Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

33 results about "Genetic model" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Genetic model. a formalised conjecture about the behaviour of a heritable structure in which the component terms are intended to have literal interpretation as standard structures of empirical genetics.

Method and apparatus for image-based photorealistic 3D face modeling

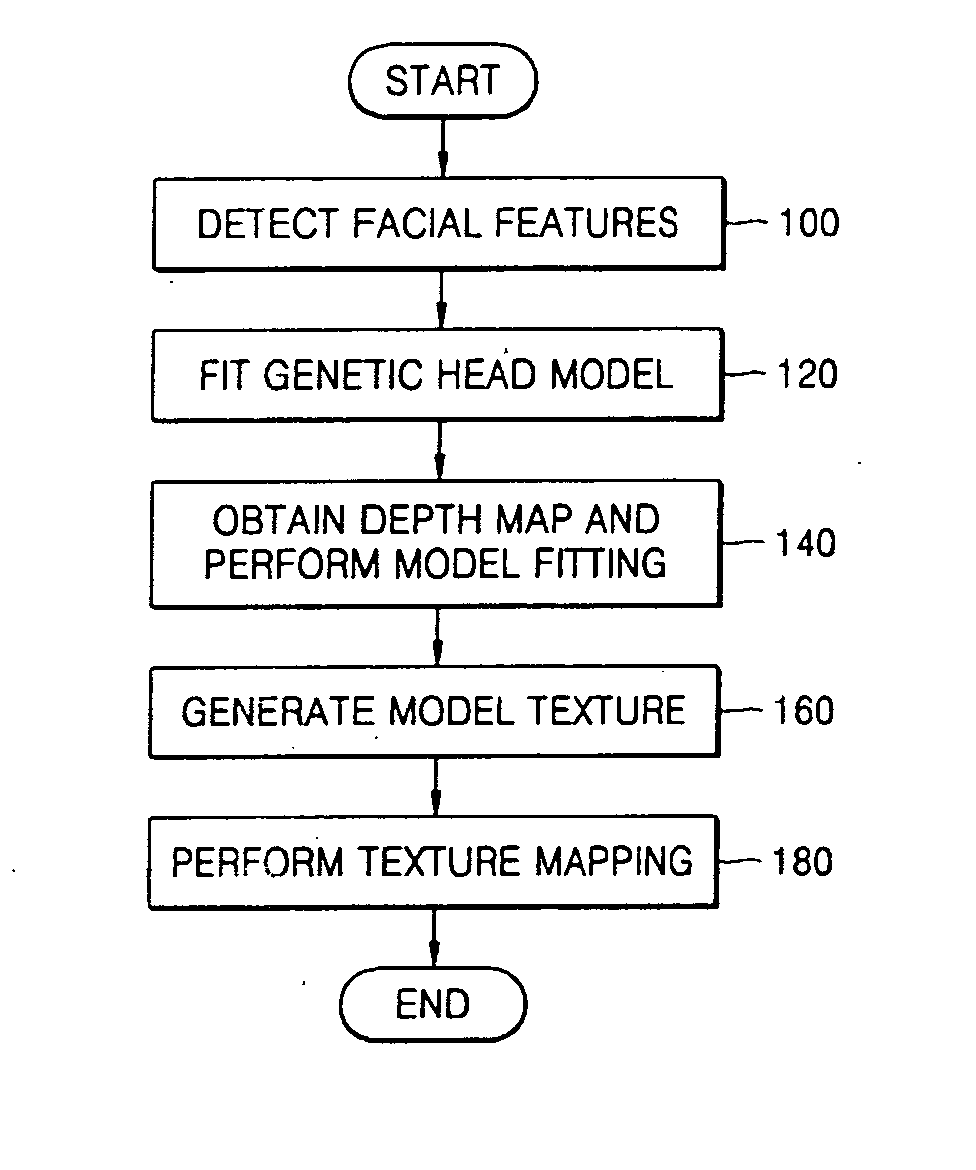

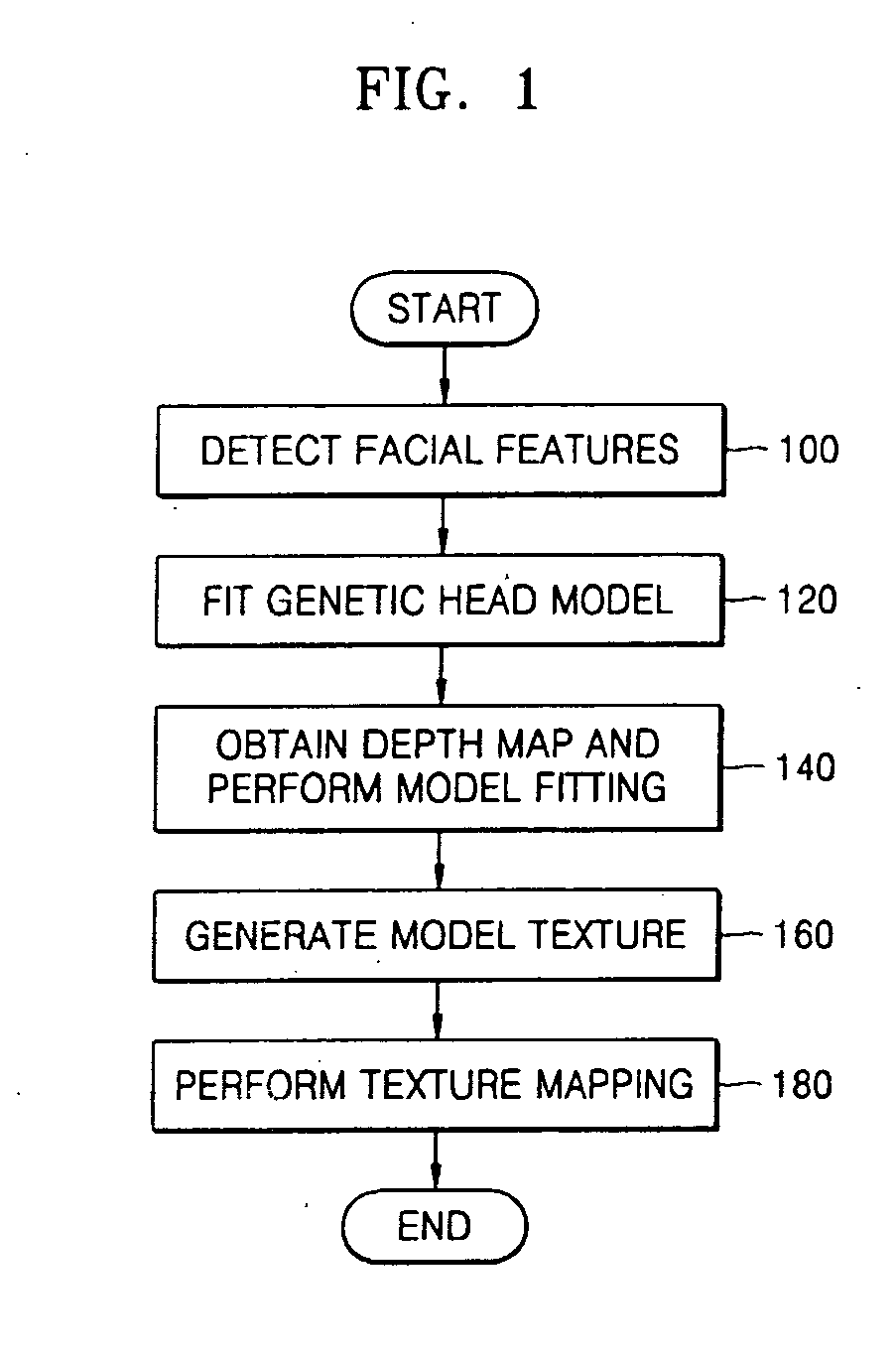

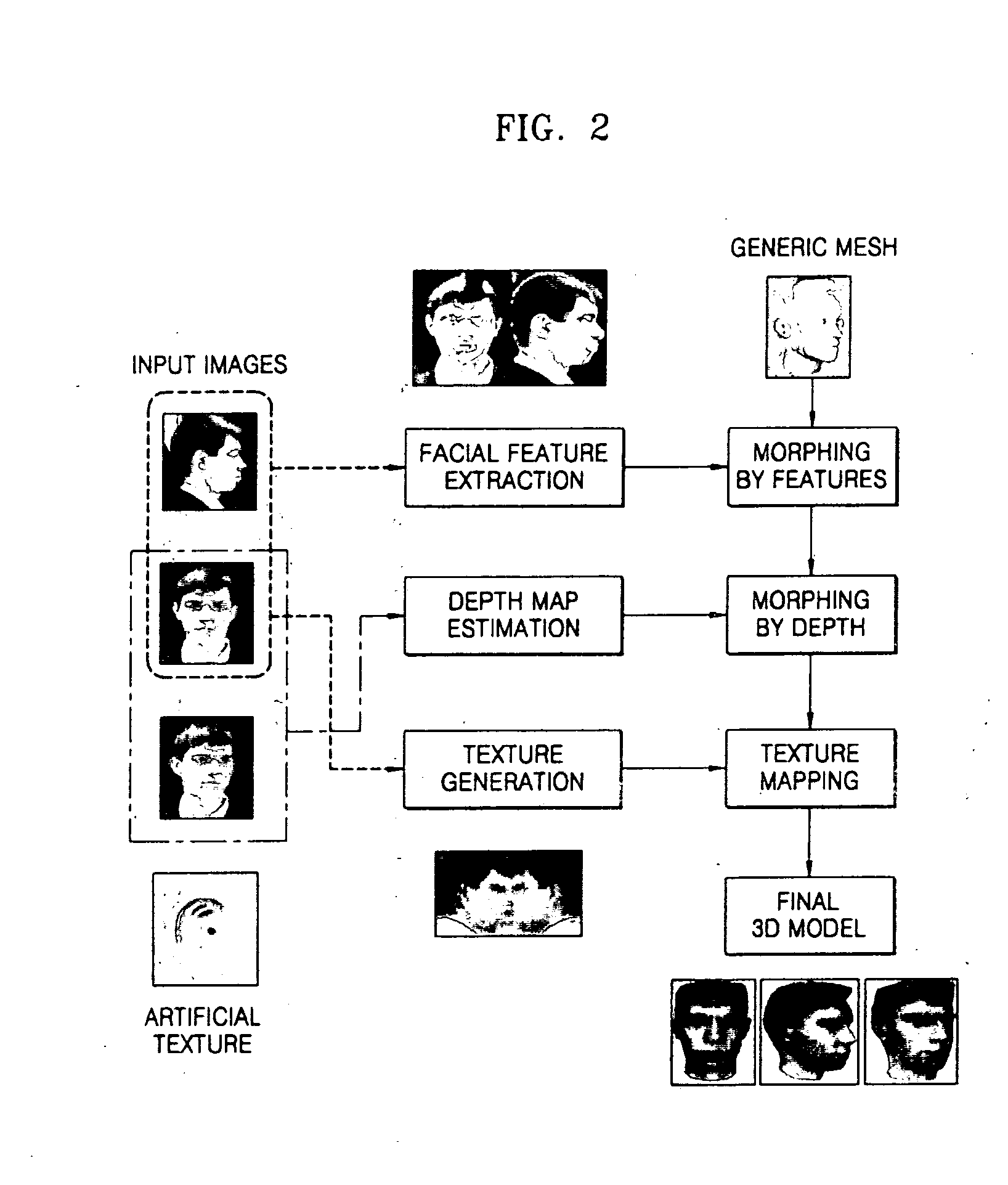

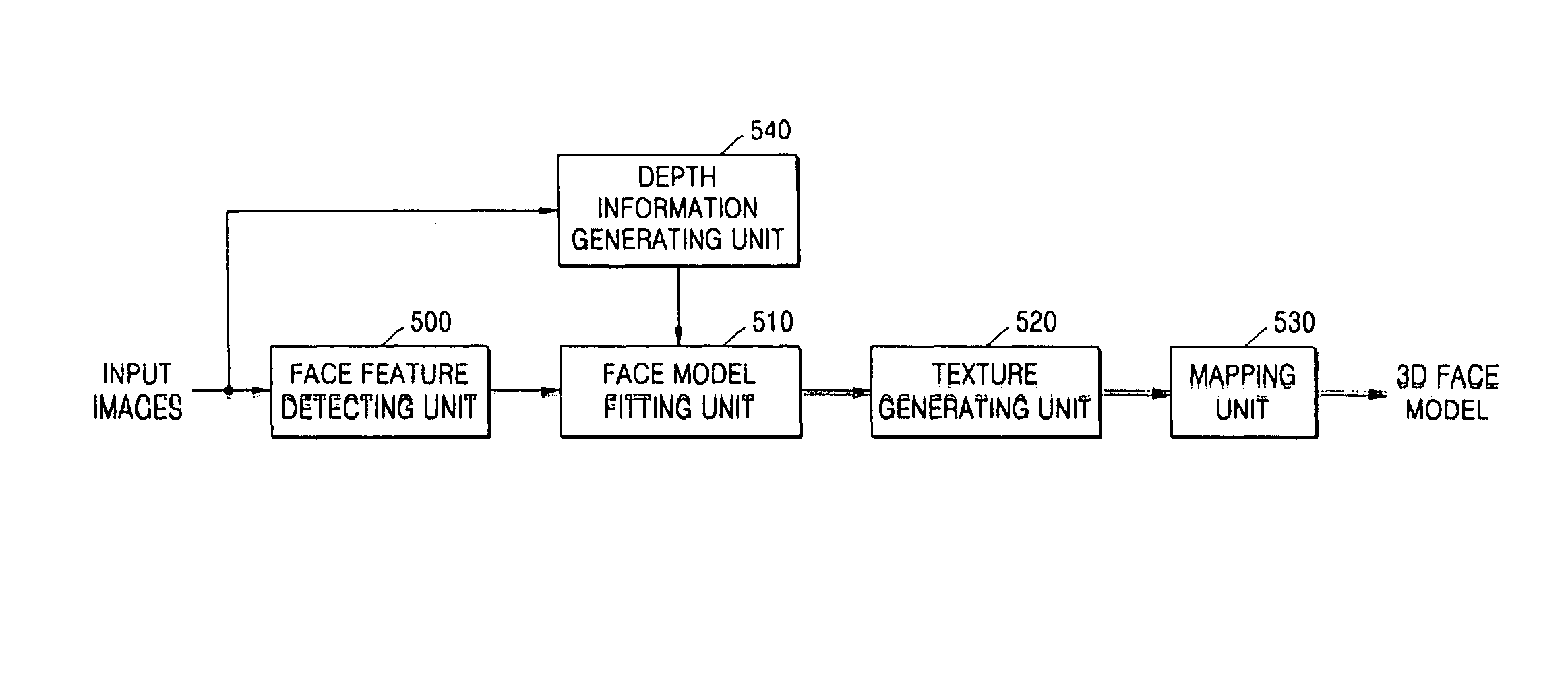

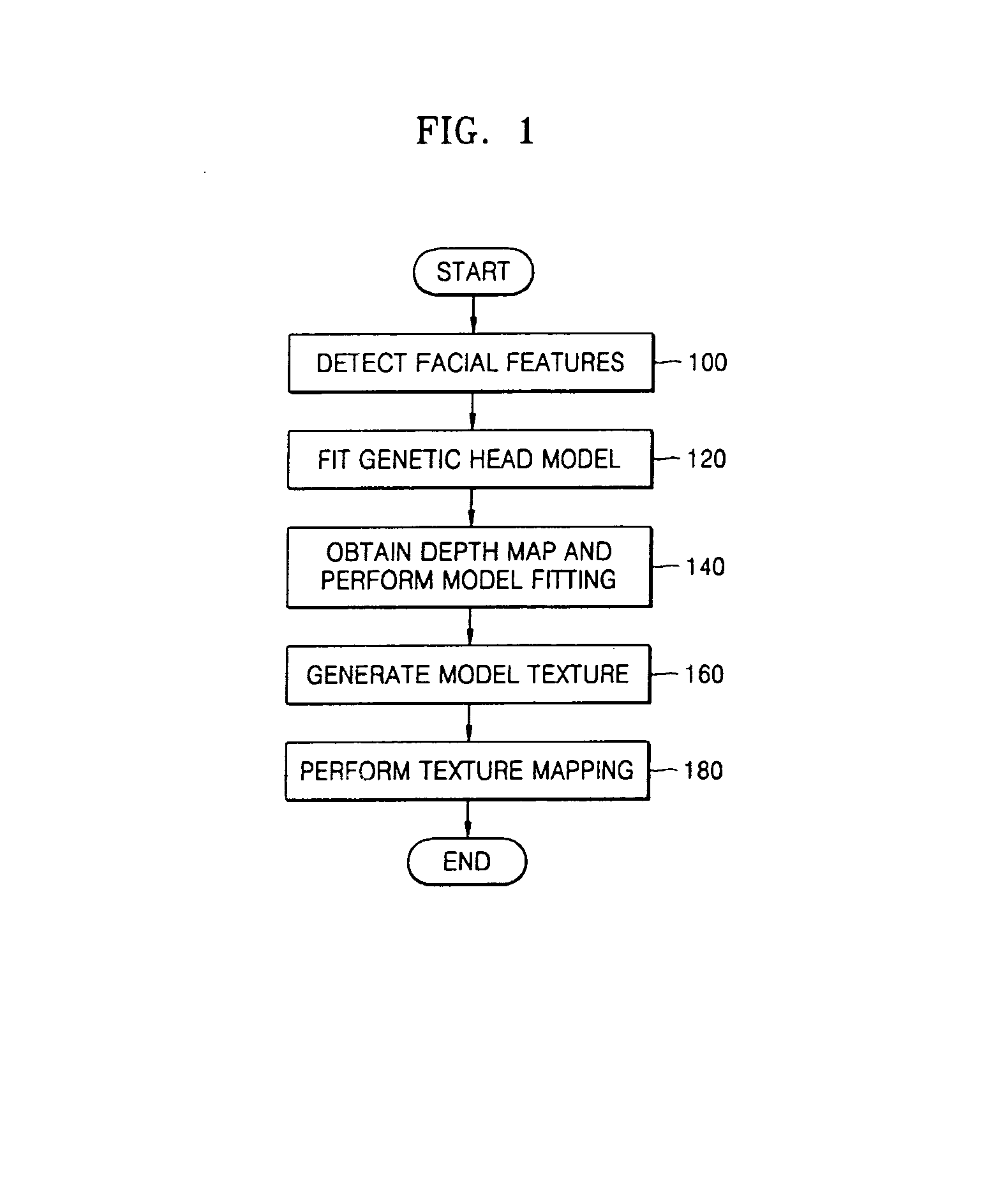

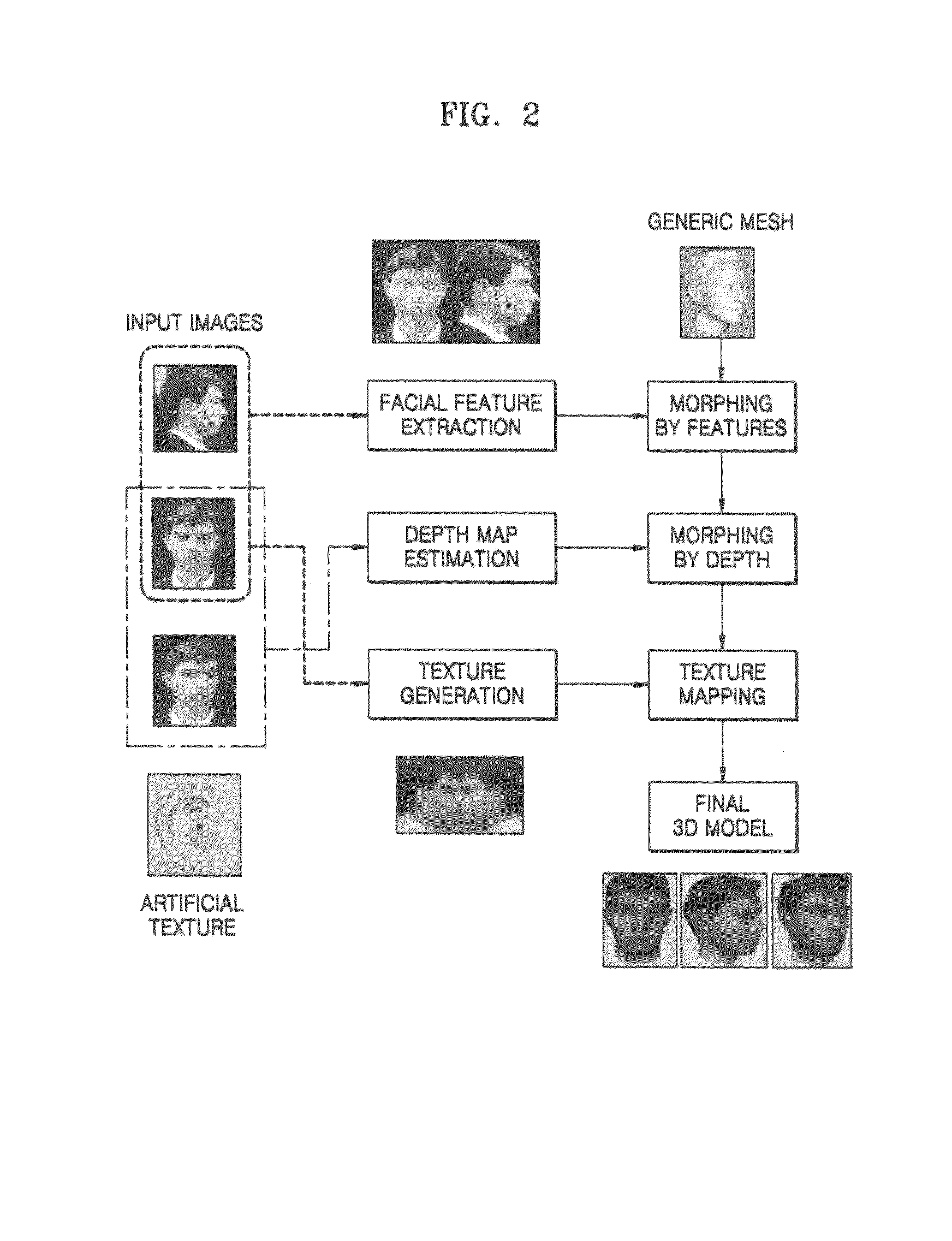

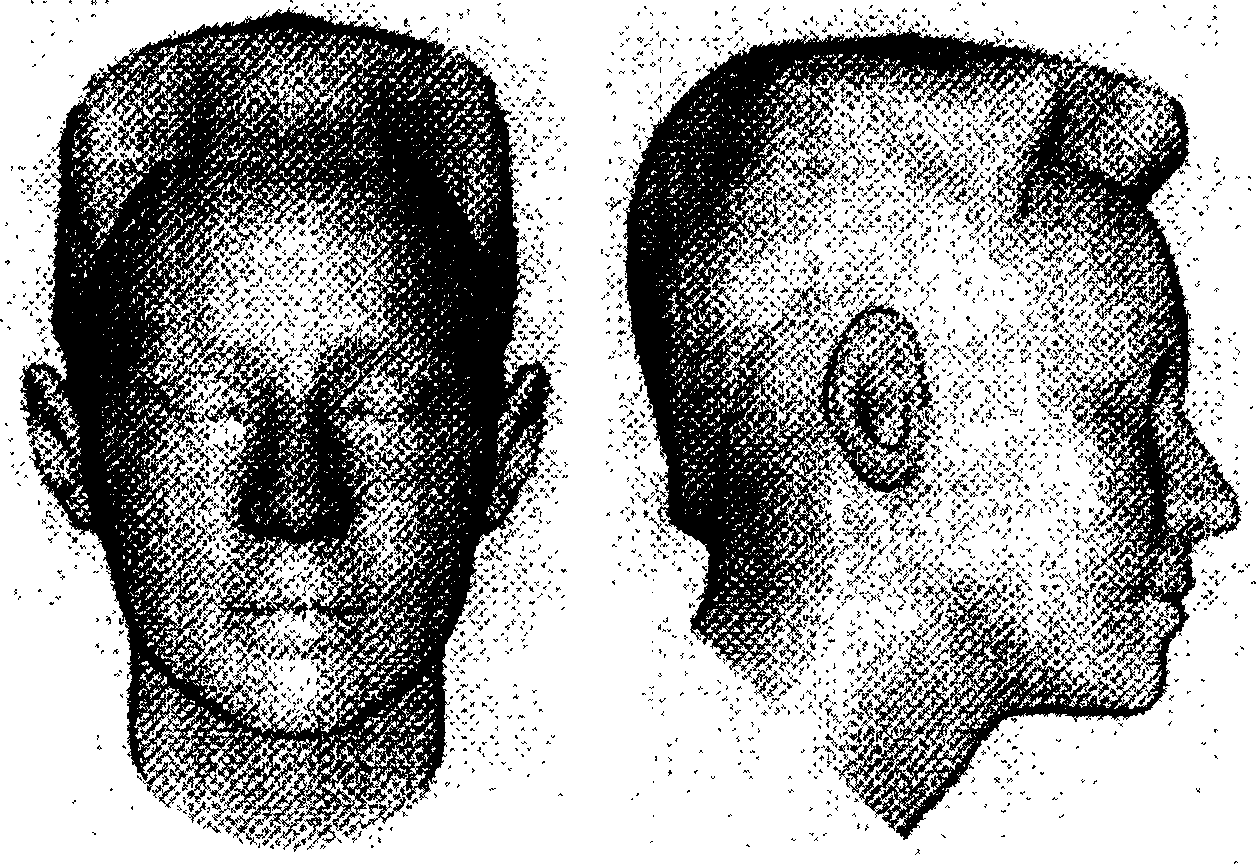

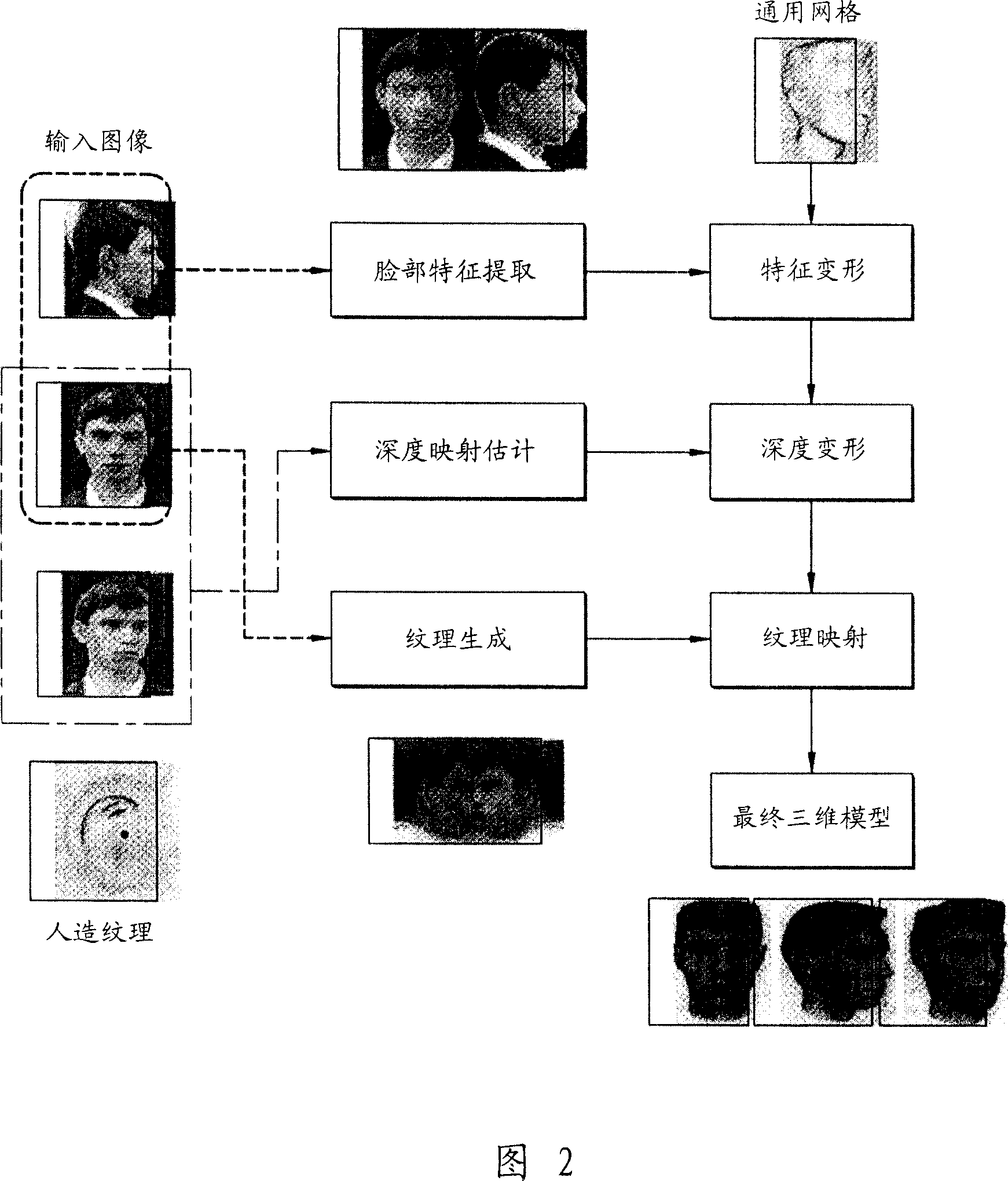

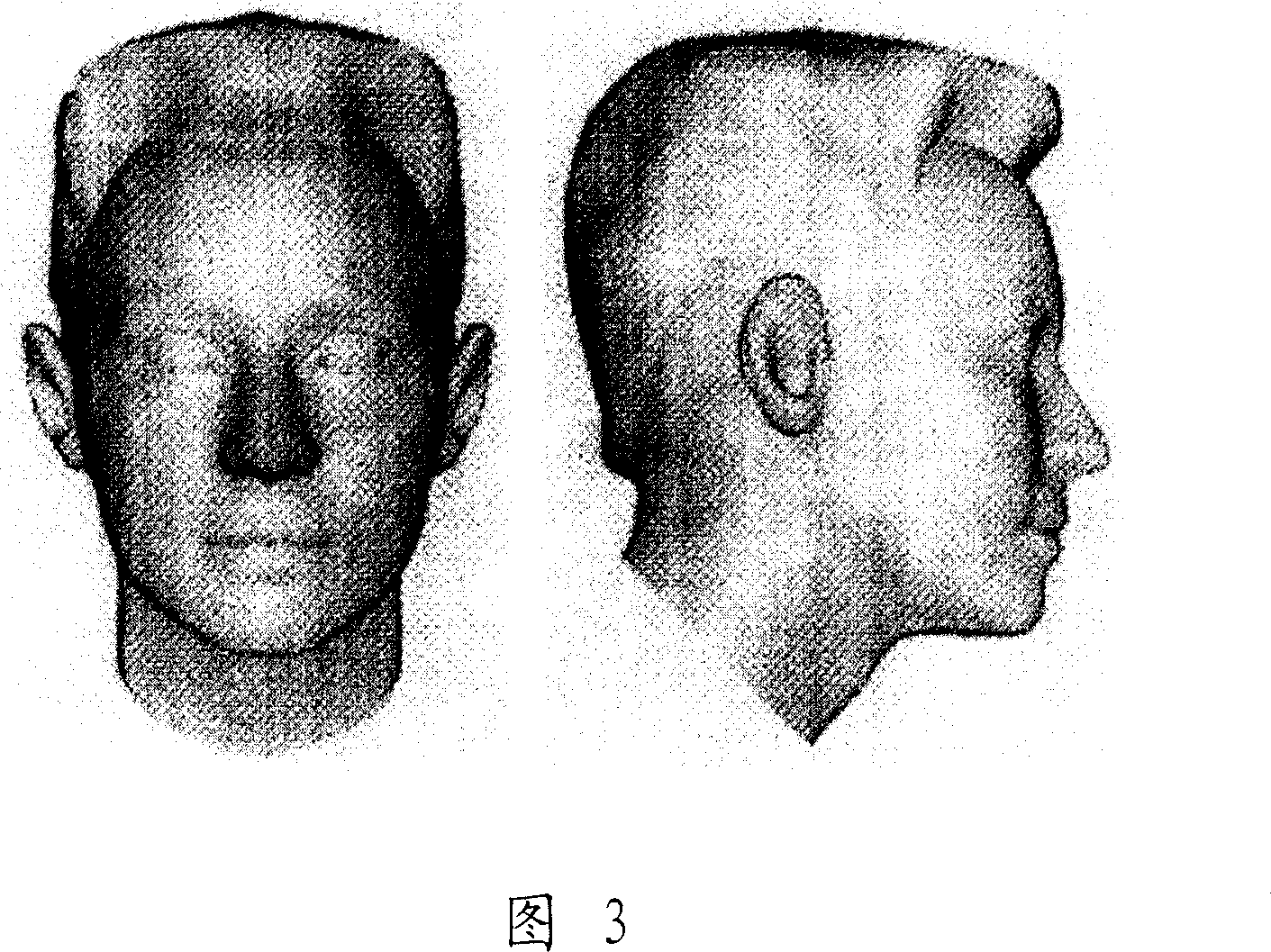

An apparatus and method for image-based 3D photorealistic head modeling are provided. The method for creating a 3D photorealistic head model includes: detecting frontal and profile features in input frontal and profile images; generating a 3D head model by fitting a 3D genetic model using the detected facial features; generating a realistic texture from the input frontal and profile images; and mapping the texture onto the 3D head model. In the apparatus and method, data obtained using a relatively cheap device, such as a digital camera, can be processed in an automated manner, and satisfactory results can be obtained even from imperfect input data. In other words, facial features can be extracted in an automated manner, and a robust “human-quality” face analysis algorithm is used.

Owner:SAMSUNG ELECTRONICS CO LTD

