Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

431results about How to "Improve shear efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

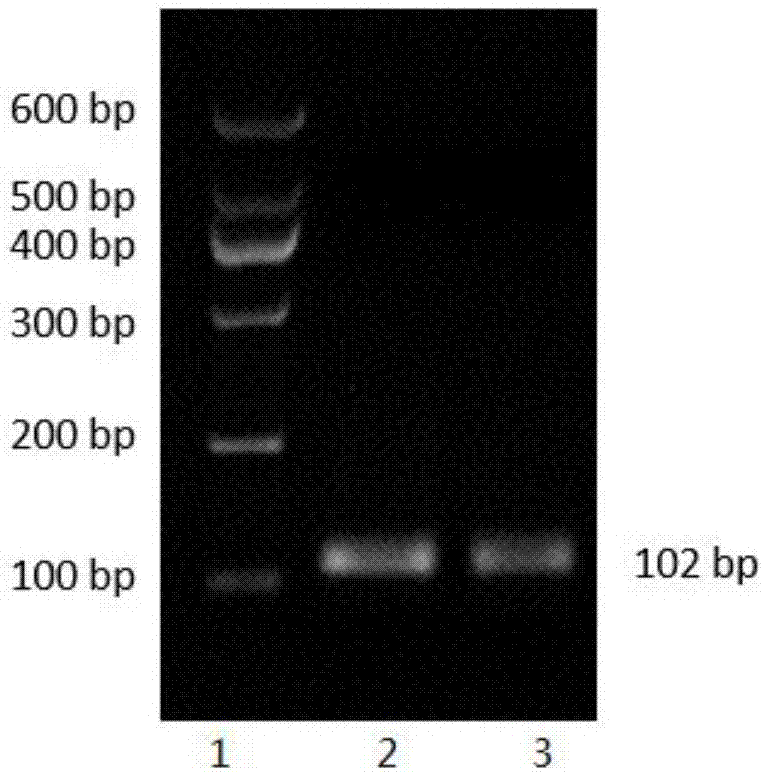

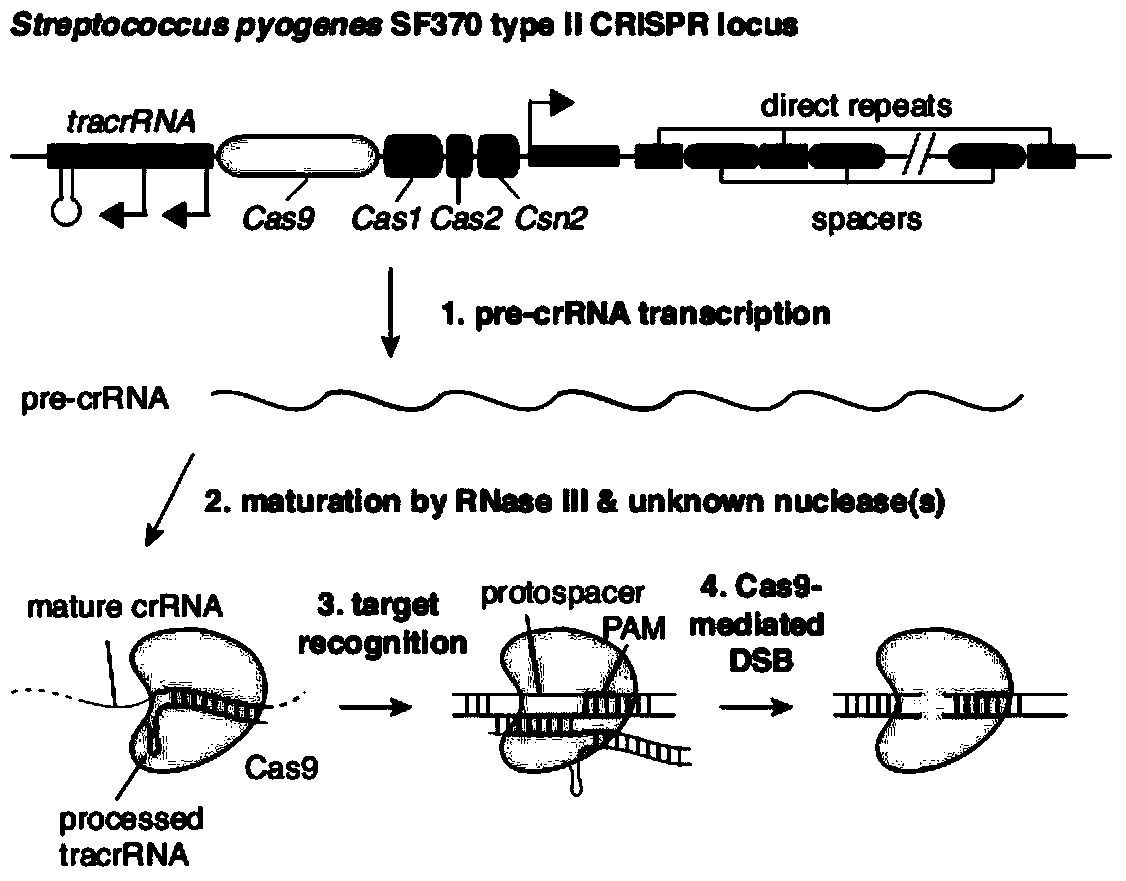

Preparation method of SD rat T cell-deficient genetic model

InactiveCN107446954AImprove shear efficiencyHigh originalityHydrolasesStable introduction of DNADiseaseLarge fragment

The invention relates to a preparation method of an SD rat T cell-deficient genetic model, and belongs to the technical fields of genetic engineering and genetic modification. Specific knockout on a key gene Lck, which is in charge of controlling development of rat T cells, is achieved in a rat by virtue of a CRISPR-Cas9 system, so that the SD rat T cell-deficient genetic model is obtained. According to the preparation method provided by the invention, two specific targeting sites, which are targeted to the rat Lck gene, are determined for the first time, and experiments prove that the specific targeting sites are quite high in shear efficiency; two sgRNAs are simultaneously adopted to conduct targeting on the rat Lck gene, and the large-fragment deficient gene knockout rat is obtained, so that in one aspect, the targeted gent completely loses functions, and in the other aspect, subsequent detection is also facilitated. The constructed T cell-deficient SD rat animal model is great significance to immunity and disease researches.

Owner:XINXIANG MEDICAL UNIV

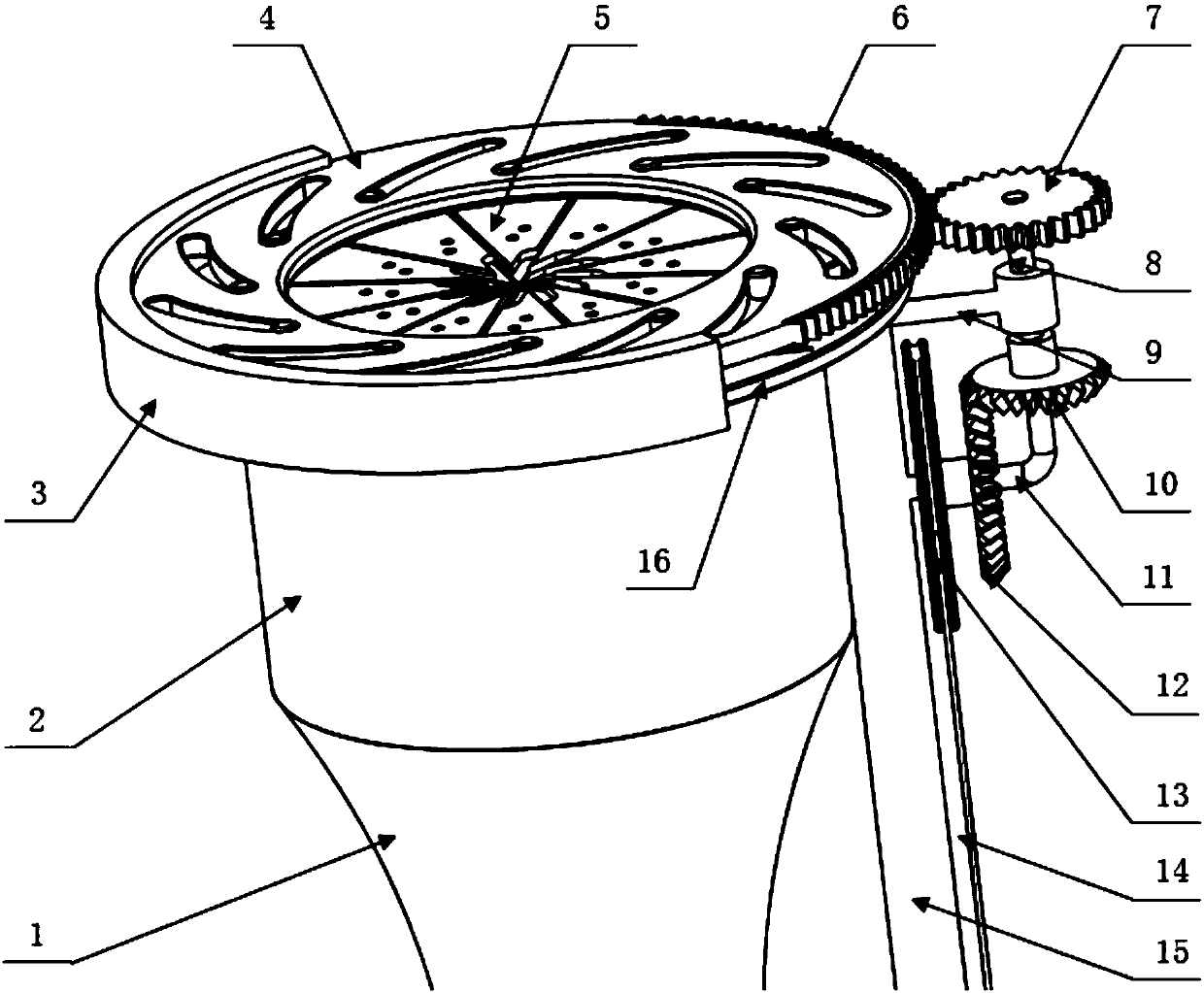

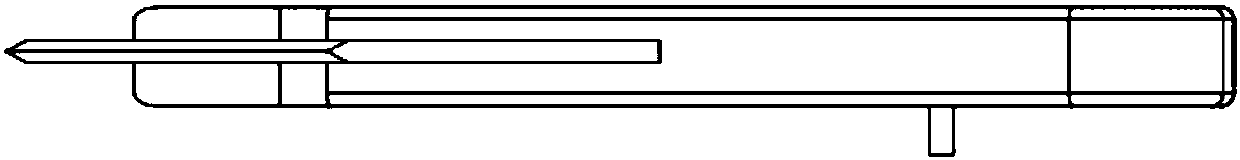

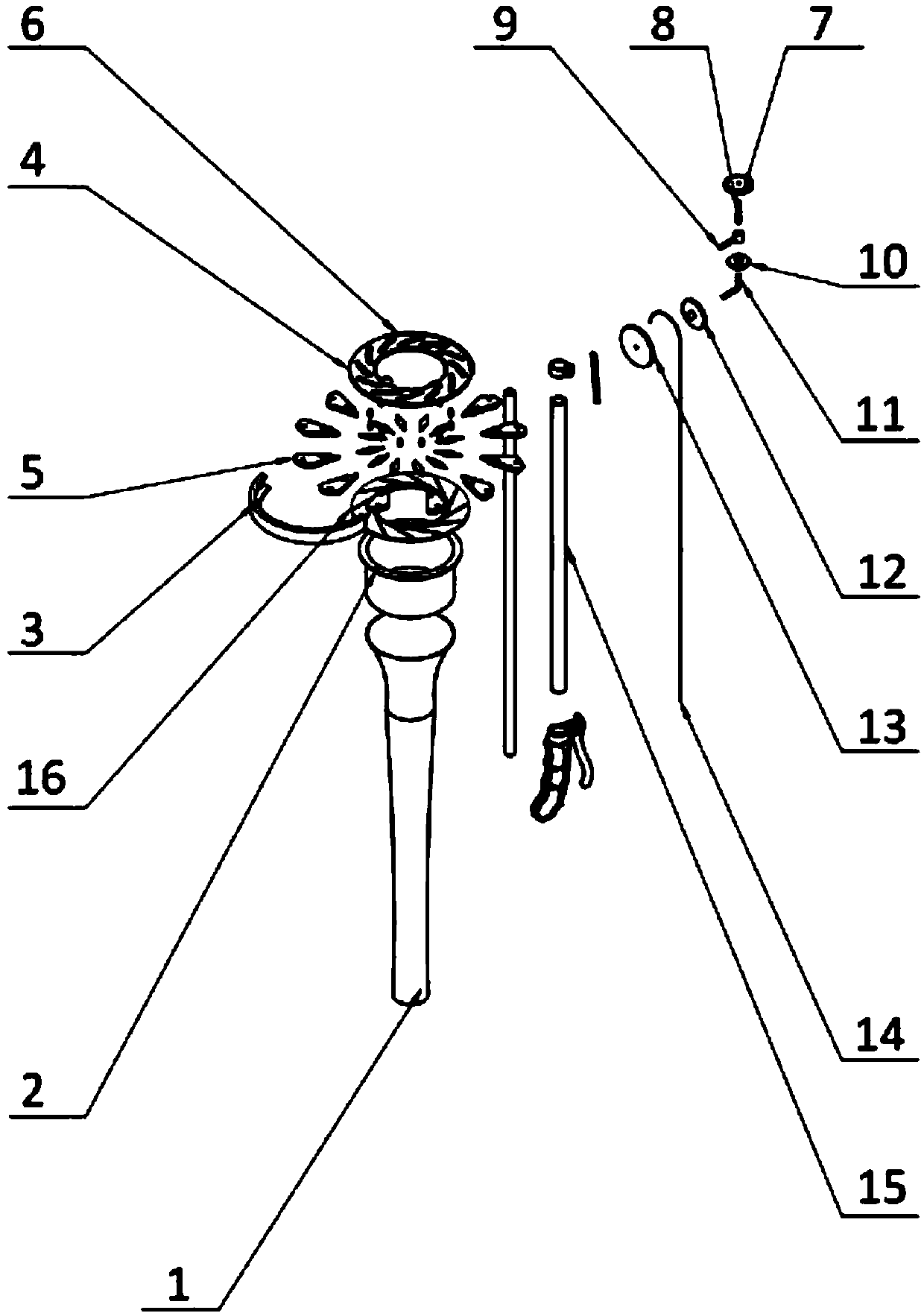

Fruit picking device

The invention discloses a fruit picking device. The fruit picking device comprises a telescopic supporting rod, wherein a pipe sleeve is arranged on the top end of the supporting rod; a containing netis arranged at a lower end opening of the pipe sleeve; a blade annular cutting mechanism is arranged in an upper end opening of the pipe sleeve; the supporting rod is provided with a mechanism whichis used for driving the blade annular cutting mechanism to open and close through a gear transmission mechanism so as to realize blade engaged cutting. According to the fruit picking device disclosedby the invention, the cam driving blade annular cutting mechanism adopted by the invention is used as a tool for cutting stems of fruits, so that the characteristic of labor saving is obtained, and the accuracy and the reliability that the fruits fall into a net after cutting can also be increased; a mode of using a big pipe to sleeve a small pipe is adopted, and a seat pipe clamp is used as a locking device, so that length stretching is realized, and risk of manual operation is greatly reduced; a multi-blade cutting mode is adopted, so that the cutting efficiency can be increased; by adoptingthe containing net which is smaller in inner diameter and has certain elasticity, cut fruits can be buffered, the fruits are prevented from being damaged due to direct falling, and meanwhile, the manual labor strength is reduced.

Owner:GUANGDONG UNIV OF TECH

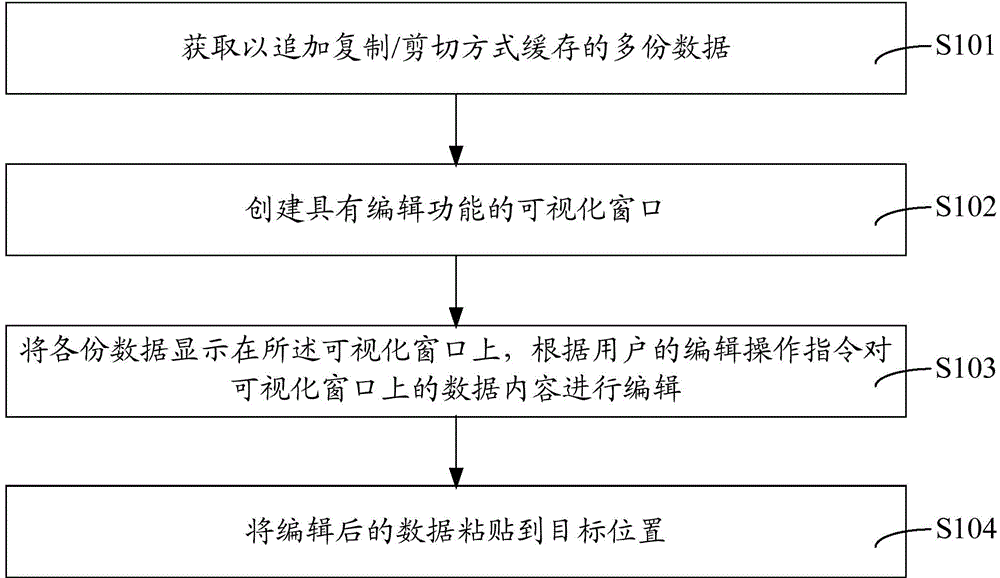

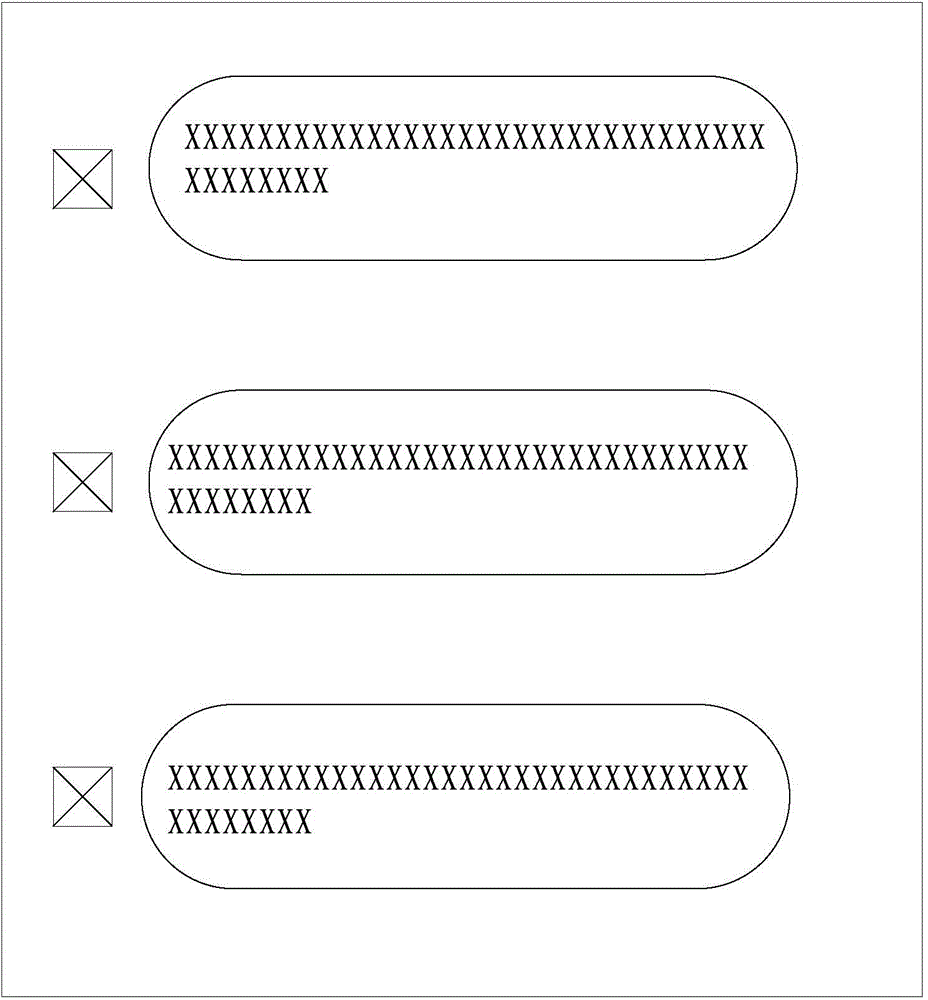

Method and system for copying/ cutting and pasting data

ActiveCN105302784ARealize visual displayEasy to viewSpecial data processing applicationsData displayComputer graphics (images)

The invention discloses a method for copying / cutting and pasting data. The method comprises the following steps: obtaining multiple pieces of data which is cached in an appending copying / cutting way; creating a visual window with an editing function; displaying each piece of data on the visual window, and editing data contents on the visual window according to an editing operation instruction of a user; and pasting the edited data to a target position. The scheme of the invention also provides a system for copying / cutting and pasting data. The scheme of the invention obtains multiple pieces of data cached in the appending copying / cutting way, after the visual window with the editing function is created, each piece of data is displayed on the visual window, and data visualization can be realized so as to bring convenience for users to check whether wrong appending or missing appending exists or not. According to the editing operation instruction of the user, the data contents on the visual window can be edited and pasted to a target position. Therefore, appended data can be processed before the data contents are pasted, and copying / cutting and pasting efficiency can be improved.

