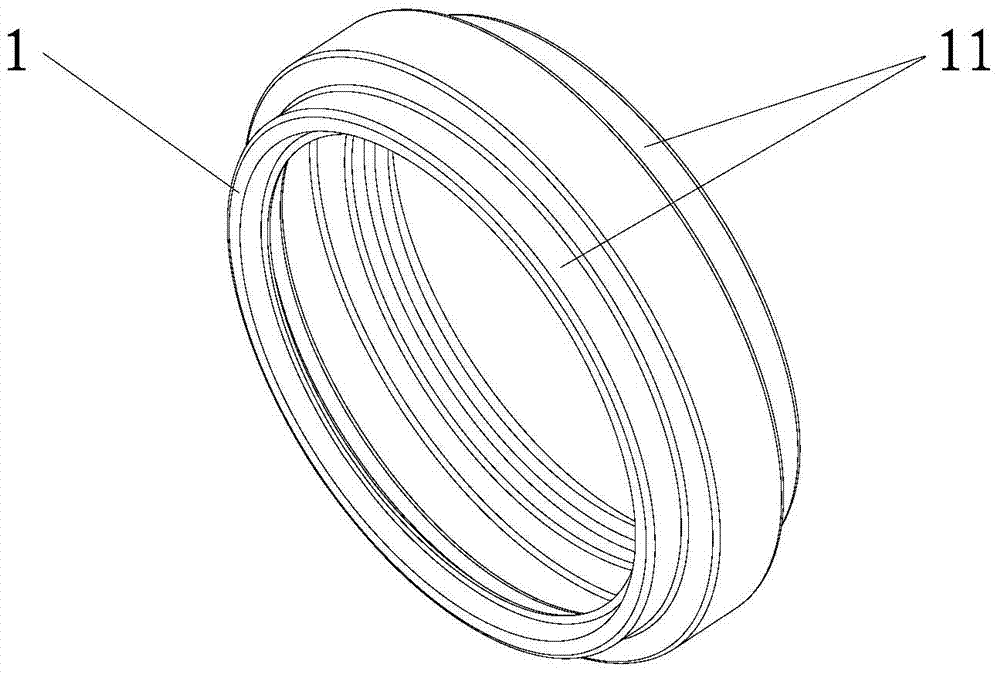

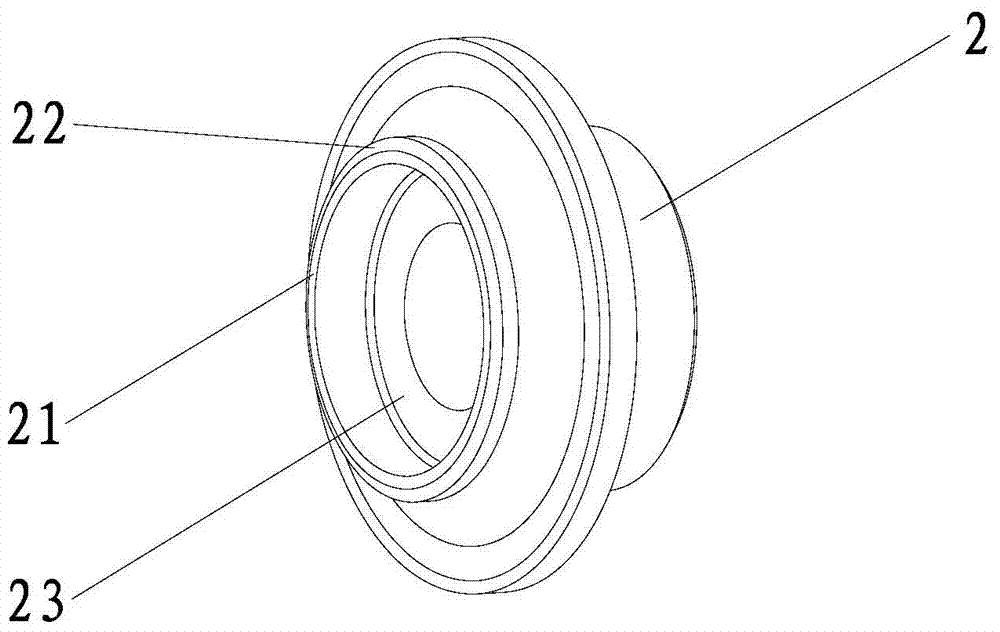

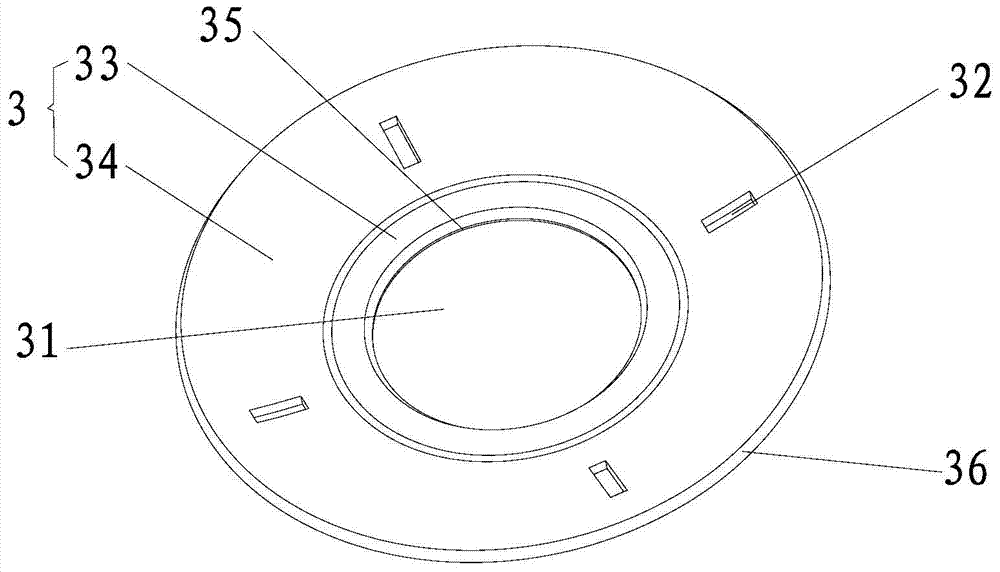

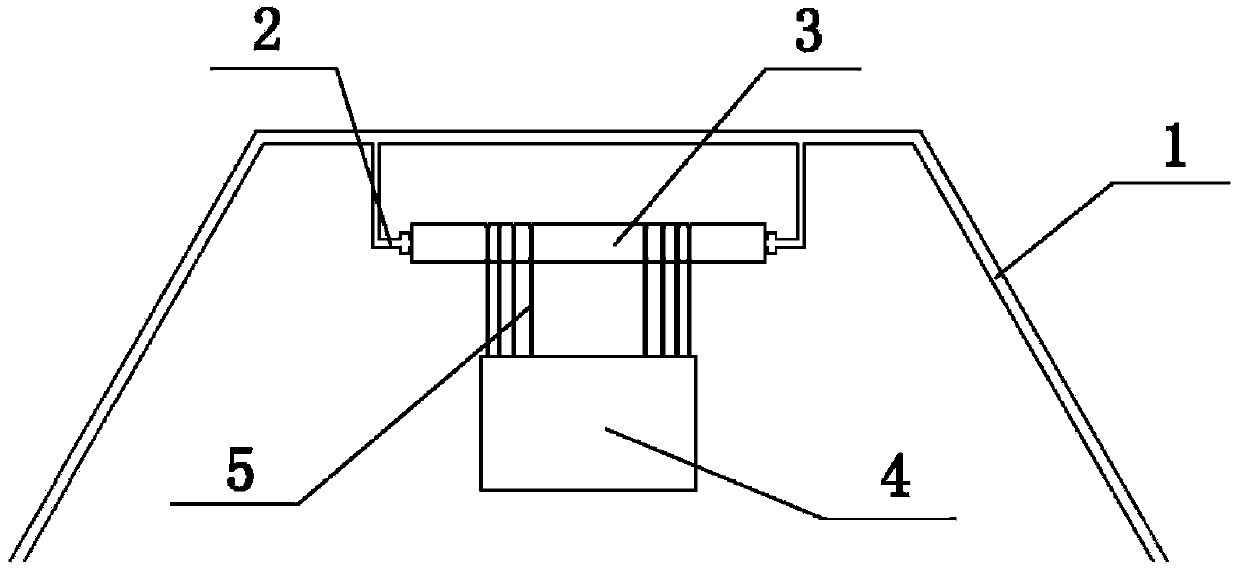

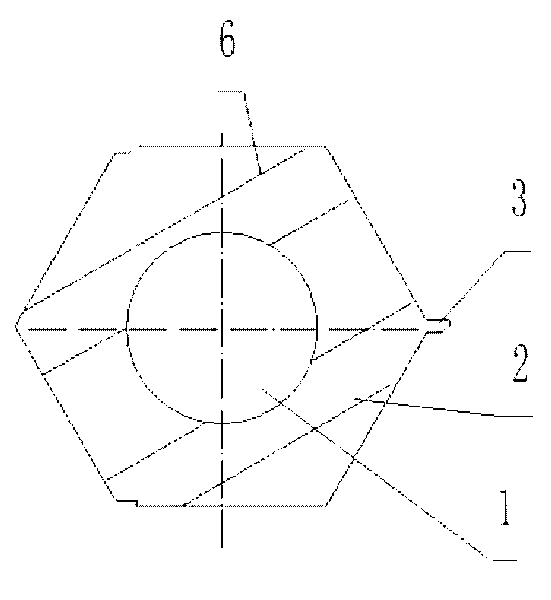

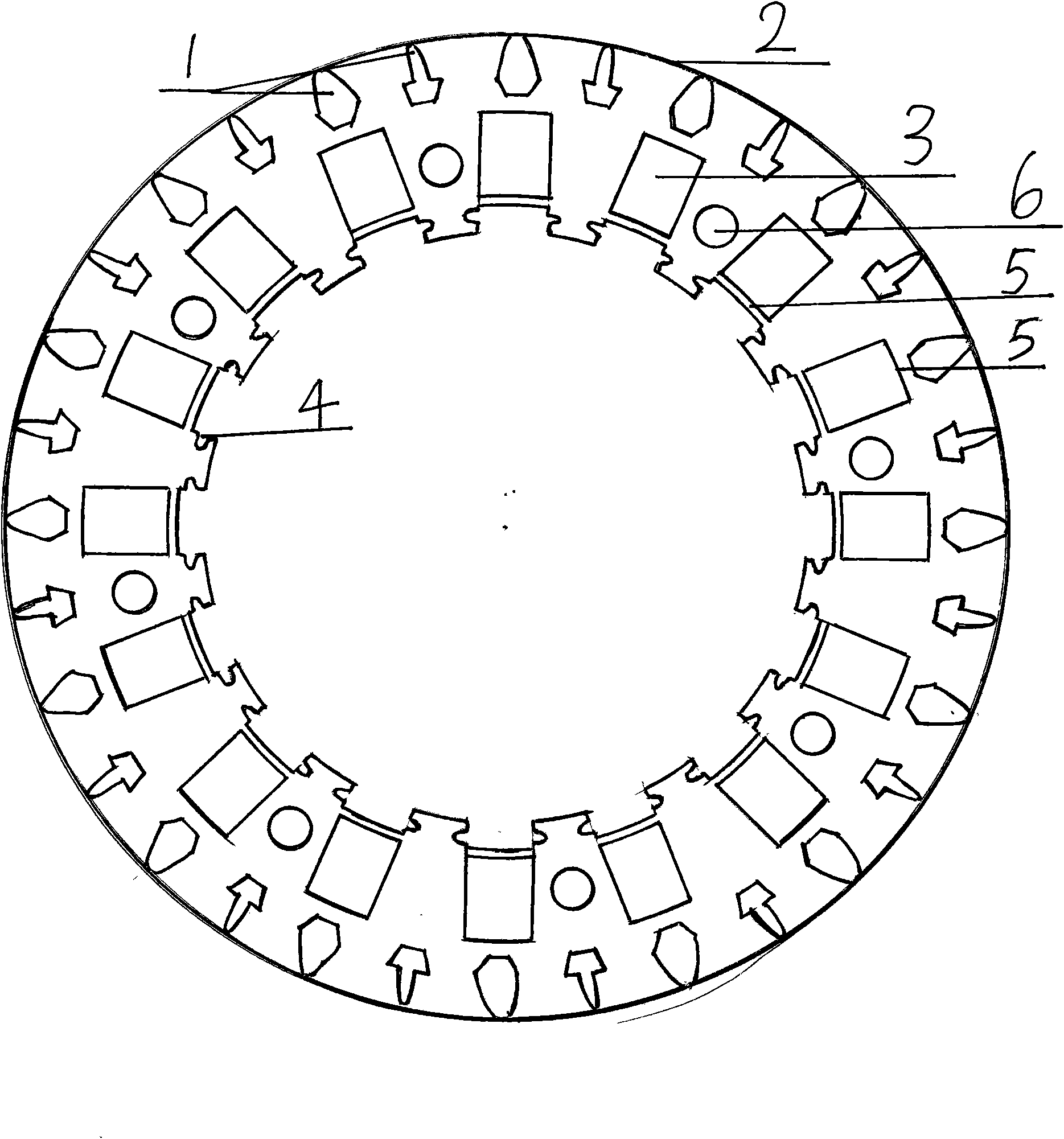

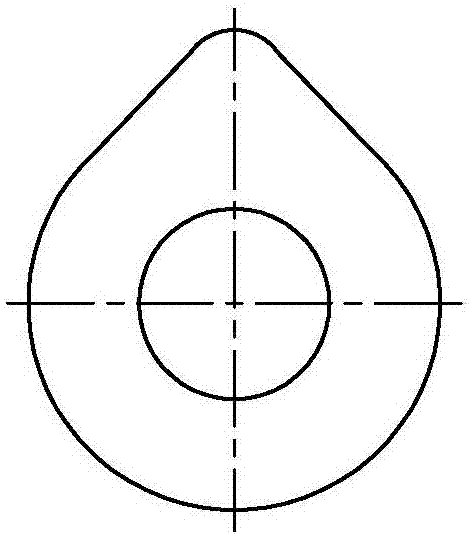

Directional punching shear and processing method for iron core pieces of stator and rotor of rotary motor

ActiveCN101719705ASolve the misalignment of inner and outer edgesSolve the appearanceManufacturing stator/rotor bodiesPunch pressDislocation

The invention discloses a directional punching shear and processing method for the iron core pieces of a stator and a rotor of a rotary motor, which is characterized in that the annular blank pieces of the iron cores of the stator, the middle part of which is provided with an installation through hole of the rotor are firstly punched and are provided with a positioning mark of a rotating orientation, the positioning mark of the rotating orientation is used for forming the annular blank pieces and a punch mould according to a preset rotating orientation during forming, and a mark which is used for correctly overlapping the iron core pieces of the same stator is manufactured on the formed iron core pieces of the stator after the iron core pieces of the stator are formed.The invention aims to provide the directional punching shear and processing method for the iron core pieces of the stator and the rotor of the rotating motor. The method effectively solves the problem of size deviation of the iron core pieces caused by different cutting edges of the mould and the problem of dislocation of the inner edges and the outer edges of the iron cores caused by the size deviation of the iron core pieces caused by different orientations of the rolling traces of materials and improves the appearance of the iron cores greatly.

Owner:陈石云

Uplift pile with upper straight rod and lower screw suitable for seasonal frozen soil regions and construction method thereof

ActiveCN107386281AImprove the pull-out capacityAffected by forceProtective foundationBulkheads/pilesEngineeringRebar

The invention discloses an uplift pile with an upper straight rod and a lower screw suitable for seasonal frozen soil regions and a construction method thereof. The uplift pile is characterized by comprising a plurality of anti-punching shear bars, a sand pulp and a sleeve pipe, wherein the anti-punching shear bars are positioned at the central position of the uplift pile; the anti-punching shear bars are wrapped with the sand pulp to form a cylindrical structure; a connector protruding out of the top of each of the uplift pile is reserved at the top of each