Method and apparatus for image-based photorealistic 3D face modeling

An apparatus and method for image-based 3D photorealistic head modeling are provided. The method for creating a 3D photorealistic head model includes: detecting frontal and profile features in input frontal and profile images; generating a 3D head model by fitting a 3D genetic model using the detected facial features; generating a realistic texture from the input frontal and profile images; and mapping the texture onto the 3D head model. In the apparatus and method, data obtained using a relatively cheap device, such as a digital camera, can be processed in an automated manner, and satisfactory results can be obtained even from imperfect input data. In other words, facial features can be extracted in an automated manner, and a robust “human-quality” face analysis algorithm is used.

Owner:SAMSUNG ELECTRONICS CO LTD

Method and apparatus for image-based photorealistic 3D face modeling

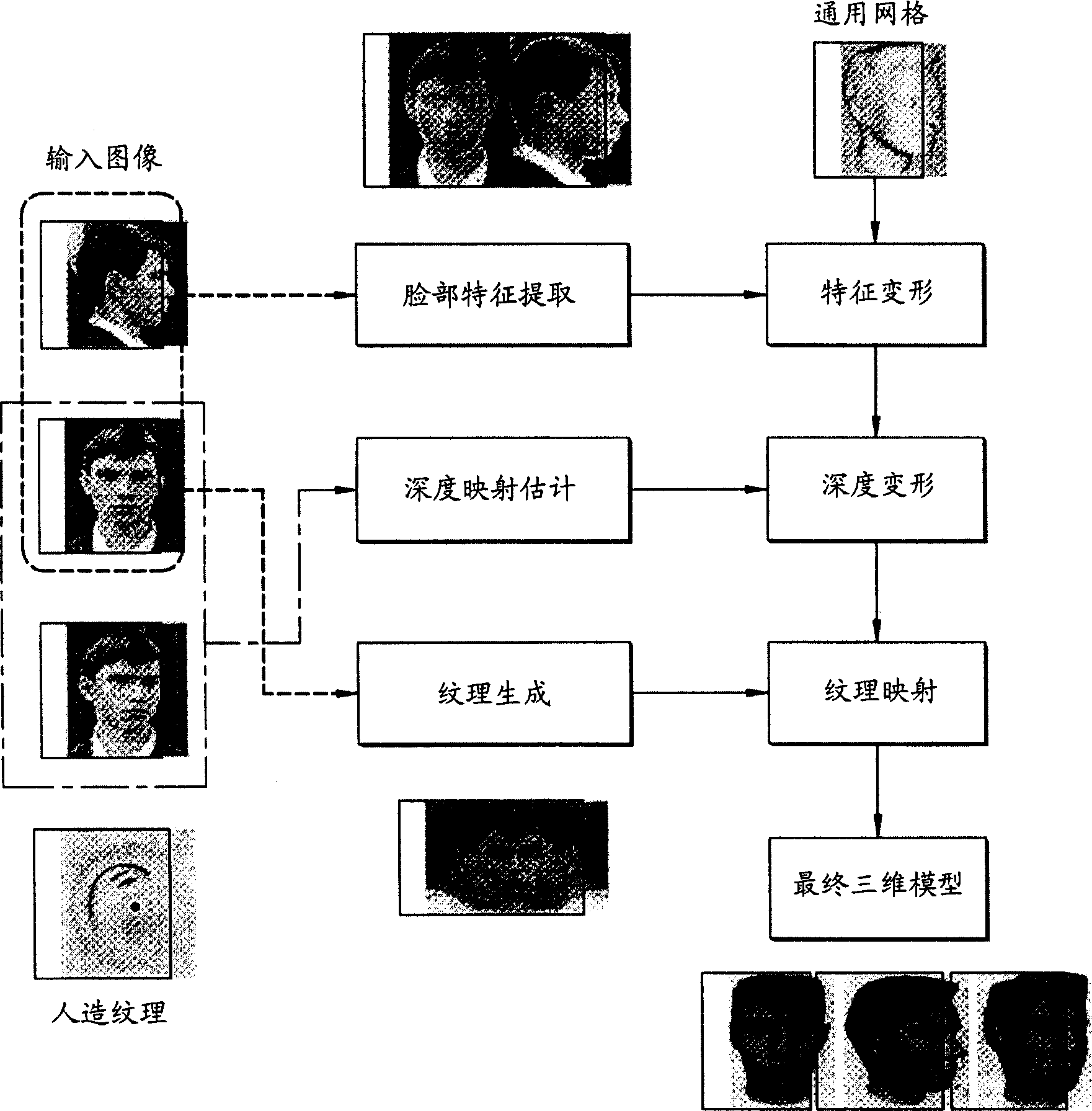

An apparatus and method for image-based three-dimensional hyperrealistic head modeling are provided. The method used to create a three-dimensional hyperrealistic head model includes: detecting frontal and side features in the input frontal and side images; generating a three-dimensional head model by fitting a three-dimensional universal model using the detected facial features; according to the input generating realistic textures from front and side images; and mapping said textures onto a 3D head model. In the described apparatus and method, data obtained using relatively inexpensive equipment