Owner:TENCENT TECH (SHENZHEN) CO LTD

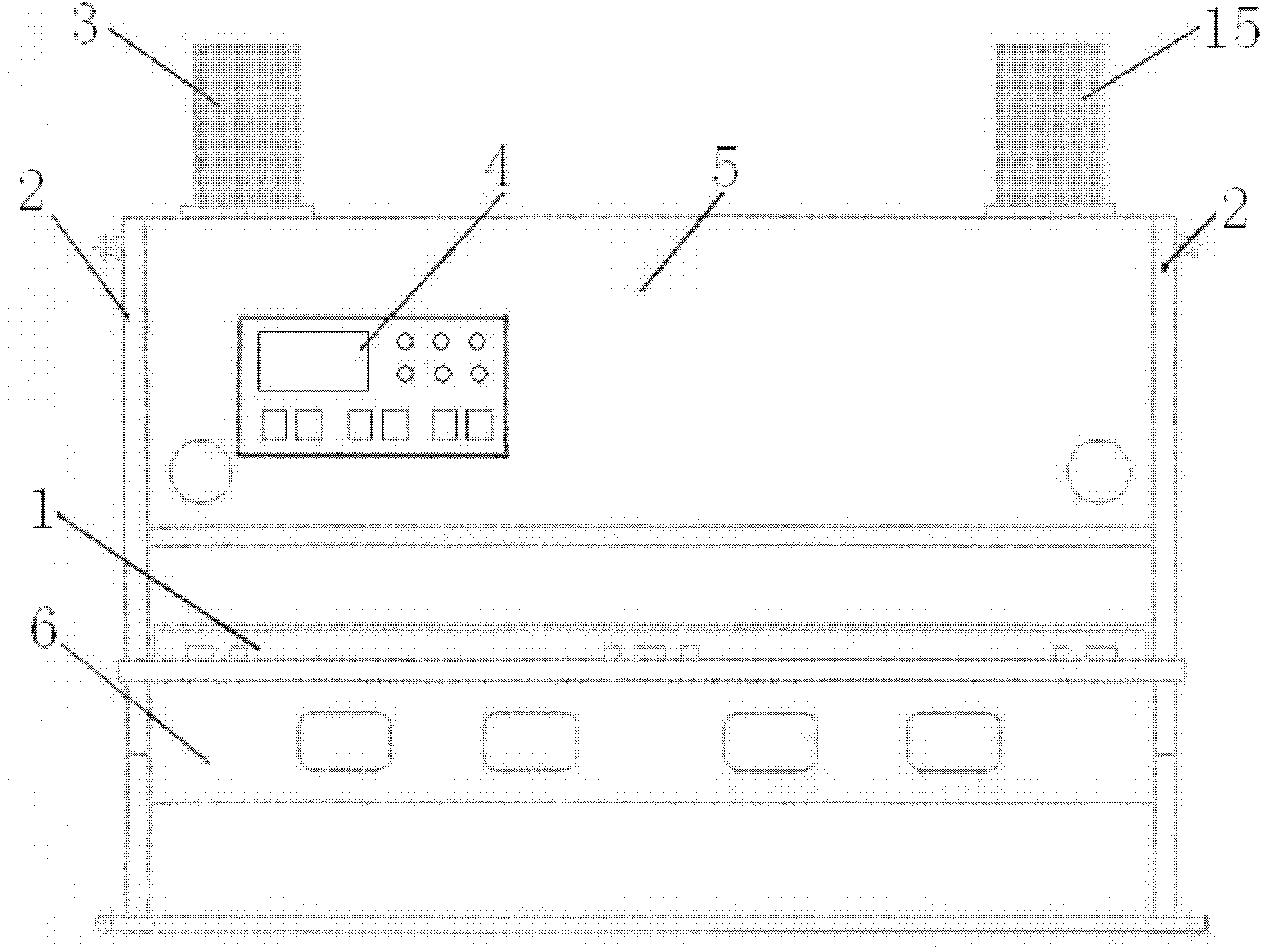

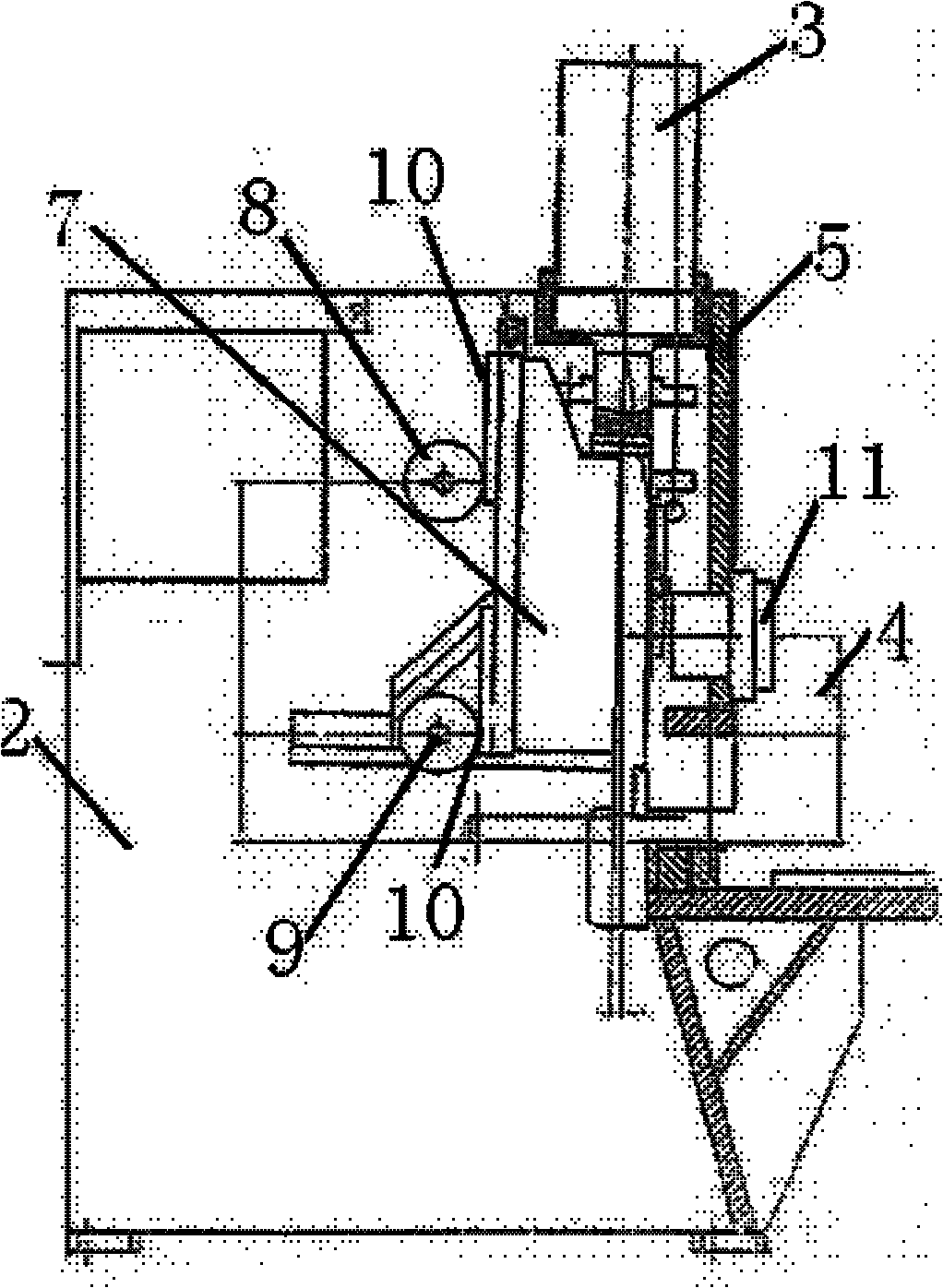

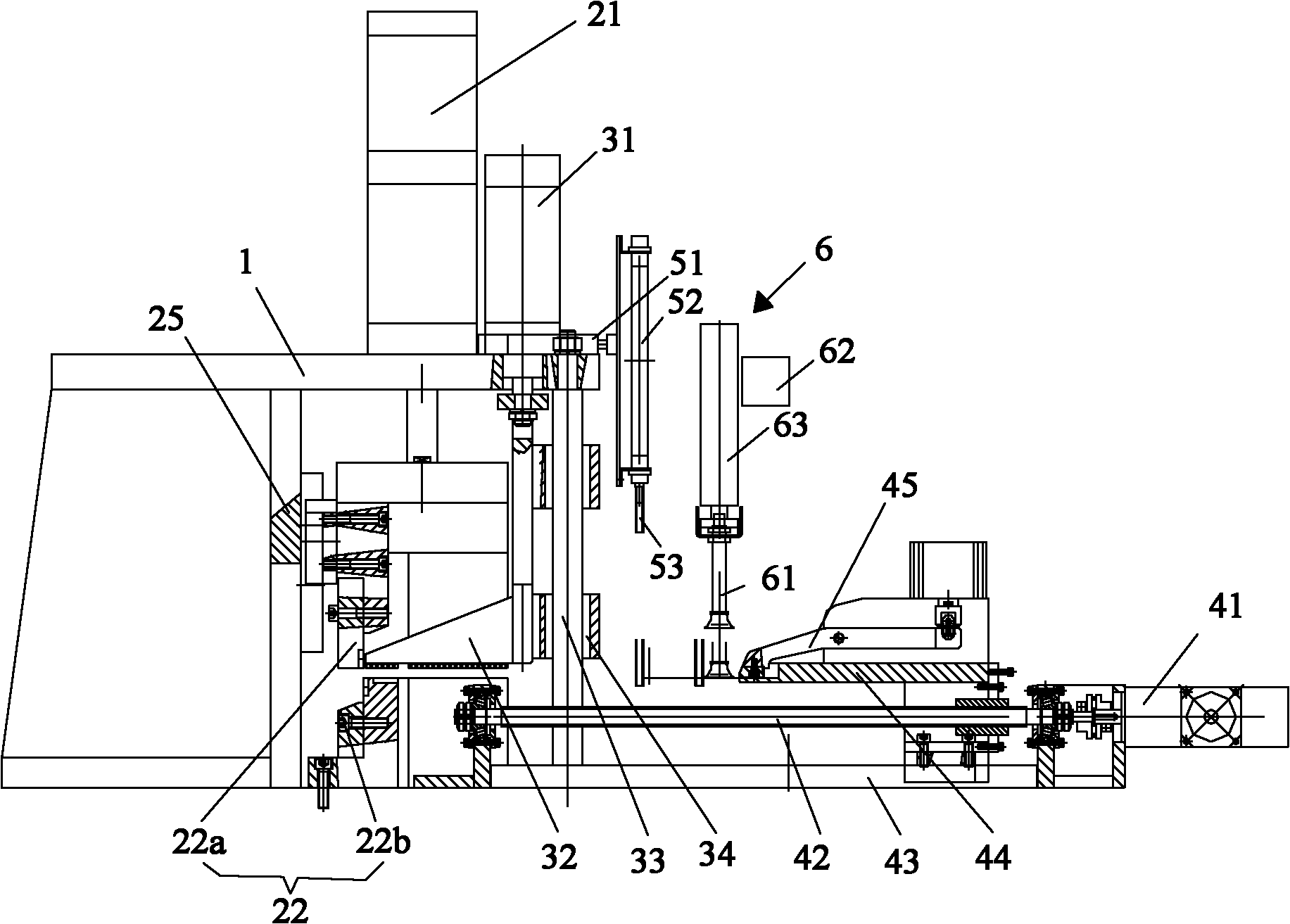

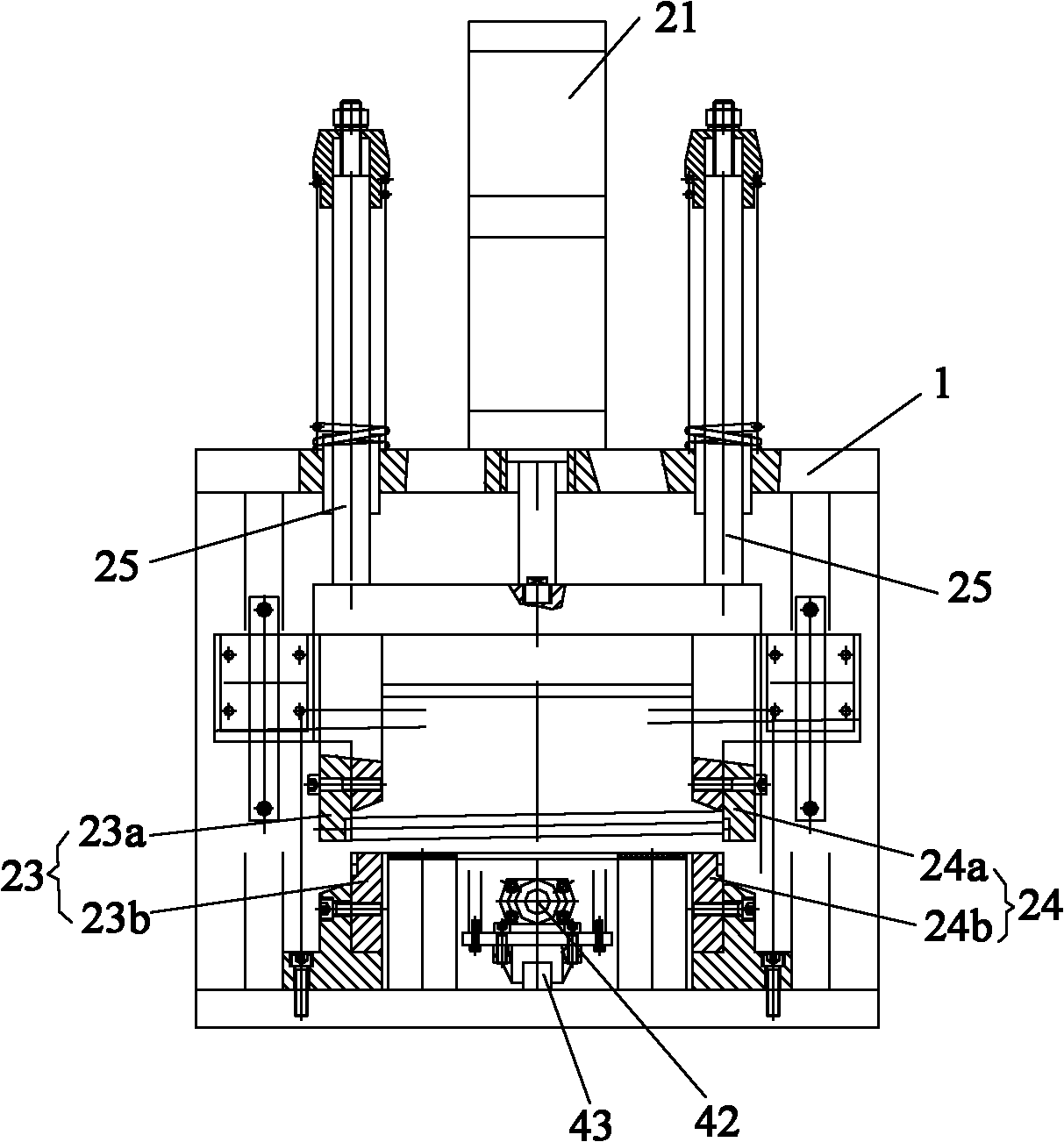

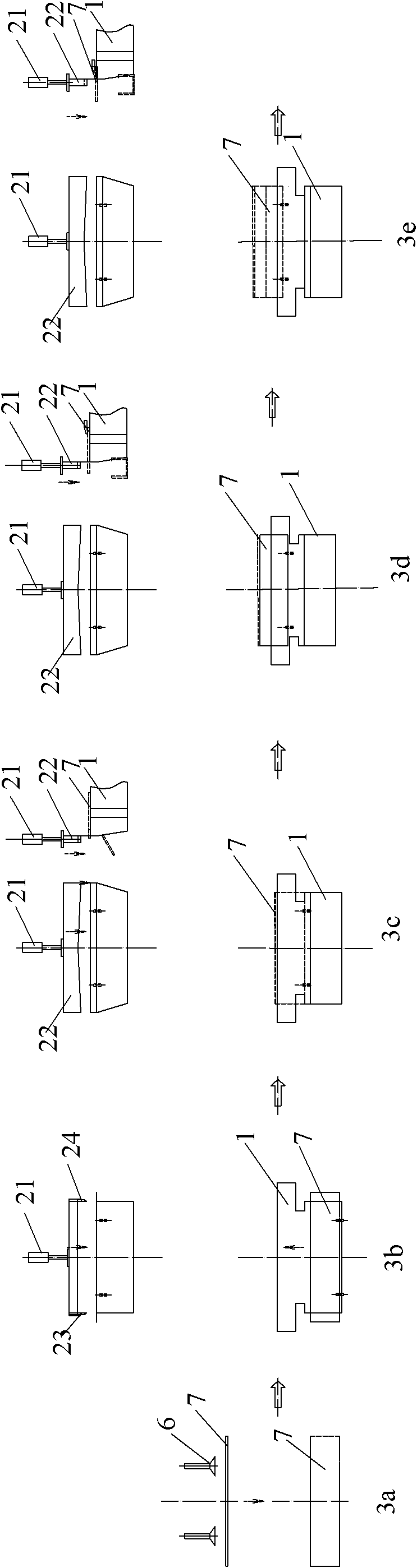

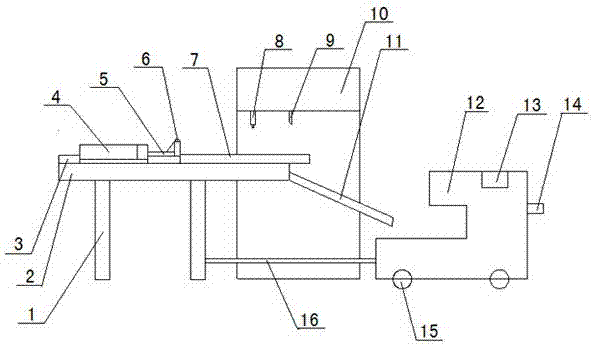

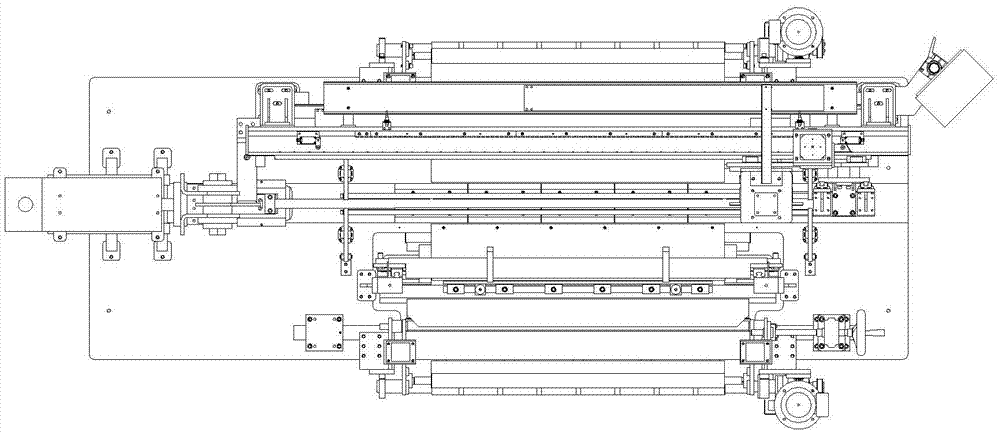

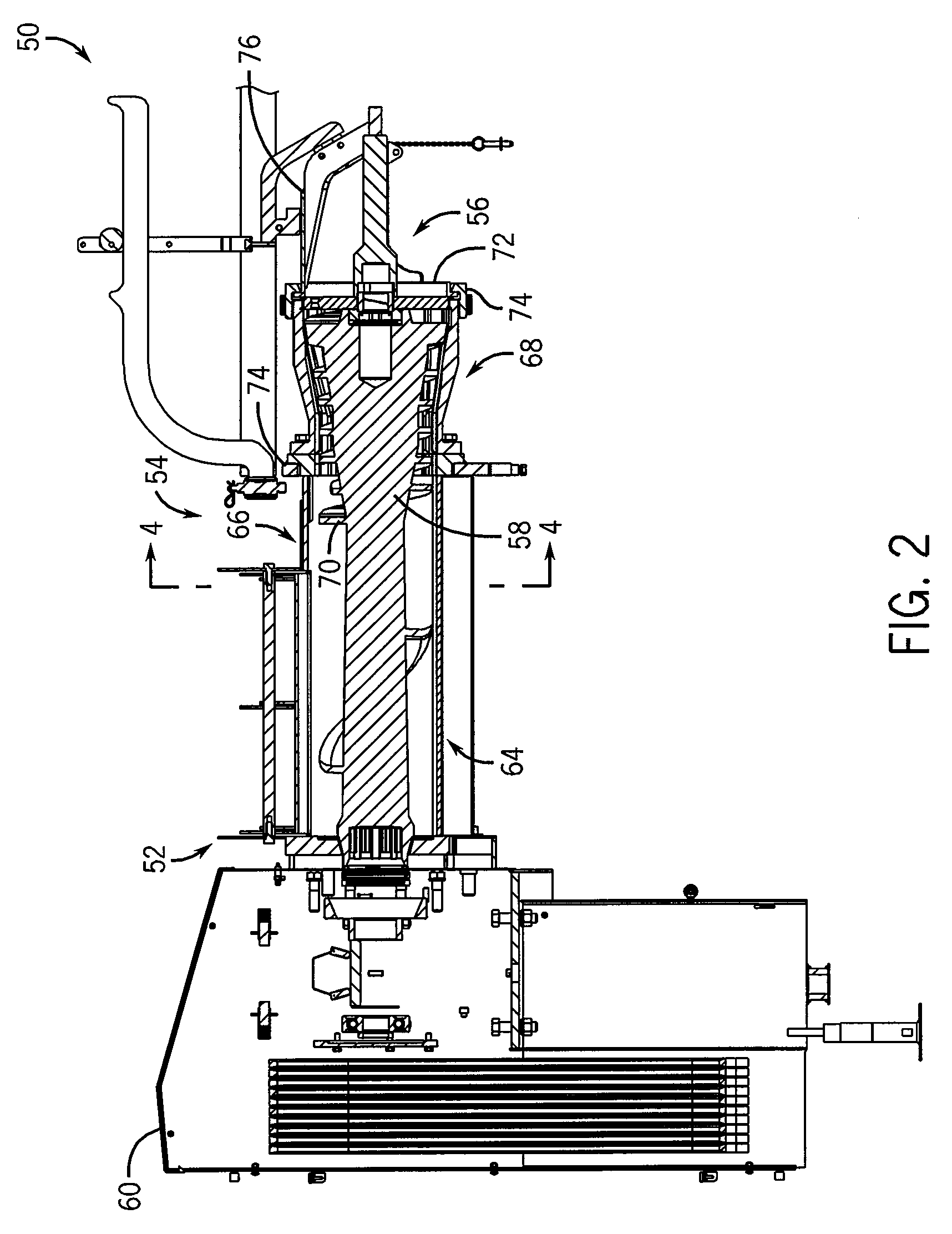

Digital control hydraulic brake type plate shearing machine

InactiveCN102198539ARealize automatic cutting workImprove cutting accuracyShearing machinesKey pressingNumerical control

The invention discloses a digital control hydraulic brake type plate shearing machine, which comprises a frame, an upper tool post, a lower tool post, a hydraulic transmission system for driving the upper tool post to reciprocate, a tool post angle adjusting device for adjusting a shearing angle of the upper tool post, a material stopping device, and a tool post interval adjusting device; the plate shearing machine also comprises a computerized numerical control (CNC) digital control system; and the CNC digital control system is connected with the hydraulic transmission system, the tool post angle adjusting device, the material stopping device and the tool post interval adjusting device. By adopting the technical scheme, the operation of the plate shearing machine is controlled by the CNC digital control system; relative working parameters are input through a key input module on a control panel of the CNC digital control system, so the automatic shearing work of the plate shearing machine is realized; and the CNC digital control system is connected with the tool post angle adjusting device, the material stopping device and the tool post interval adjusting device of the plate shearing machine, the error caused by manual operation is removed, and the shearing precision and the shearing efficiency of the plate shearing machine are improved.

Owner:芜湖中能机械制造有限公司

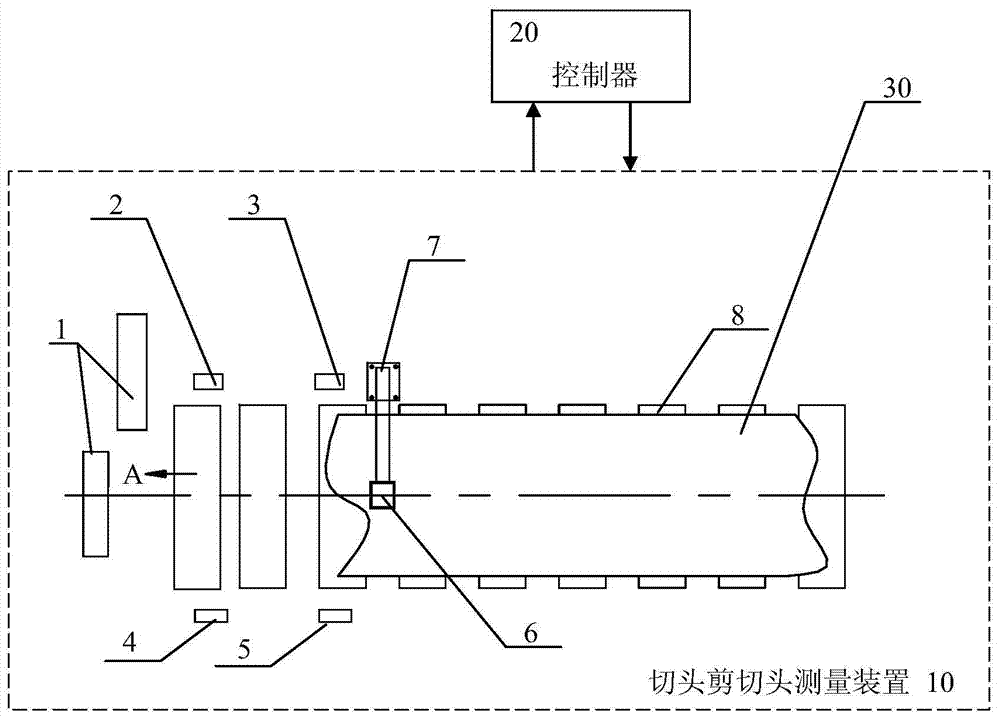

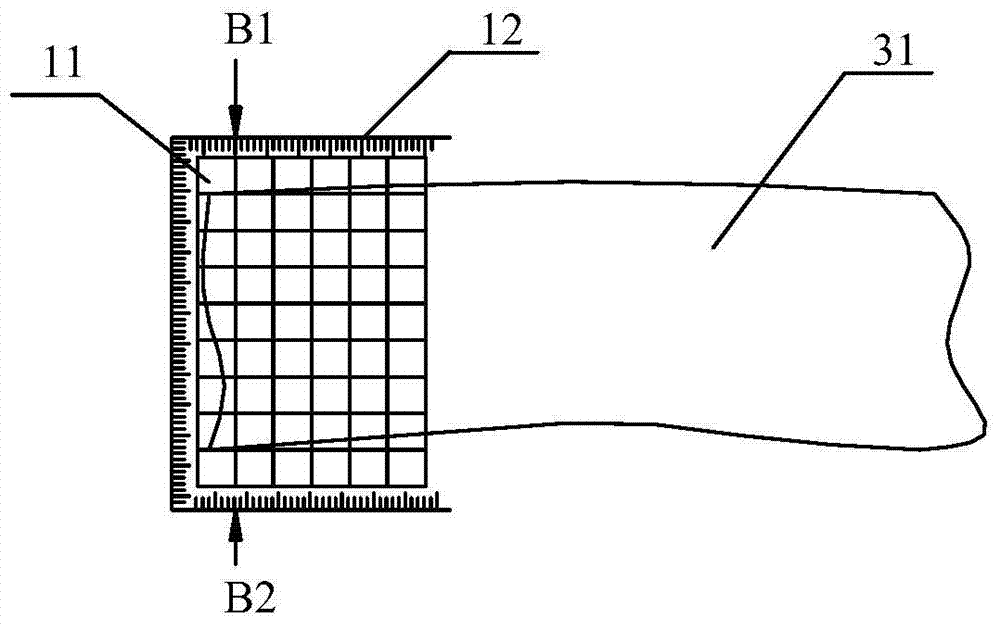

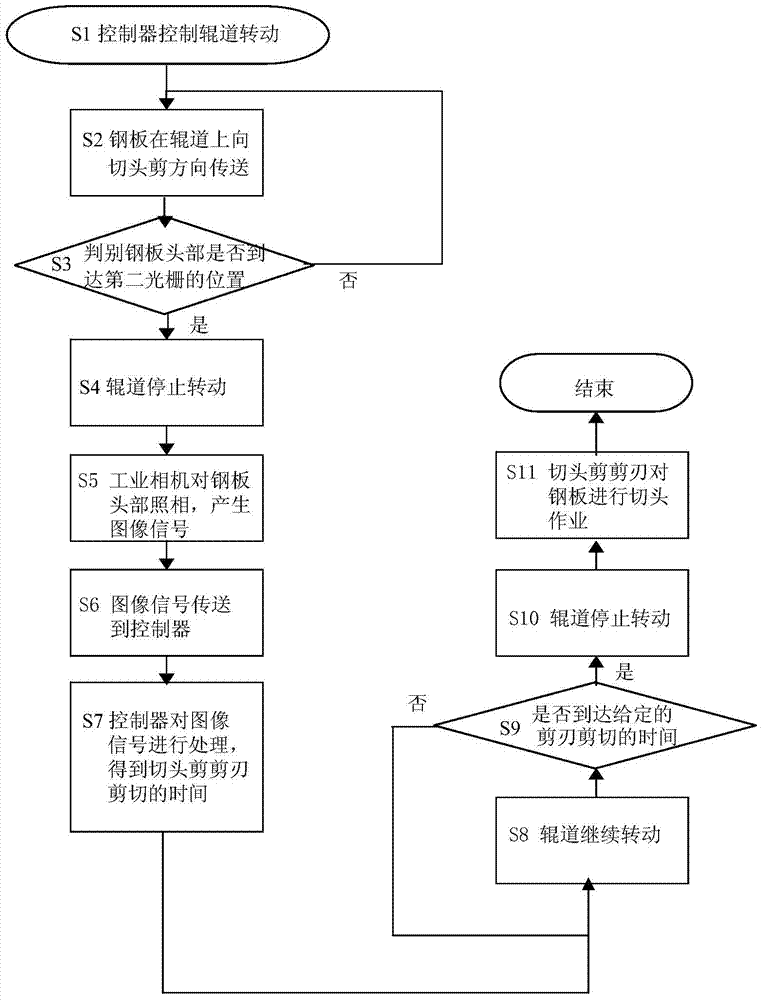

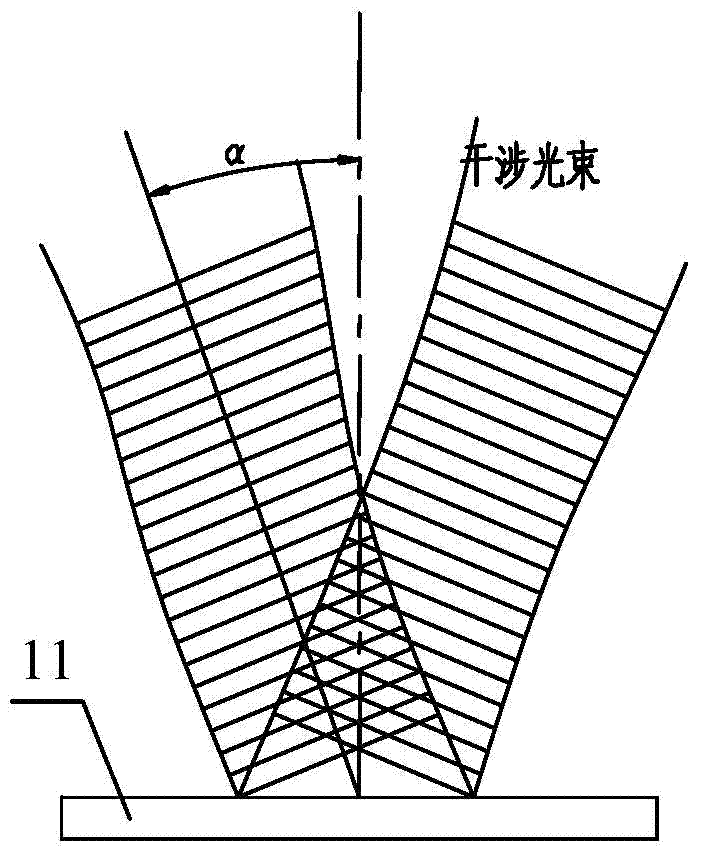

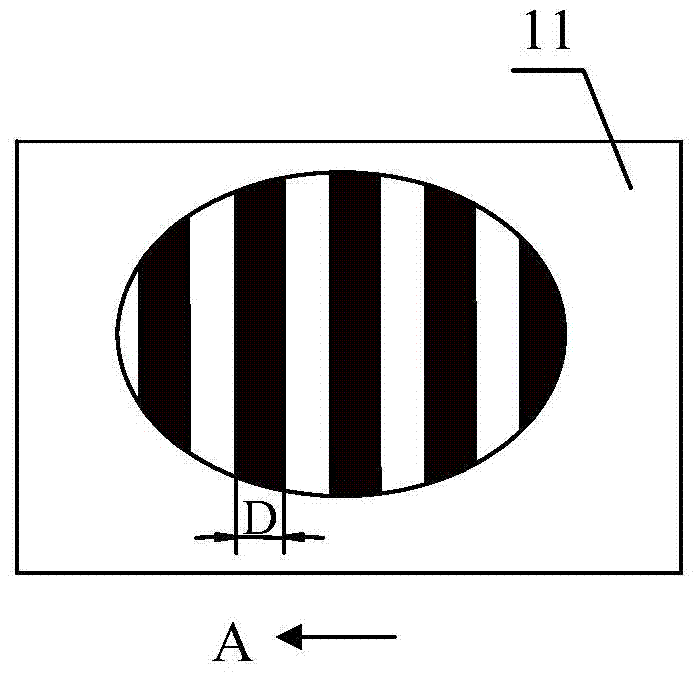

Method for optimizing steel plate head shearing

A method for optimizing steel plate head shearing relates to a method of shearing steel plate head, and solves the problem that the existing method cannot precisely locate the portion needs to be sheared; the method comprises the following steps: controlling a roller bed to rotate by a controller in order to transmit a steel plate; controlling the roller bed to stop rotating when the head of the steel plate reaches a second optical grating; using an industrial camera to take a picture of the head of the steel plate, so as to generate a steel plate head image signal and send the signal into the controller; processing the steel plate head image signal by the controller, so as to obtain a shearing time of a head shear blade based on the image signal; keeping the rotation of the roller bed; judging that the shearing time of the head shear blade is reached, stopping the rotation of the roller bed, and stopping the transmission of the steel plate; shearing the head of the steel plate by the head shear blade. In the method, the industrial camera is used for precisely taking a picture of the outline of the steel plate head; by meshing and scanning the image, the length should be sheared from the steel plate head can be precisely calculated, thereby effectively increasing the precision of shearing the steel plate head, thus increasing the shearing efficiency and the yield.