of the anti-punching shear bars; a thread is arranged on the outer wall of the lower part of the cylindrical structure to form the screw part of the uplift pile; no thread is formed on the outer wall at the upper part of the cylindrical structure so as to form the straight rod part of the uplift pile; the outer wall of the straight rod part of the uplift pile is sleeved with the sleeve pipe; the sleeve pipe comprises an inner layer sleeve pipe and an outer layer sleeve pipe; the outer layer sleeve pipe can produce displacement relative to the inner layer sleeve pipe in the axial direction of the uplift pile; the inner wall of the inner layer sleeve pipe is in contact with the sand pulp; and the outer wall of the outer layer sleeve pipe is in contact with the frost-heaving and thawing-settlement foundation.

Owner:CHONGQING JIAOTONG UNIVERSITY

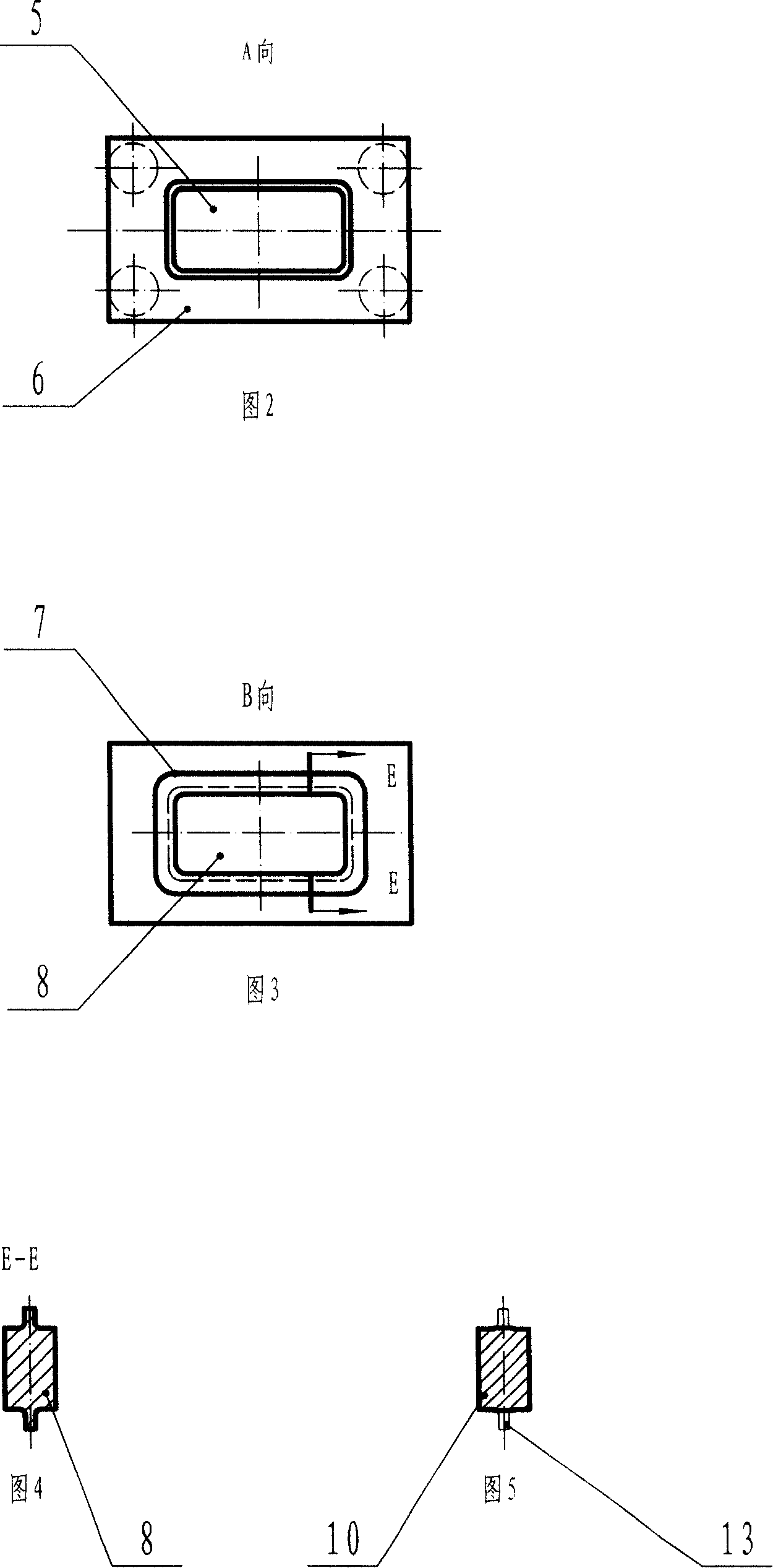

Battery differential thickness steel casing and its manufacturing technique

InactiveCN101197432AImprove discharge performanceIncrease the inner volumeCell component detailsPunch pressStructural engineering

The invention relates to a cell differential steel shell and a process for producing the same. The cell differential steel shell is a hollow cylinder which has a closed anode head and an enlarged and open shell opening, with the wall thickness of the middle segment of the hollow cylinder being smaller than that of the anode head as well as of the shell opening. The process comprises the following: a step of blanking and light drawing by means of a multi-stage punch, which forms a bow-shaped blank; a step of redrawing, which reduces the diameter of the blank, increases the height of the blank and reduces the wall thickness of the middle segment of the hollow cylinder, keeping the wall thickness of the anode head; a step of deep drawing, which reduces the diameter, increases the height and reduces and keeps the outer diameter of the hollow cylinder and the wall thickness of the middle segment to the standard thickness required by the design; a step of deep drawing, which forms the shell opening and keeps the thickness of the shell opening equal to that of the blank; a step of shaping the anode head and punching two steps, which keeps the thickness of the anode as well as the two steps equal to that of the blank; a step of punching shear of the scrap of the shell opening, which forms the finished product of the differential steel shell. The invention is capable of increasing the capacity of the cell steel shell, thereby increasing the filling amount of an active substance, improving the discharge performance of the cell and prolonging the service life of the cell.