such as digital cameras can be processed in an automated manner, and satisfactory results can be obtained even from imperfect input data. In other words, facial features can be extracted in an automated manner and using stable "human quality" facial analysis algorithms.

Owner:SAMSUNG ELECTRONICS CO LTD

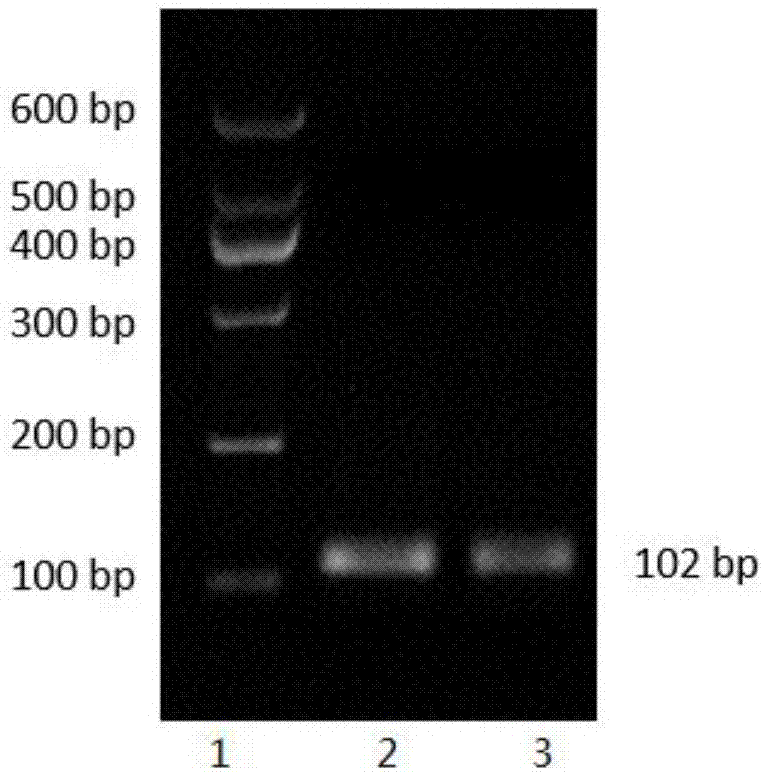

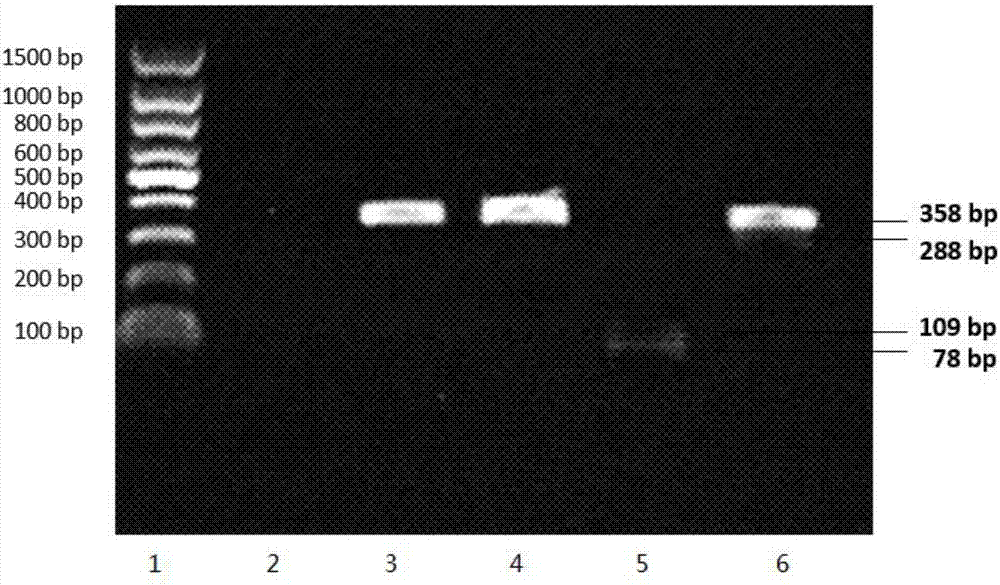

Preparation method of SD rat T cell-deficient genetic model

InactiveCN107446954AImprove shear efficiencyHigh originalityHydrolasesStable introduction of DNADiseaseLarge fragment

The invention relates to a preparation method of an SD rat T cell-deficient genetic model, and belongs to the technical fields of genetic engineering and genetic modification. Specific knockout on a key gene Lck, which is in charge of controlling development of rat T cells, is achieved in a rat by virtue of a CRISPR-Cas9 system, so that the SD rat T cell-deficient genetic model is obtained. According to the preparation method provided by the invention, two specific targeting sites, which are targeted to the rat Lck gene, are determined for the first time, and experiments prove that the specific targeting sites are quite high in shear efficiency; two sgRNAs are simultaneously adopted to conduct targeting on the rat Lck gene, and the large-fragment deficient gene knockout rat is obtained, so that in one aspect, the targeted gent completely loses functions, and in the other aspect, subsequent detection is also facilitated. The constructed T cell-deficient SD rat animal model is great significance to immunity and disease researches.