Owner:BAOSHAN IRON & STEEL CO LTD +1

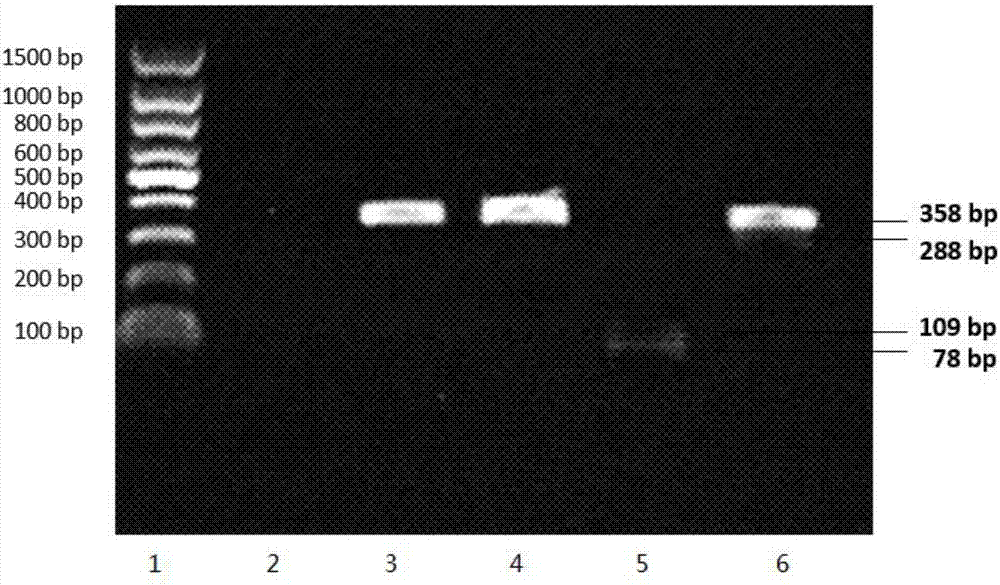

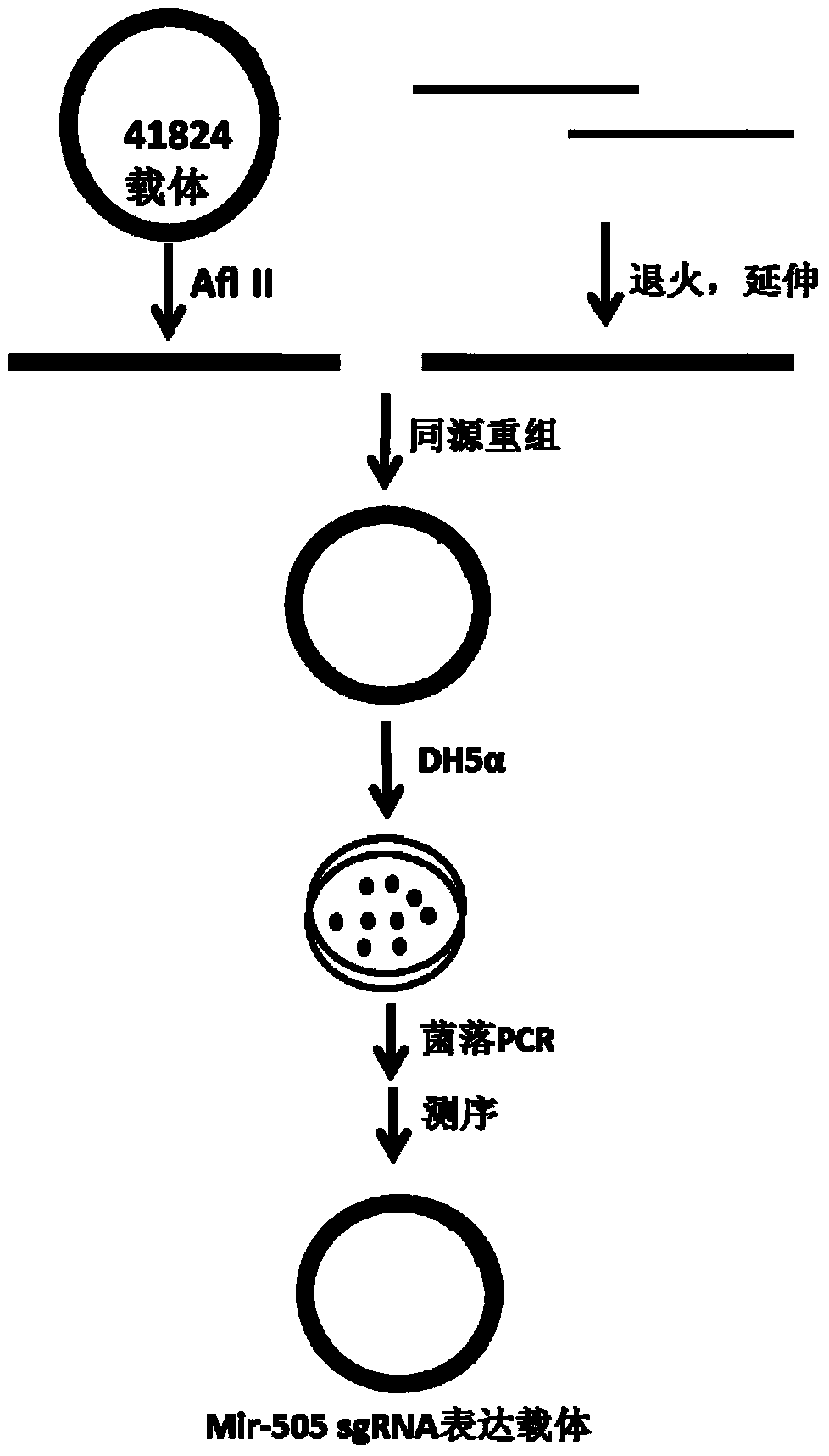

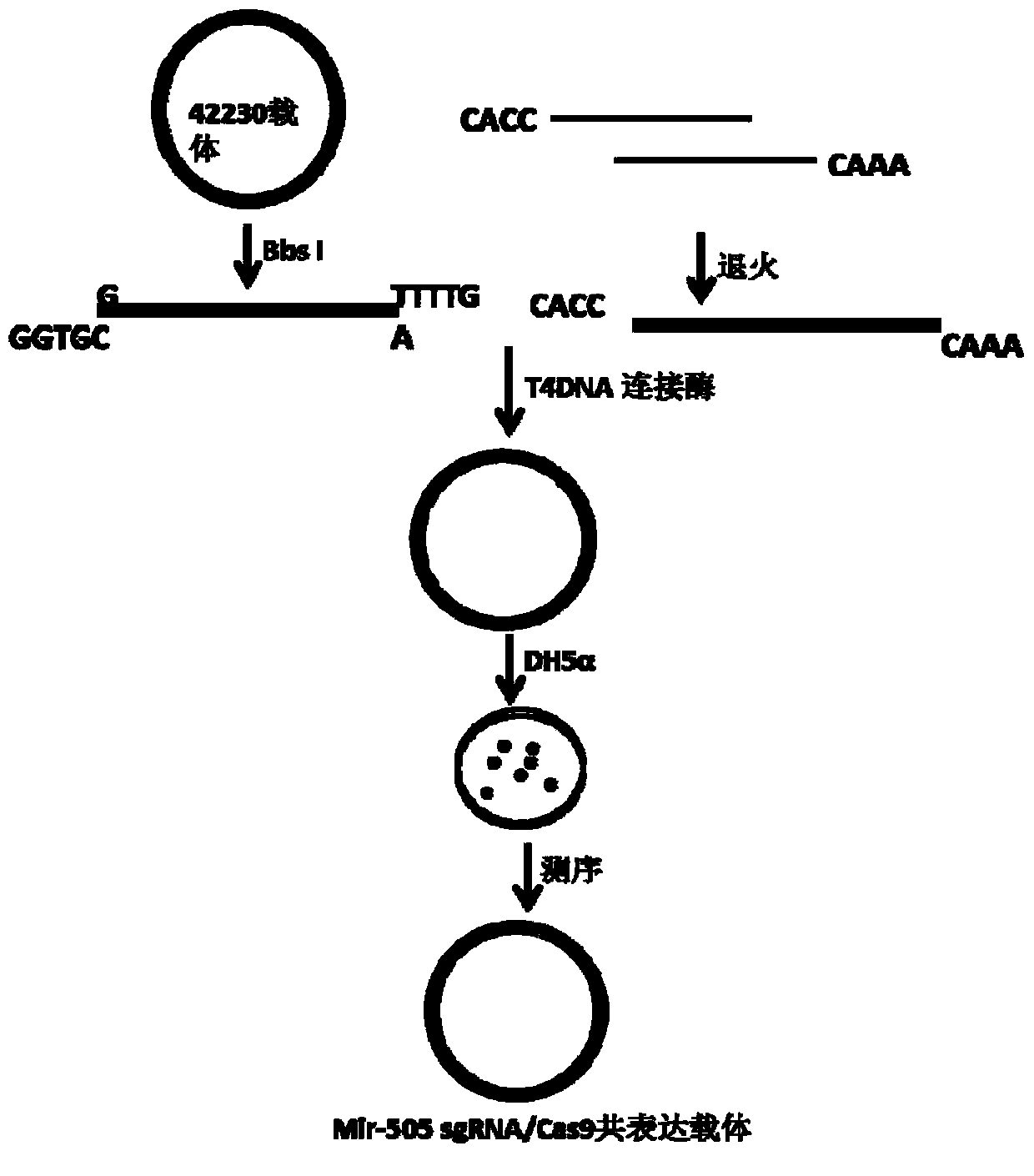

Method for knocking out mir-505 from mammal cell line

InactiveCN104212836AReduced shear efficiencyImprove shear efficiencyVector-based foreign material introductionEscherichia coliEnzyme digestion

The invention relates to a method for knocking out mir-505 from a mammal cell line, which comprises the following steps: synthesizing an sgRNA nucleotide single chain in vitro, treating to obtain an insertion element, inserting the sgRNA into a 41824 vector or 42230 vector by homologous recombination or T4 connection, transforming into competent cells of Escherichia coli, carrying out bacterial colony PCR (polymerase chain reaction) detection and sequencing confirmation on the vector to obtain an expression vector, denaturing the PCR product, annealing to form a heterologous hybrid double chain, and determining the shear efficiency of the CRISPR-Cas9 system on the mir-505 gene by using a T7E1 enzyme digestion test. The method provides references for selecting the sgRNA expression vector.

Owner:DONGHUA UNIV

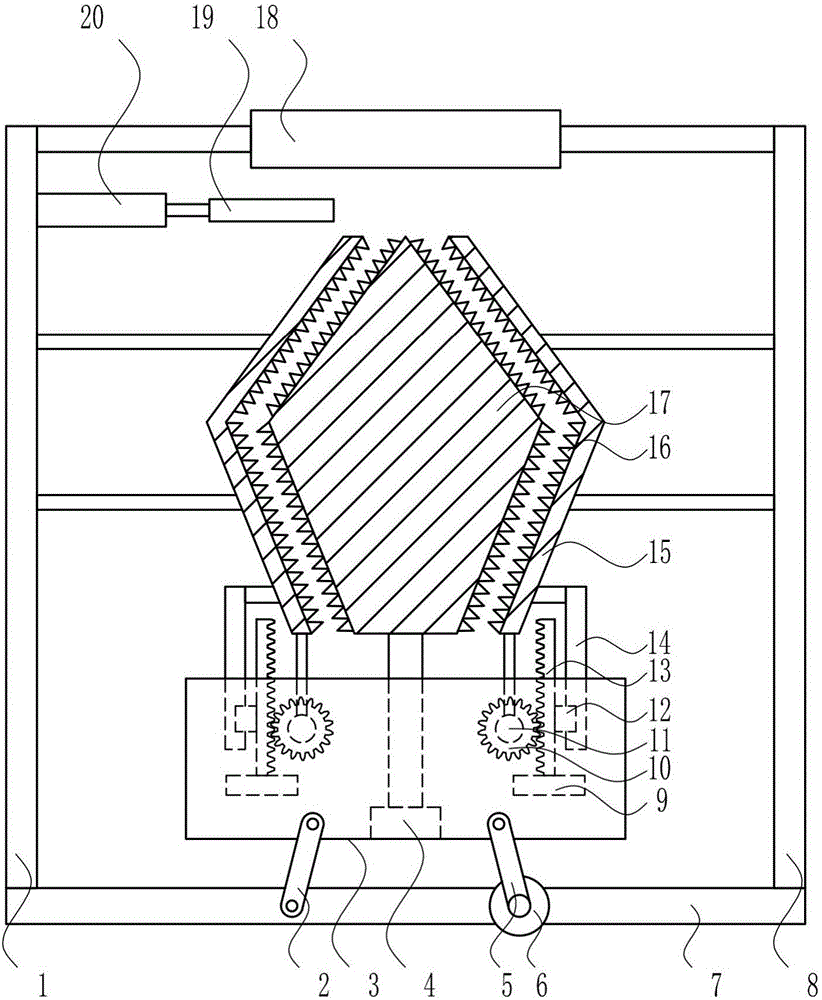

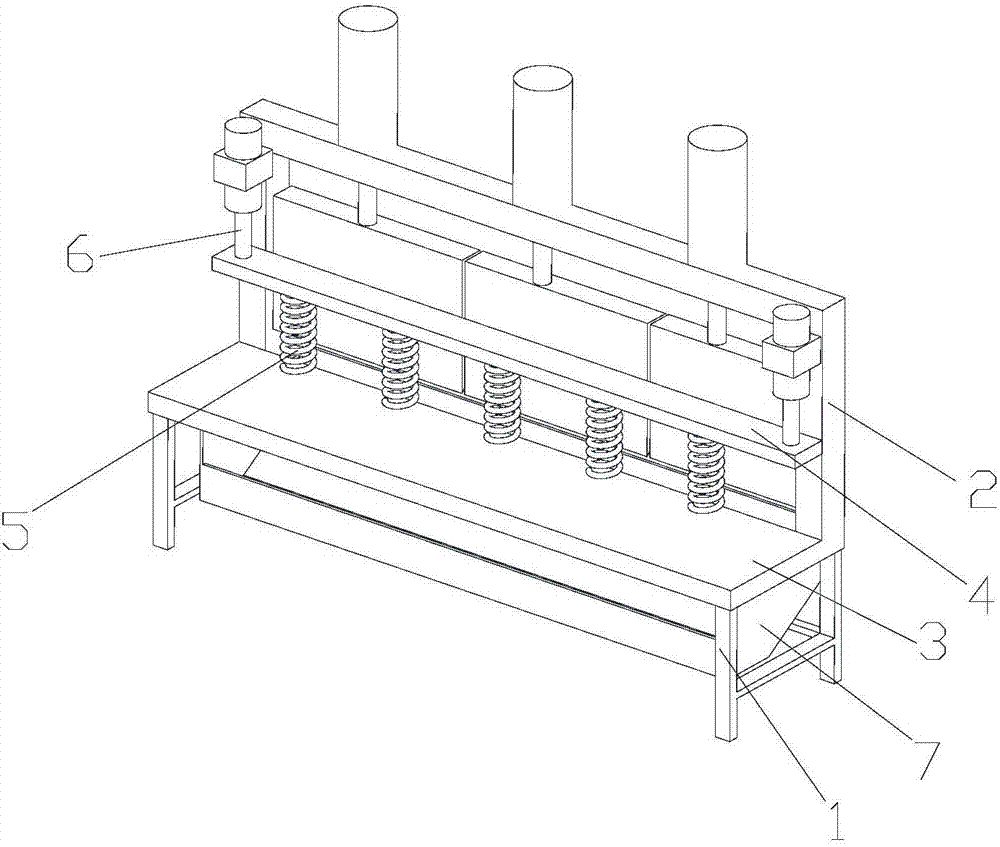

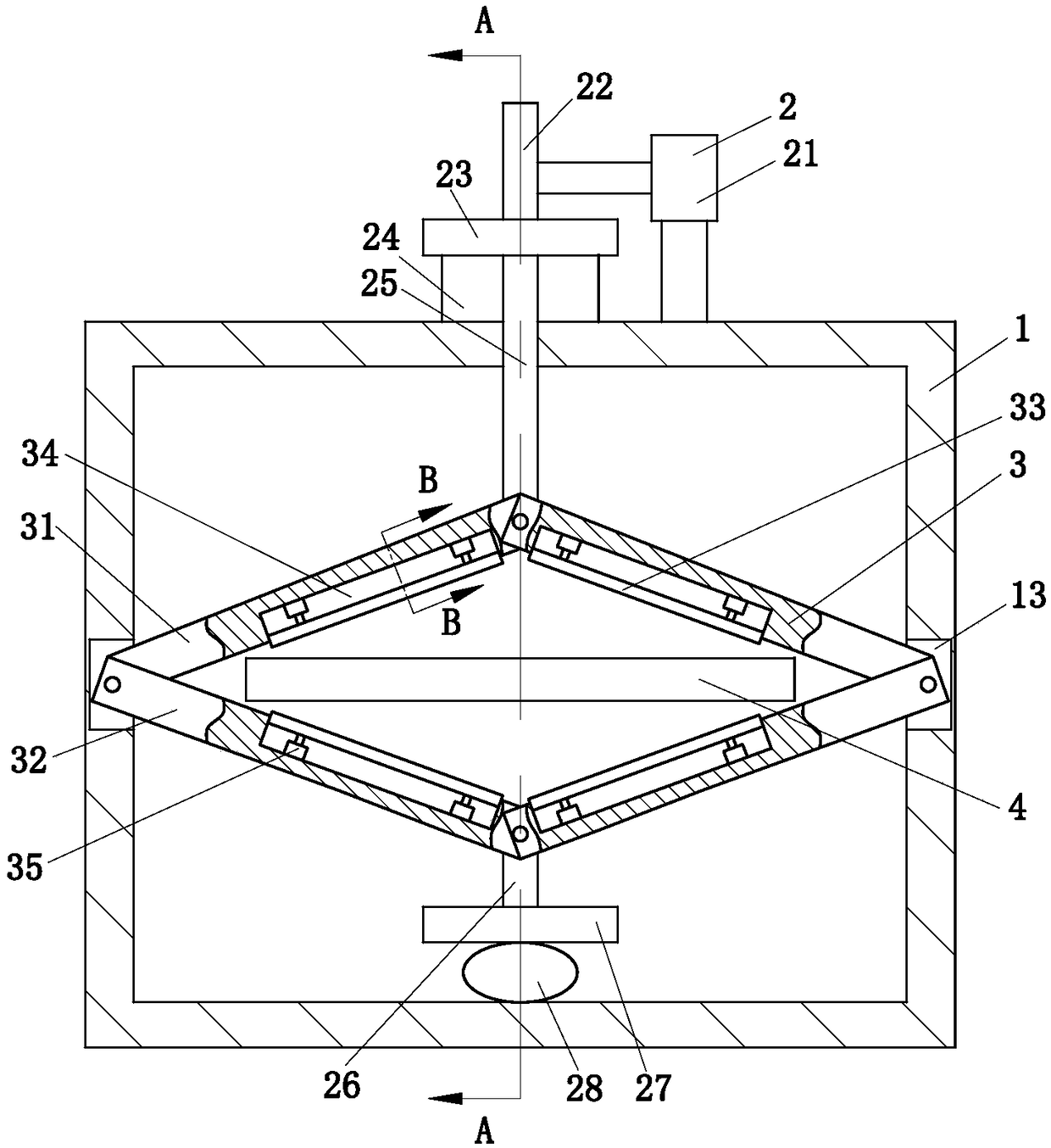

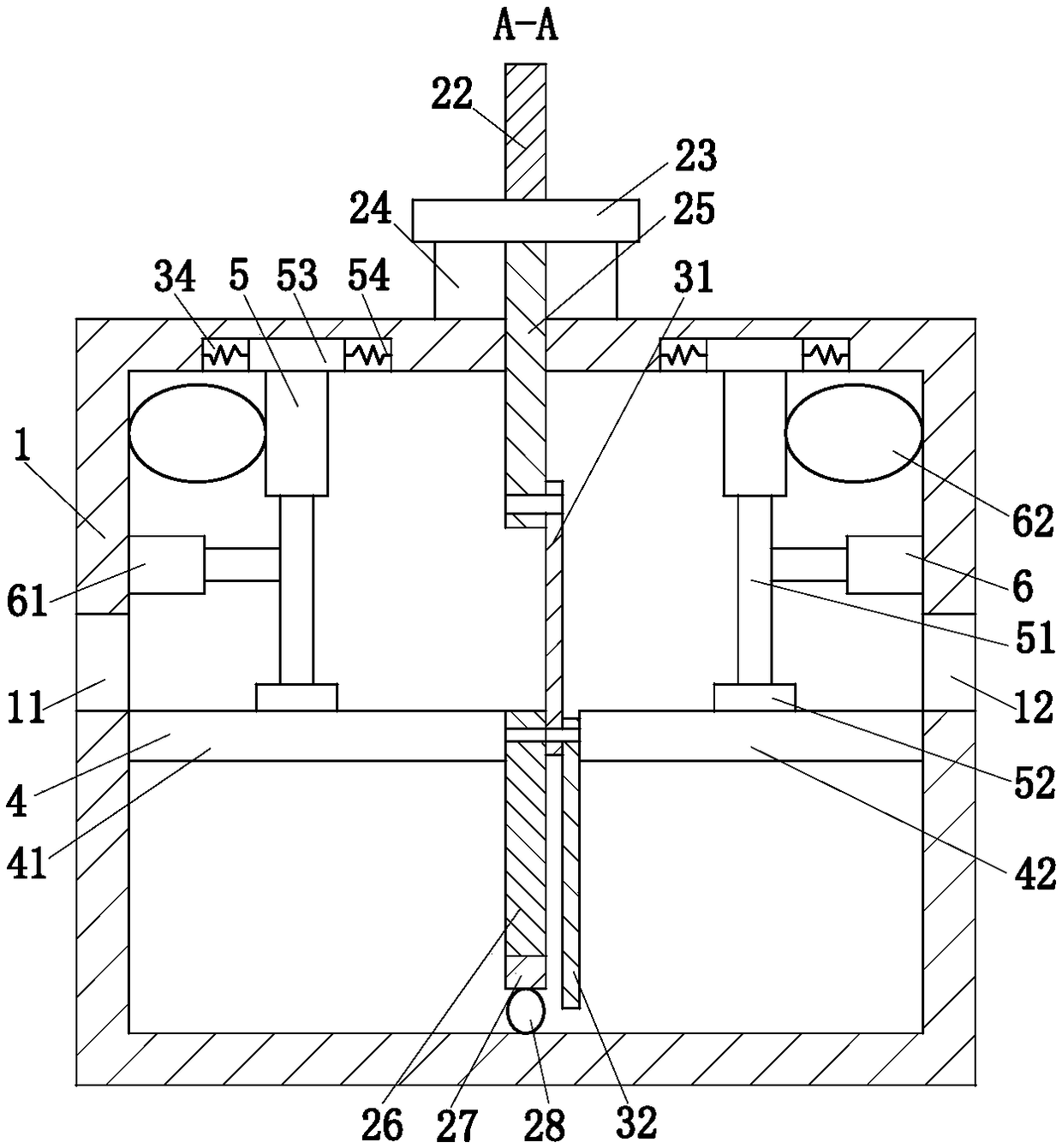

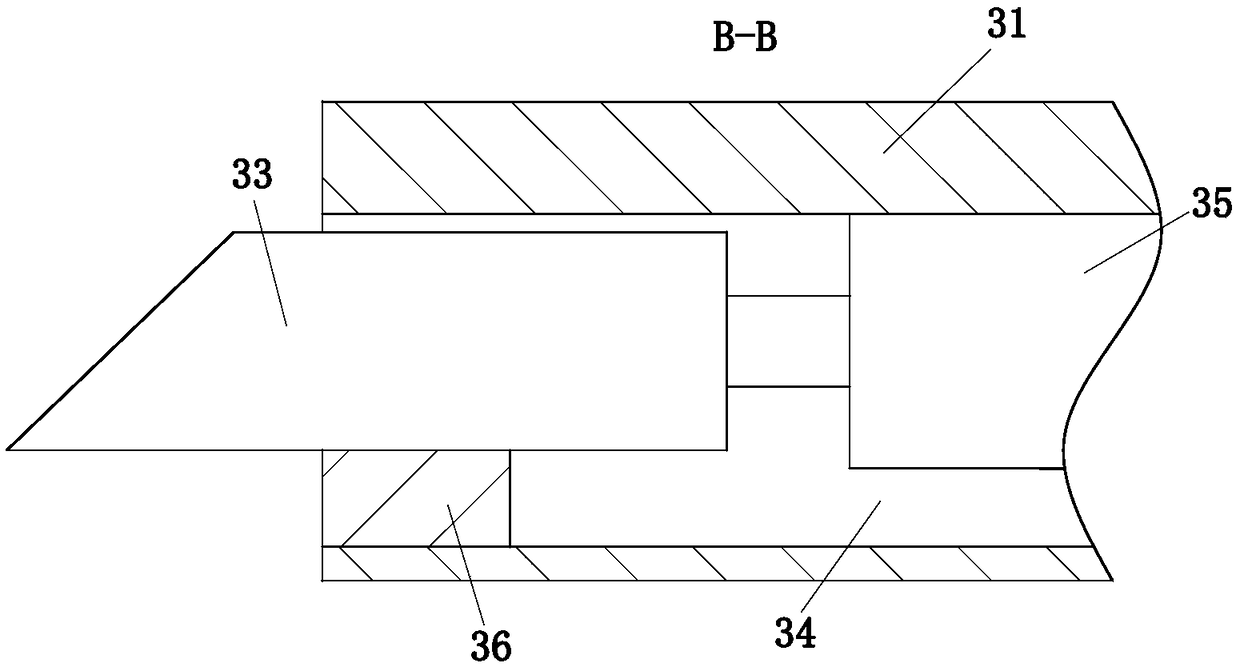

Metal sheet shearing machine

InactiveCN102069231AImprove shear efficiencyAvoid situations where the intersection of long and short sides does not meet the requirementsShearing machinesShearing machine accessoriesHydraulic cylinderReciprocating motion

The invention discloses a metal sheet shearing machine, which comprises a rack, a shearing mechanism arranged on the rack, a material pressing mechanism and a feeding mechanism, wherein the shearing mechanism comprises a shearing hydraulic cylinder arranged on the top of the rack, a front end shearing device arranged at the front end of the rack, and a left shearing device and a right shearing device correspondingly arranged at the left side and the right side of the rack, the front end shearing device, the left shearing device and the right shearing device respectively comprise an upper tool carrier connected with the shearing hydraulic cylinder and a lower tool carrier fixed on the rack, and the upper tool carrier and the lower tool carrier are correspondingly provided with blades; the material pressing mechanism comprises a material pressing hydraulic cylinder arranged on the top of the rack and a material pressing device connected with the material pressing hydraulic cylinder, and the material pressing device is positioned behind the front end shearing device and between the left shearing device and the right shearing device; and the feeding mechanism can be arranged at the rear end of the rack in a back and forth reciprocating mode. The metal sheet shearing machine can complete four-side shearing in the state of one-step clamping, has high working efficiency and is safe and reliable.