Owner:GUANGDONG ZHENGLONG

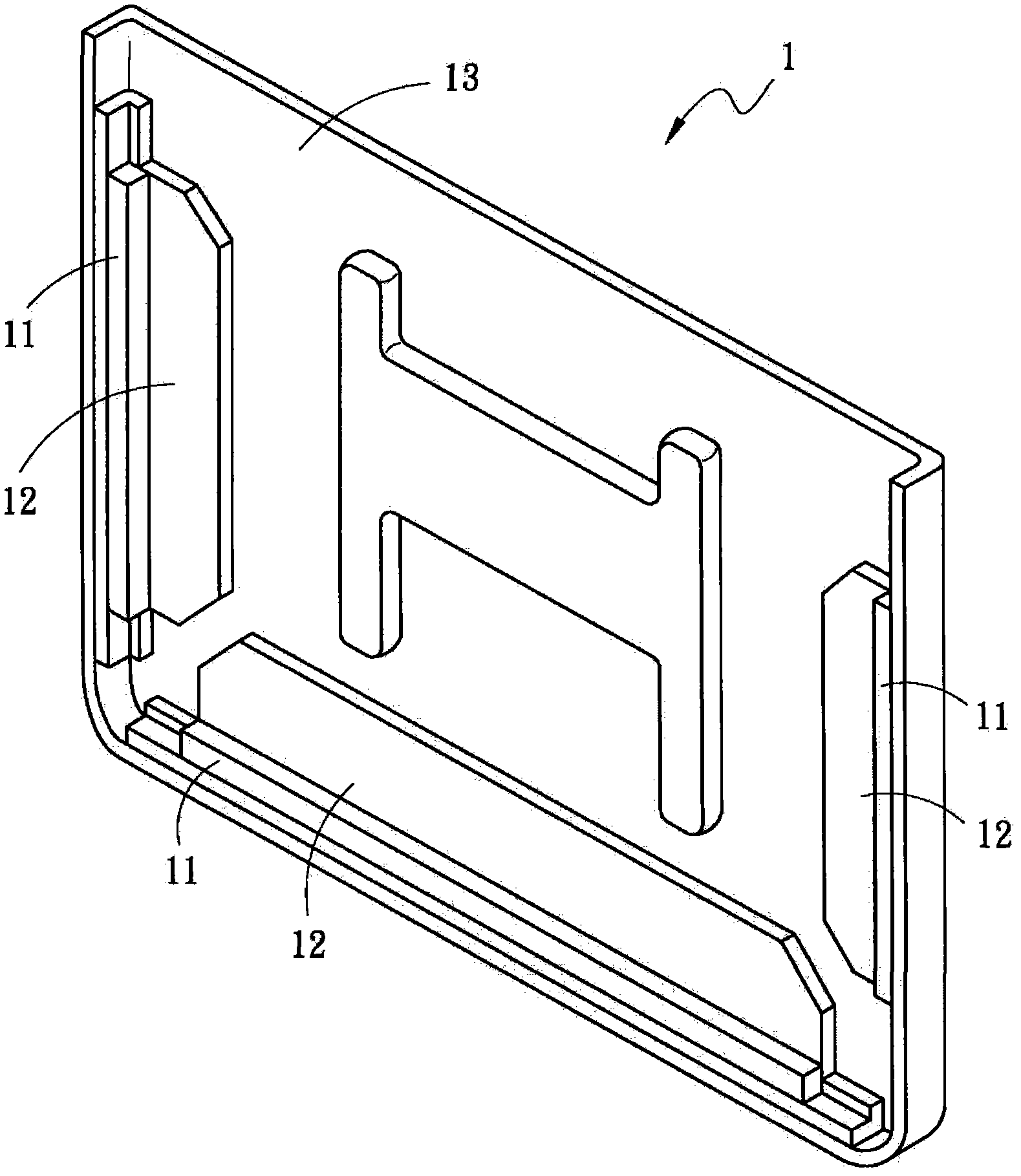

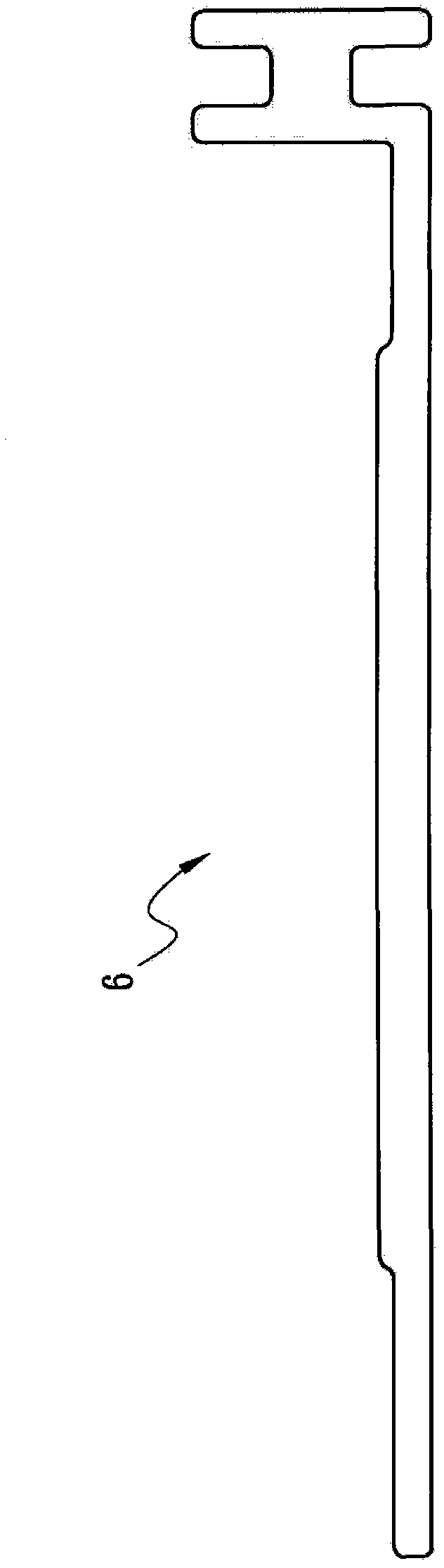

Heat dissipation frame manufacturing method and products thereof

InactiveCN103042370AReduce processing stepsOvercome the shortcomings that affect the efficiency of heat transferNon-linear opticsThermal energyManufacturing cost reduction

The invention relates to a heat dissipation frame manufacturing method and products thereof. The heat dissipation frame manufacturing method comprises the following steps: firstly extruding an aluminum product into a cooling fin prototype; after measuring the cooling fin prototype according to needed dimensions, carrying out a local punching shear on a position to bend of the cooling fin prototype to form a plurality of punching shear gaps; bending the cooling fin prototype at the position of the punching shear gaps and forming a plurality of bending angles in a mutual butt joint mode; and fixedly jointing the butt joint positions of the punching shear gaps and the head and tail butt joint positions of the bended cooling fin to form a frame. Therefore, an extruding type cooling fin formed through a punching shear and bending can effectively reduce the procedures and save materials and reduce the cost of work hours and reach the aims of improving the heat conduction performance and lowering the manufacturing cost.

Owner:GOANG HANN ENTERPRISE

Round felt piece punching shear device

InactiveCN106738047AGood punching qualityConvenient post-packagingMetal working apparatusEngineeringMechanical equipment

The invention provides a round felt piece punching shear device and belongs to the technical field of mechanical equipment. The problems that the felt piece punching quality is low and use is troublesome in the prior art are solved. The round felt piece punching shear device comprises a rack; the rack is fixedly connected with a punching shear platform connected with pressing rods; pressing wheels are hinged to the pressing rods; the rack is connected with a lifting table fixedly connected with a plurality of punching knives; the punching knives are sleeved with cutters; material collection claws are fixedly inserted and connected into the punching knives; limiting feet are provided with limiting portions; a supporting boss capable of pushing felt pieces obtained by punching shear to the position above the multiple limiting portions is arranged on the upper side face of the punching shear platform; and the lifting table is further connected with a positioning base. The round felt piece punching shear device is good in punching shear quality, and can collect the felt pieces obtained by punching shear more conveniently.