Owner:XINXIANG MEDICAL UNIV

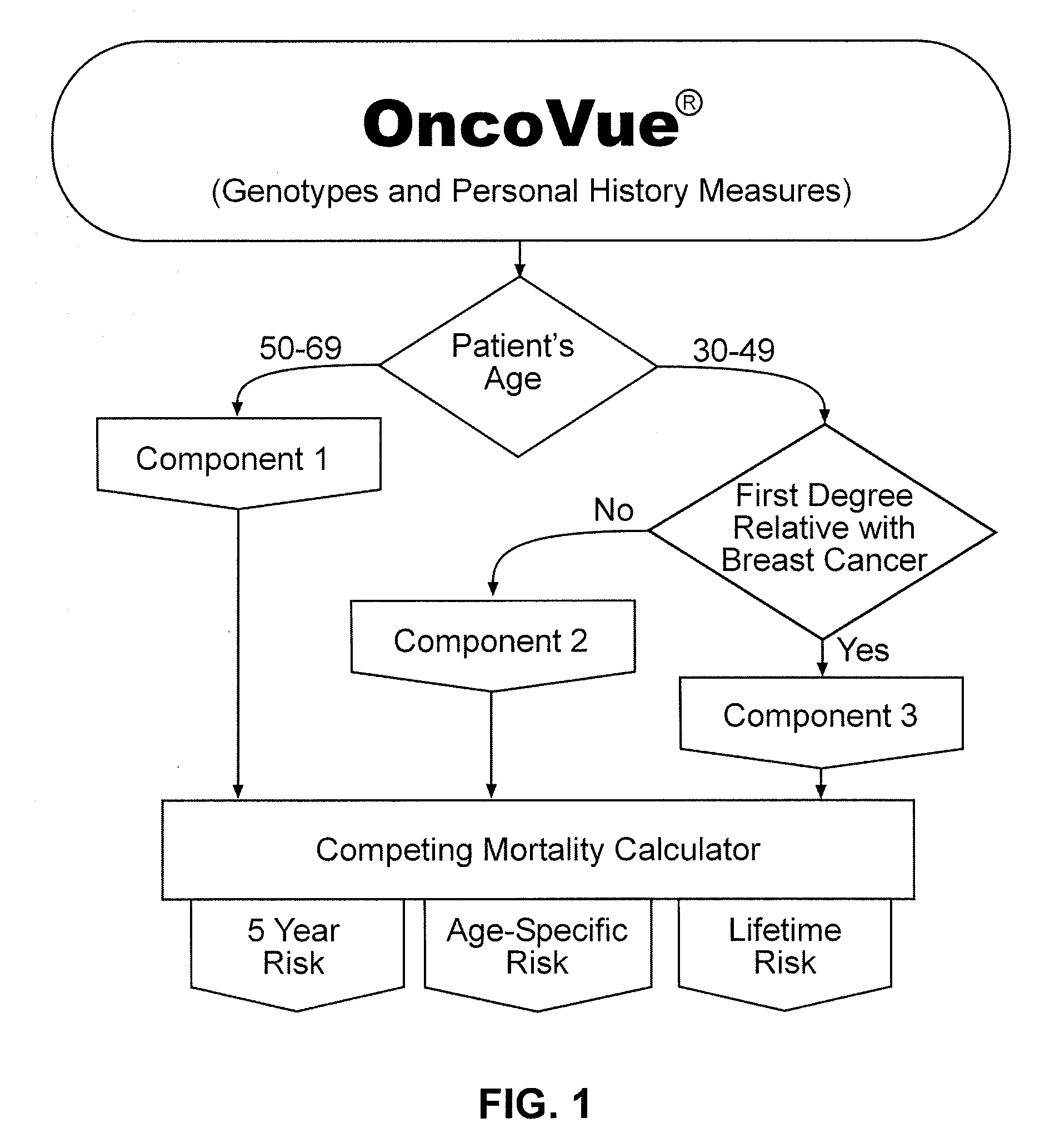

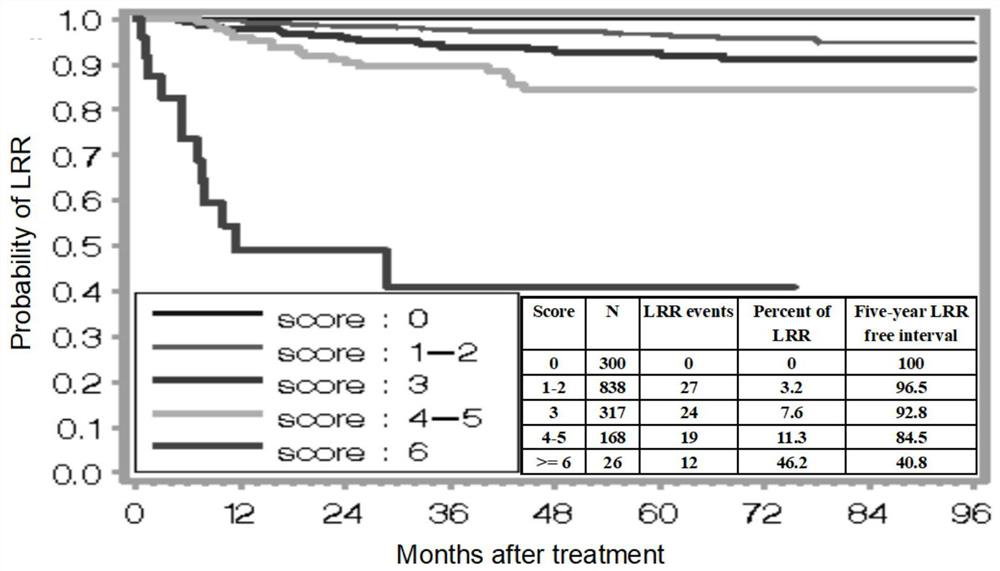

Genetic models for stratification of cancer risk

InactiveUS20090029375A1Microbiological testing/measurementProteomicsHeightened Cancer RiskProphylactic treatment

The present invention provides new methods for the assessment of cancer risk in the general population. These methods utilize particular alleles of in multiple selected genes to identify individuals with increased or decreased risk of breast cancer. In addition, personal history measures such as age and family history are used to further refine the analysis. Using such methods, it is possible to reallocate healthcare costs in cancer screening to patient subpopulations at increased cancer risk. It also permits identification of candidates for cancer prophylactic treatment.

Owner:INTERGENETICS +1

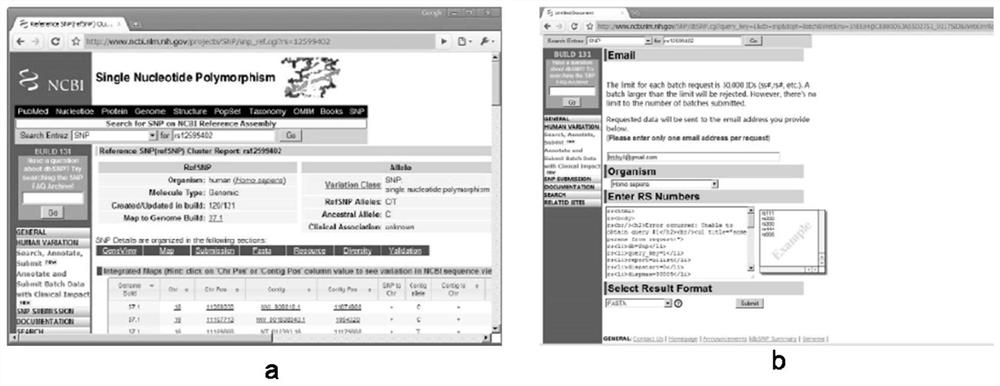

Restrictive two-stage genome-wide association study (GWAS) method based on SNPLDB mark

InactiveCN104651517AShorten the attenuation distanceMultiple allelic variationMicrobiological testing/measurementProteomicsMulti siteRegression analysis

The invention discloses a restrictive two-stage genome-wide association study (GWAS) method based on an SNPLDB mark, and aims at solving the problems that a traditional method cannot be used for estimating multiple allele information, and is high in false positive rate and low in efficiency of detection on inbreeding crops. By combination of the SNPLDB mark constructed on the basis of a haplotype block, correction of deviation of an inbreeding population relation analysis model and a two-stage relation analysis strategy under a multi-site model, the GWAS method suitable for conventional breeding of inbreeding crops is built; the SNPLDB mark is applied to GWAS, so that a method is provided for multiple allele estimation; candidate sites are screened on the basis of a single-site model in the first stage, and are further screened on the basis of a progressive regression analysis method in the multi-site model in the second stage, so as to balance the problems of missing of heritability and over-high heritability estimation. Therefore, the interpretation ratio of a final genetic model is controlled at trait heritability. The positioning accuracy and efficiency are improved by a feature vector and an appropriate significant level of a similarity coefficient matrix estimated by the SNPLDB mark by GWAS.

Owner:NANJING AGRICULTURAL UNIVERSITY

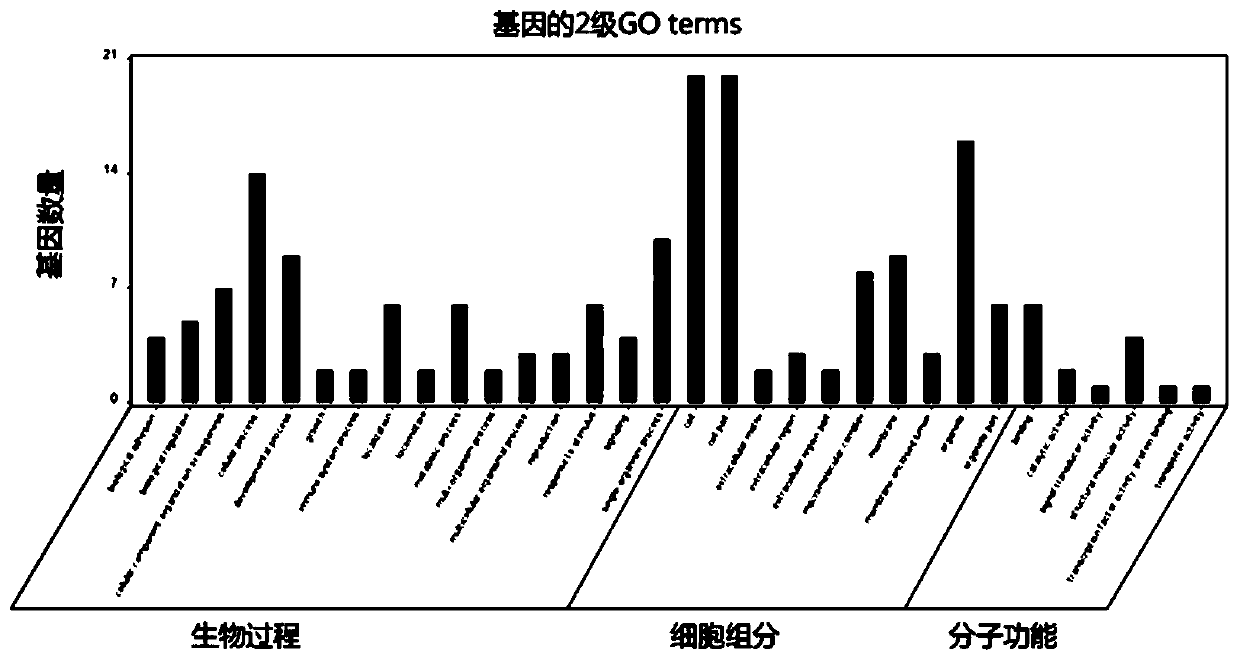

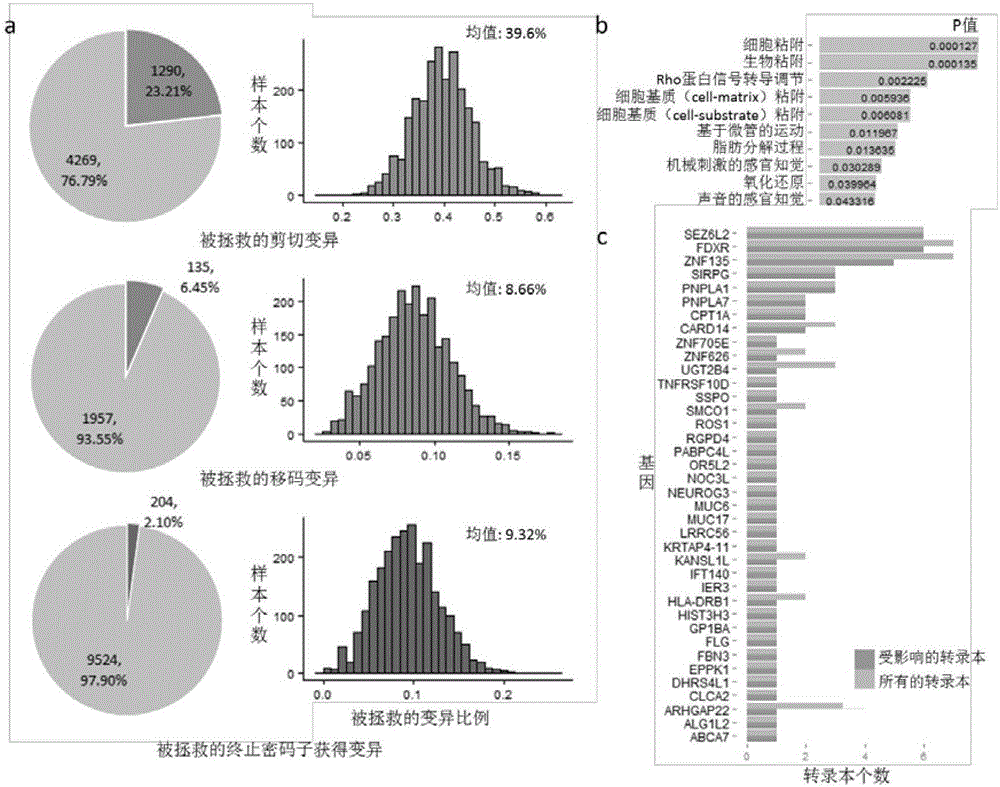

Biological information analysis method for human single-gene genetic disease detection

InactiveCN110931081AAnalyze content clearlyEasy to analyzeProteomicsGenomicsCandidate Gene Association StudyGenotype

The invention provides a biological information analysis method for human single-gene genetic disease detection. The method comprises the following steps: S1, screening mutation harmful sites; S2, screening the sample relationship of human single-gene genetic disease detection; S3, performing gene function screening. According to the method, harmful mutation sites can be quickly and clearly screened from human exon sequencing data; the annotation analysis on the detected SNP, InDel and other genomic variations and an external database is carried out to determine the genomic position, variationfrequency, protein harmfulness, genotype heterozygosity, functional pathways and other information of the variations; the candidate genes are screened by using an autosomal invisible genetic model, an autosomal dominant genetic model, new mutation screening and common mutation gene screening, so the candidate genes are determined, GO and KEGG enrichment analysis is performed on the candidate genes, and powerful evidences are provided for determining the candidate genes related to diseases.

Owner:GUANGZHOU GENE DENOVO BIOTECH

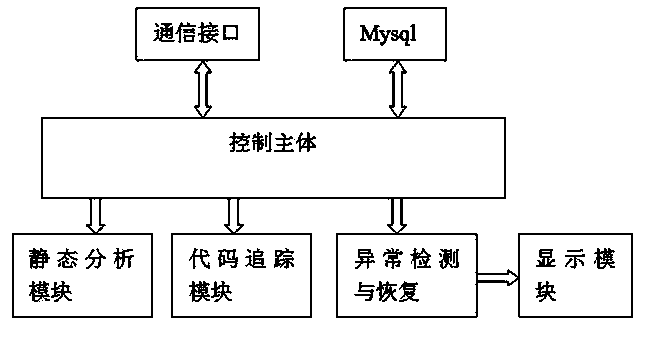

Fuzz testing system on basis of multi-swarm collaboration evolution genetic algorithm

InactiveCN103914383AIncrease coverageImprove mining efficiencySoftware testing/debuggingTest sampleCode coverage

The invention discloses a fuzz testing system on the basis of a multi-swarm collaboration evolution genetic algorithm, and belongs to the field of software safety tests. The fuzz testing system comprises a fuzz testing end and a test sample generating end. The fuzz testing end is responsible for inputting test samples into systems to be tested and repeatedly testing and observing the systems to be tested; the test sample generating end is used for generating the test samples and transmitting the test samples to the fuzz testing ends via networks, computes individual adaptability values by the aid of collected information according to coverage frequencies of basic blocks and trigger conditions of unsafe functions, combines the individual adaptability values with the types of the unsafe functions and enables the test samples to evolve by the aid of a multi-swarm collaboration evolution genetic model, so that new samples can be generated. The fuzz testing system has the advantages that a code coverage rate can be increased when application programs of the networks are tested, and the vulnerability mining efficiency can be improved.