Owner:武钢集团有限公司

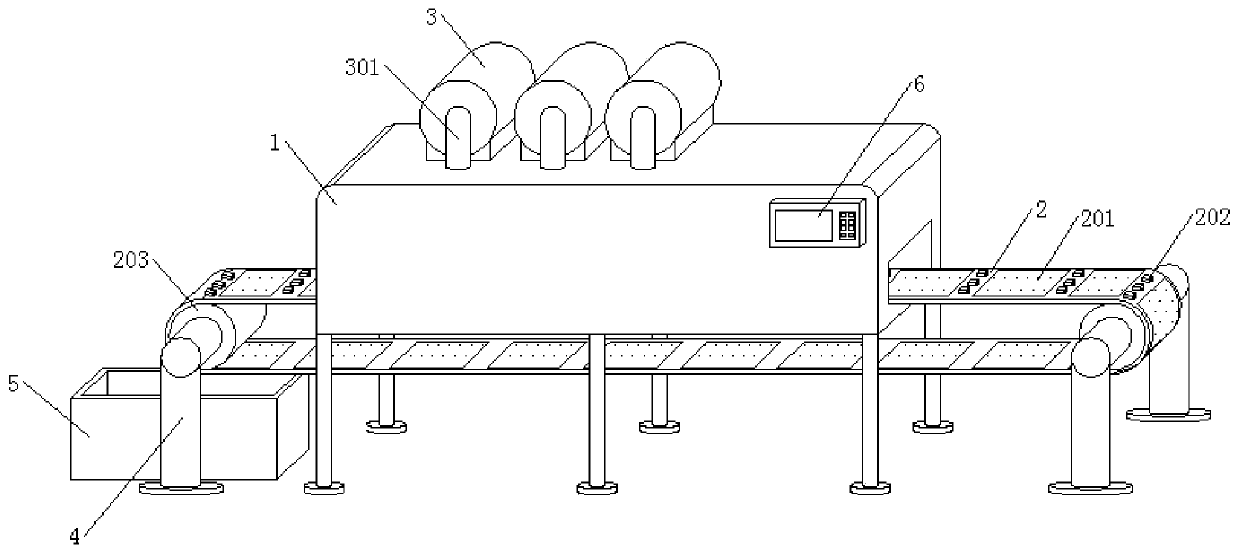

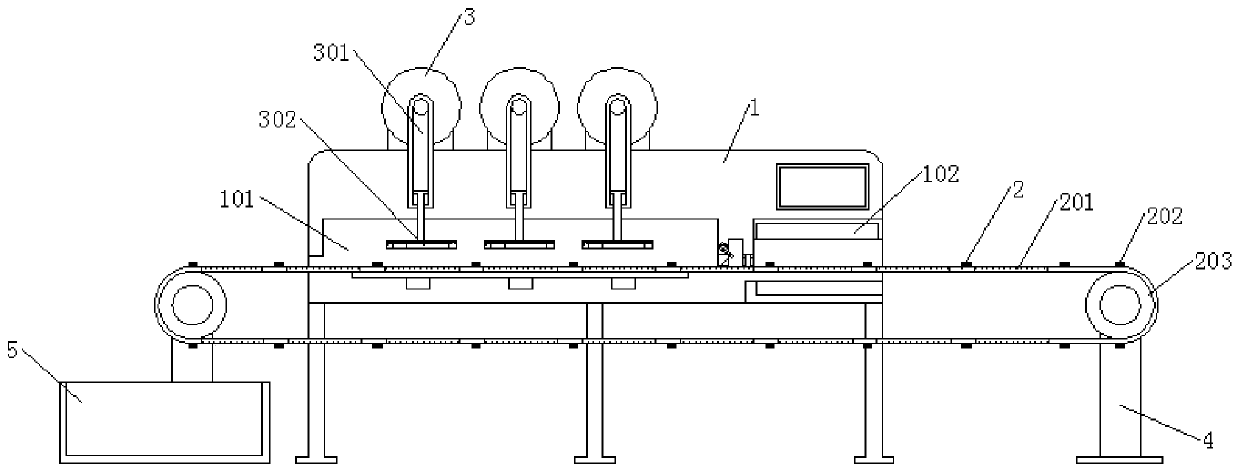

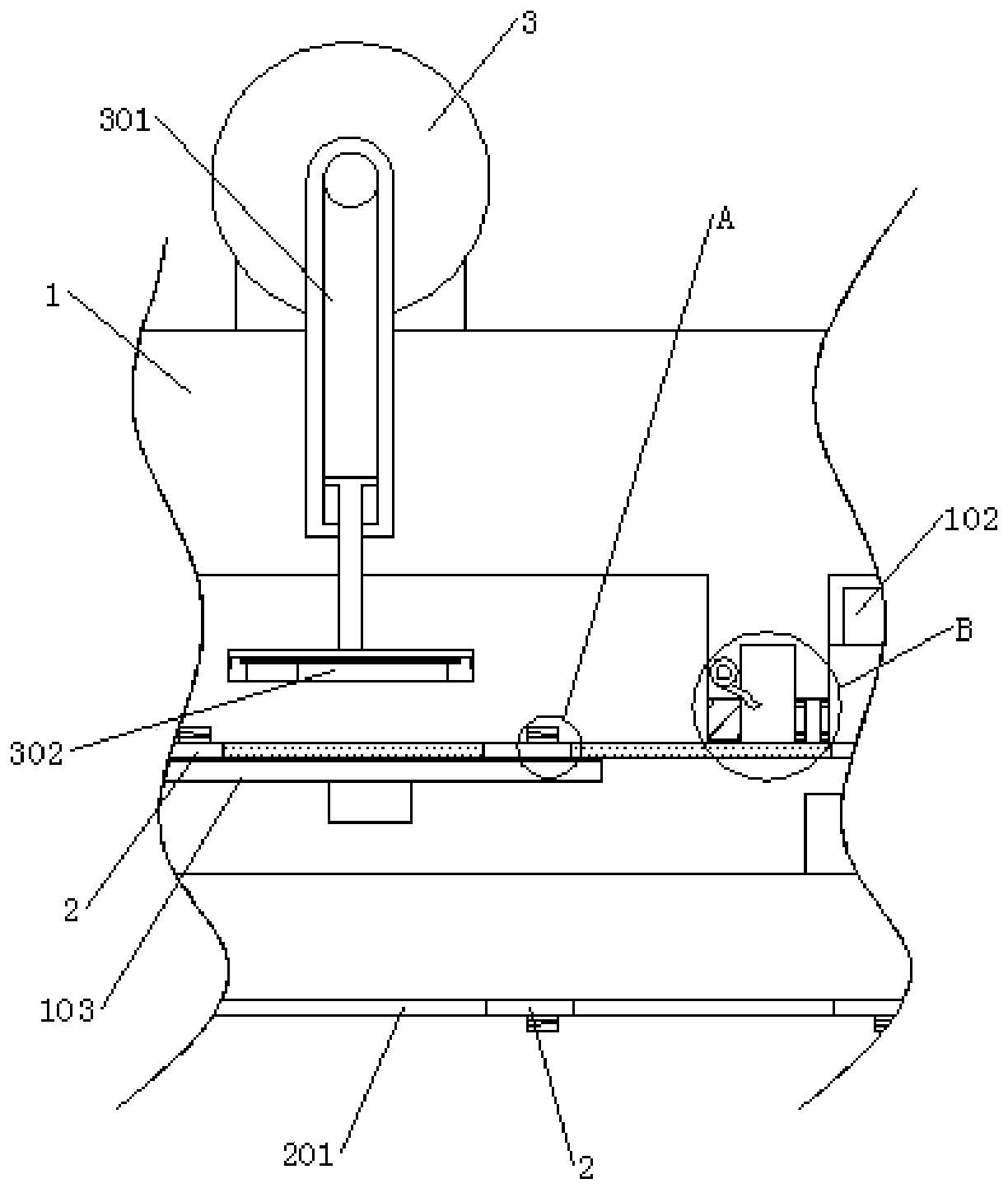

Feather correcting and shearing integrated device for badminton production

ActiveCN111467770AImprove barrier propertiesAvoid blowing awaySport apparatusHydraulic pumpStructural engineering

The invention provides a feather correcting and shearing integrated device for badminton production. The device comprises a box, a conveying belt, a hydraulic pump, supporting columns, a collecting box and control equipment, wherein the conveying belt is arranged on the inner side of the bottom end of the box, the hydraulic pump is arranged at the top of the box, the supporting columns are arranged on the left and right sides of the bottom of the conveying belt, the collecting box is arranged at the bottom of the left side of the conveying belt, and the control equipment is embedded in the front end of the box. The whole device is stable in structure, high in feather carding capacity, simple and convenient in shearing operation step, high in feather shearing efficiency, convenient in feather fixing operation and high in stability.

Owner:江山市三鑫体育用品有限公司

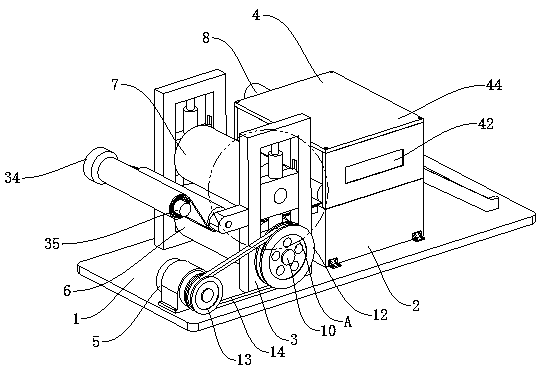

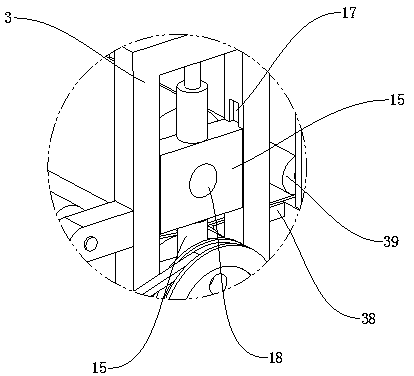

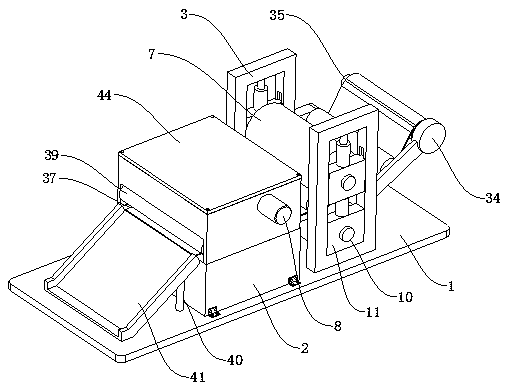

Automatic accurate cutting equipment of PVC (Poly Vinyl Chloride) wired hose

InactiveCN107053297ALabor intensiveReduce labor intensityMetal working apparatusBatch operationEngineering

The invention relates to automatic accurate cutting equipment of a PVC (Poly Vinyl Chloride) wired hose. The equipment comprises a baseplate, wherein a support device, a tension device, an auxiliary device, a driving device and a shearing device are sequentially arranged on the baseplate from back to front and are cooperated to complete the automatic accurate cutting of the PVC wired hose. By means of the equipment disclosed by the invention, the problems that in a conventional PVC wired hose shearing process, cuts are uneven during manual shearing process of the PVC wired hose, error exists during the manual measurement process of the PVC wired hose, the using effect of the PVC wired hose is influenced, the PVC wired hose is easily deformed during manual tensioning process, the manual shearing of the PVC wired hose is high in the labor intensity and low in the working efficiency and is not suitable for batch operation and the like can be solved; and the function of automatically and accurately cutting the PVC wired hose can be realized.

Owner:绍兴天波制伞有限公司

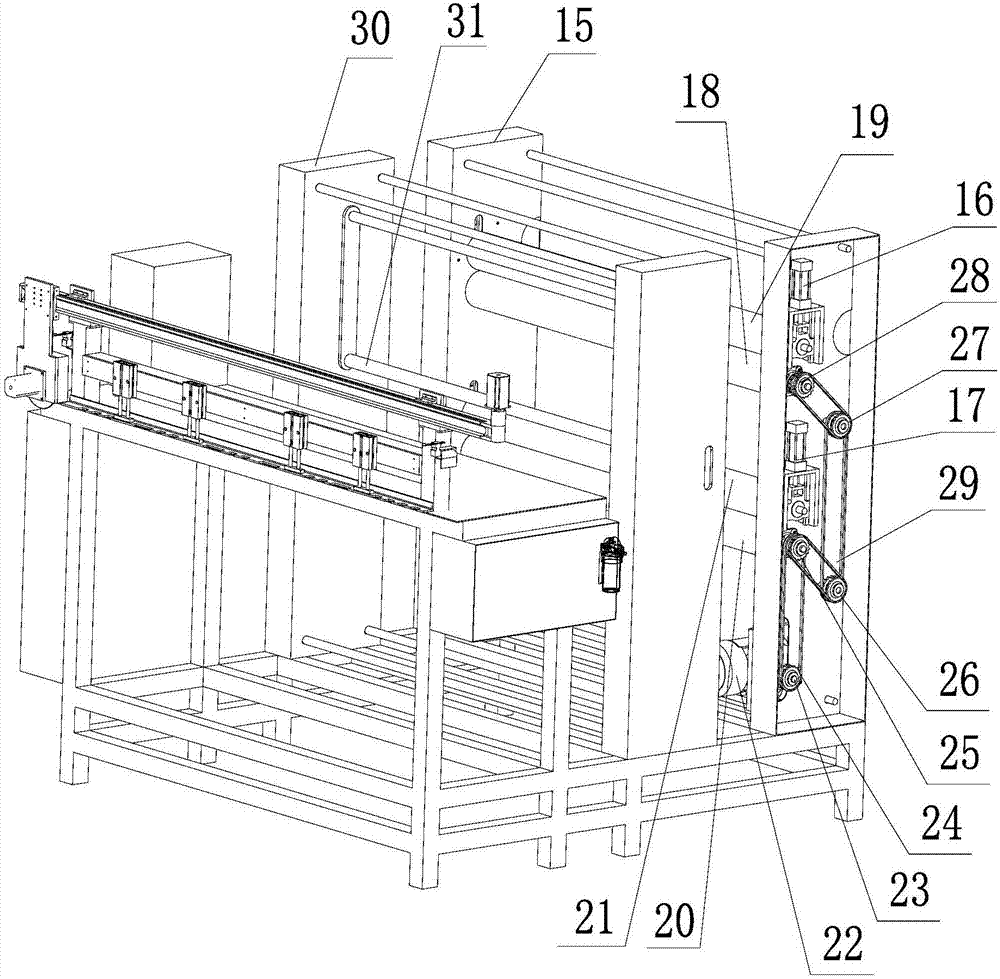

Cloth leveling and shearing equipment for garment manufacturing

ActiveCN110117897ATight textureImprove textureSevering textilesArticle deliveryAssistive device/technologyEngineering

The invention relates to the technical field of garment manufacturing auxiliary equipment, in particular to cloth leveling and shearing equipment for garment manufacturing. The equipment comprises a base seat, a supporting table, two supporting frames, a compacting mechanism and a shearing mechanism, wherein the compacting mechanism is arranged between the two supporting frames to feed cloth ontothe supporting table and compact the cloth; the shearing mechanism is arranged above the supporting table through a protective outer cover to shear the cloth; the compacting mechanism comprises a first motor, a first pressing roller and a second pressing roller; and the shearing mechanism comprises a second motor and a cutter. The cloth leveling and shearing equipment for garment manufacturing hasthe functions of feeding and blanking, and is convenient to use; the designed compacting mechanism can compact the cloth to make the texture more compact, and thus the texture of the cloth is improved; and meanwhile, a designed observation window can watch the operation of the cutter in real time, and thus the occurrence of faults is prevented, and the cloth processing process is transparent andefficient, so that the shearing efficiency of the cloth is improved, and corporate earnings are increased.

Owner:浙江新衣诚服装有限公司

Filter metal shell recycling device for high-voltage harmonic wave processing

ActiveCN106733069APromote recoveryEasy to operateProcess efficiency improvementGrain treatmentsHarmonicHigh pressure

The invention relates to a recycling device, in particular to a filter metal shell recycling device for high-voltage harmonic wave processing. The filter metal shell recycling device for high-voltage harmonic wave processing is thorough in crushing, easy and convenient to operate and high in shearing efficiency and comprises a left bracket, a first swing rod, a crushing box body, a second motor, a second swing rod, a first motor, a bottom plate, a right bracket, a pressing plate, a gear, a third motor and the like. The left bracket and the right bracket are arranged at the top of the bottom plate. A flattening device is arranged between the left bracket and the right bracket. According to the filter metal shell recycling device for high-voltage harmonic wave processing, the effects of being thorough in crushing, easy and convenient to operate and high in shearing efficiency are achieved; metal shells of waste filters can be rapidly recycled, and the next batch of practical filters can be manufactured as soon as possible to be put into use.

Owner:靖江市华信科技创业园有限公司

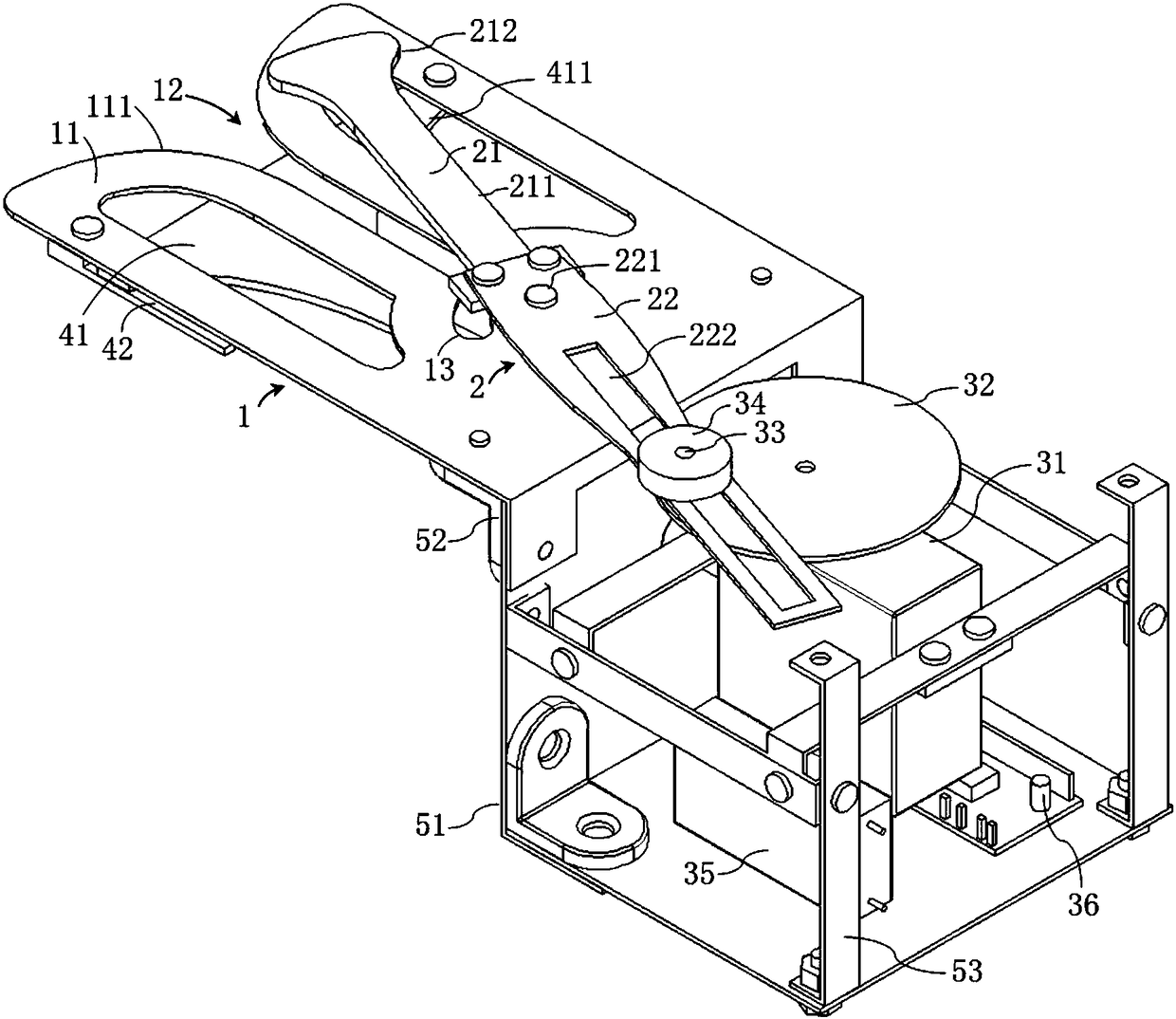

Efficient fruit picking end effector, fruit picker and picking vehicle

PendingCN108419520ARealize automatic pickingImprove picking efficiencyPicking devicesBlade plateSwitching signal

The invention discloses an efficient fruit picking end effector, a fruit picker and a picking vehicle, belonging to the field of picking devices. The fruit picking end effector disclosed by the invention comprises a blade, a triggering actuating lever, an actuating device and a controller, wherein the blade is hinged to a cutting board through a shaft rod, and the cutting edge of the blade cooperates with the fixed cutting board of the cutting board to form a shearing opening; the triggering actuating lever is movably installed on the cutting board, one end is positioned at the shearing opening, and the other end is provided with a limiting switch; the controller is in signal connection with the limiting switch and the actuating device and used for receiving a limiting switch signal and sending an execution signal to the actuating device. The actuating device drives the blade to swing around the shaft rod, and the shearing opening is closed to perform shearing operation, so that the automatic picking of fruit is realized. In the process of operation, the manual intervention of the blade is not required, and the fruit picking end effector is practical, convenient and fast, thereby improving the picking efficiency greatly.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

Plate shearing machine

ActiveCN104117722AImprove cutting accuracyImprove shear efficiencyShearing machinesShearing machine accessoriesEngineeringElectrical and Electronics engineering

The invention discloses a plate shearing machine. The plate shearing machine comprises a support, a workbench and a machine body. The workbench is provided with a feeding device. The machine body is provided with a shearing device. A push rod pushes a plate forwards in the horizontal direction under the action of a feeding power device. The push rod is provided with a signal emitter. The shearing device comprises a shearing power device and a shearing blade. The side, close to the workbench, of the shearing blade is provided with a signal receiver. The signal receiver is used in cooperation with the signal emitter. According to the plate shearing machine, the signal emitter and the signal receiver are used in cooperation, the signal emitter is arranged on the push rod, the signal receiver is arranged on the side, close to the workbench, of the shearing blade, when the push rod moves to the position of the signal receiver, the signal receives a signal sent by the signal emitter and transmits the signal to a control device, the control device controls the shearing power device to drive the shearing blade to move downwards to shear the plate, and the shearing accuracy and shearing efficiency are high.