Owner:RUGAO JIABAI PLASTIC PROD CO LTD

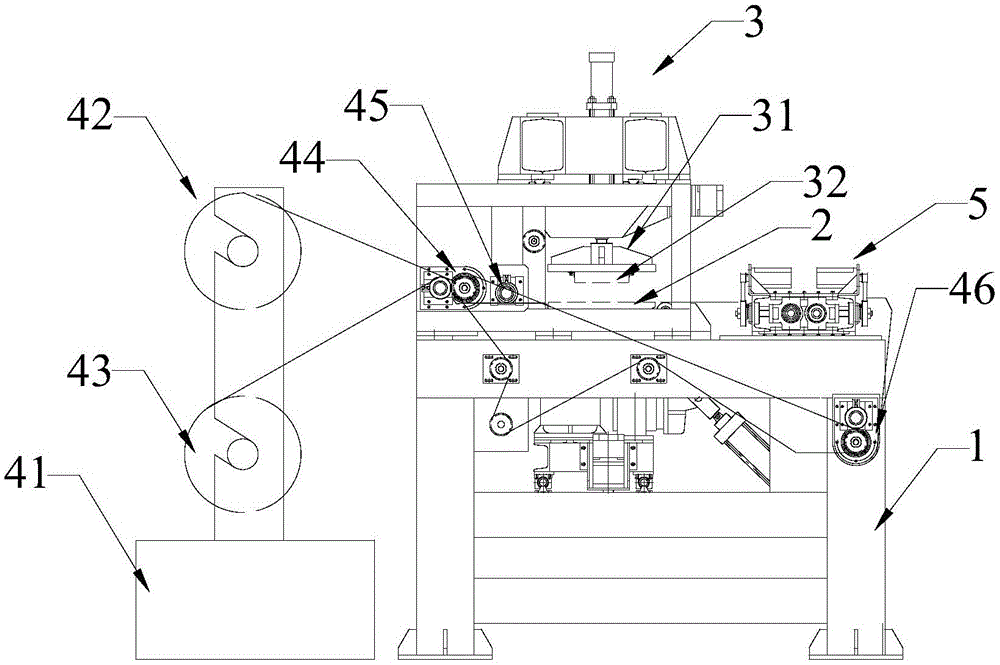

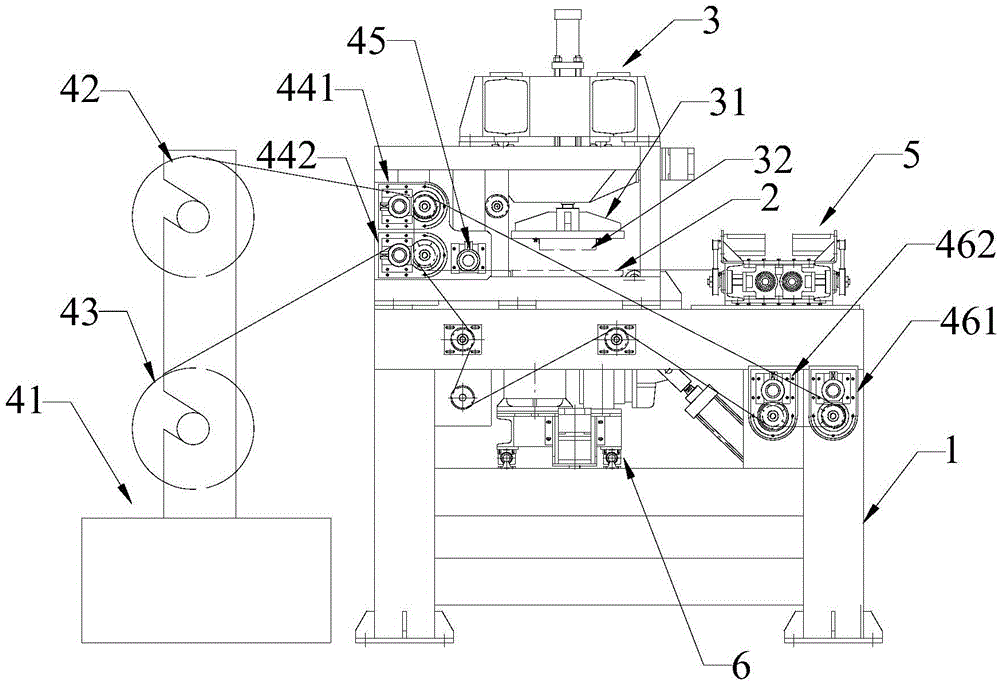

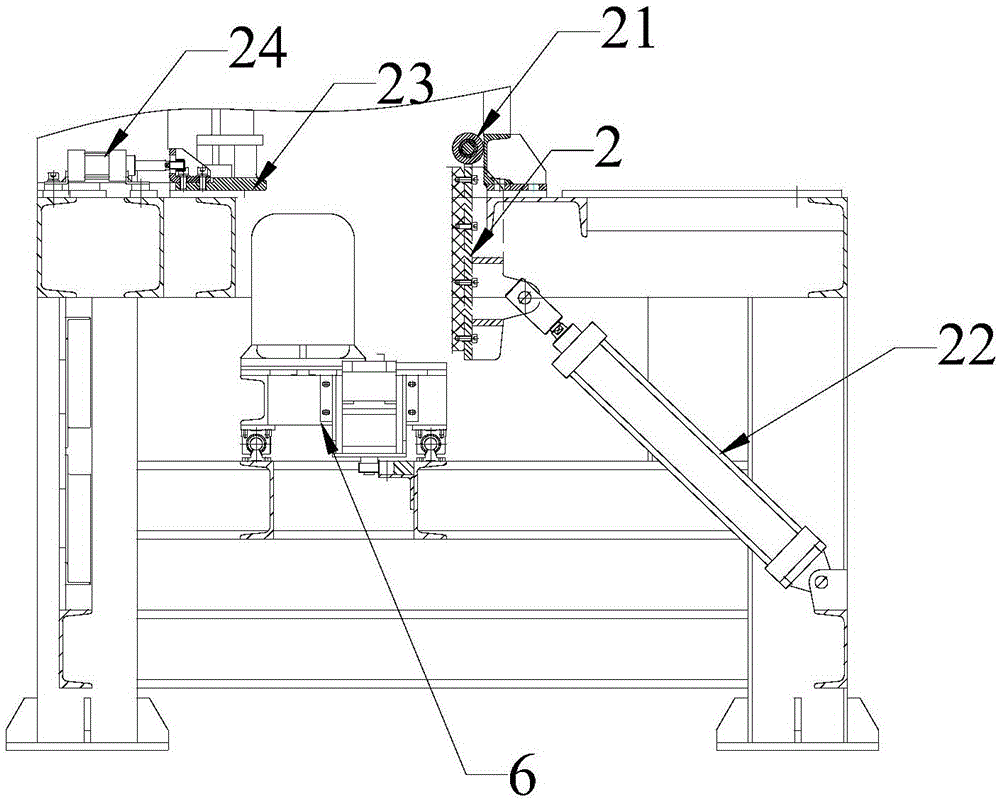

Automatic shearing machine for soft sheets

ActiveCN105000415AImprove shear efficiencyImprove cutting accuracySevering textilesMetal working apparatusEngineeringDrive motor

The invention provides an automatic shearing machine for soft sheets. The automatic shearing machine comprises a rack, a workbench, a feeding device and a punching shear device. The punching shear device is arranged above the workbench. The punching shear device comprises a punch, a punch driving motor and a punching shear die. A horizontal sliding rail is arranged on the rack. The punch is arranged on the horizontal sliding rail and driven by the punch driving motor to move along the horizontal sliding rail. The feeding device comprises a roller frame, feeding rollers and collecting rollers. The roller frame is vertically arranged beside the rack. A first material roller and a second material roller are arranged on the roller frame in parallel. The first material roller is arranged over the second material roller. The feeding rollers are arranged at the feeding end of the workbench on the rack. The collecting rollers are arranged at the discharging end of the workbench on the rack. The feeding rollers and the collecting rollers draw materials on the first material roller and the second material roller to penetrate through the workbench in a vertically-stacked mode. The automatic shearing machine for the soft sheets is high in shearing efficiency and high in shearing accuracy.

Owner:尤涛

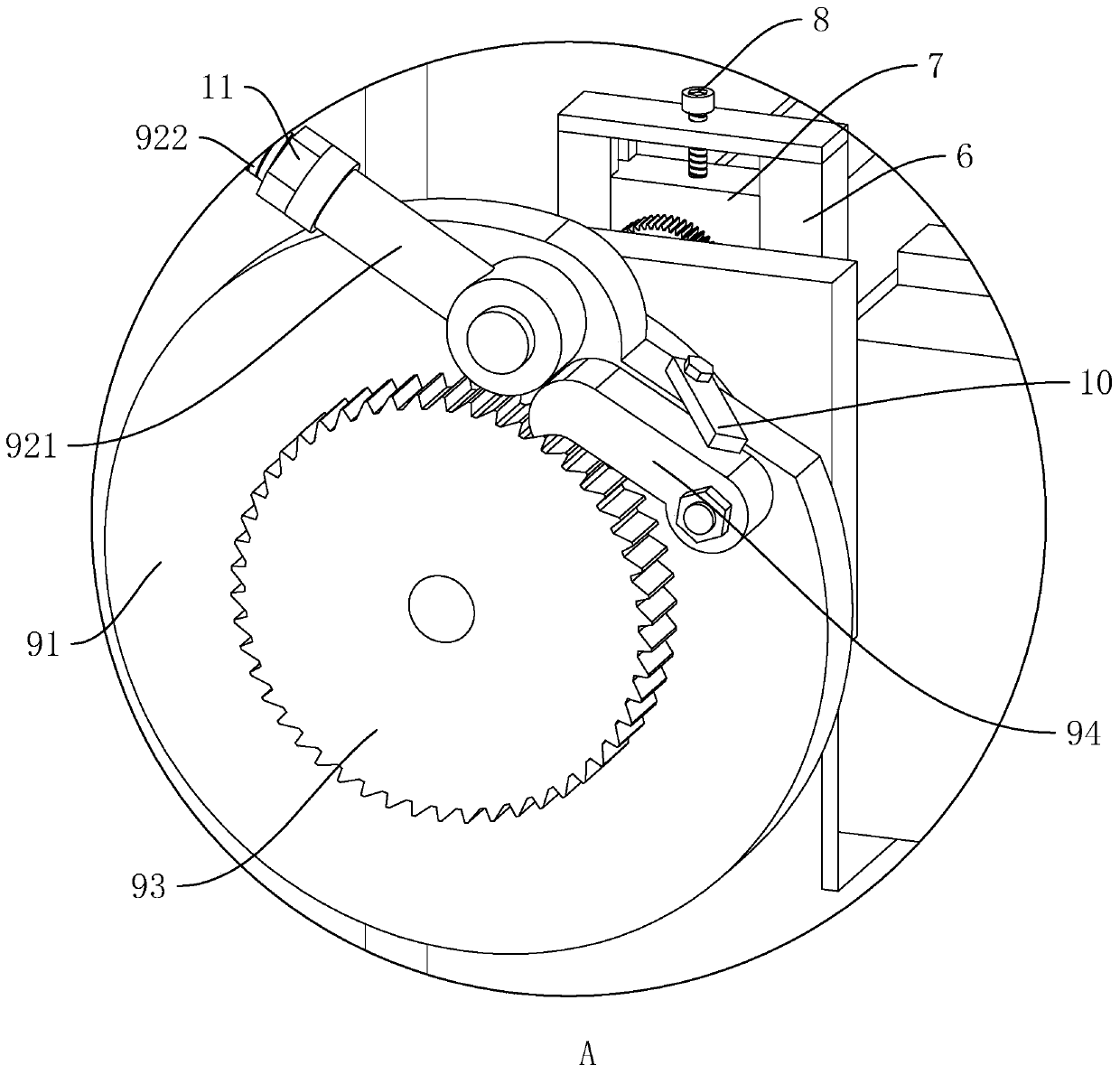

Steel plate net punching and shearing machine

InactiveCN111069679AAdjustable positionAdjustable feed amountMetal-working feeding devicesShearing machinesRatchetElectric machinery