Owner:FUZHOU UNIV

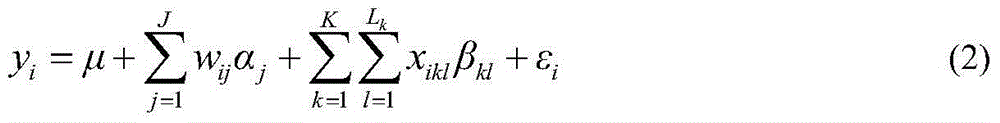

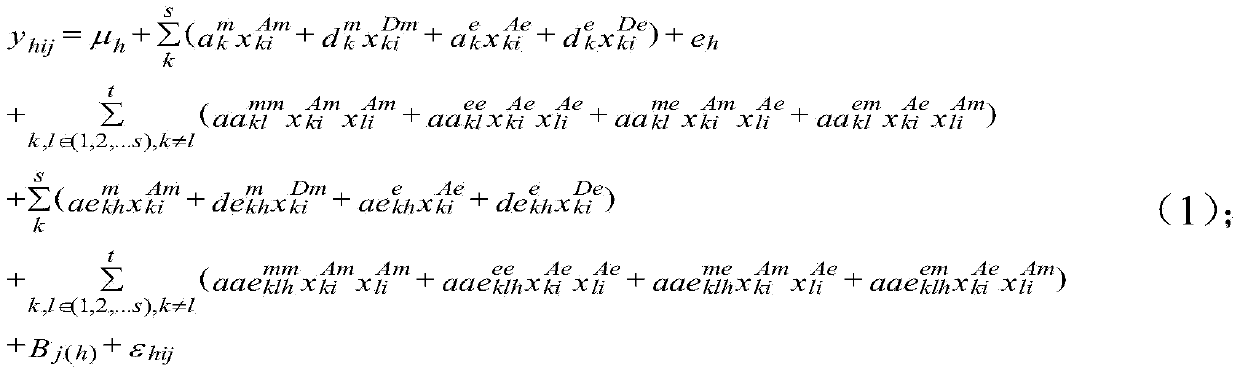

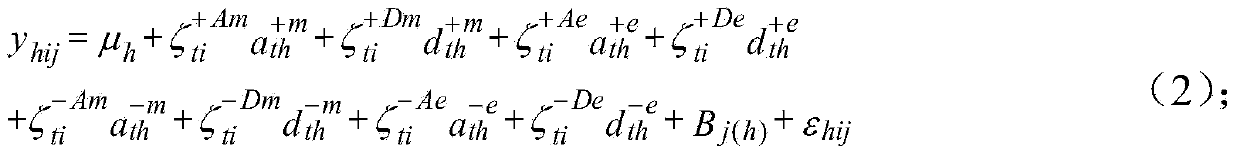

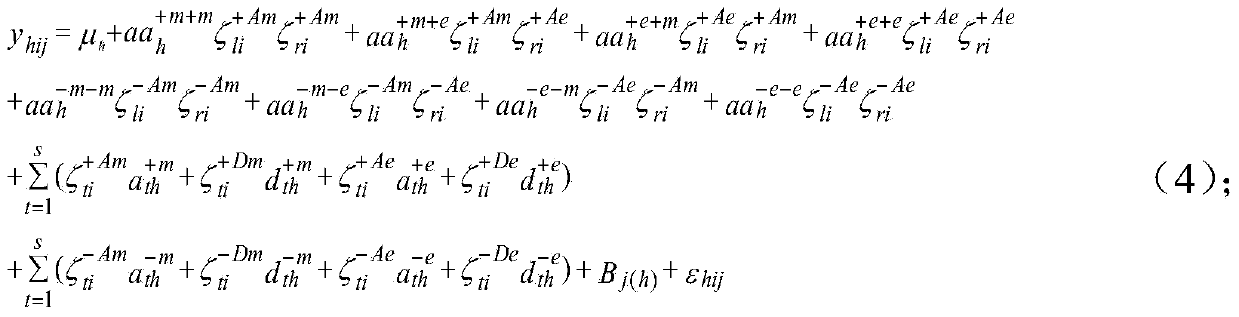

Seed quantitative trait locus positioning method based on mixed linear model

ActiveCN103632067AQuick estimateImprove efficiencySpecial data processing applicationsQuantitative trait locusPhenotypic trait

The invention discloses a seed quantitative trait locus positioning method based on a mixed linear model. The method comprises the step of establishing a statistics genetic model, the step of searching the range of a whole genome for all candidate label sections in which an OTL probably exists, the step of regarding the candidate label sections as a concomitant variable, and searching the range of the whole genome for obvious QTLs and a two interaction label section, the step of regarding the QTLs and the two interaction label section as the concomitant variables and searching an obvious interaction label section for obvious loca of a two interaction epistasis, and the step of obtaining coefficients of various effects in the statistics genetic model based on the QTLs and the loca of the two interaction epistasis and calculating the effect of the loca and estimating the heritability of all loca according to the statistics genetic model. The seeds are divided into diploid seeds and triploid seeds according to the traits of the seeds, the epistasis effect and the effect of interaction of genes and the environment are taken into consideration, and the positions of the seed quantitative trait loca and various effects can be fast estimated in an unbiased mode.

Owner:ZHEJIANG UNIV

Genetic models for stratification of cancer risk

InactiveUS20080009419A1Easy to optimizeMicrobiological testing/measurementLibrary screeningGeneral Population CohortHeightened Cancer Risk

The present invention provides new methods for the assessment of cancer risk in the general population. These methods utilize particular alleles of selected genes, and particular combinations of genotypes, to identify individuals with increased or decreased risk of breast cancer. In addition, personal history measures such as age and race are used to further refine the analysis. Using such methods, it is possible to reallocate healthcare costs in cancer screening to patient subpopulations at increased cancer risk. It also permits identification of candidates for cancer prophylactic treatment.

Owner:INTERGENETICS +1

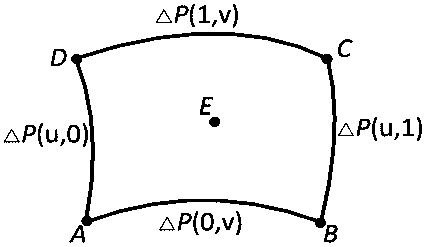

Hole site correction method applied to automatic drilling and riveting of curved surface products

ActiveCN111469125ASimple calculationHigh precisionProgramme-controlled manipulatorAircraft assemblyEngineeringComputational physics

The invention discloses a hole site correction method applied to automatic drilling and riveting of curved surface products. The hole site correction method comprises the following steps that S1, thetheoretical positions and the actual positions of four reference holes are compared to obtain vector errors of the four reference holes, and an error curved surface function is constructed by combining the vector errors and a normal fitting bilinear hybrid Coons error curved surface; S2, the fifth reference hole is introduced into a hole making area, and the error which should be compensated by the reference hole is obtained through substitution; S3, a multi-objective optimization genetic model is established by combining the actual vector errors of the reference hole, and the optimal value ofthe tangent vector model length of the four reference holes is calculated within a certain range, so that the error curved surface function is determined; and S4, the corresponding value is calculated by utilizing the theoretical coordinates of the hole to be machined, then the hole site error of the hole to be machined can be calculated, and finally the error is compensated to the theoretical coordinates to obtain new theoretical coordinates, namely the hole site correction process is completed. The hole site correction method has the advantages of being good in correction effect, wide in application range and capable of meeting the hole making position precision requirement.