Owner:丹阳市科尔精密电子有限公司

Water gap separation device and water gap separation method thereof

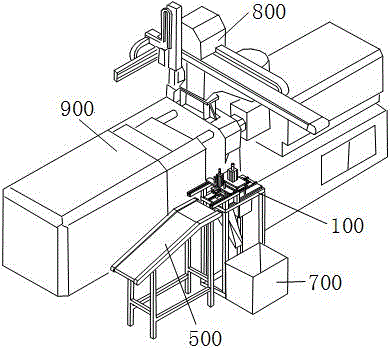

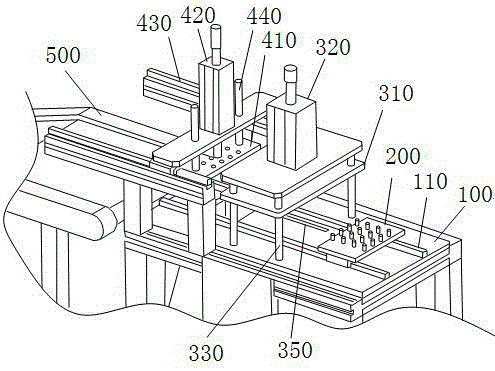

InactiveCN105922522AImprove shear efficiencyReduce separation costsProcess engineeringTransfer mechanism

The invention discloses a water gap separation device and a water gap separation method thereof. The device comprises a machine, a sliding bench arranged on the machine and used for bearing a product, a positioning and shearing mechanism used for positioning the product on the sliding bench and severing a water gap, and a transferring mechanism used for respectively transferring the separated product and the water gap to a discharging position, the machine is provided with a first slide rail used for guiding the sliding bench to move, the positioning and shearing mechanism and the transferring mechanism are sequentially arranged along the first slide rail, and the product borne on the sliding bench sequentially goes through the shearing mechanism and the transferring mechanism to complete processing. The device has the advantages of realization of automatic separation of the product and the water gap, manpower omission, great increase of the water gap shearing efficiency, reduction of the water gap separation cost, ensuring of the qualified rate of the product, timely realization of effective separation of the product and the water gap after the water gap shearing, avoiding of the product quality lowering problem caused by colliding of the water gap to the product, and effective increase of the product separation efficiency.

Owner:FOSHAN CHUANDONG MAGNETOELECTRICITY +1

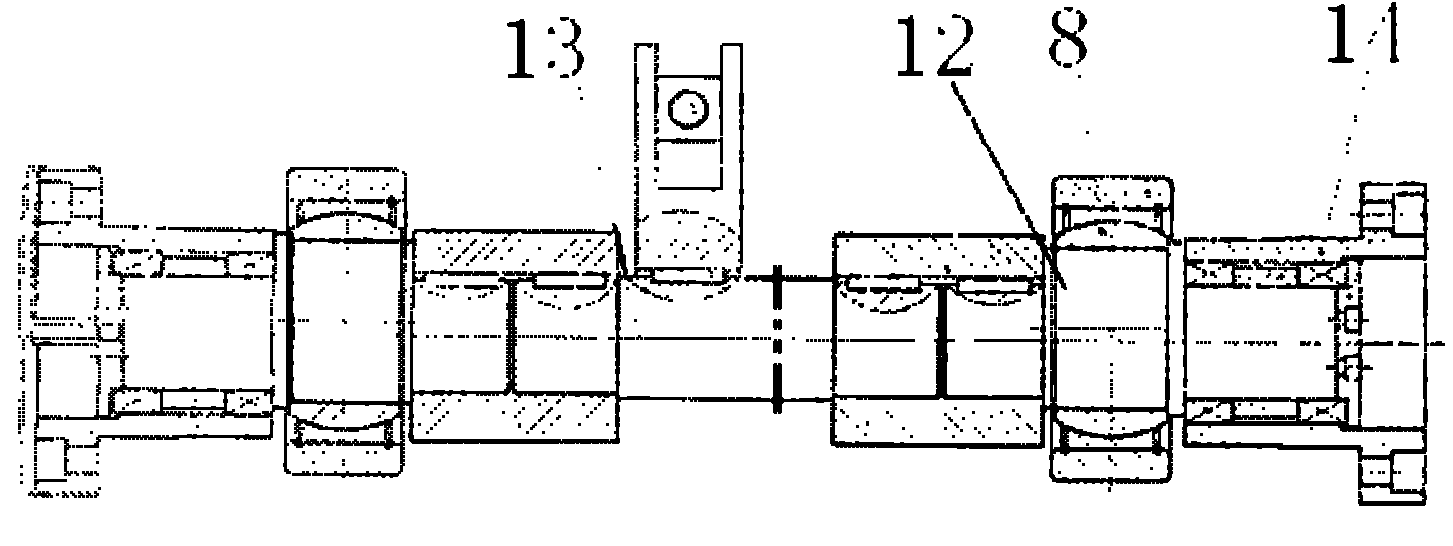

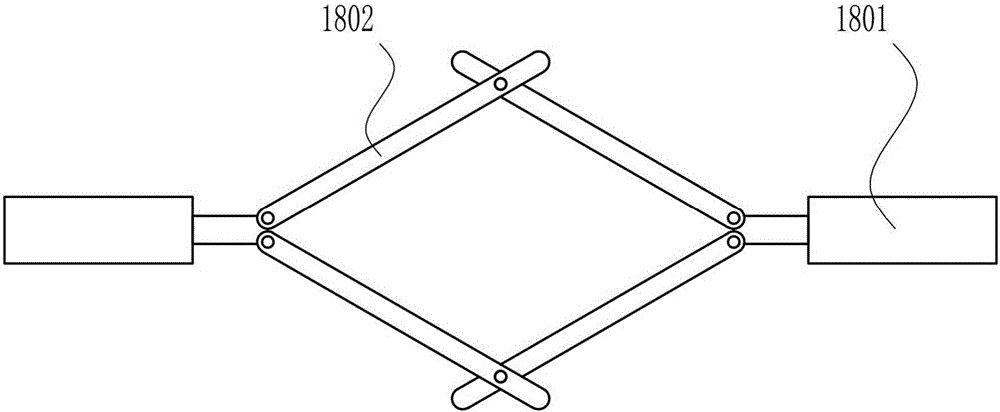

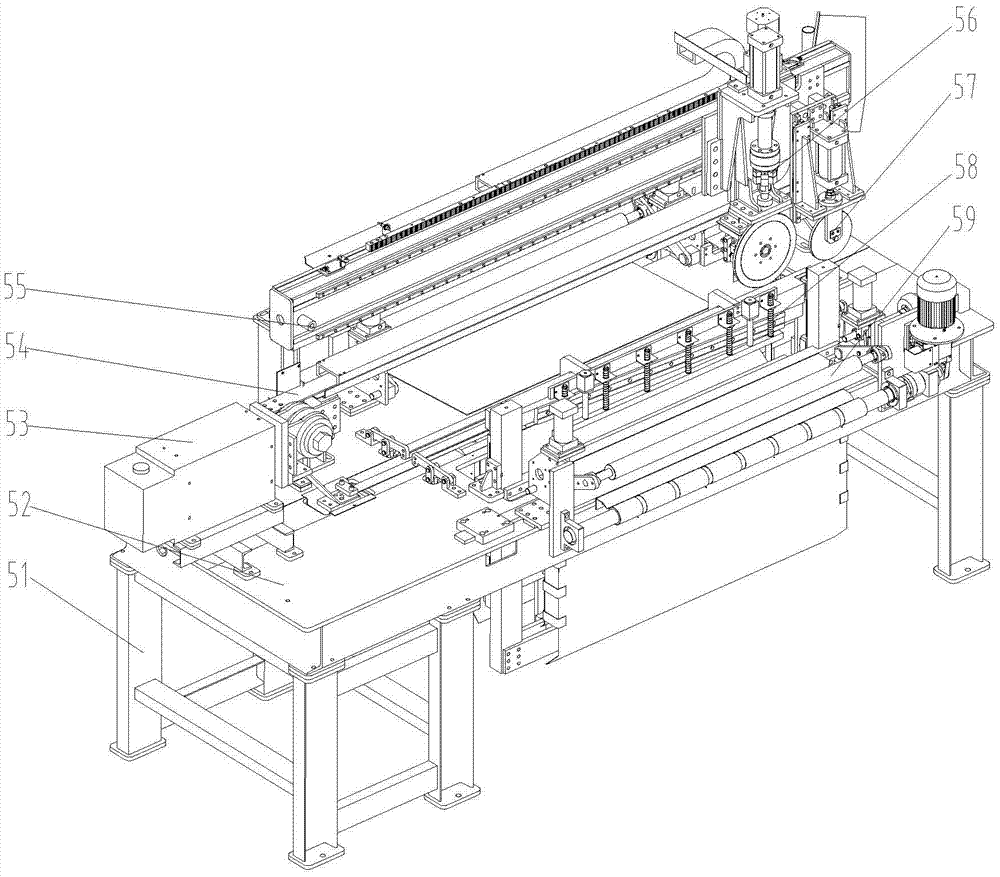

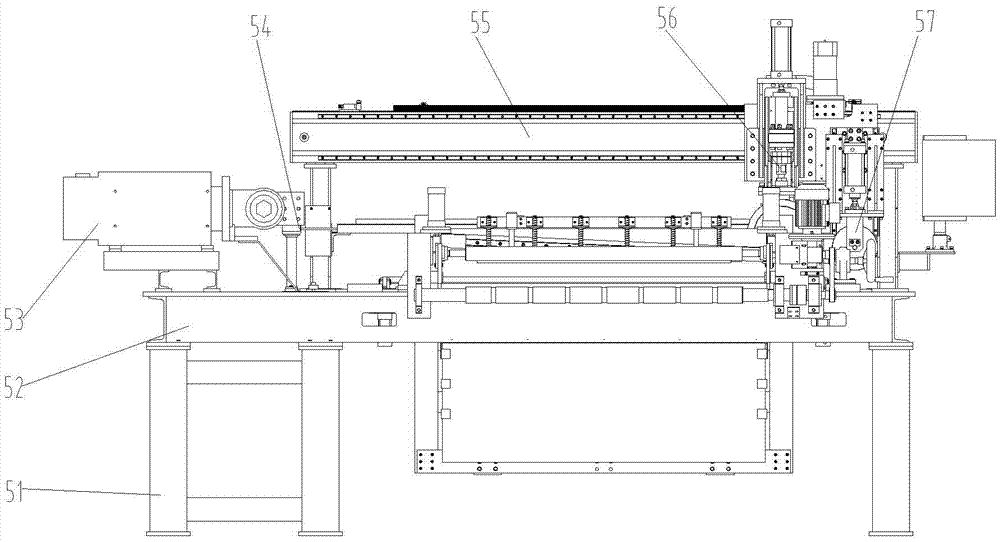

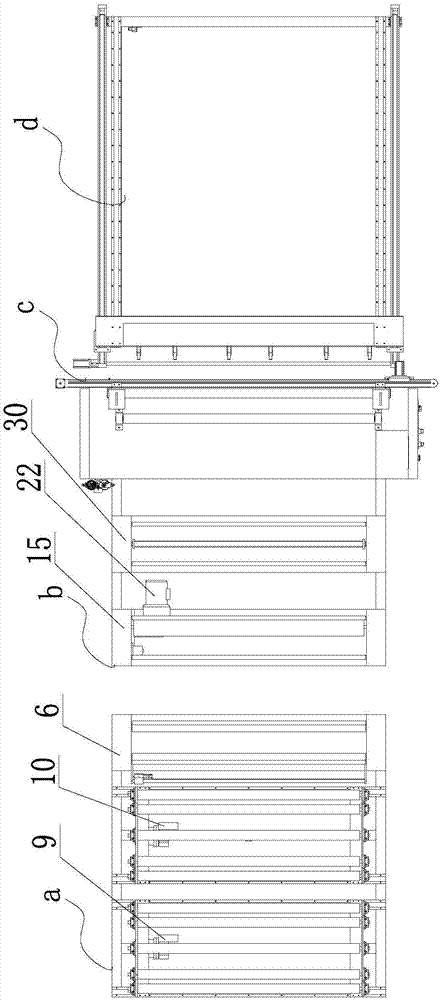

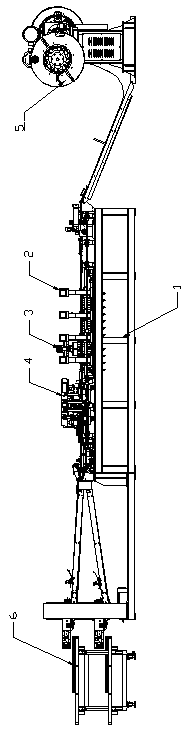

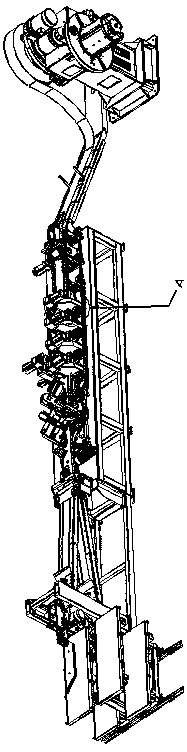

Fully-automatic narrow lap electric-resistance seam-welding machine for thin plates

ActiveCN105436681AReduce processing timeReduce processing efficiencyResistance electrode holdersShearing machinesEngineeringMetal sheet

The invention discloses a fully-automatic narrow lap electric-resistance seam-welding machine for thin plates, belongs to a thin plate seam-welding machine in the welding technical field, and aims to provide the fully-automatic narrow lap electric-resistance seam-welding machine, which is high in shearing efficiency and long in service life, for thin plates. According to the technical scheme, the fully-automatic narrow lap electric-resistance seam-welding machine comprises a rack and a workbench, wherein a clamping and delivering device and a single-blade shear are arranged on the rack or the workbench; a beam assembly is connected on the rack; a resistance welding device and a grinding device are connected on the beam assembly; the single-blade shear comprises a framework, wherein an upper shearing sheet, a lower shearing sheet and a shearing air cylinder are connected on the framework; a synchronous slide block is connected on the shearing air cylinder; link mechanisms are connected on the synchronous slide block; the two groups of link mechanisms are symmetrically arranged at left and right sides of the synchronous slide block, the upper shearing sheet and the lower shearing sheet; and the other ends of the link mechanisms are connected to the upper shearing sheet or the lower shearing sheet. The fully-automatic narrow lap electric-resistance seam-welding machine is suitable for shearing and welding metal thin plates in a finish machining continuous line of the metal thin plates.

Owner:CHENGDU HANYAN TECH

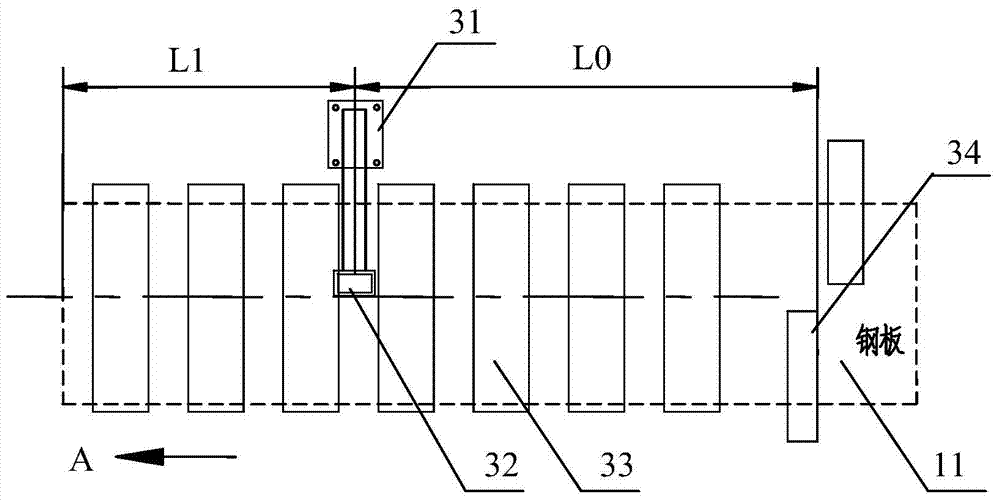

Method for measuring length of steel plate

InactiveCN104515471AHigh precisionReal-time running speed measuredUsing optical meansProduction lineSheet steel

The invention discloses a method for measuring length of a steel plate, relates to end cutting technology of a finishing line of a thick plate production line and solves the problem that existing steel plates are low in sectional cutting accuracy. The method includes enabling an end cutting conveying roller way to start running, enabling the steel plate to move forwards, enabling a laser velocimeter mounted at an outlet of an end cutting shear and at a position of L0 away from a cutting edge of a lower shear blade of the end cutting shear to emit laser, and transmitting feedback signals when the laser irradiates the steel plate to a PLC (programmable logic controller); enabling the PLC to start performing length measuring detection on the steel plate; comparing L with target length Lm preset in the PLC; when L is equal to Lm, enabling the conveying roller way to stop running, enabling the steel plate to stop moving, starting the end cutting shear, and automatically cutting the steel plate at a position of Lm; if the last section is not cut, cutting a next section, and continuing to execute the above steps until the last section is cut. In the method, the laser velocimeter is utilized to measure length of the steel plate, so that accuracy in sectional cutting of the steel plate is improved effectively, yield is increased, and cutting efficiency is improved while labor intensity is lowered.

Owner:BAOSHAN IRON & STEEL CO LTD +1

Plate shearing machine

The invention discloses a plate shearing machine. The plate shearing machine comprises a support seat, a support plate, a support frame body and a plurality of plate cutting units; the support frame body is fixedly connected to the support seat, and two adjacent The cutting board units are detachably connected to form a cutting board; both ends of the cutting board are slidably connected to the support frame body, and the piston rods of multiple cylinders pass through the support frame body one by one One is correspondingly fixed on the cutting board unit, so that the cutting board can move in the vertical direction when the piston rod is stretched in the vertical direction; the cutting board unit is detachably connected with a cutting knife ; The support plate is fixedly connected to the support base; The cutting edge of the cutter is provided with a sawtooth shape or a cutting edge shape. The shearing machine can adapt to shearing various lengths of plates to be sheared, and has high shearing efficiency during the shearing process.

Owner:WUHU TIANHANG TECH GRP

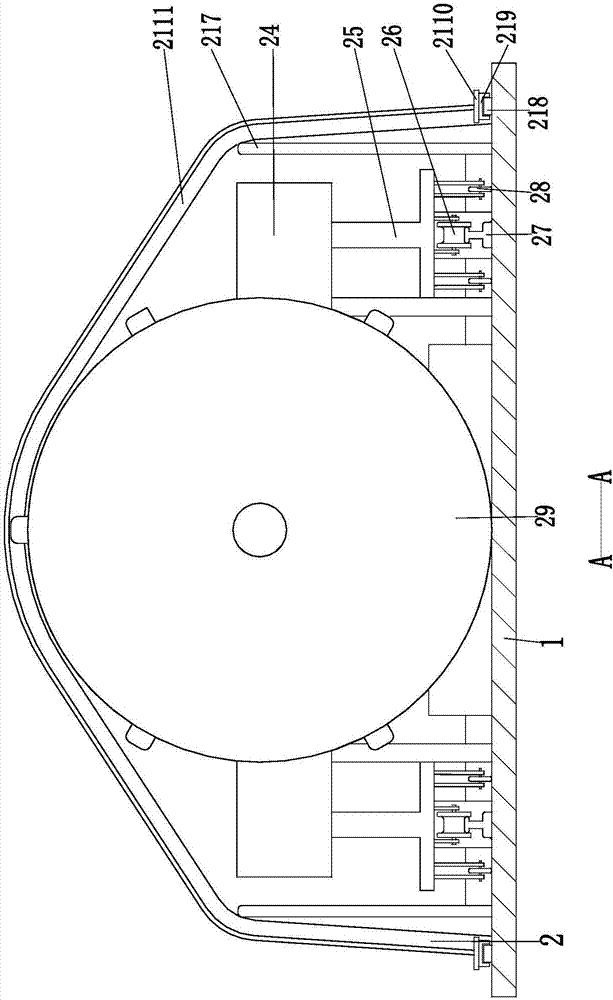

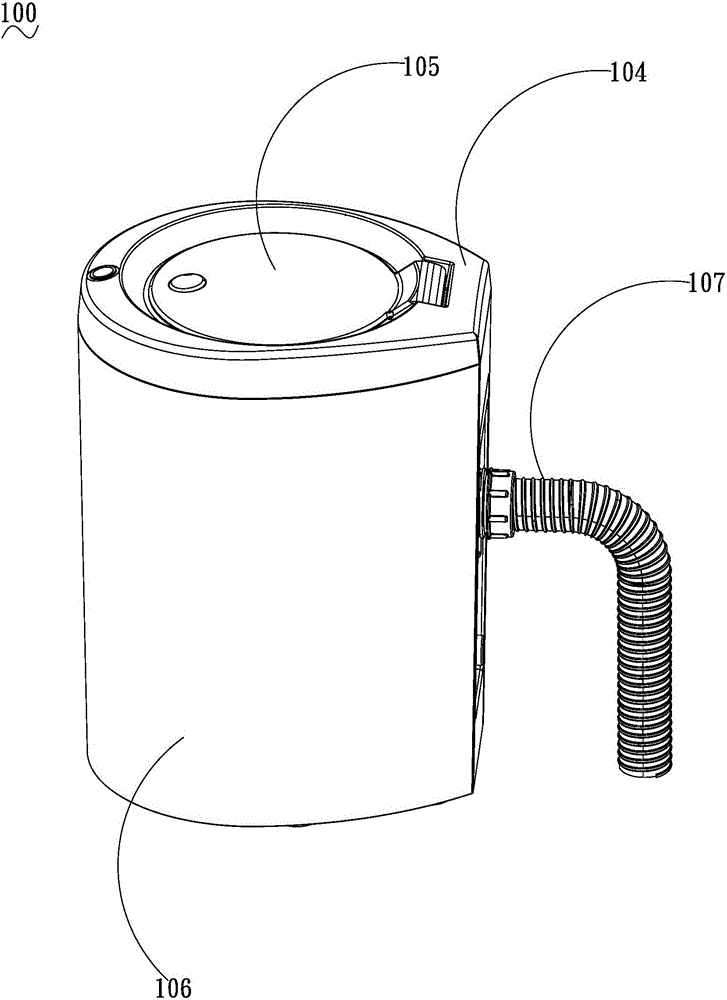

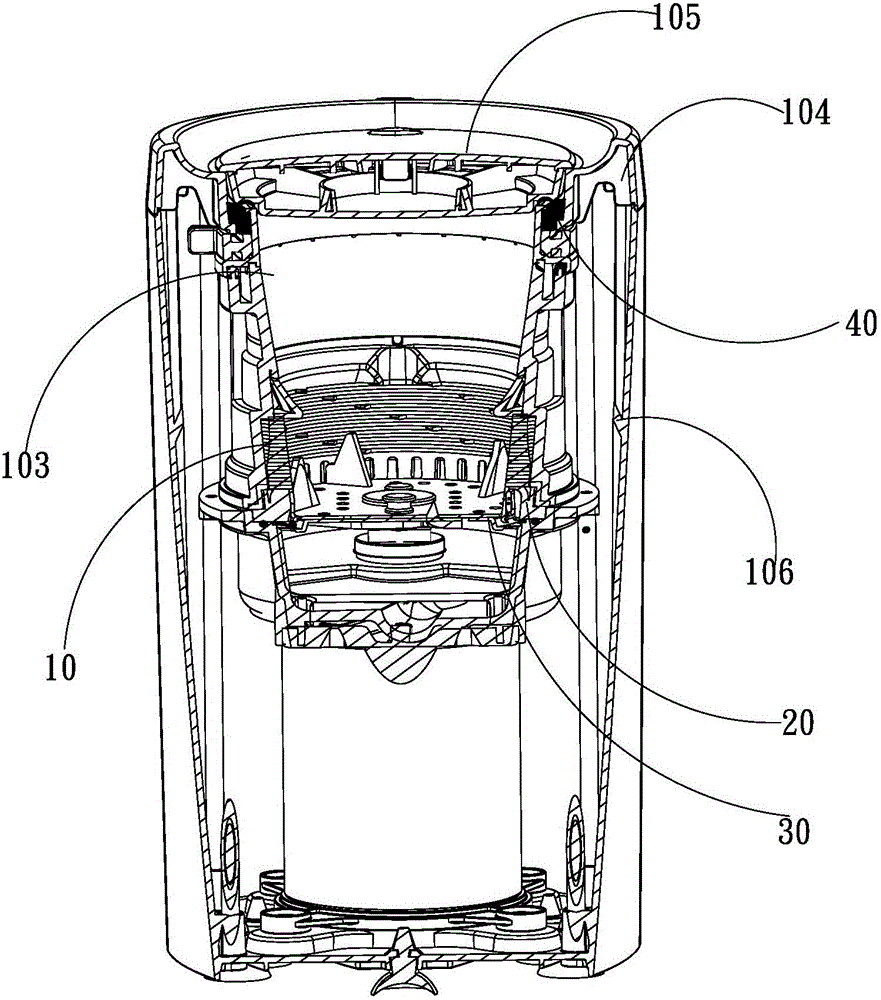

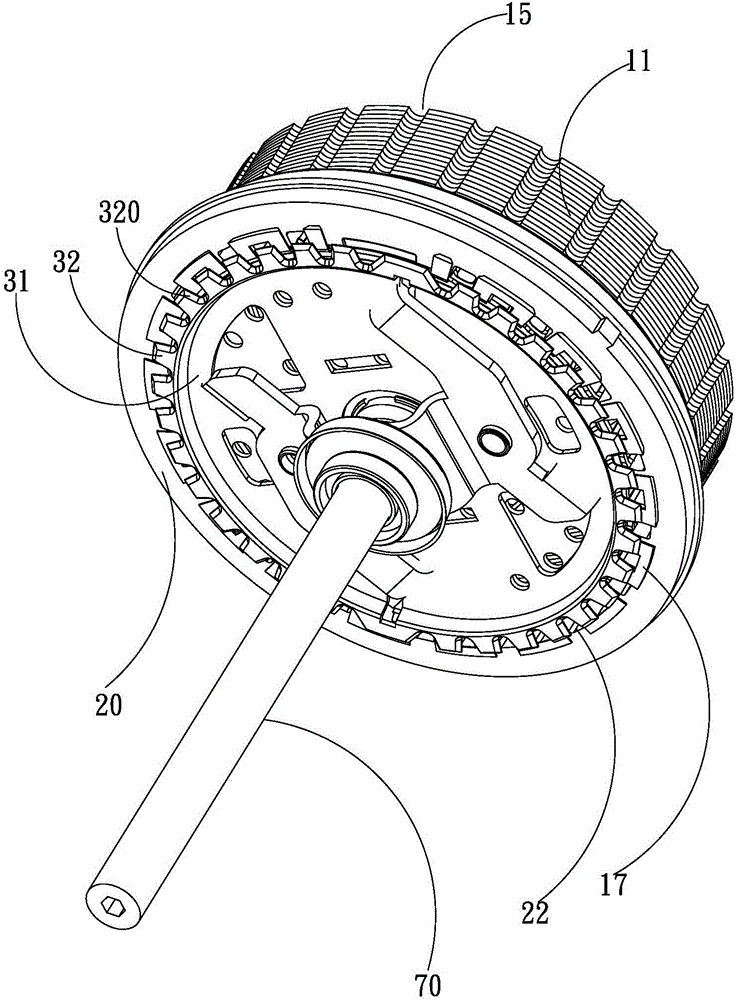

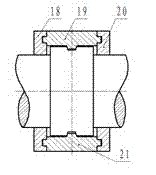

Household garbage disposer

The invention relates to a household garbage disposer which comprises a resilience-preventive turnover cover mechanism, a rotary knife flywheel and a fixed knife wall. The fixed knife wall comprises a tearing knife, a shearing knife ring and a fixed ring; the shearing knife ring comprises an annular side and a plurality of shearing teeth, and the adjacent shearing teeth are connected with one another and form a plurality of shearing tooth groups; the tearing knife comprises a plurality of first knife wall rings which are arranged in a stacked manner; a plurality of fixed teeth which are arranged at intervals are inwardly protruded on the inner walls of the first knife wall rings and are matched with the shearing tooth groups, and garbage can be shorn by the fixed teeth, the shearing tooth groups and the rotary knife flywheel. The household garbage disposer has the advantages that shearing surfaces are arranged on the rotary knife flywheel and the fixed knife wall, and accordingly shearing effects can be improved; the multiple knife wall rings are stacked on one another to form the fixed knife wall and are provided with the fixed teeth, and fixed tooth groups are matched with the rotary knife flywheel, so that the garbage can be shorn, and the shearing efficiency further can be improved; devices such as a flexible connecting sleeve and the resilience-preventive turnover cover mechanism are transformed, and accordingly the service performance of the household garbage disposer in various aspects can be effectively improved.