The invention discloses a steel plate net punching and shearing machine, and relates to the technical field of steel plate net production. The steel plate net punching and shearing machine comprises arack, an upper tool rest is slidably arranged on the rack, a driving device is further arranged and comprises a cam mechanism, a reset spring and a driving motor which are rotationally connected to the rack, a feeding assembly is further arranged and comprises two conveying rollers, a transmission mechanism is connected between the cam mechanism and one of the conveying rollers and comprises a rotating part, a hinging rod, a ratchet wheel and a ratchet matched with the ratchet wheel, the ratchet wheel is coaxially and fixedly connected with the corresponding conveying roller, the rotating part is rotationally arranged relative to the ratchet wheel, the rotating axis of the rotating part is arranged coaxially with the ratchet wheel, the ratchet is correspondingly hinged to the rotating part, one end of the hinging rod is hinged to the rotating part, the other end of the hinging rod is hinged to the cam mechanism, and the hinging axis of the hinging rod and the cam mechanism and the rotating axis of the cam mechanism are arranged in a staggered mode. Through cooperation of the hinging rod, the rotating part, the ratchet wheel and the ratchet, using of a clutch is avoided, and the overall structure is simpler.

Owner:浙江高盛钢结构有限公司

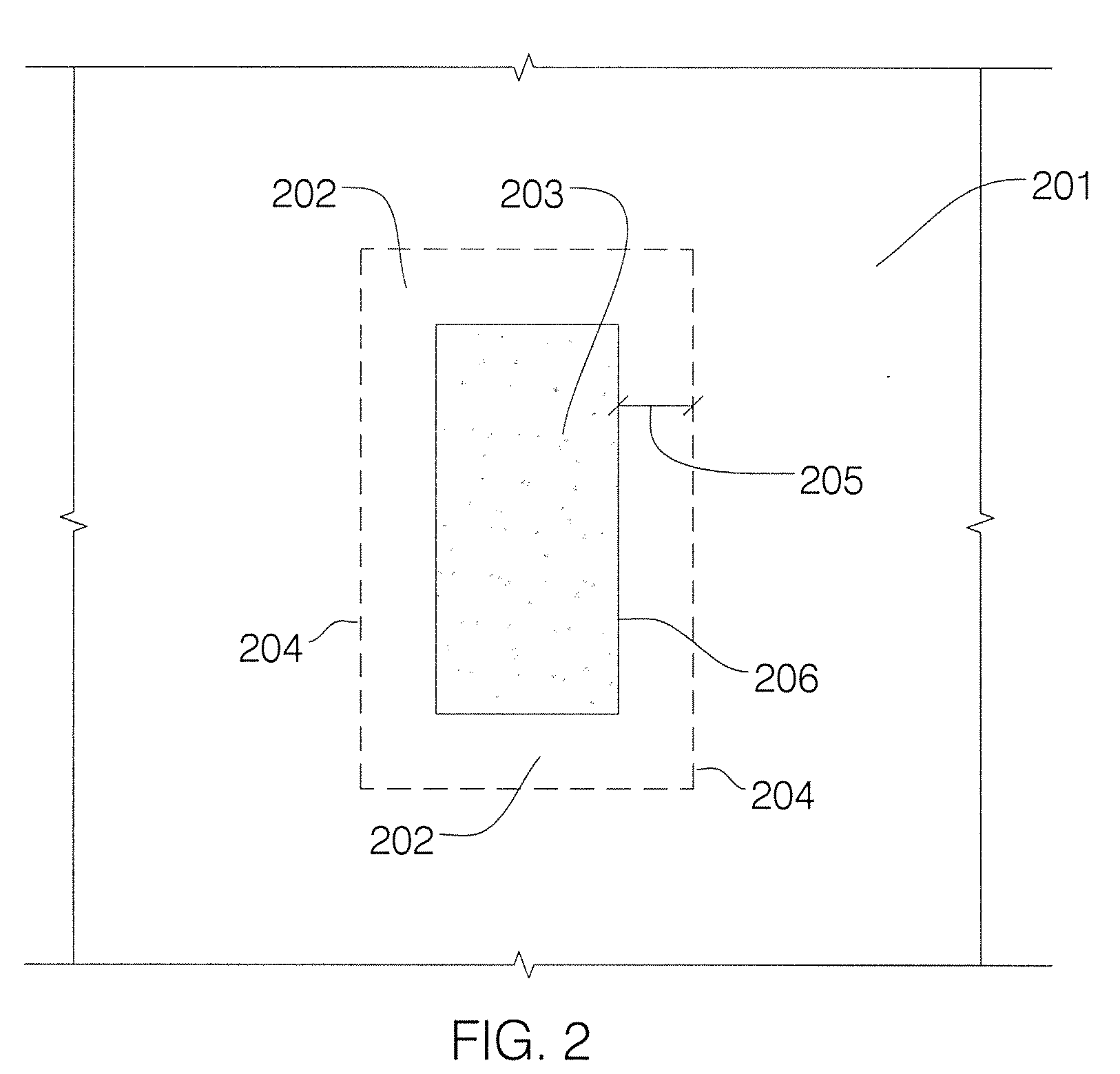

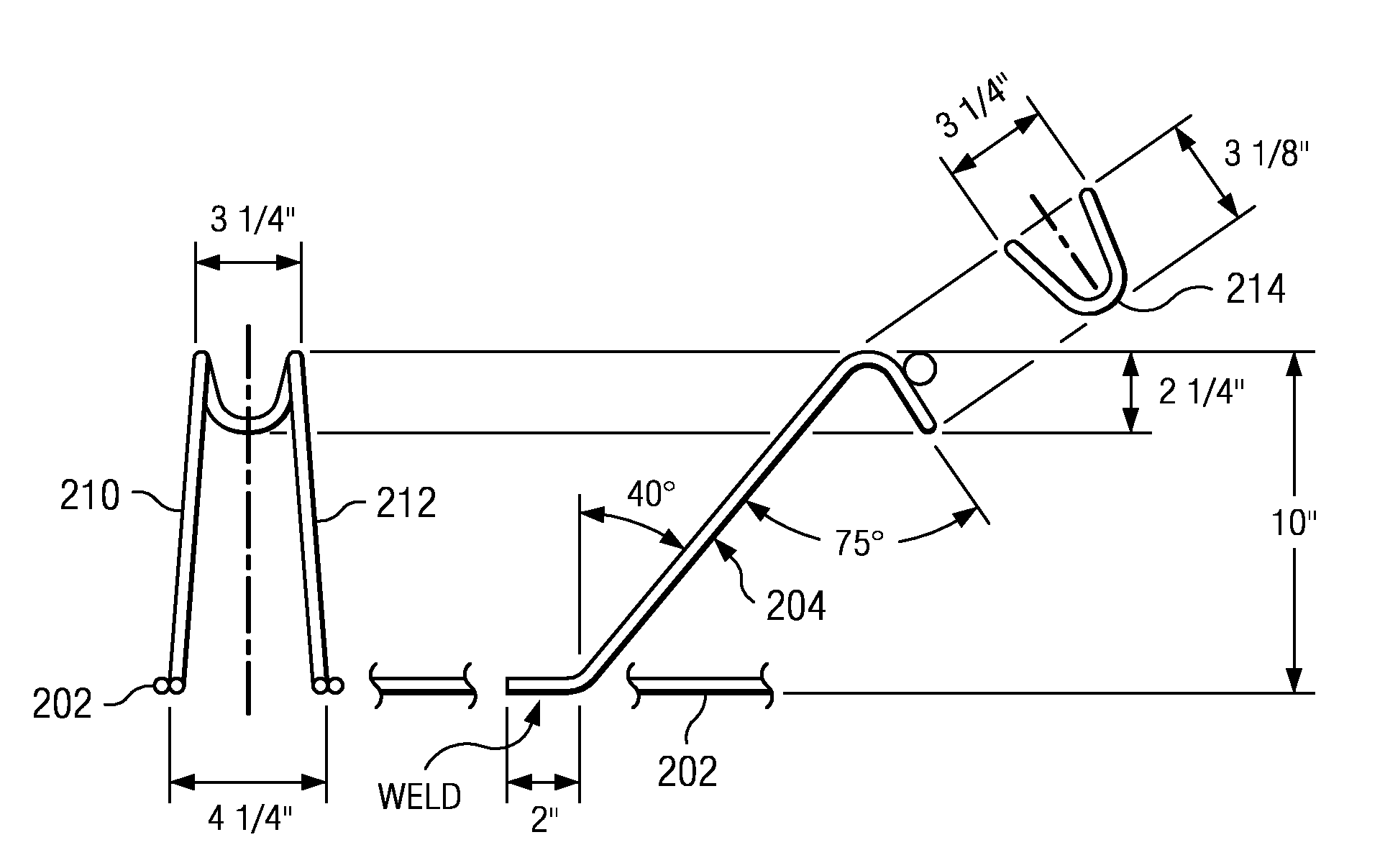

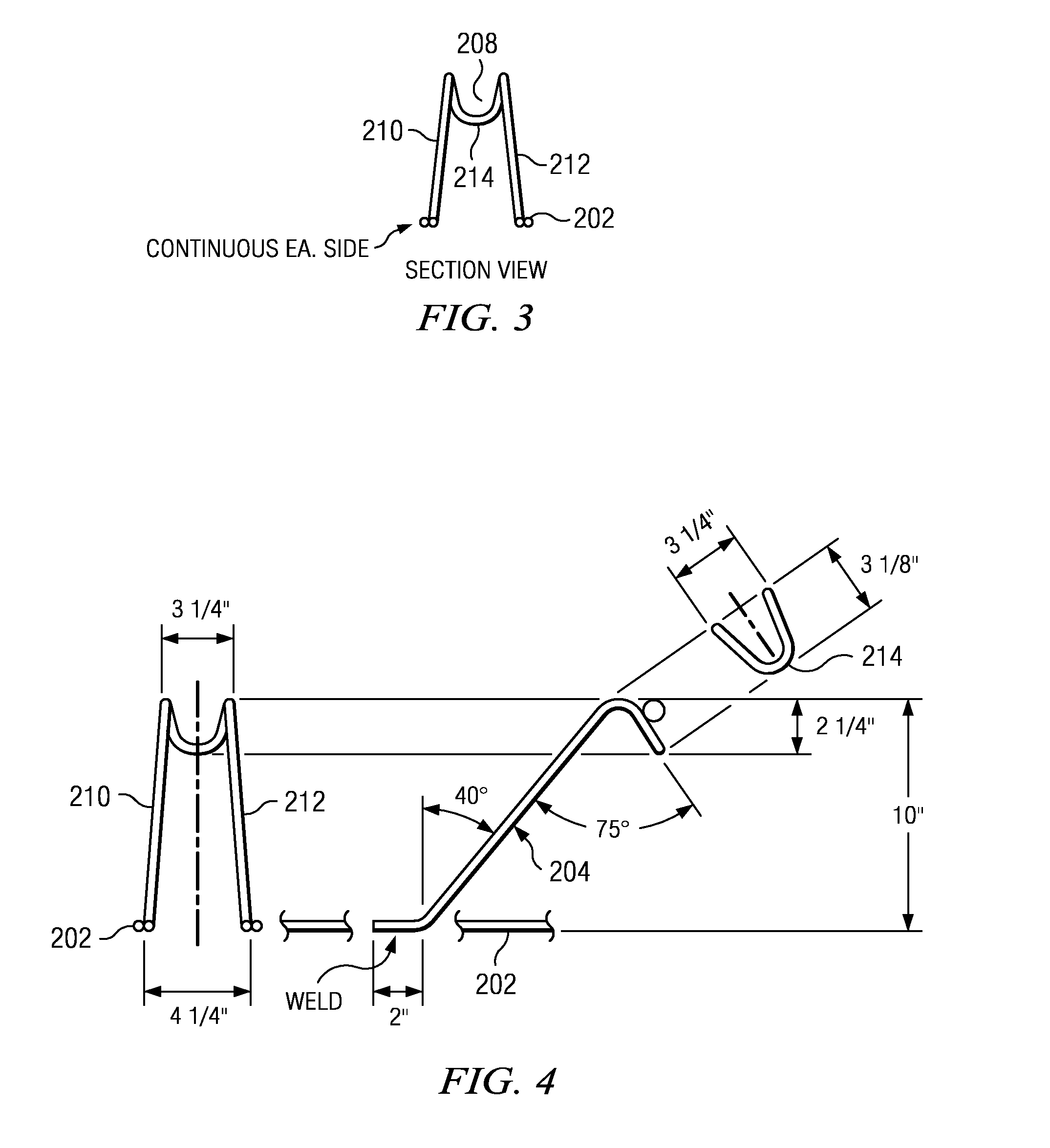

Reinforcing assembly, and reinforced concrete structures using such assembly

InactiveUS20120137618A1Great punching shear reinforcement protectionIncrease surface areaFloorsBuilding repairsDiagonalRebar

A reinforcing assembly to address this problem comprises a plurality of diagonal working members (preferably formed of #3 rebar) each of which is “ribbed” to provide increased surface area for bonding to the concrete, and each of which is attached to a horizontal runner independently such that the diagonal working members are variably spaced along the assembly. Relative to the horizontal runner, each diagonal member is “bent” at a given angle, preferably in the range of 45° plus or minus 25°. The reinforcing assembly is designed for use to provide punching shear reinforcement in a reinforced concrete structure such as, without limitation, a slab (in which the assembly is supported) located adjacent a structural column. The top of each diagonal member in the reinforcing assembly preferably comprises a double hook that is configured to fit within reinforcing bars that run along the top of the slab. The horizontal runner comprises a pair of spaced-apart, longitudinally-extending carrier (or “support”) bars, each of which preferably terminates on one end (namely, at the support column) at one end in a structure that is bent upwards and hooked. Preferably, the hooked structure of each runner bar extends into the structural column to provide additional reinforcement, thereby converting the runner bar into a reinforcing member that provides the same function as the other diagonal members, and at a confined location at a highest point of stress (i.e. where the slab attaches to the column) where it would not be possible otherwise to fit a diagonal member.