Owner:JITRI INST OF PRECISION MFG

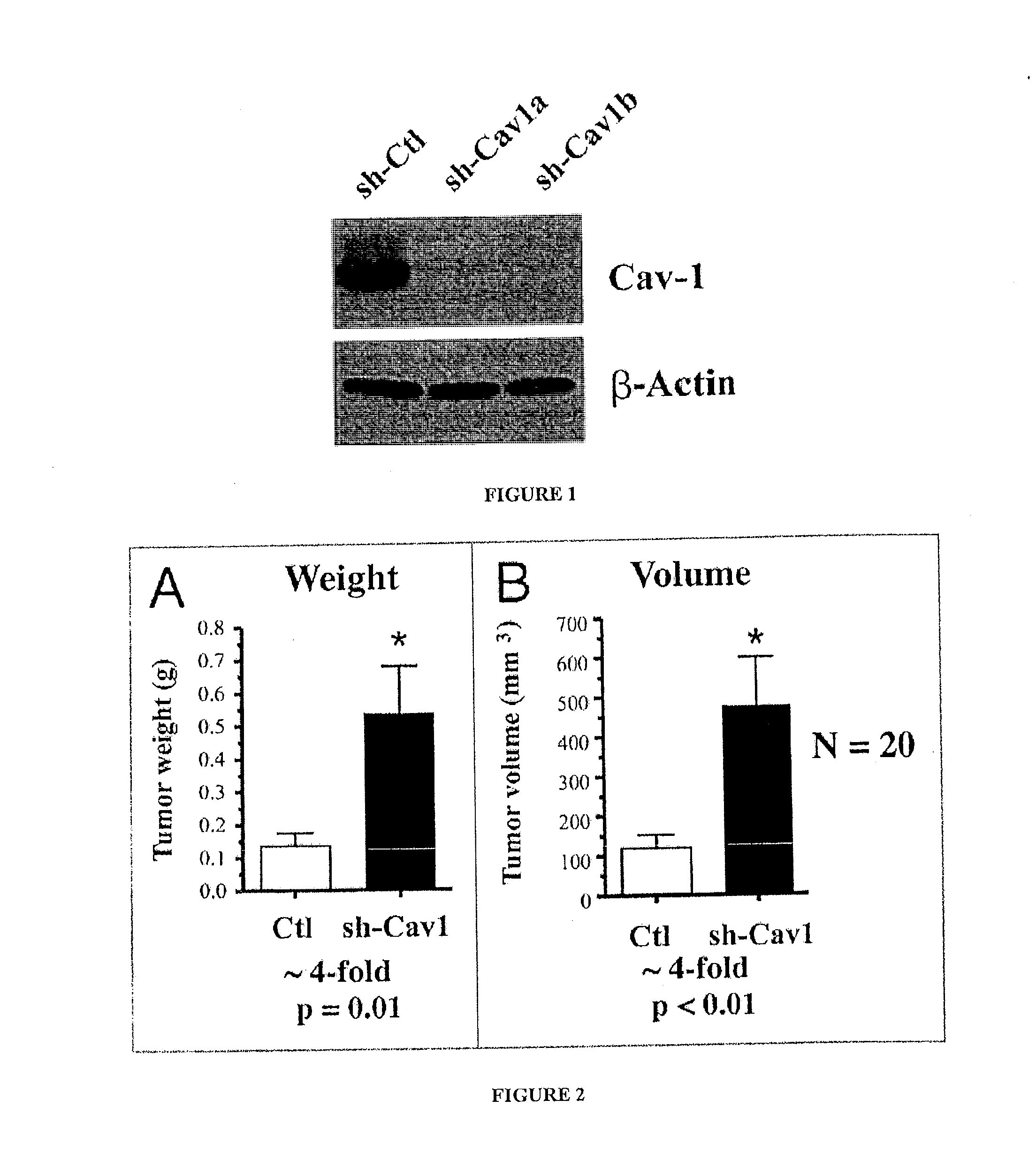

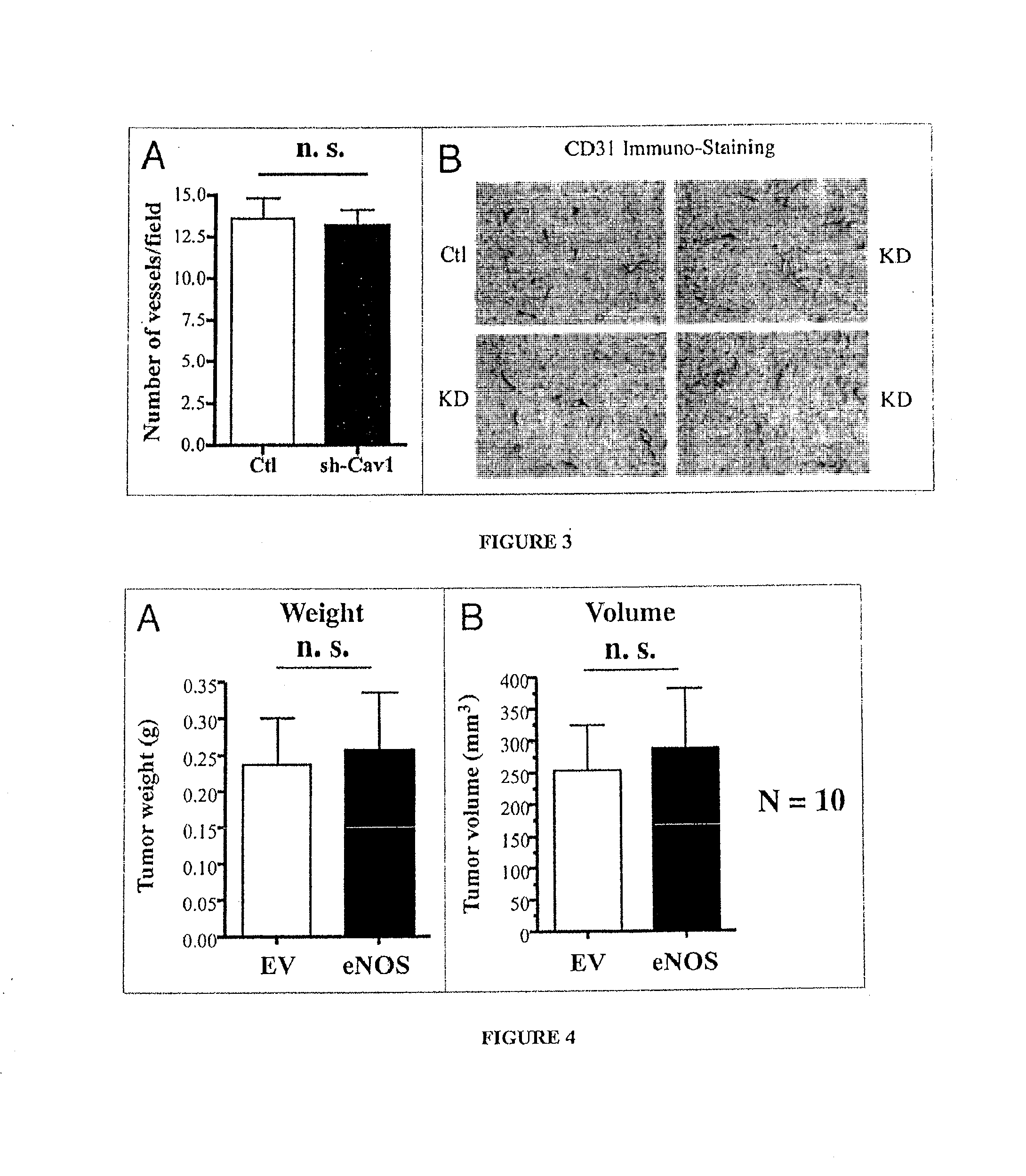

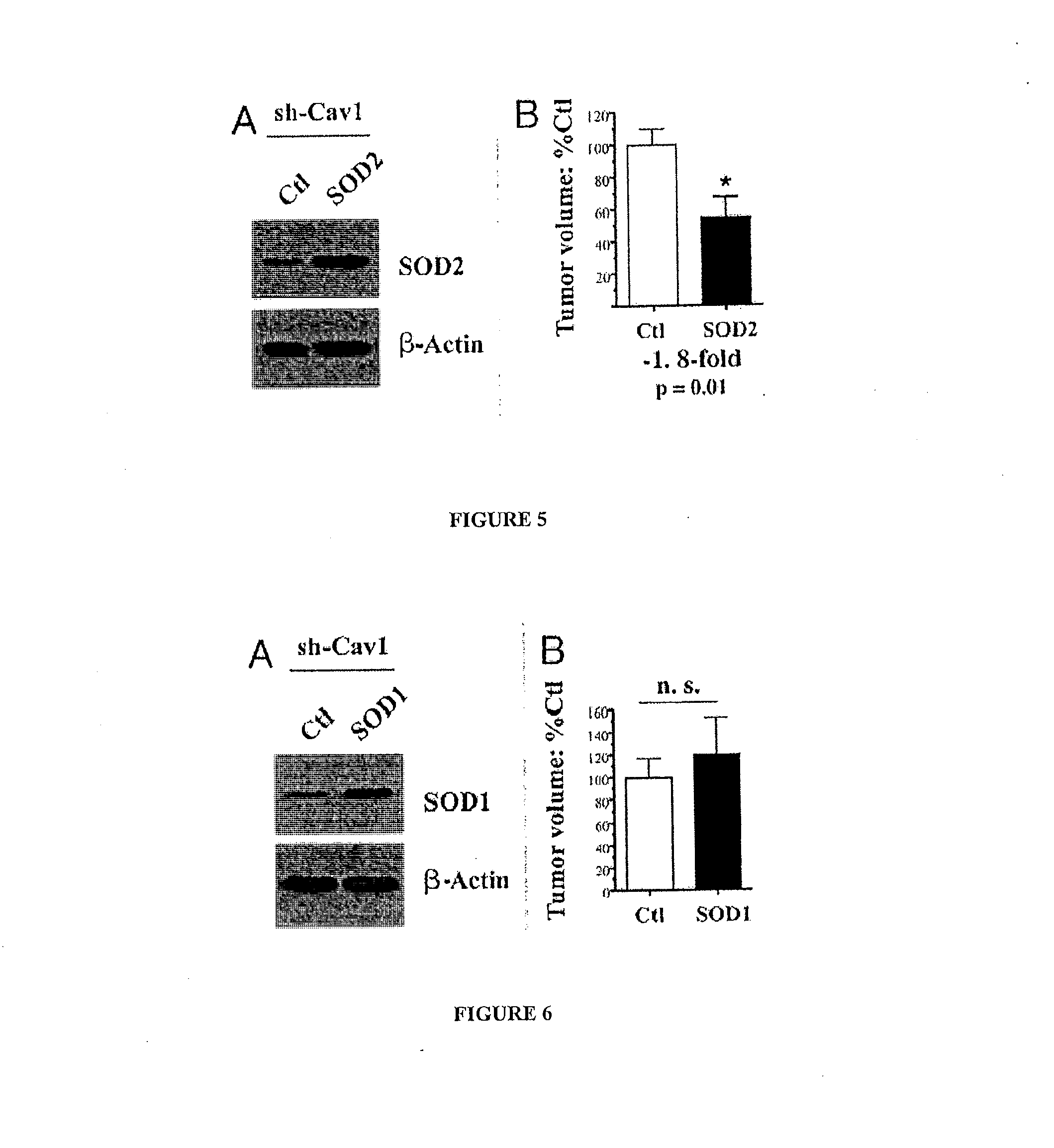

Biomarkers and their uses in cancer detection and therapy

InactiveUS20140026234A1Promote growthAdd additional massLibrary screeningBiological testingCancer researchGenetic model

Presented herein are novel protein biomarkers related to cancers with stromal components. These newly identified biomarkers create the basis for multiple (single) assays using traditional bioassay technologies and when used in combination yield exceptional clinical sensitivity and specificity in the determination of diagnosis and / or prognosis of cancer. A new genetic model able to identify potential genetic suppressors and / or potential therapeutic agents for treating stromal cancers is also described. Means and methods for evaluating data generated using multiple biomarkers in order to validate findings and further the use of the biomarkers and the genetic model system in clinical, diagnostic and therapeutic uses is also included.

Owner:THOMAS JEFFERSON UNIV

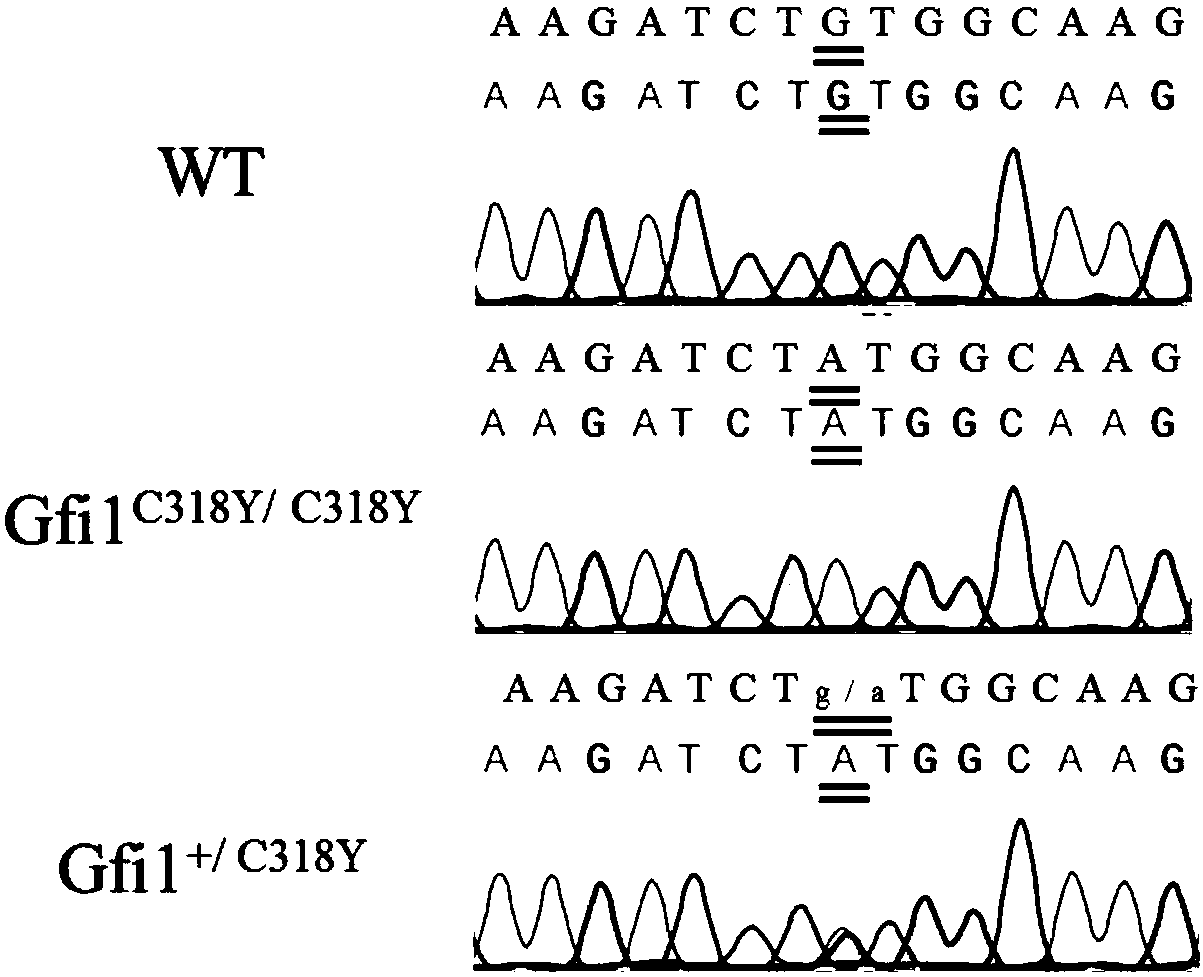

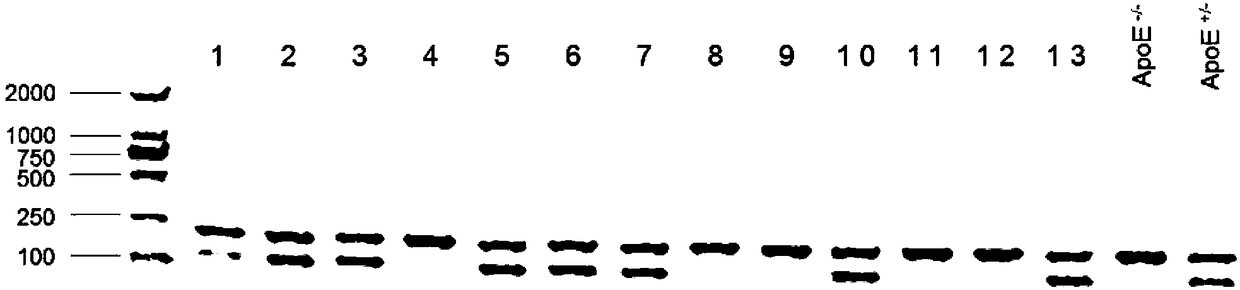

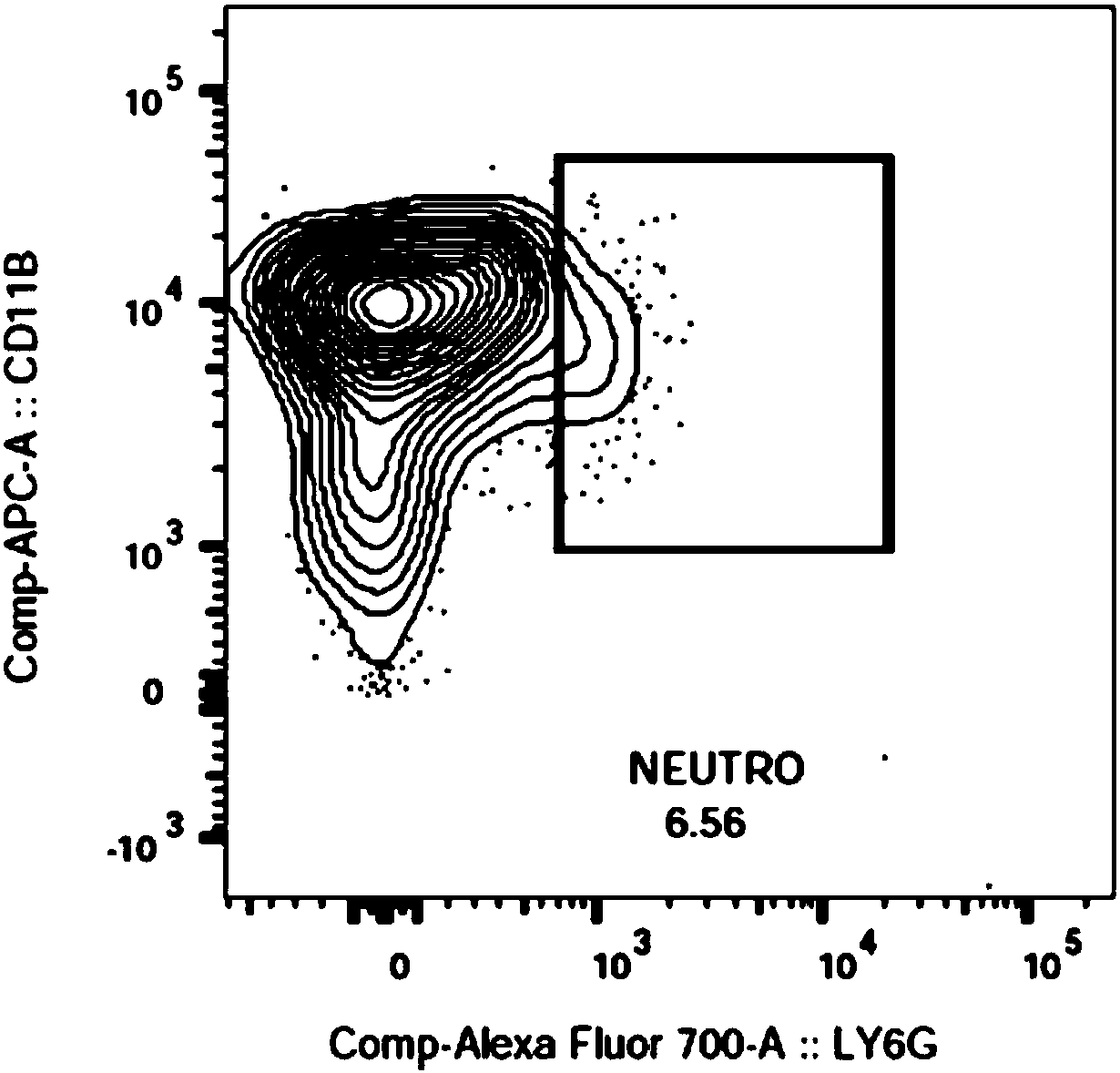

Establishing method of neutropenia atherosclerosis model rat

ActiveCN108271740ASuccessful breedingAlleviate disease symptomsMicrobiological testing/measurementAnimal husbandryNeutrophil granulocyteAtheroma

The invention relates to an establishing method of a neutropenia atherosclerosis model rat, and belongs to the technical field of genetic engineering and genetic modification. A first neutropenia atherosclerosis rat genetic model is established by introducing the Gfi1 point mutation into an ApoE-knocked-out rat gemone for the first time. It is proved through experiments that in the model rat, atherosclerosis plaque is remarkably reduced and atherosclerosis symptoms are remarkably relieved; it is shown that the neutropenia atherosclerosis model rat is successfully established and the atherosclerosis lesion degree can be relieved by neutropenia. The obtained neutropenia cocurrent atherosclerosis model rat has quite important potential application value in the disclosing of the effects of neutrophils on forming and repairing of atherosclerosis and in the diagnosis and treatment of atherosclerosis.