Owner:DONGGUAN JIEMEI ELECTRIC APPLIANCE

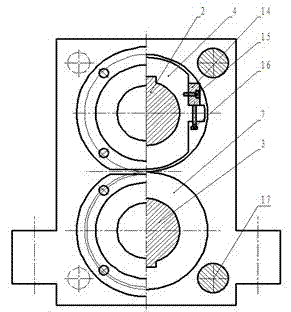

Circle shearing machine capable of determining width and smashing edges of lead belt for storage battery

InactiveCN102513595AEasy axial positioningLess investmentShearing machinesStructural engineeringKnife blades

The invention relates to a circle shearing machine capable of determining the width and smashing the edges of a lead belt for a storage battery. According to the technical scheme, an upper width adjusting component (8) is mounted on an upper knife shaft (2); an upper right blade (9) and a right knife holder (10) are sequentially fixedly mounted by means of being tightly adhered to the right side of the upper width adjusting component (8); 1-4 right edge smashing knifes (14) are mounted on the right knife holder (10); the knife opening of each right edge smashing knife (14) is located on the concentric circumference of the knife shaft (2); an upper left blade (6) and a left knife holder (4) are sequentially fixedly mounted by means of being tightly adhered to the left side of the upper width adjusting component (8); 1-4 left edge smashing knifes (5) are mounted on the left knife holder (4); the knife opening of each left edge smashing knife (5) is located on the concentric circumference of the knife shaft (2); a lower width adjusting component (11) is mounted on a lower knife shaft (3); a lower right blade (12) is fixedly mounted by means of being tightly adhered to the right side of the lower width adjusting component (11); and a lower left blade (7) is fixedly mounted by means of being tightly adhered to the left side of the lower width adjusting component (11). The circle shearing machine disclosed by the invention has the characteristics of less investment, convenience for installation and high shearing efficiency.

Owner:WUHAN UNIV OF SCI & TECH

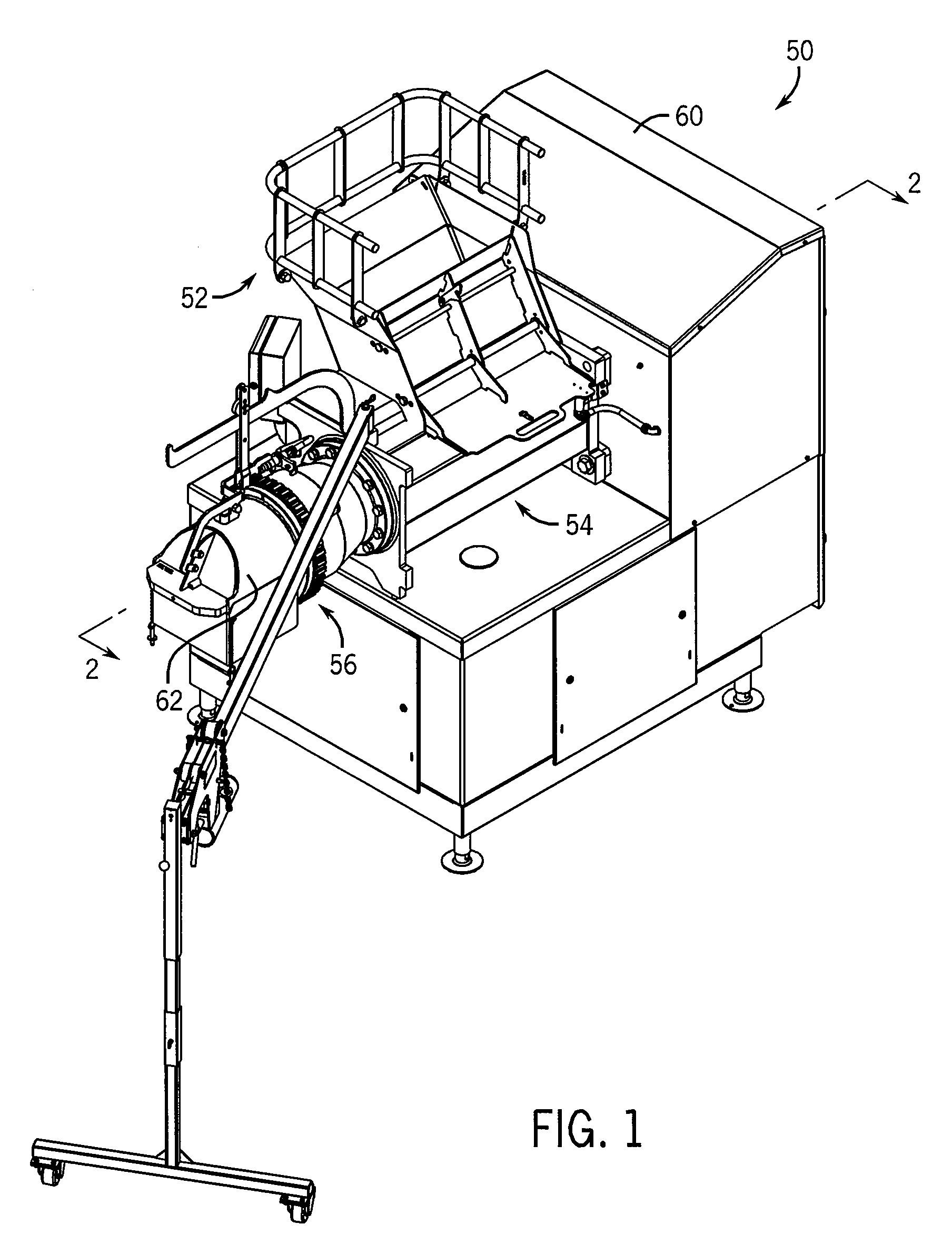

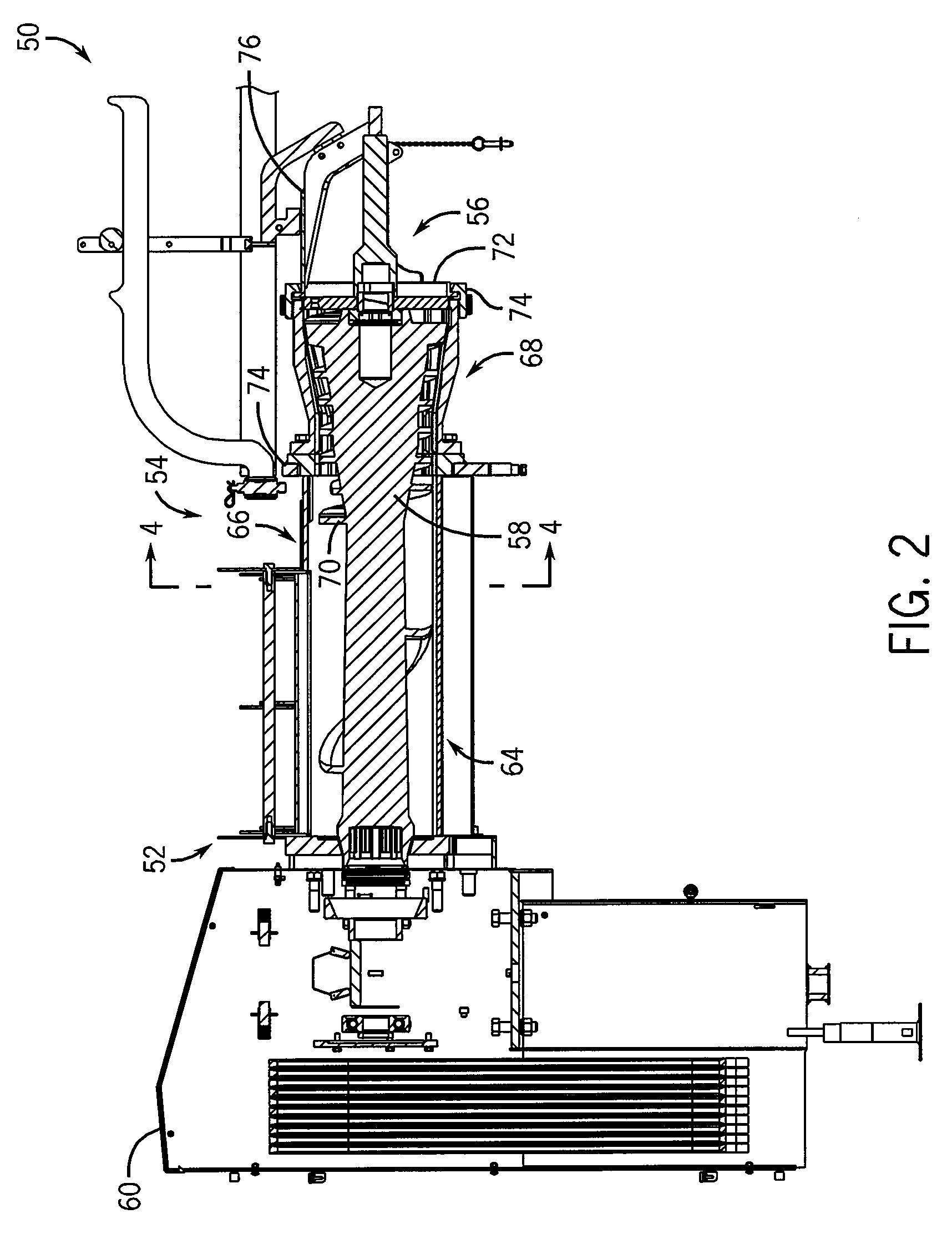

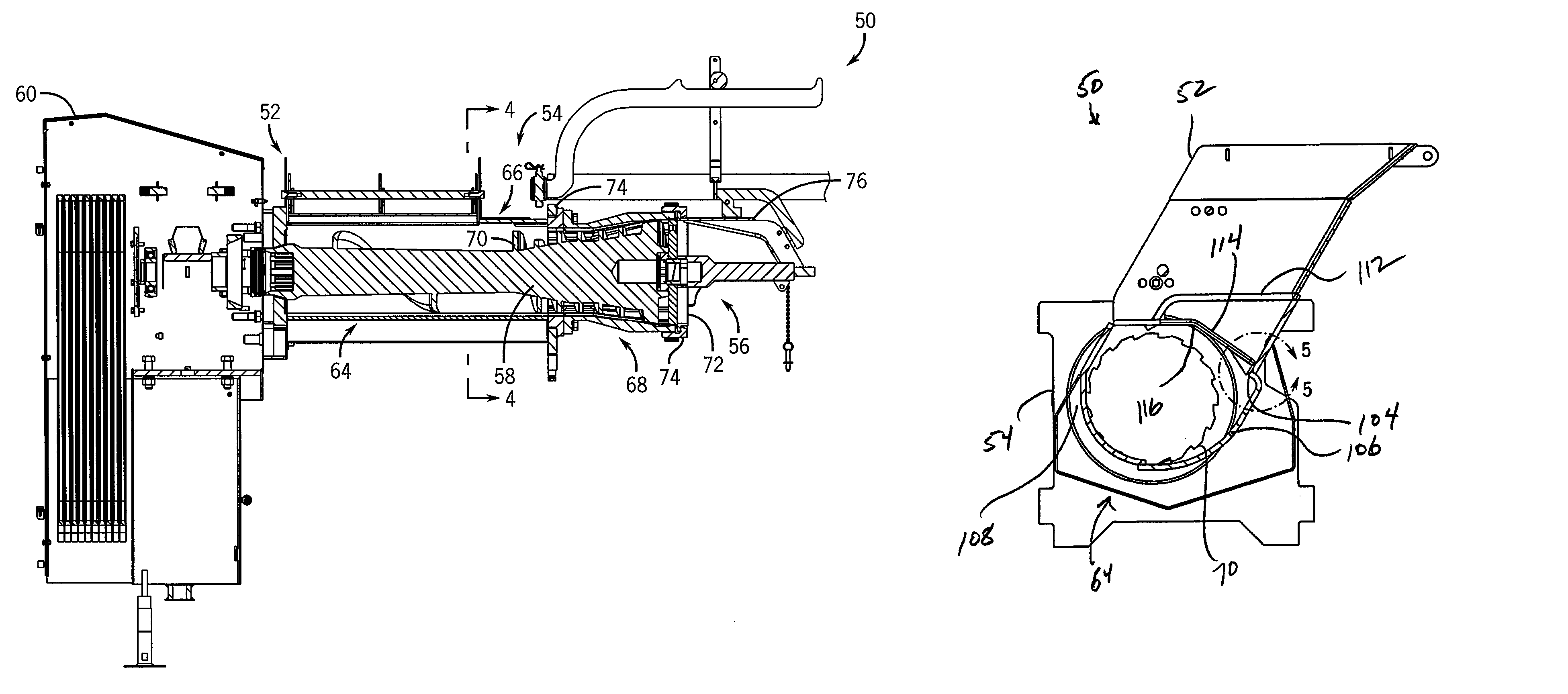

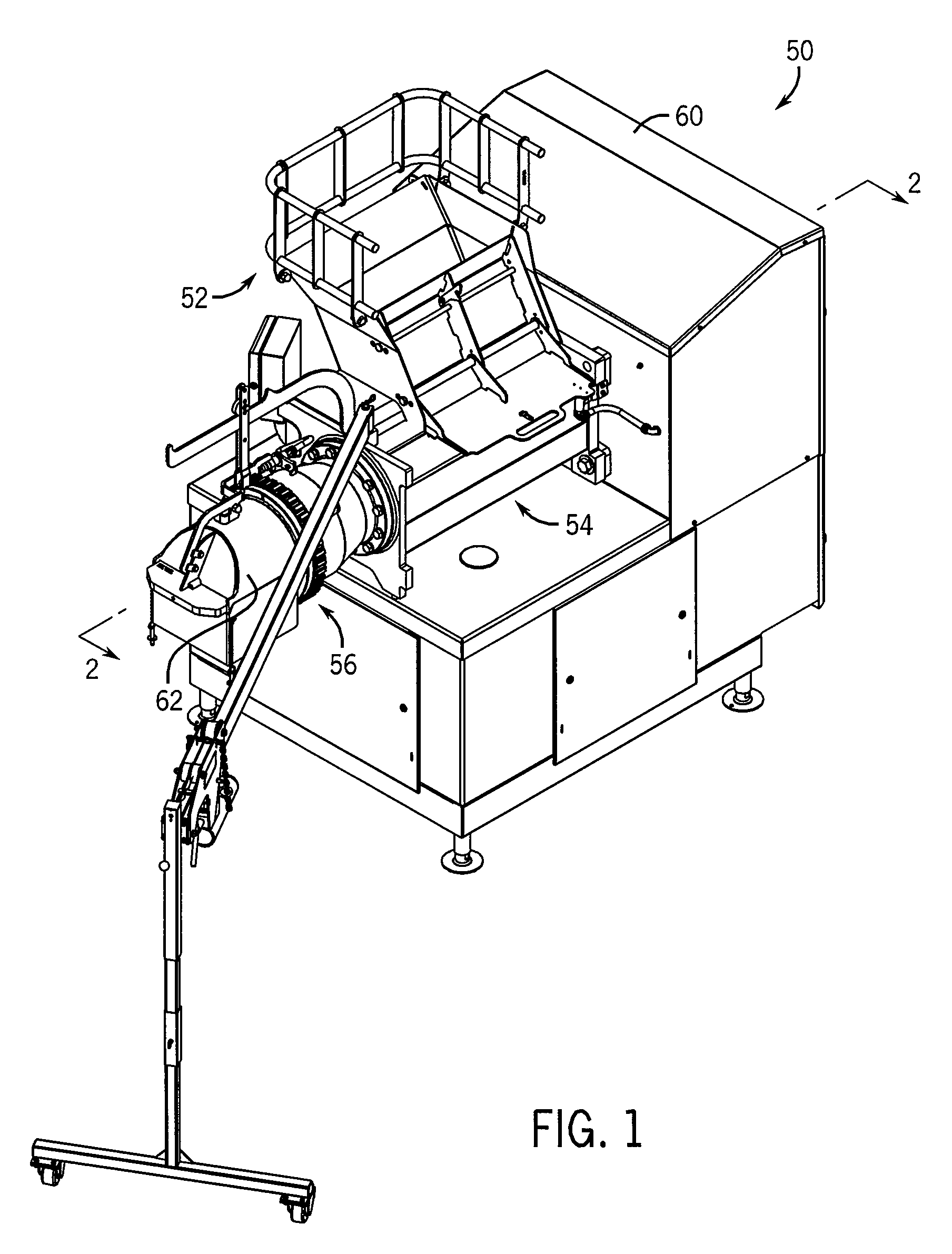

Frozen Block Grinder

ActiveUS20090001202A1Improve shear efficiencyEasy to controlGrain huskingGrain polishingVena contracta diameterEngineering

A grinding machine has a shearing chamber that includes one or more edges that provide fulcrum points against which frozen block of material, such as frozen blocks of meat, can be held against during a reduction or shearing process. The edges may be arranged to limit the advancement of reduced blocks of material to provide more control on the size of the ground material that is ultimately output by the grinding machine. The grinding machine may also include an expansion zone into which reduced blocks can be temporarily held to accommodate volume increases during the reduction process. A feed screw advances the frozen blocks through the shearing chamber and includes pressure flighting to help shear material from the frozen blocks. The feed screw may include a knife holder that provides support for a knife held therein against the lateral forces experienced by the knife as the knife shears material adjacent the orifice plate.

Owner:PROVISUR TECHNOLOGIES INC

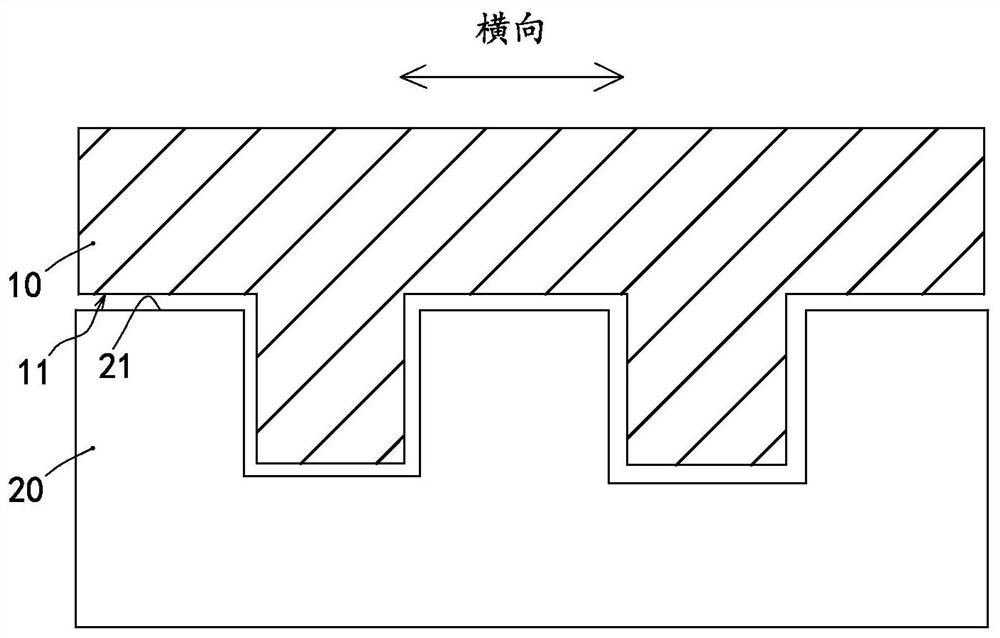

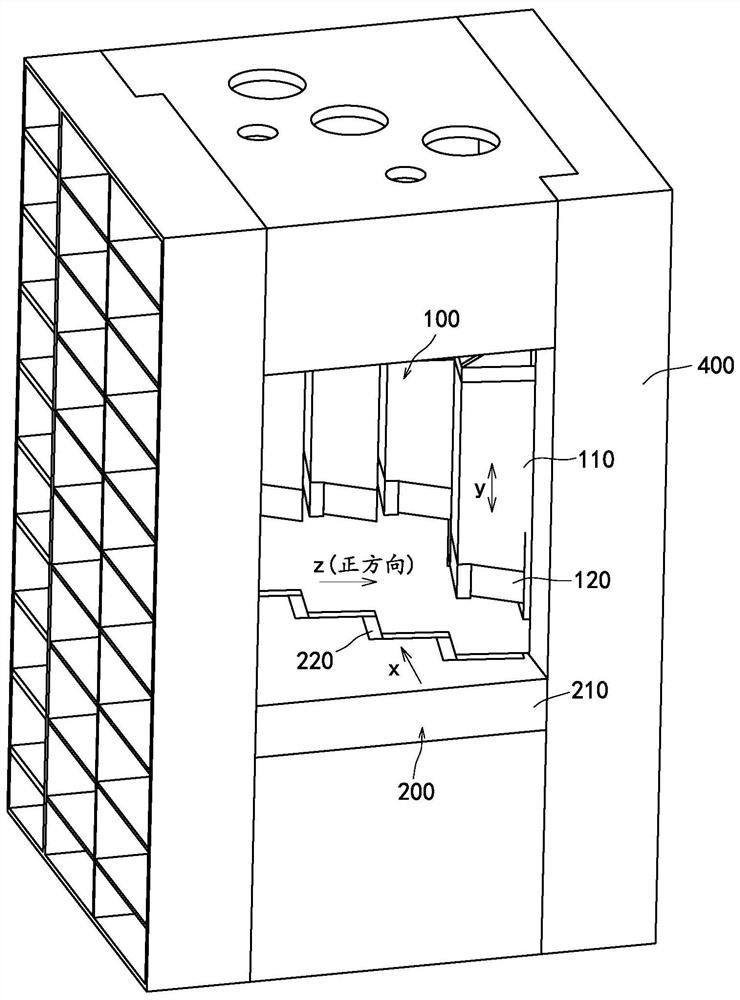

Shearing assembly and shearing machine

ActiveCN112893957AImprove shear efficiencyReduce abnormal wearShearing machinesEngineeringMechanical engineering

The invention provides a shearing assembly and a shearing machine, and relates to the technical field of shearing machines. The shearing assembly comprises a movable cutter assembly, a fixed cutter assembly and a power source; the movable cutter assembly comprises a movable cutter holder and a movable cutter installed on the movable cutter holder; the movable cutter is provided with a shearing cutting edge consisting of a transverse cutting edge and a longitudinal cutting edge; and the orthographic projection of the shearing cutting edge in the y-axis direction is in a step shape. The y-axis direction is the moving direction of the movable cutter assembly; the longitudinal cutting edge is provided with a front end close to the feeding side and a rear end close to the discharging side; and in the z-axis direction, the front end and the rear end are the same in position or the rear end is located in the positive direction of the front end. The z-axis direction is perpendicular to the x-axis direction and the y-axis direction; the x-axis direction is a feeding direction; in the z-axis direction, the direction from the fixed cutter to the movable cutter is set to be the positive direction; and according to the shearing assembly, on the basis that the step-shaped shearing cutting edge is adopted, the material can be sheared into a plurality of blocks at a time, and higher production efficiency is achieved.