Owner:MARTTER RICHARD P

Method for preparing anti-bacterial anti-mildew styrene-butadiene rubber foamed plate

InactiveCN101070405AHigh impact strengthImprove wear resistanceFlat articlesGlyceryl monostearateAntibacterial agent

The present invention relates to a preparation method of antibacterial and antifungal, styrene-butadiene-rubber, foamed sheet. Using 62-70 % SBR as basic material, 14-20% SIS, 0.6-1.2% antibacterial agent, 0.5-1.0% antifungal agent, 5-8% naphthenic oil, 6-10% clay, 1.4-2.2% OBSH, 0.5-1.0% sodium butyl dithiocarbonate, 0.5-1.0% DCP, and 0.6-1.2% glyceryl monostearate are added, after passing through plasticization, twin-roll mixing, first moulding foaming, cooling, second moulding foaming, cooling pitching, and punching shear, the production is formed. The foamed sheet prepared by this method, has low density, high impact resistance, good compression reducibility, wear resistance and slip resistance, good damping effect, no poison and no smell, especially, has excellent antibacterial and antifungal ability, is suitable for the floor board of indoor fitness and exercise sites, and can effectively inhibit pathogenic bacteria and mildew's reproduction and living, thus improves the sanitarian condition of the fitness and exercise sites.

Owner:FUJIAN NORMAL UNIV

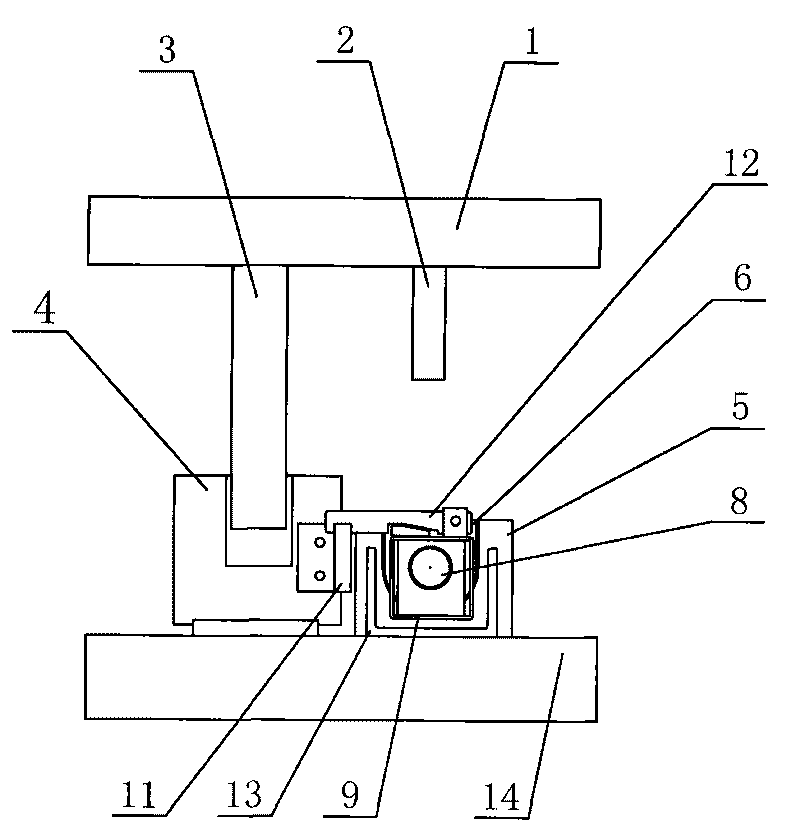

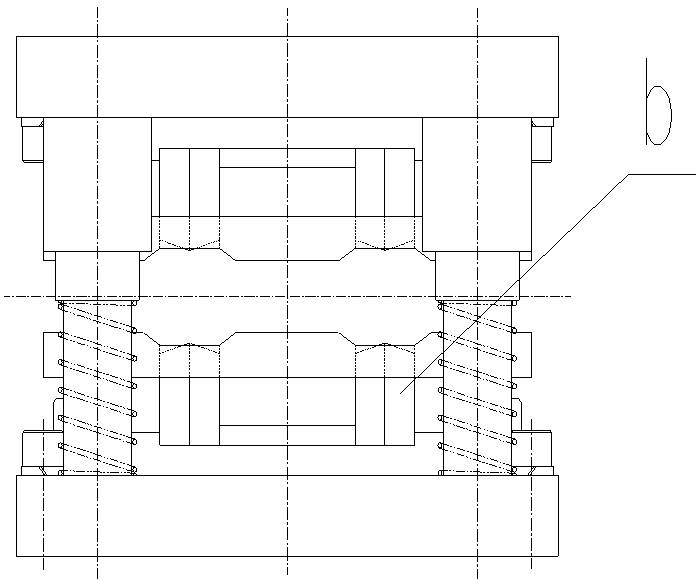

Micro-punching-shear testing device and method for micro-area mechanical property of welding joint

ActiveCN105203453ASimple test methodThe result is accurate and reliableUsing mechanical meansMaterial analysisCircular coneData acquisition

The invention provides a micro-punching-shear testing device for the micro-area mechanical property of a welding joint. The device comprises a base and four guide posts connected to the base. The guide columns are sleeved with a punching disc, a guiding disc and an upper disc from bottom to top. The punching disc is a disc provided with a boss and a center hole. The lower plane of the punching disc is provided with a conical hole. The upper plane of the punching disc is provided with a radial groove and two pressing pieces. The guiding disc is provided with a center hole for allowing a punch bar to be inserted therein in a penetrating mode. Two notches are symmetrically formed in the outer circumference of the guiding disc. The upper disc is provided with a center hole and notches corresponding to the guiding disc and a counter bore coaxial with the center hole. The punch bar is a cylinder, wherein the upper end of the punch bar is provided with a flange, the lower end of the punch bar is provided with a center blind hole, and the middle of the punch bar is provided with a radial through hole. A frame bar penetrates into the through hole, and the two ends of the frame bar are provided with displacement sensors, wherein the lower ends of the displacement sensors penetrate through the notches of the guiding disc to be connected with the punching disc, and the lower ends of the displacement sensors stretch into the notches of the upper disc. A force sensor is arranged on the end face of the flange of the punch bar. The displacement sensors and the force sensor are connected with a data acquisition system through wires. The invention further discloses a micro-punching-shear testing method.