Owner:XINXIANG MEDICAL UNIV

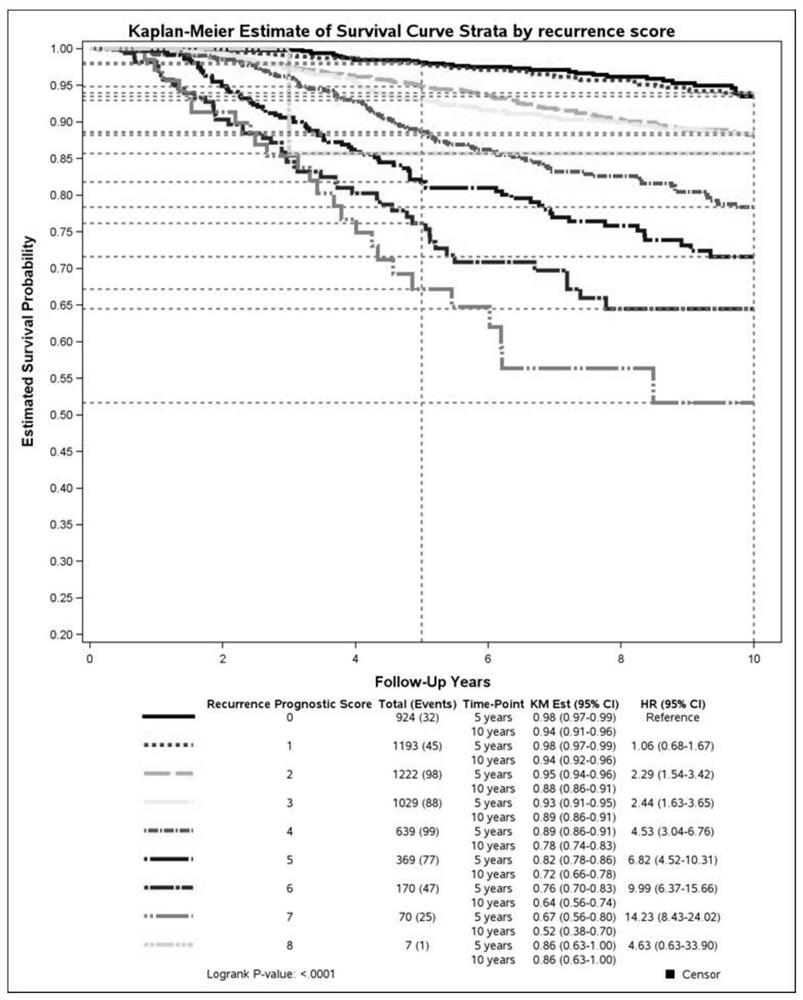

Polygene detection primers for predicting risk of distant recurrence of early breast cancer

PendingCN112646890AStrong specificityHigh detection sensitivityMicrobiological testing/measurementDNA/RNA fragmentationPIM1Molecular diagnostic techniques

The invention discloses polygene detection primers for predicting a risk of a distant recurrence of early breast cancer and belongs to the technical field of molecular diagnosis. The polygenes comprise BUB1B, BLM, TPX2, DTX2, PIM1, OBSL1, YWHAB, CLCA2, SF3B5, ESR1 and ERBB2. Primer sequences are shown as SEQ ID NO.1-22. The primers have good specificity, all amplicons generated by a PCR amplification are short, and detection sensitivity of RNA extracted from an FFPE sample can be enhanced. The invention further discloses a method for predicting a risk of a distant recurrence of early breast cancer. The relative expression quantity of the polygenes in the FFPE sample is quantified through SEQ ID NO.1-28, a statistical method of a distant recurrence genetic model is established, the risk of the distant recurrence of the early breast cancer can be predicted, patients with low-risk and high-risk breast cancer are divided, and guidance is provided for treatment of postoperative breast cancer.

Owner:郑鸿钧

Induction and culture line establishment method for mammal parthenogenetic epiblast stem cells and obtained parthenogenetic epiblast stem cell line

InactiveCN107523539AMaintain parthenodiploidyCulture processDead animal preservationMammalStem cell line

The invention discloses an induction and culture line establishment method for mammal parthenogenetic epiblast stem cells and an obtained parthenogenetic epiblast stem cell line. The method comprises the following steps: executing the superovulation to two varieties of female mice ICR and 129, and executing the parthenogenetic activation to ovocyte; after 5 h of the activation, cultivating for 96 h in KSOM, and generating blastaea, and executing the line establishment by using the blastaea. The line establishment method is capable of efficiently inducing mice parthenogenetic embryo to form the parthenogenetic epiblast stem cells pa-EpiLSCs, keeping the parthenogenetic diploid features and steady growing for more than 30 generations. The method is capable of providing a new tool for rapid generation of a recessive trait genetic model, and providing the new technical and theoretical basis for other mammals establishing the pa-EpiLSCs from the parthenogenetic embryos.

Owner:INNER MONGOLIA UNIVERSITY

Method and apparatus for image-based photorealistic 3D face modeling

An apparatus and method for image-based 3D photorealistic head modeling are provided. The method for creating a 3D photorealistic head model includes: detecting frontal and profile features in input frontal and profile images; generating a 3D head model by fitting a 3D genetic model using the detected facial features; generating a realistic texture from the input frontal and profile images; and mapping the texture onto the 3D head model. In the apparatus and method, data obtained using a relatively cheap device, such as a digital camera, can be processed in an automated manner, and satisfactory results can be obtained even from imperfect input data. In other words, facial features can be extracted in an automated manner, and a robust 'human-quality' face analysis algorithm is used.

Owner:SAMSUNG ELECTRONICS CO LTD

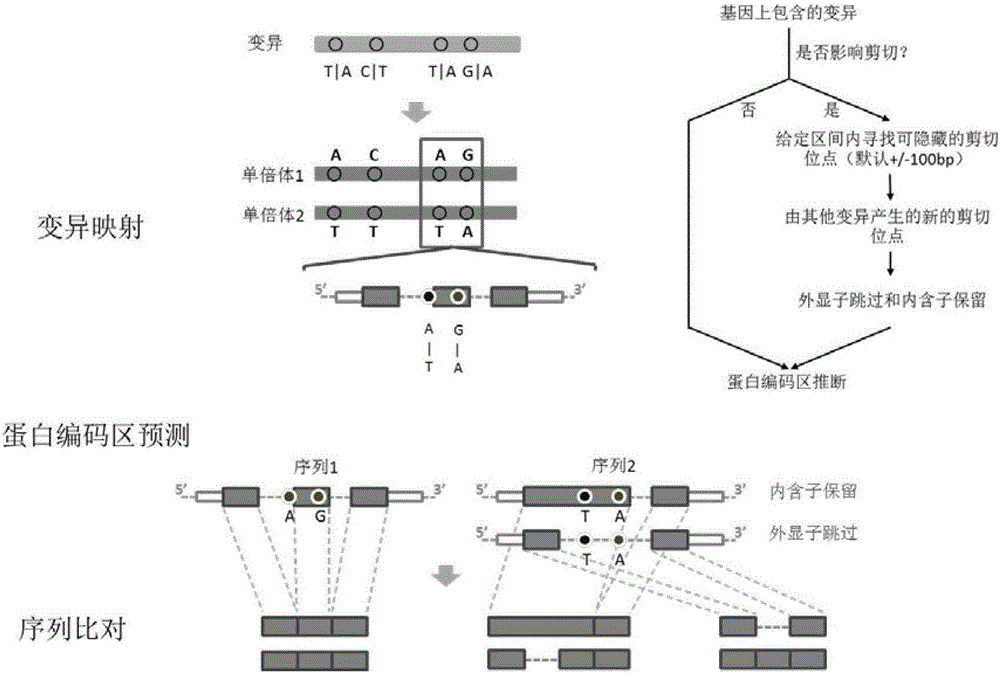

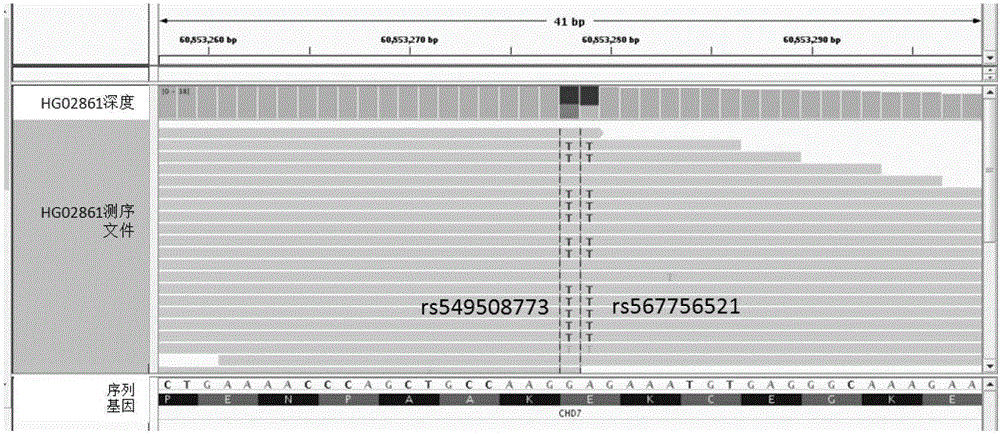

Method for determining influence of genetic variation on function based on genomic environment

The invention provides a method for determining the influence of genetic variations on function based on a genomic environment. According to the method, each gene serves as a unit, and the common influence of all variations on the gene is annotated. The method includes the following steps: 1, all the variations are mapped to all genes of a given genetic model according to the coordinate positions of the variations; 2, according to all the variations on all the genes, the individualized sequence of each gene is reconstructed; 3, all the individualized sequences are analyzed, and the influences of the variations on the genes are obtained. The method fully considers the genomic environment where the variations are located, a large quantity of annotation errors are avoided, and the accuracy of the annotation variation effect is remarkably improved.

Owner:PEKING UNIV

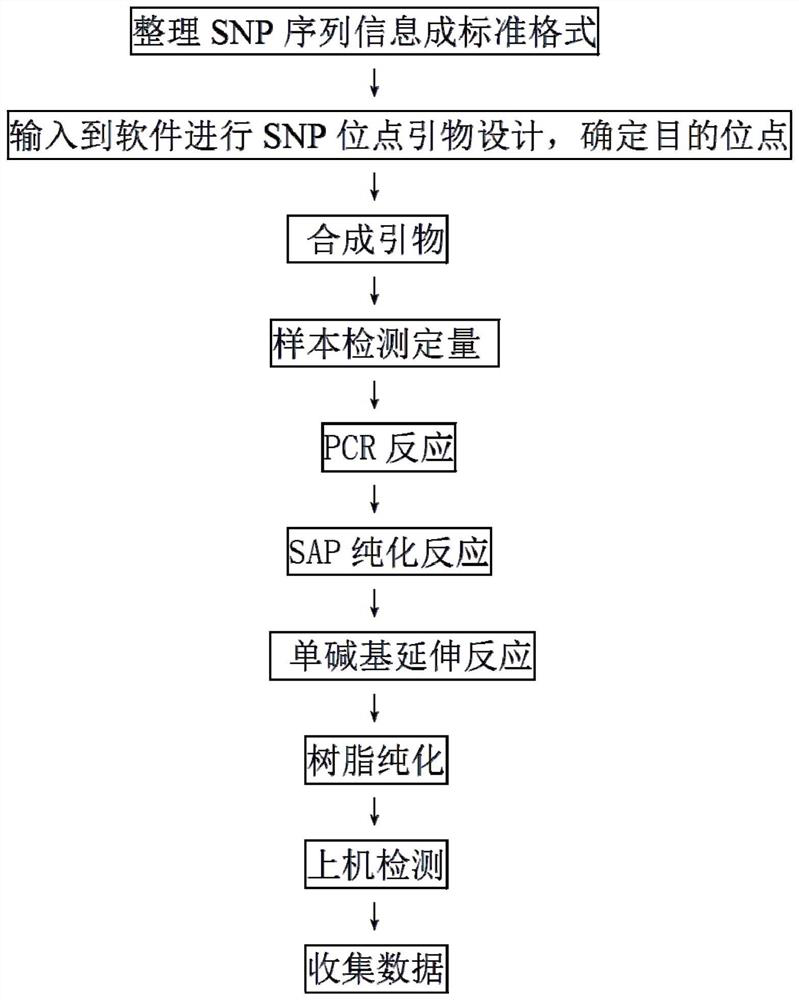

Nonfunctional pituitary adenoma detection device and application thereof

ActiveCN108753970AHigh clinical application valueSimple and reliable diagnostic methodMicrobiological testing/measurementDNA/RNA fragmentationClinical valueDiagnosis methods

The invention provides a nonfunctional pituitary adenoma detection device and application thereof. The device is used for carrying out Massarray SNP parting detection on a mononucleotide polymorphic site rs2981582 of a sample to be detected; the site has significant correlation with the attack of the nonfunctional pituitary adenoma; different genetic models of the site can provide certain basis for diagnosis of the nonfunctional pituitary adenoma and have higher clinical values. Through the nonfunctional pituitary adenoma detection device and the application thereof, a simple and reliable diagnosis method is provided for early diagnosis of patients with nonfunctional pituitary adenoma.

Owner:BEIJING TIANTAN HOSPITAL AFFILIATED TO CAPITAL MEDICAL UNIV

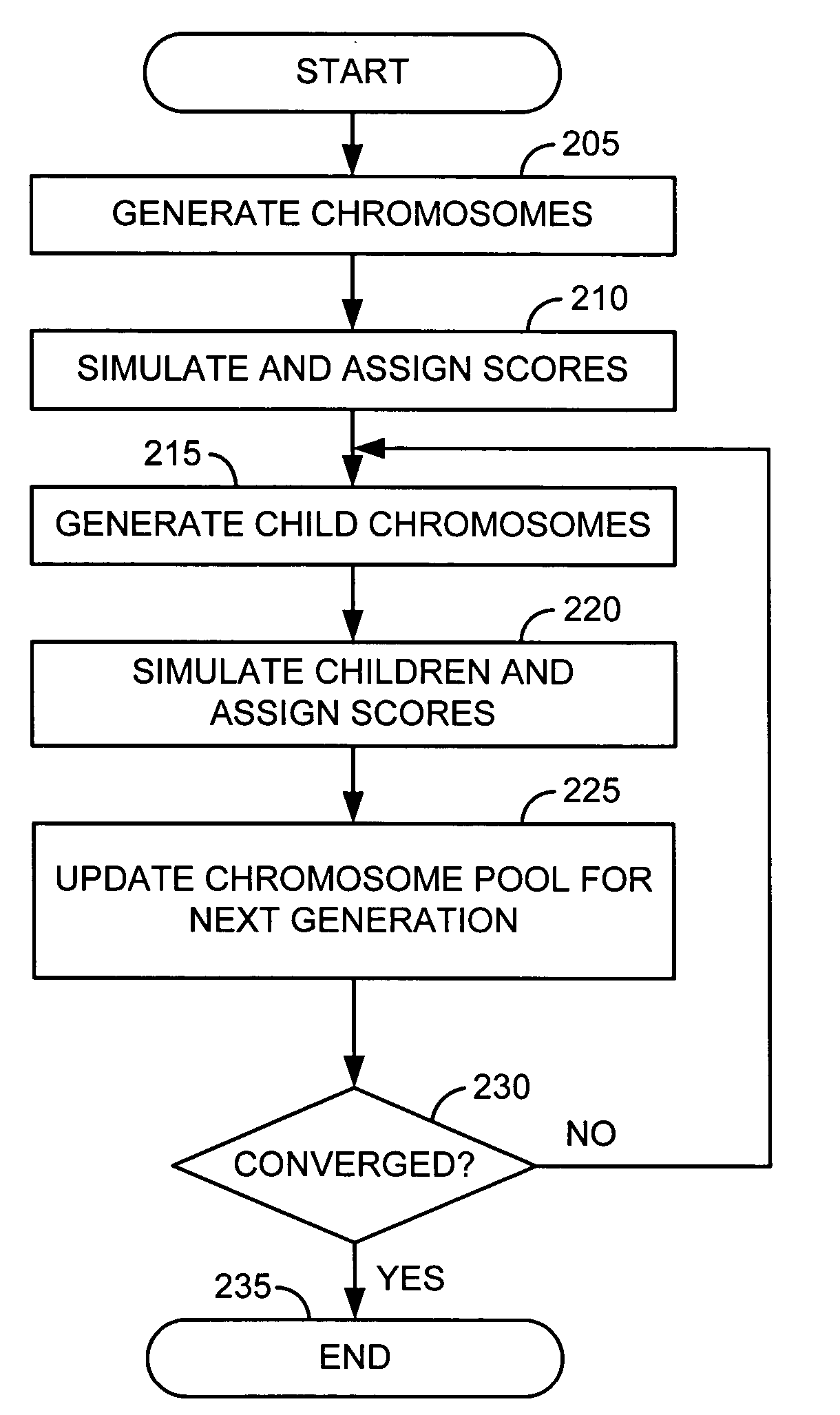

Method and system for mapping genes to characteristics in a genetic optimization process

InactiveUS20050071302A1Digital computer detailsElectric digital data processingFeature mappingGenetic model

The iterations required for the convergence of a computer-implemented optimization process based on a genetic model are reduced, and the flexibility of the process is increased through mapping multiple characteristics of a system to be optimized to a single gene within a chromosome.