Owner:长沙中金智能装备有限公司

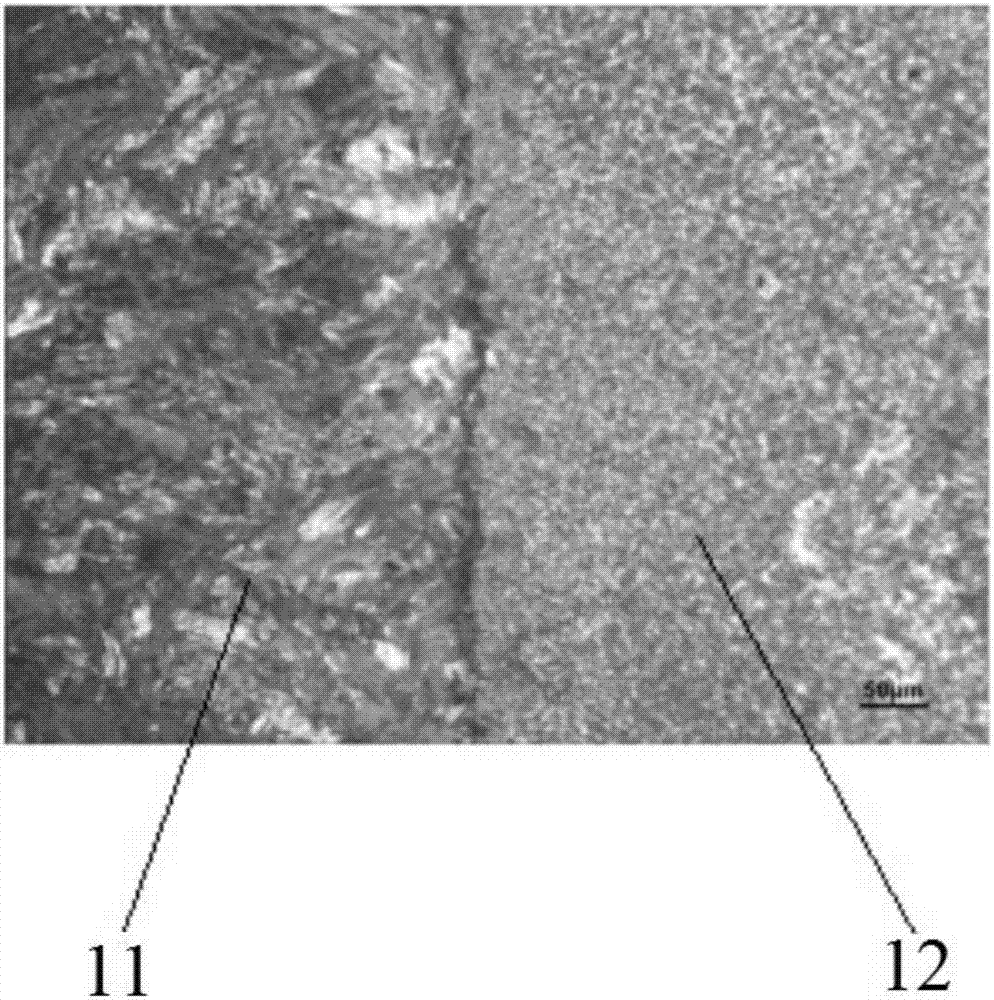

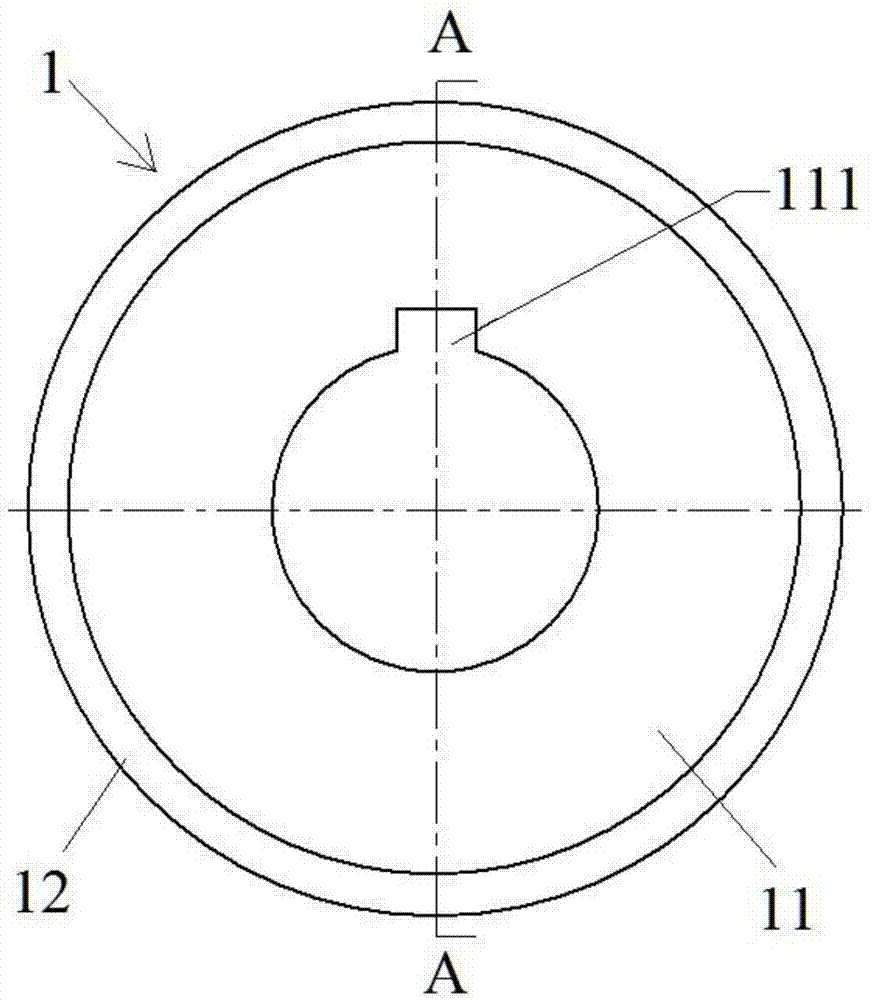

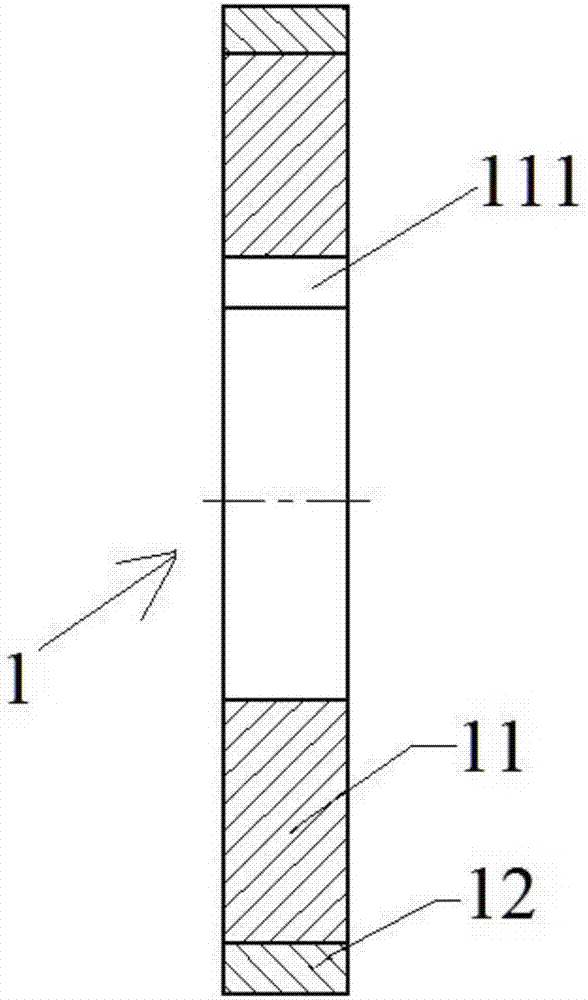

Blade of disc shearing machine and preparing method thereof

ActiveCN107538013AExtended service lifeReduce manufacturing costShearing toolsCircular discSheet steel

The invention relates to the field of preparation of mechanical blades and provides a blade of a disc shearing machine and further provides a preparation method of the blade of the disc shearing machine. The blade is used for shearing stainless steel and a high-strength steel plate and is high in cost performance. The preparation method of the blade of the disc shearing machine comprises the stepsthat a blade base body is prepared and wrapped with a blade sheath, the space between the outer side wall of the blade sheath and the outer side wall of the blade base body is filled with alloy powder through a powder filling channel in an annular cover plate located on the blade sheath, and a top cover is mounted on the powder filling channel after filling and vibrating compaction; the blade sheath internally provided with the blade base body and the alloy powder is placed in a degassing furnace, vacuumizing and degassing heat preservation are conducted, then the blade sheath is placed in ahot isostatic pressure furnace to be subjected to hot isostatic pressure treatment, and thus a blade edge layer is formed; and the blade sheath is removed through machining, thus a blade blank is obtained, then annealed, quenched and tempered, and the blade is obtained through finish machining. The blade prepared through the method is uniform in edge thickness, resistant to abrasion, long in service life, low in cost and high in cost performance.

Owner:ADVANCED TECHNOLOGY & MATERIALS CO LTD

Garment fabric cutting device

ActiveCN108914528ACropping effectImprove shear efficiencySevering textilesUltimate tensile strengthUtilization rate

The invention belongs to the technical field of garment processing machinery and specifically relates to a garment fabric cutting device. The device comprises a box body; the device also comprises a drive unit, a cutting unit and a cutting table; the drive unit is used for driving the cutting unit to cut fabric; the cutting unit is used for cutting fabric; the cutting table is used for providing cutting position for fabric. By means of the cooperation of the drive unit, the cutting unit and the cutting table, the fabric is cut by the cutting unit which is driven by the drive unit, which not only alleviates labor intensity, but also increases fabric cutting efficiency; at the same time, the power source generated in the drive unit during driving is utilized so that the source utilization rate is increased; the fabric scraps in the fabric cutting drops to the bottom of the box to avoid the fabric scraps affecting the cutting of the fabric, thus improving the cutting effect of the fabric.

Owner:浙江平步服饰股份有限公司

Double-layer sheet transverse cutting machine

InactiveCN107953395AHigh accuracy of deviation correctionImprove work efficiencyLamination ancillary operationsLaminationCross cutEngineering

The invention discloses a double-layer sheet cross-cutting machine. According to the conveying direction of the sheet, a discharging mechanism, a traction mechanism, a cutting mechanism and a receiving hopper are sequentially arranged on a support; the cutting mechanism includes a front clamping assembly, a rear clamping assembly, a transverse The cutting guide assembly and the circular knife assembly, the front clamp assembly is installed on the bracket, the rear clamp assembly is installed on the receiving hopper and moves reciprocally on the receiving hopper along the sheet conveying direction, the cross cutting guide assembly is arranged above the front clamp assembly, The circular knife assembly is arranged on the cross-cut guide assembly and moves back and forth along the cross-cut guide assembly. This double-layer sheet cross-cutting machine can realize the synchronous and stable conveying and cutting of corrugated paper and bubble paper on the same equipment, filling the gap in the market, reducing manual operations, and effectively improving the work efficiency of the cross-cutting machine; It avoids the inconsistent size of corrugated paper and bubble paper, reduces subsequent trimming work, and effectively controls and improves the packaging efficiency of distribution boxes.

Owner:昇辉控股有限公司

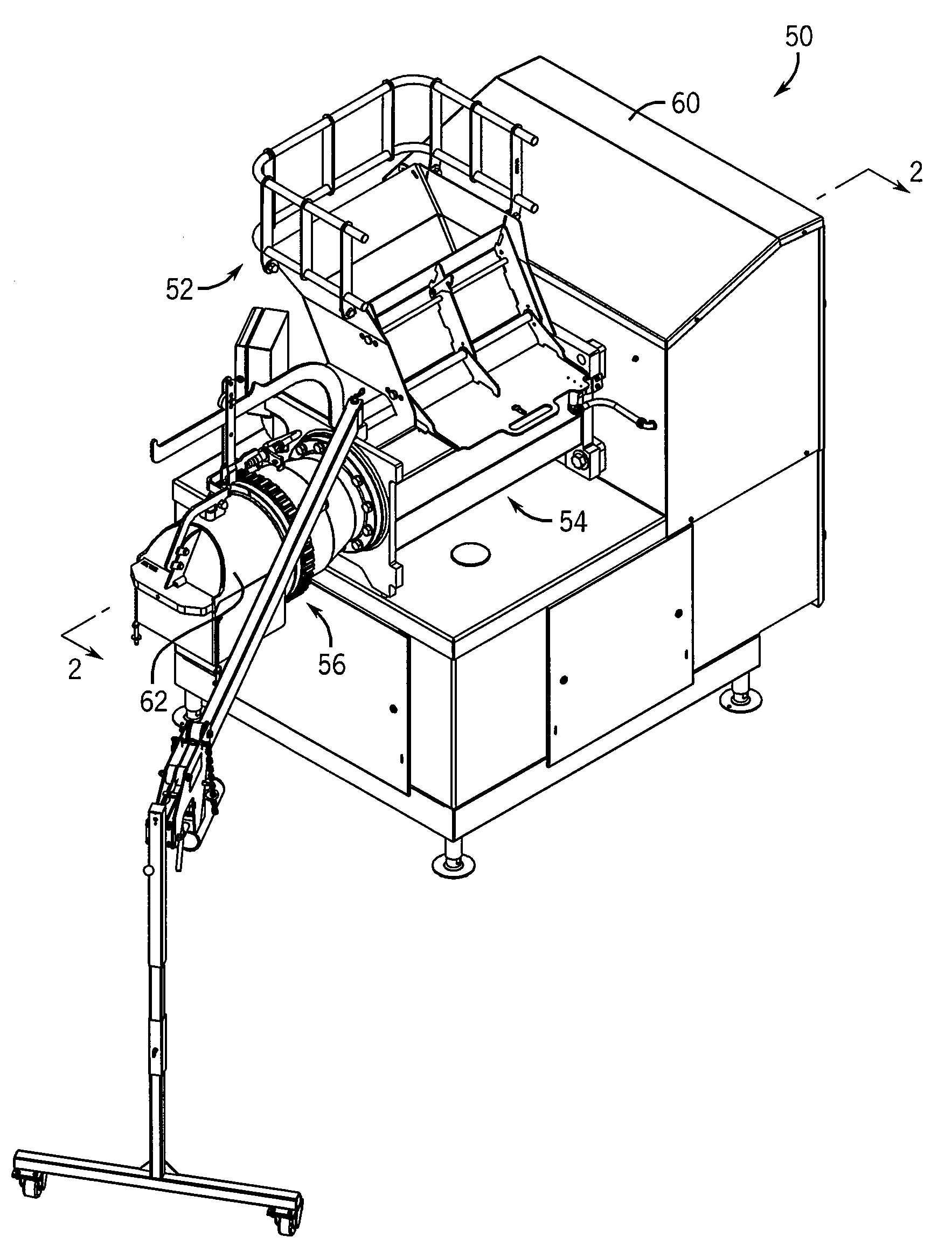

Frozen block grinder

ActiveUS7946517B2Improve shear efficiencyEasy to controlGrain huskingGrain polishingVena contracta diameterEngineering

A grinding machine has a shearing chamber that includes one or more edges that provide fulcrum points against which frozen block of material, such as frozen blocks of meat, can be held against during a reduction or shearing process. The edges may be arranged to limit the advancement of reduced blocks of material to provide more control on the size of the ground material that is ultimately output by the grinding machine. The grinding machine may also include an expansion zone into which reduced blocks can be temporarily held to accommodate volume increases during the reduction process. A feed screw advances the frozen blocks through the shearing chamber and includes pressure flighting to help shear material from the frozen blocks. The feed screw may include a knife holder that provides support for a knife held therein against the lateral forces experienced by the knife as the knife shears material adjacent the orifice plate.

Owner:PROVISUR TECHNOLOGIES INC

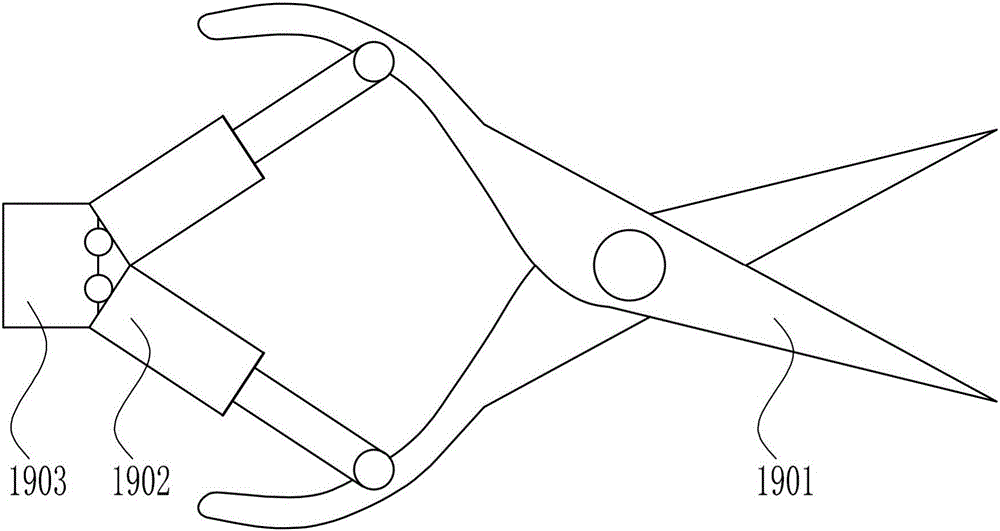

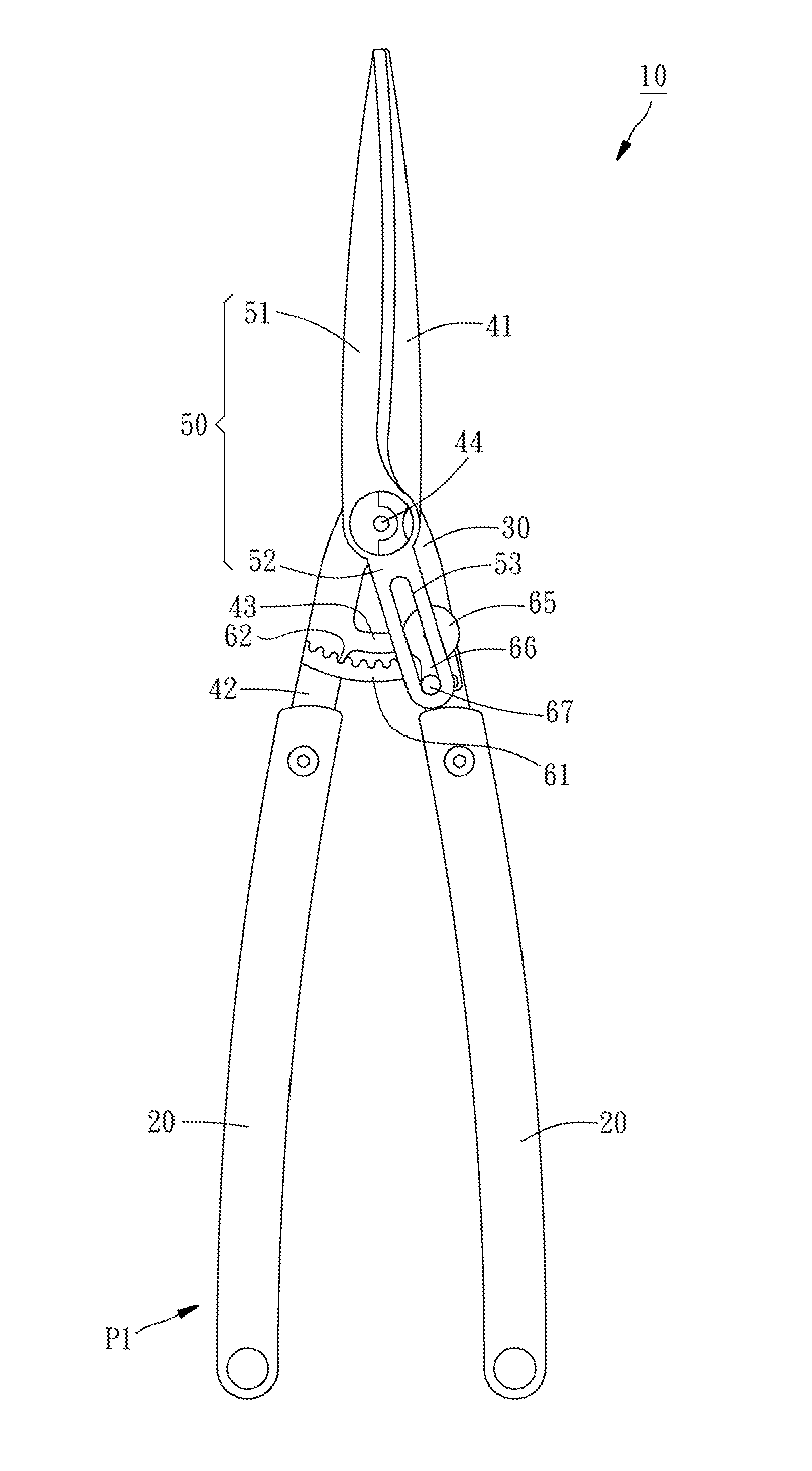

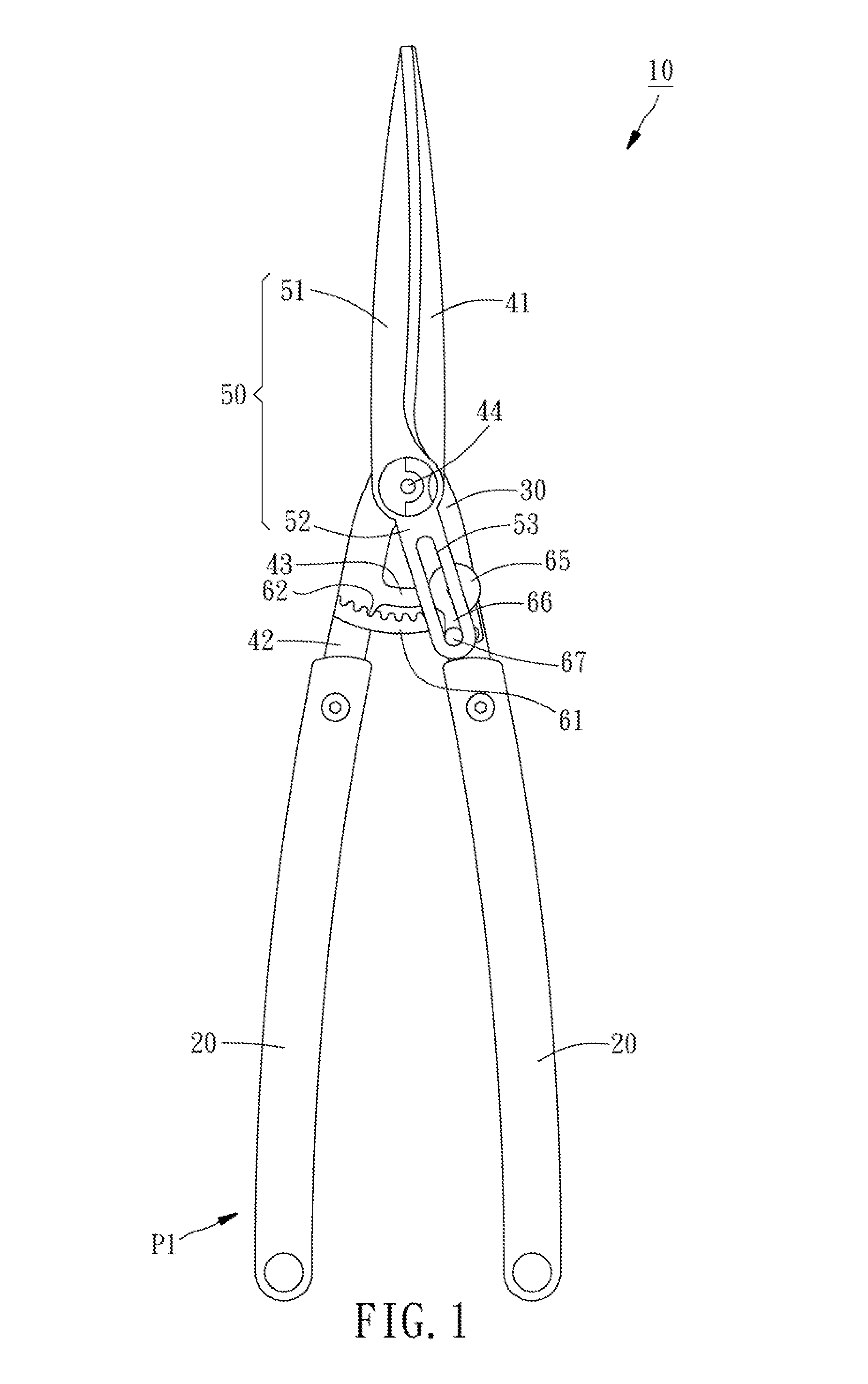

Gardening shears with improved shearing efficiency

ActiveUS20160270299A1Simple structureEasy to operateCuttersCutting implementsEngineeringMechanical engineering

A gardening shears includes two handles, a first shear blade connected to one handle and providing a suspension arm portion, a linking rod connected to the other handle, a second shear blade coaxially pivoted to the first shear blade and the linking rod and providing an elongated slot, and a control unit including an arched guide member fixedly connected with its one end to the linking rod and a guide wheel pivotally connected to the suspension arm portion of the first shear blade with a guiding protrusion thereof inserted into the elongated slot of the second shear blade.Thus, when opening and closing the handles, the mating arrangement of the arched guide member, the guide wheel and the elongated slot of the second shear blade enables the first and second shear blade to implement the shearing action twice.

Owner:LIN THOMAS

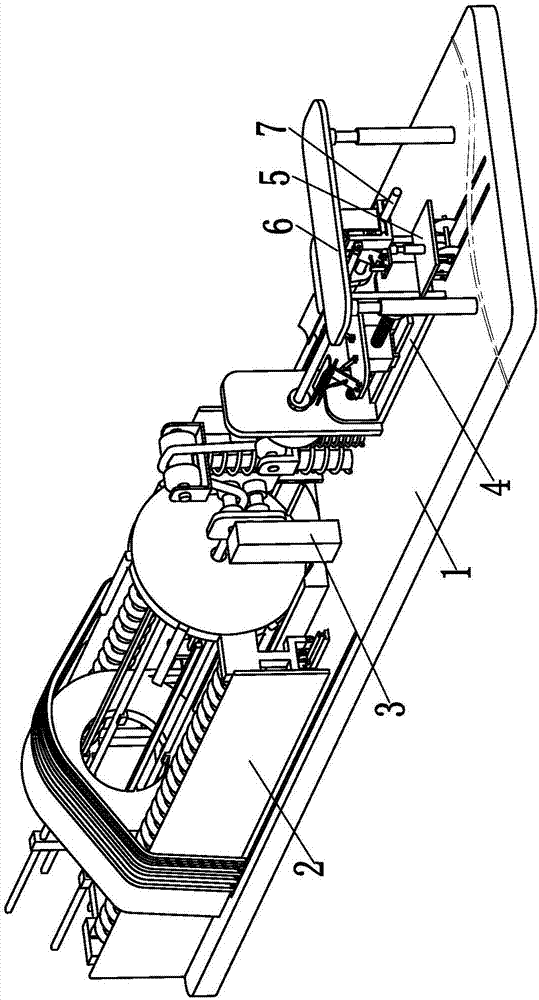

Feather positioning and trimming device for badminton production

ActiveCN111467771AGuaranteed uptimeImprove shear efficiencySport apparatusStructural engineeringMechanical engineering

The invention relates to the field of badminton production equipment, and particularly relates to a feather positioning and trimming device for badminton production. The device comprises a device mainbody, a limiting plate is fixedly mounted at the upper end of the left side in the device main body, a shearing device is fixedly mounted at the upper end in the device main body, a shearing rotatingwheel is fixedly mounted in the shearing device, the baffle is arranged in an arc shape, the distance from the outer side of the shearing rotating wheel is gradually reduced from bottom to top, an extrusion plate can thus be continuously driven to drive the feathers to be in contact with the shearing block, therefore, the feathers are sheared by utilizing the shearing block; when the previous feather is sheared, the next feather also enters the shearing groove, multiple feathers can be sheared at one time, and the feather shearing efficiency is greatly improved; guide block which is arrangedin a right-angled triangle shape is fixedly installed on the outer side of the conveying belt, so that the efficiency of the feathers entering the shearing groove can be improved, meanwhile, the extrusion plate can be guided into the inner side of the baffle, and normal operation of the shearing rotating wheel is guaranteed.