Owner:HUAWEI TEHCHNOLOGIES CO LTD

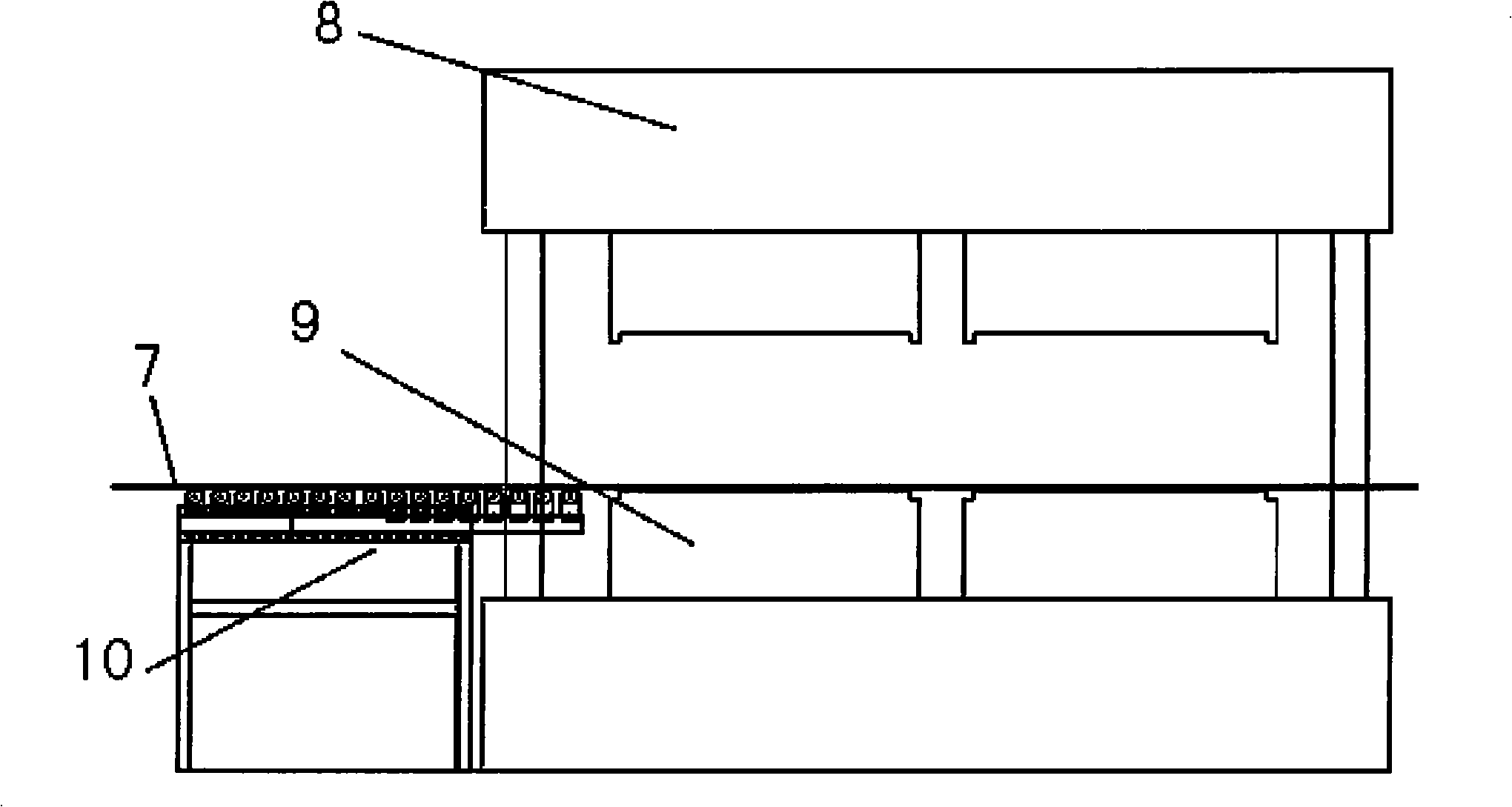

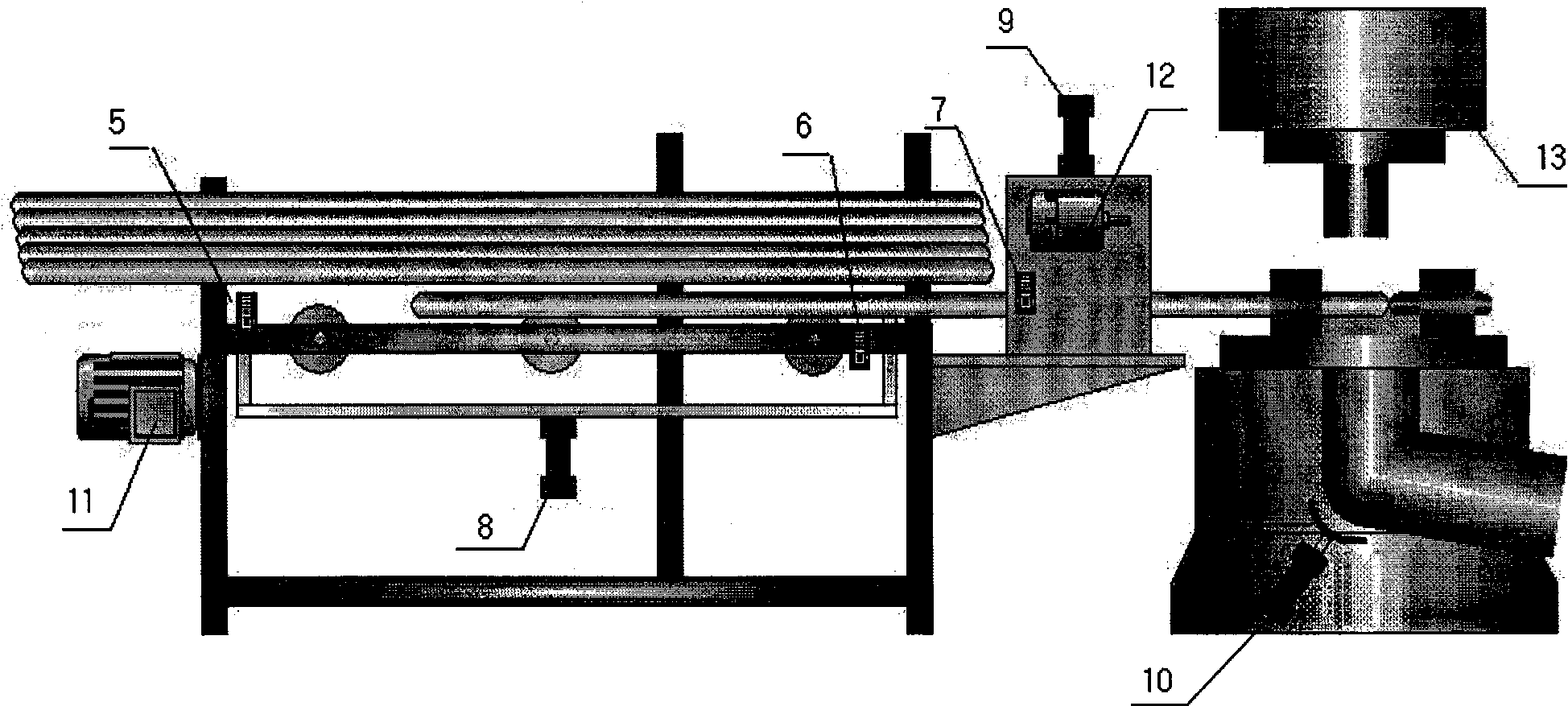

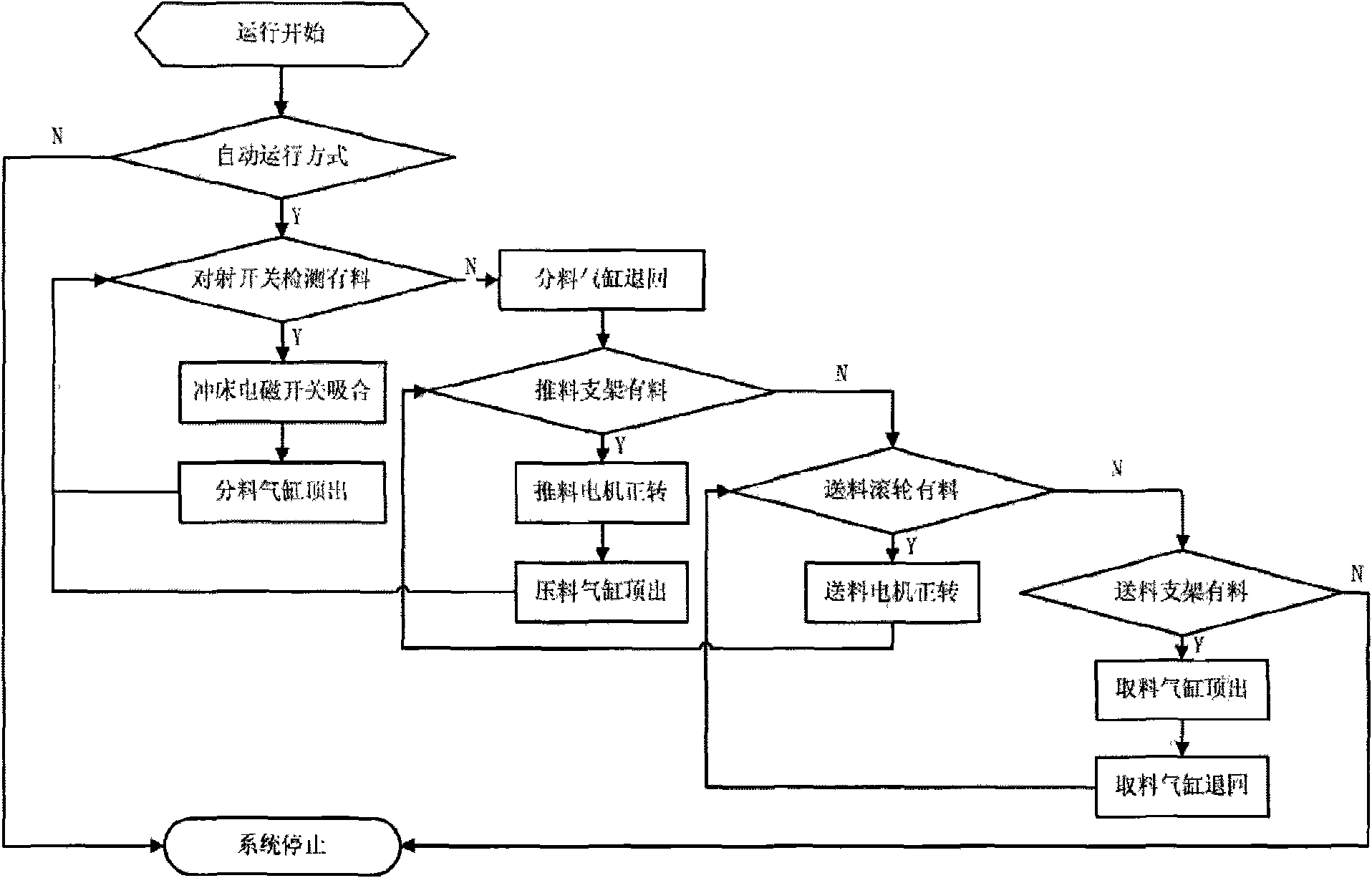

Control system and control method of steel punching shear production line

ActiveCN101561670AGuaranteed uptimeProgramme control in sequence/logic controllersPunch pressControl manner