Owner:江山市三鑫体育用品有限公司

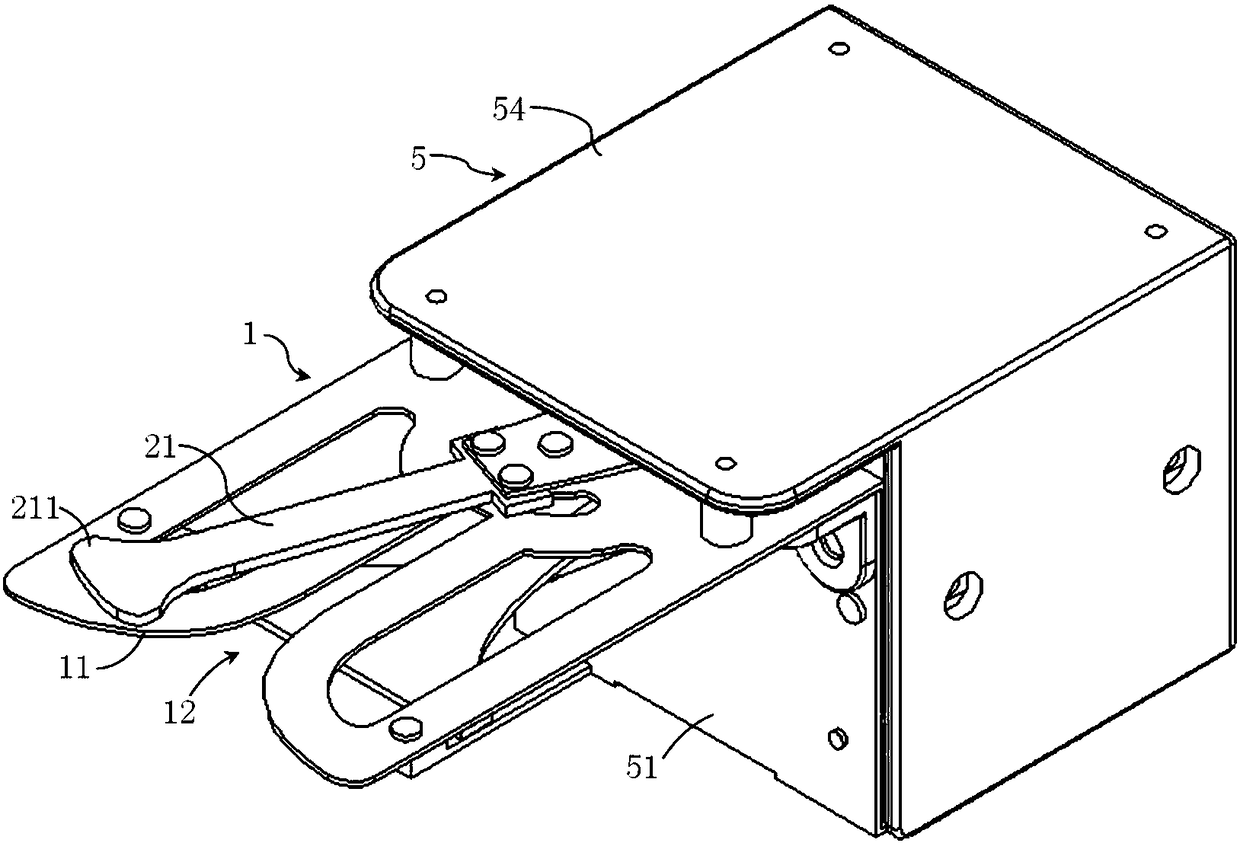

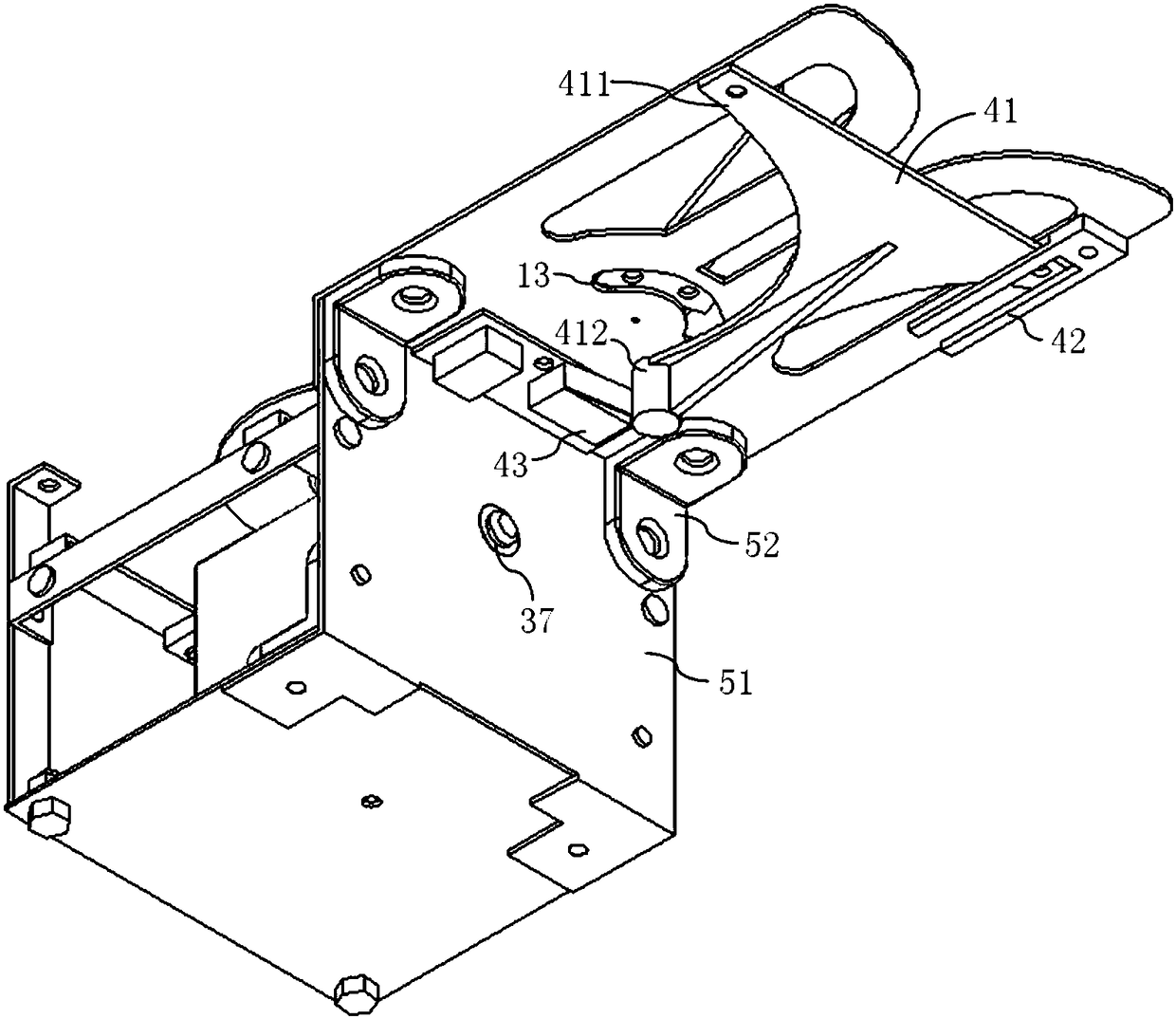

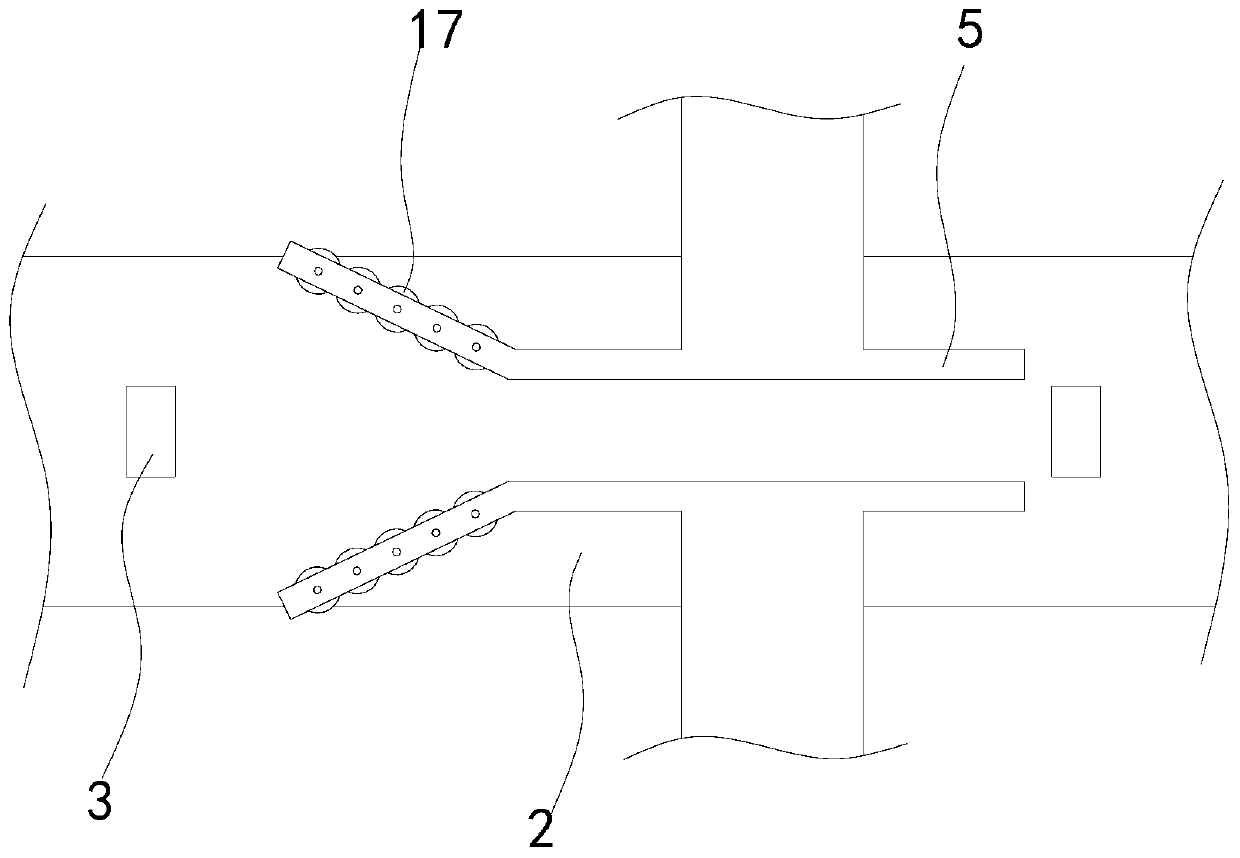

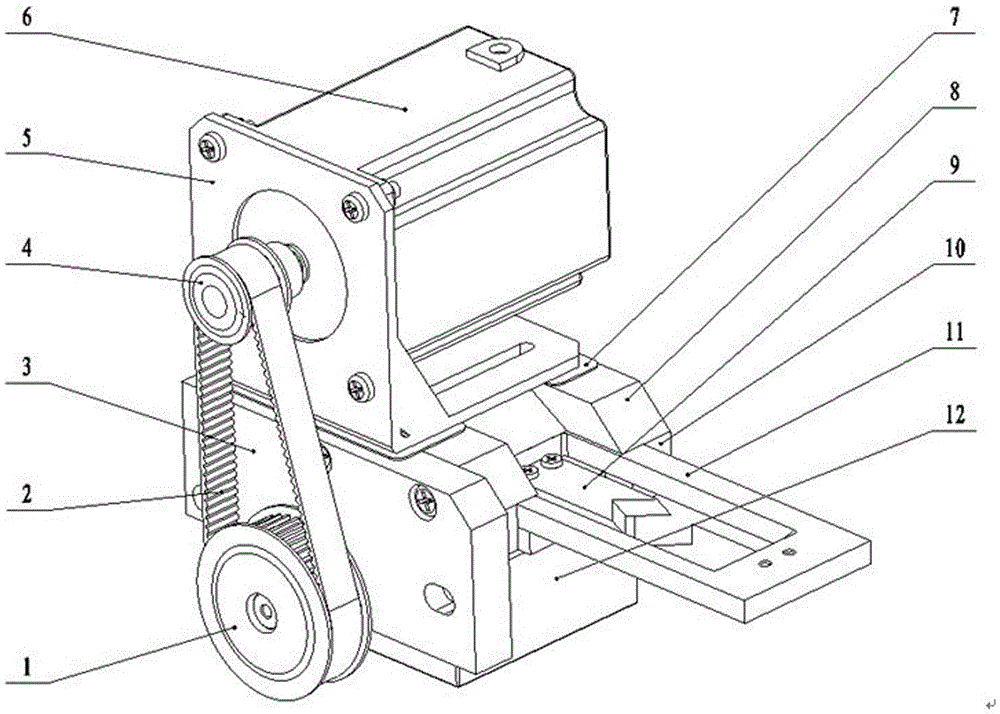

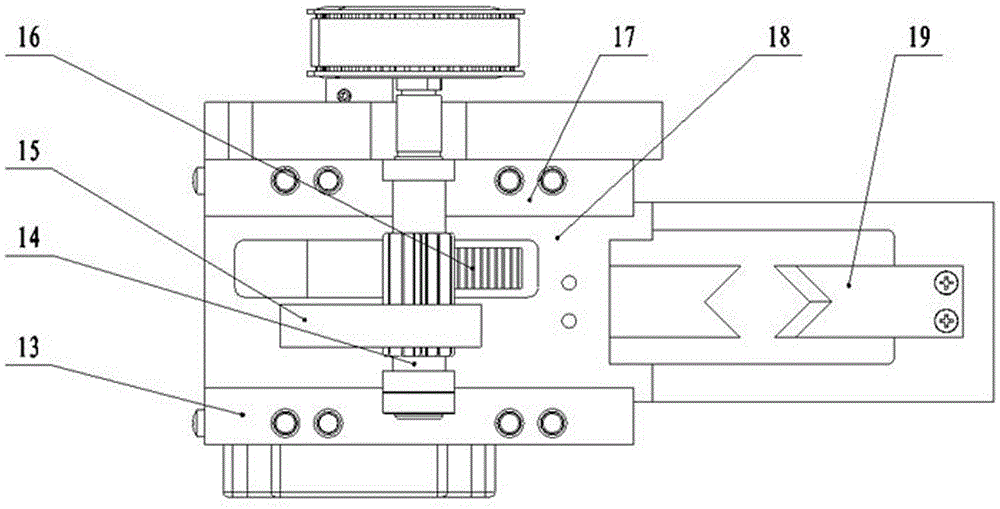

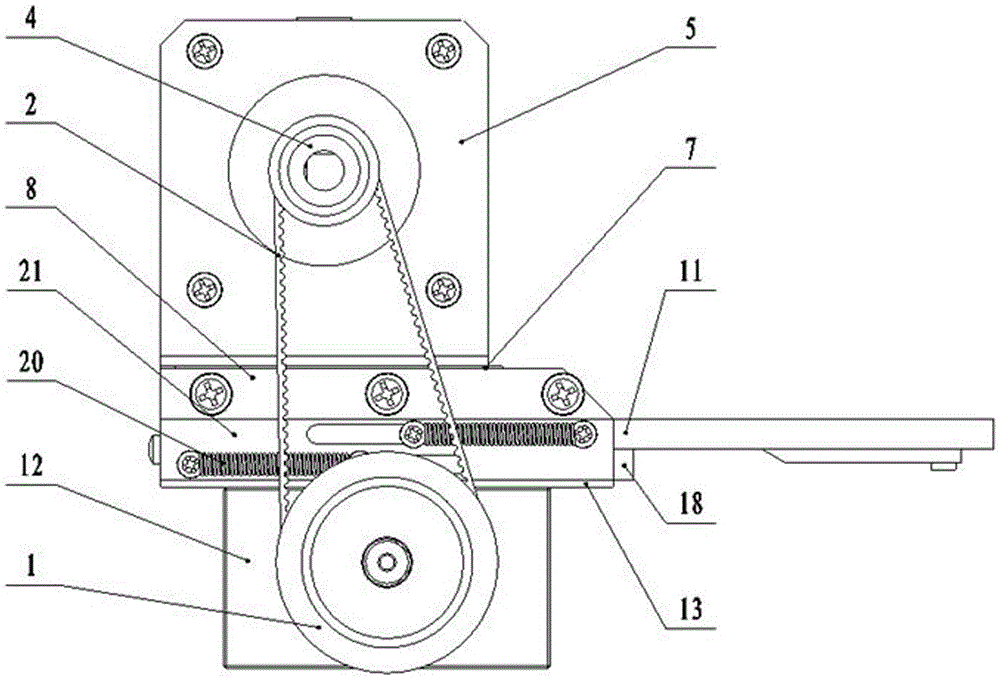

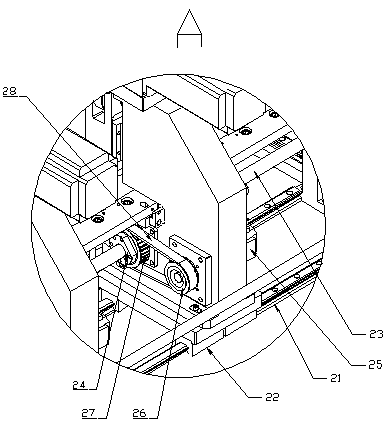

Shearing device of automatic wire harness binding equipment

The invention discloses a shearing device of automatic wire harness binding equipment. The shearing device comprises a drive mechanism, a transmission mechanism and a shearing mechanism. The upper portion of the whole device serves as a motor part, and the lower portion of the whole device serves as a box part. The drive mechanism comprises a motor, a small synchronizing wheel, a large synchronizing wheel and a synchronizing belt. The transmission mechanism is located in a box and is a gear and rack transmission mechanism, and two racks are fixed to two sliding tool rests of the shearing mechanism. The shearing mechanism comprises the sliding tool rests, blades arranged on the sliding tool rests and sliding rails used for allowing the sliding tool rests to slide. The two sliding tool rests are stacked vertically and can slide oppositely, and the sliding rails are located in the box. The device is short in work time, accurate and stable in shearing action and convenient and easy to operate, a good shearing effect is achieved, the wire harness shearing efficiency is high, and the device can be matched with various kinds of small wire harness binding equipment.

Owner:GUILIN UNIV OF ELECTRONIC TECH

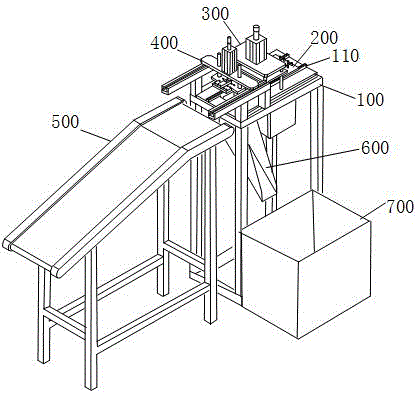

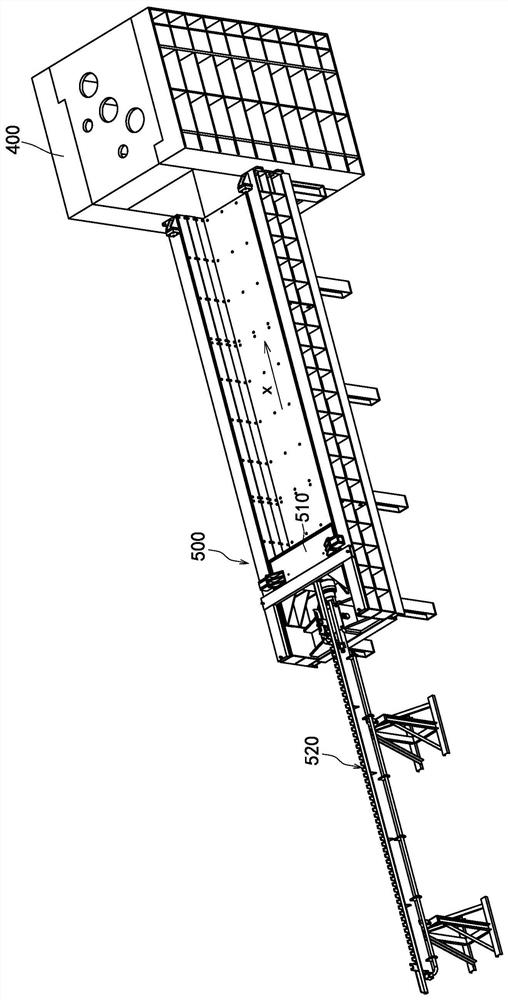

High-speed cut-to-length line for transformer silicon steel sheet machining

PendingCN109352345AImprove shear efficiencyEasy to moveOther manufacturing equipments/toolsPunchingTransformer

The invention relates to a high-speed cut-to-length line for transformer silicon steel sheet machining. The high-speed cut-to-length line for transformer silicon steel sheet machining comprises a cut-to-length bracket; the cut-to-length bracket is provided with a feeding channel; the feeding channel is provided with at least one punching device, a V scissoring device and a pair of cut-to-length devices; each punching device is driven to transversely move through an independent punching transverse moving mechanism; the V scissoring device is driven to transversely move by a V scissoring transverse moving mechanism; the punching devices, the V scissoring device and any one cut-to-length device are respectively driven to synchronously perform the punching work; and an emptying device and a collecting device are arranged at two ends of the feeding channel. The high-speed cut-to-length line has the following advantages: through arrangement of the transverse moving mechanisms, gaps among thepunching devices, the V scissoring device and the cut-to-length devices can be transversely adjusted, so that the punching devices, the V scissoring device and any one cut-to-length device can synchronously perform the punching work, and the shearing efficiency is greatly improved.

Owner:NANTONG SIRUI ENG

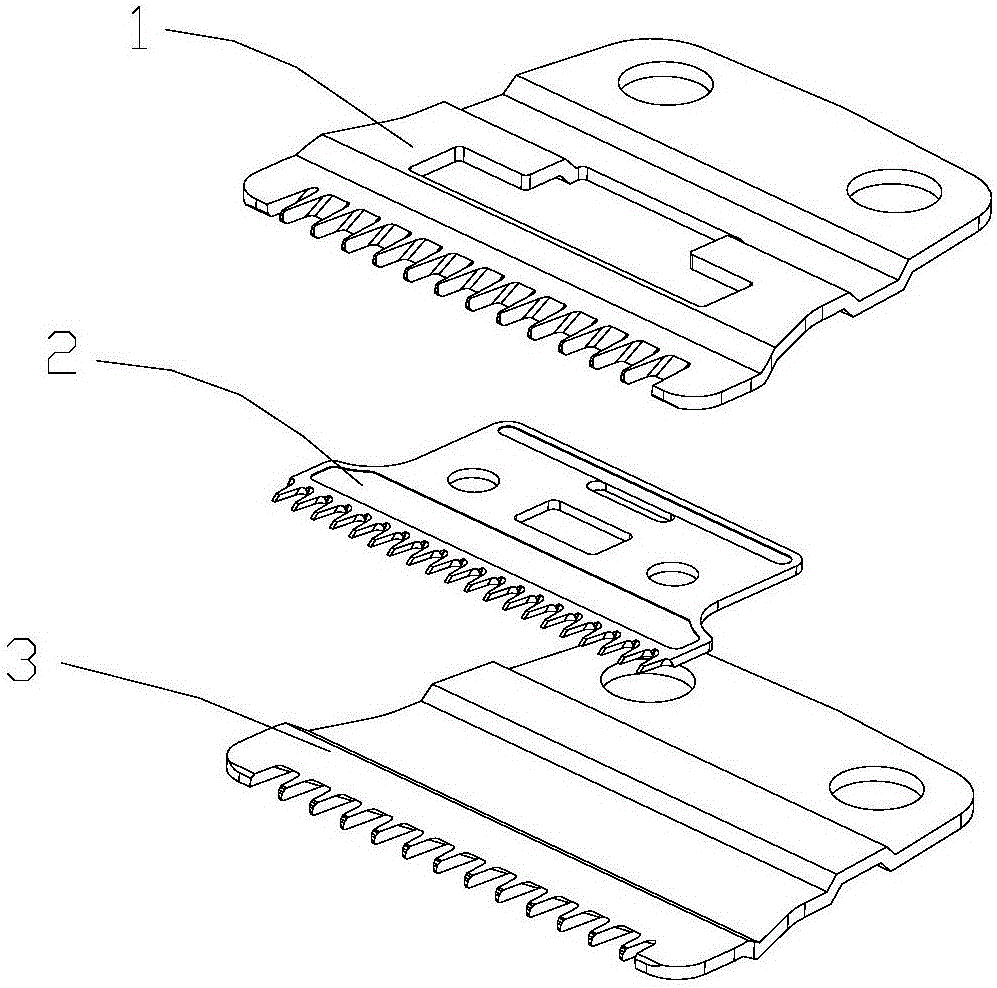

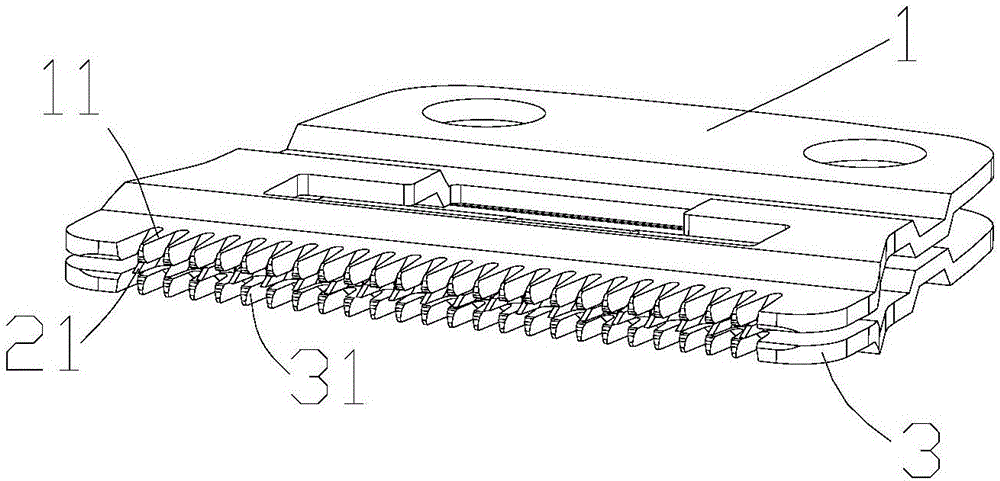

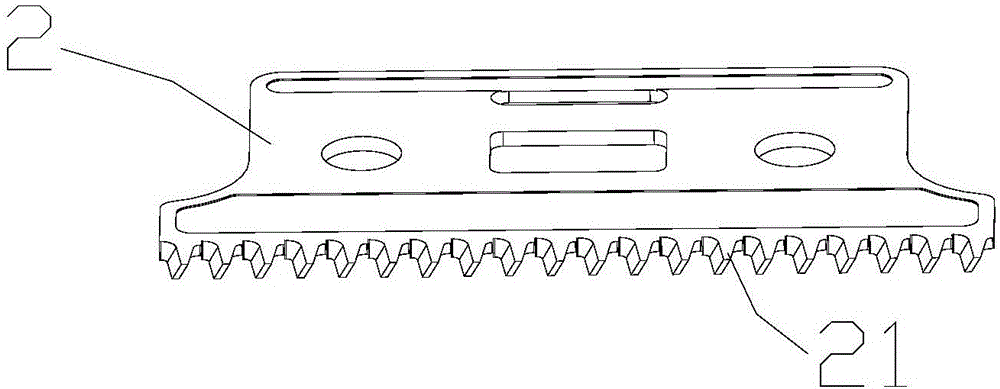

Knife of sandwich structure and personal care hair shear with same

InactiveCN106313140AAvoid exposureImprove securityMetal working apparatusPersonal careAerospace engineering

Owner:SPECIALIFE ZHUHAI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com