The invention discloses a control system and a control method of a steel punching shear production line, capable of ensuring the safe and reliable operation of the steel punching shear production lineby means of the control mode of multi-layered logical judgment. The control system comprises a PLC 1, a server 2, a workstation computer 3, a client computer 4, a proximity position sensor I 5, a proximity position sensor II 6 and a proximity position sensor III 7. The server 2 and the client computer 4 are connected and communicated with the workstation computer 3 through an Ethernet. The PLC 1is communicated with the workstation computer 3 through SPC omm serial communication controls. the PLC 1 serves as a component executing the input or output of external signals; the workstation computer 3 operates the multi-layered logical judgment control programs and sends results to PLC 1, in turn controls a fetching cylinder 8, a swaging cylinder 9, a distribution cylinder 10, a feeding motor11, a pushing motor 12 and an electromagnet used in punching 13 to work according to the operation outcomes of the multi-layered logical judgment.

Owner:江苏网商精益管理软件有限公司

Punching shear punch capable of automatically changing tools

InactiveCN103084654AReduce tool change timeIncrease productivityNibbling shearing machinesPositioning apparatusPush pullEngineering

The invention provides a punching shear punch capable of automatically changing tools. The punching shear punch capable of automatically changing the tools comprises a main rack, a reciprocating power device and a moving tool connecting seat. Particularly, a moving tool locking device is arranged on the moving tool connecting seat, and a static tool locking device is arranged on the main rack. The punching shear punch capable of automatically changing the tools further comprises tool rests and at least two tool assemblies, wherein the tool rests are arranged on one side or two sides of the main rack, the tool rests are provided with placing positions, the number of the placing positions are no smaller than that of the tool assemblies, and each placing position corresponds to a push-pull device. The tool assemblies stay on the main rack or the placing positions of tool rests, and a push-out head and a clasp piece capable of swinging relative to the push-out head are installed on a moving part of each push-pull device. Each tool assembly comprises an upper tool and a lower tool, each lower tool is provided with a drag hook, a tappet capable of rotating relative to the drag hook is arranged beside the drag hook, one end of the tappet is a transmission end, the other end of the tappet is a unclasping end, and the transmission end of the tappet and the static tool locking device are in a linkage. The punching shear punch capable of automatically changing the tools is short in tool changing time and can effectively promote the manufacturing efficiency.

Owner:佛山市诺创智能设备有限公司

Reinforcing assembly, and reinforced concrete structures using such assembly

Owner:MARTTER RICHARD P

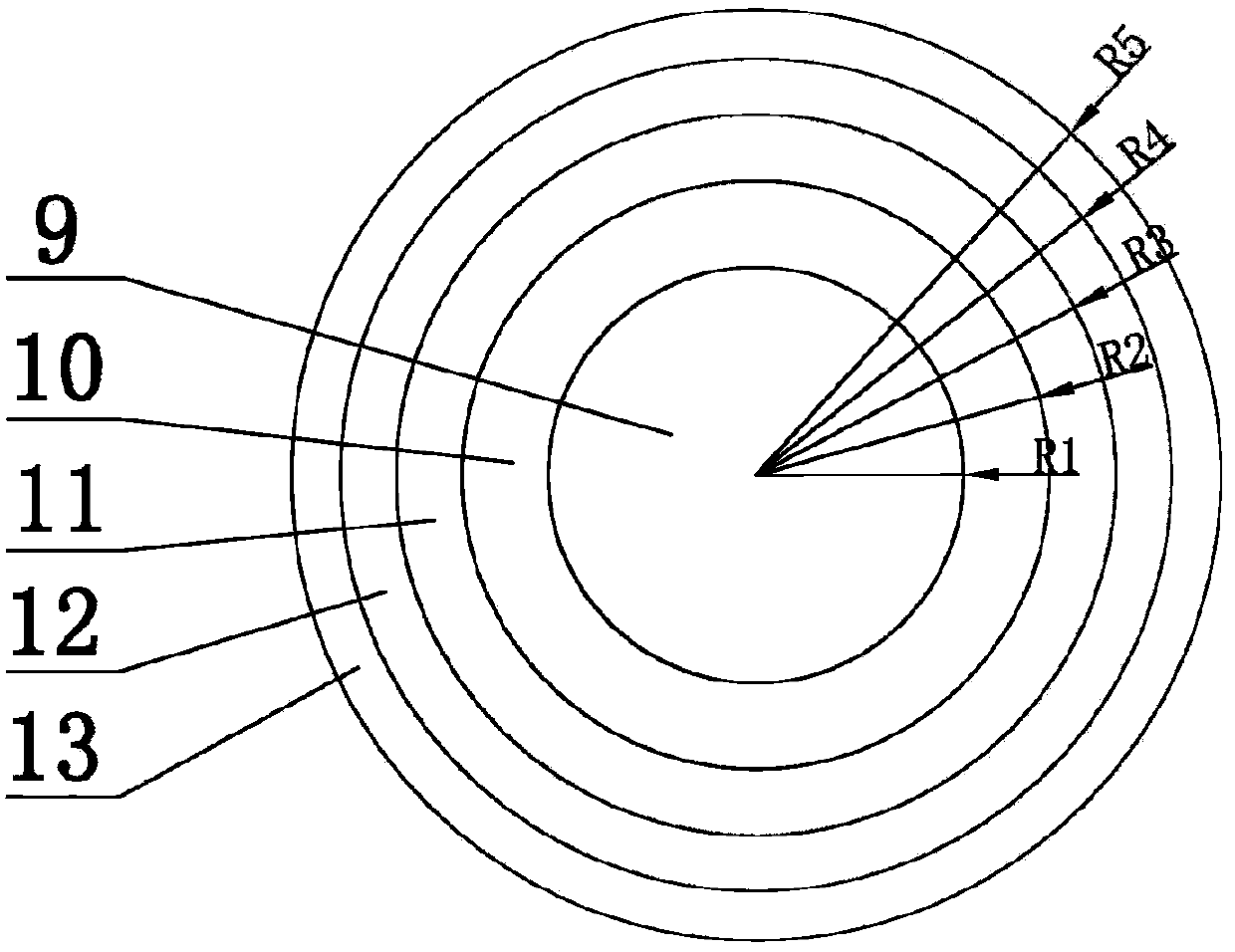

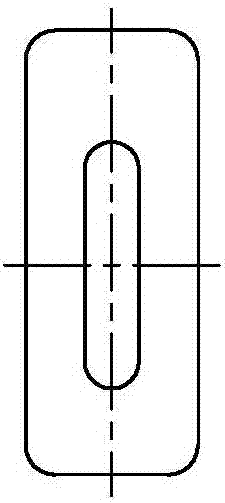

Rotor sheet of asynchronously-started PMSM (permanent magnet synchronous motor)

InactiveCN102170184AImprove punching efficiencyMagnetic circuit rotating partsSynchronous machinesPermanent magnet synchronous motorEconomic benefits

The invention relates to the field of the rotor sheet of a PMSM (permanent magnet synchronous motor), and in particular provides a rotor sheet of an asynchronously-started PMSM. The rotor sheet comprises asynchronously-started cage conducting bar slots, magnetic steel slots and a bolt fixing hole. The sheet does not have an interference spindle hole; the plurality of magnetic steel slots are formed at edges of the inner diameter circumference of the sheet in a punching shear mode, and magnet-isolating magnetic bridges, holddown grooves, asynchronously-started cage conducting bar slots at mouse cage parts at outer diameter edges of the fixed holddown grooves and bolt fixing holes in poles are reserved to constitute a high-intensity rotor sheet of the PMSM without coordination of a heating jacket. The rotor sheet has the beneficial effects that the punching efficiency is high, the labor and time are saved, the number of steel plates is reduced, the residual part without a center can be used for punching other small-size motor rotor sheets, and economic benefits in a motor sheet industry are improved greatly.

Owner:王乃兵 +1

Combined shaping anchor cushion plate and its manufacturing method

PendingCN107956273ASimple production processEnvironmental shortBuilding reinforcementsSteel platesSheet steel

The invention discloses a combined shaping anchor cushion plate, which comprises a pressure bearing cushion plate in a separating structure and a horn pipe; an installing thread hole and a grouting hole are arranged on the pressure bearing cushion plate, and a stopping opening is arranged on the pressure bearing cushion plate; the stopping opening is a continuous groove stopping edge or a stoppingedge with an intermittent groove tooth; the horn pipe is formed by assembling 2-6 steel plates in the manner of welding, riveting or buckling and laminating; a reinforcing rib I is punched on the horn pipe at the bending corner of the joint of the horn pipe and the pressure bearing cushion plate, and reinforcing ribs II with different sizes are punched on the height direction of the horn pipe; under the using state, the combined shaping anchor cushion plate is combined by welding, riveting or buckling and laminating the pressure bearing cushion plate in a separating manner with the horn pipe.The manufacturing method includes steps of manufacturing the pressure bearing cushion plate and the horn pipe through punching shear or stretching, wherein the horn pipe is formed by processing 2-6 steel plates; then combining the whole horn pipe with the pressure bearing cushion plate in the manner of welding, riveting or buckling and laminating; forming the combined shaping anchor cushion plate. The anchor cushion plate is good in quality and high in structure safety.

Owner:LIUZHOU OVM MACHINERY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com