Owner:HEWLETT PACKARD DEV CO LP

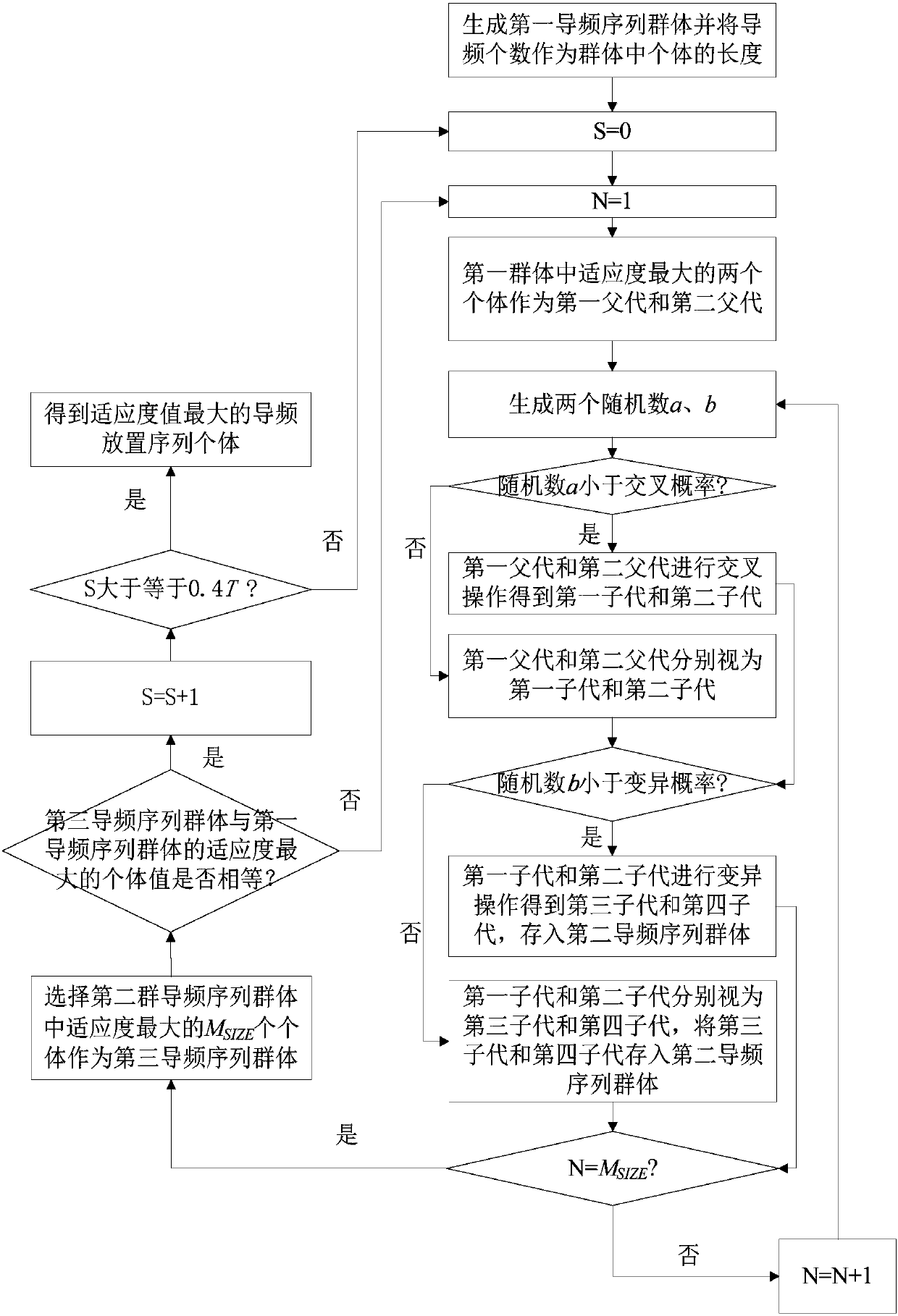

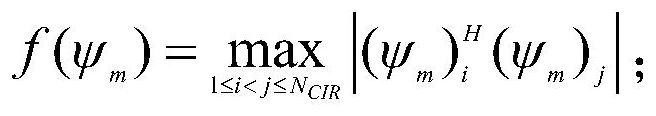

Pilot design method for large-scale MIMO system

ActiveCN108023842AImprove estimation performanceReduce in quantityBaseband system detailsRadio transmissionEngineeringDesign methods

The invention relates to a wireless communication technology, in particular to a pilot design method for a large-scale MIMO system. The method comprises the following steps of randomly generating a first pilot sequence group by adopting real value coding, and taking two individuals with the largest fitness values in the group as a first parent and a second parent; carrying out crossover and mutation operation on the first parent and the second parent to acquire a third filial generation and a fourth filial generation, and storing the third filial generation and the fourth filial generation into a second pilot sequence group; storing a plurality of individuals with the larger fitness values of the second pilot sequence group into a third pilot sequence group; and selecting an optimal individual and an individual with the largest fitness value in the third pilot sequence group, and if the fitness value of the optimal individual in the third pilot sequence population is equal to the fitness value of the optimal individual of the first pilot sequence for many times, acquiring an optimal pilot position sequence. According to the method, a genetic model is built, and meanwhile, inner andouter circulation mechanisms are introduced to ensure the acquisition of the optimal individual in the population, so that the accuracy of channel estimation is improved while the pilot overhead is reduced.

Owner:CHONGQING UNIV OF POSTS & TELECOMM

Augmented triple-test cross design QTL mapping method based on RIL population

InactiveCN107169311AReduce the workload of one hybridizationSave manpower and material resourcesHybridisationSpecial data processing applicationsTriple testWorkload

A QTL mapping method based on augmented TTC design is provided, which is based on recombinant inbred line group as the basic group; based on the genetic expectation values of RIL, L1i, L2i and L4i under the F infinity scale, the genetic expectation values s of Z1i, Z2i and Z4i under RIL-based aTTC are deduced; and then according to the genetic expectation values of Z1i, Z2i and Z4i, the phenotype value representation formulas of Z1i, Z2i and Z4i are simplified. Then the Bayesian method was used to carry out two-dimensional scanning of the whole genome to obtain various pure-effect and epistatic effects of each QTL locus in the genetic model in two steps. Compared with the TTC design, the aTTC design QTL mapping method can reduce the workload of a one-time hybridization, which eliminates the process of basic group RIL and F1 hybrids and constructing the population of L3i population. For the field work, manpower and resources are greatly saved; but the statistical efficiency of QTL mapping and estimation of genetic effects are not reduced.

Owner:HUNAN AGRICULTURAL UNIV

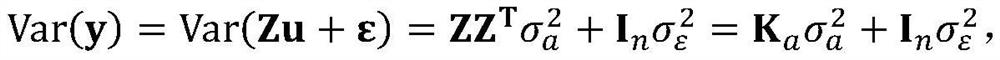

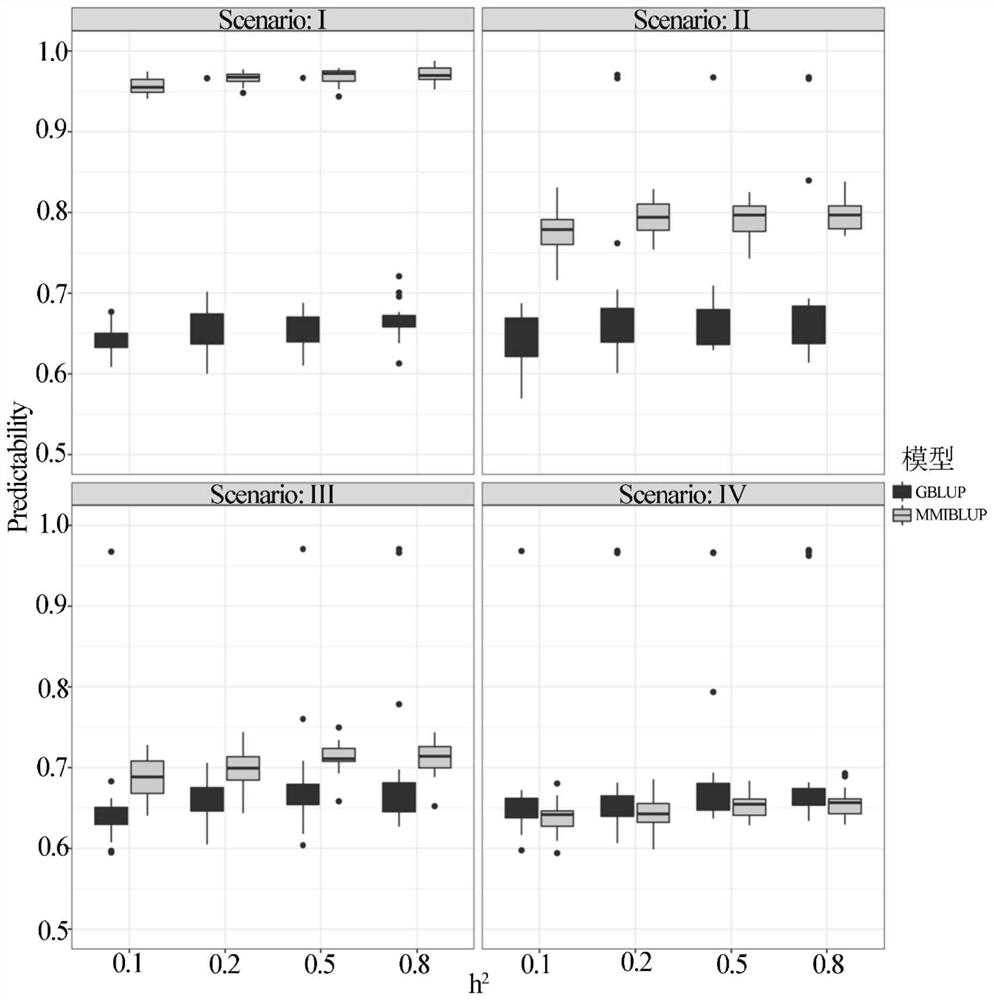

Genome selection method for complex character genetic improvement

ActiveCN113223606AImprove selection accuracyIn line with the law of biological inheritanceProteomicsGenomicsStatistical geneticsLinear model

The invention discloses a genome selection method for complex character genetic improvement. The genome selection method comprises the following steps: (1) establishing a statistical genetic model; (2) positioning a major gene; (3) estimating genetic parameters; (4) performing selection based on an individual whole genome breeding value. Compared with the prior art, the method provided by the invention has the beneficial effects that a) compared with a GBLUP model hypothesis, the model hypothesis provided by the invention is more in line with a biological genetic law and has higher predictive power, namely higher genome selection precision; and b) the method is based on a mixed linear model, has great flexibility and is convenient for model expansion.

Owner:ZHEJIANG UNIV

Non-functional pituitary adenoma detection device and application

ActiveCN108753970BHigh clinical application valueSimple and reliable diagnostic methodMicrobiological testing/measurementDNA/RNA fragmentationFunctioning pituitary tumorPituitary tumors

The invention provides a non-functional pituitary adenoma detection device and its application. The device of the present invention performs Massarray SNP typing detection on the single nucleotide polymorphism site rs2981582 of the sample to be tested. This site has a significant correlation with the pathogenesis of non-functioning pituitary tumors. The different genetic models of this locus can provide a certain basis for the diagnosis of non-functioning pituitary tumors and have high clinical value. The invention can provide a simple and reliable diagnostic method for the early diagnosis of patients with non-functional pituitary tumors.

Owner:BEIJING TIANTAN HOSPITAL AFFILIATED TO CAPITAL MEDICAL UNIV

Pilot Design Method for Massive MIMO System

ActiveCN108023842BImprove estimation performanceReduce in quantityBaseband system detailsRadio transmissionOperations researchIndustrial engineering

The invention relates to a wireless communication technology, in particular to a pilot design method for a large-scale MIMO system. The method comprises the following steps of randomly generating a first pilot sequence group by adopting real value coding, and taking two individuals with the largest fitness values in the group as a first parent and a second parent; carrying out crossover and mutation operation on the first parent and the second parent to acquire a third filial generation and a fourth filial generation, and storing the third filial generation and the fourth filial generation into a second pilot sequence group; storing a plurality of individuals with the larger fitness values of the second pilot sequence group into a third pilot sequence group; and selecting an optimal individual and an individual with the largest fitness value in the third pilot sequence group, and if the fitness value of the optimal individual in the third pilot sequence population is equal to the fitness value of the optimal individual of the first pilot sequence for many times, acquiring an optimal pilot position sequence. According to the method, a genetic model is built, and meanwhile, inner andouter circulation mechanisms are introduced to ensure the acquisition of the optimal individual in the population, so that the accuracy of channel estimation is improved while the pilot overhead is reduced.

Owner:CHONGQING UNIV OF POSTS & TELECOMM

A genomic selection method for genetic improvement of complex traits

ActiveCN113223606BImprove selection accuracyIn line with the law of biological inheritanceProteomicsGenomicsStatistical geneticsLinear model

The invention discloses a genome selection method for genetic improvement of complex traits, comprising the following steps: (1) establishment of a statistical genetic model; (2) main effect gene positioning; (3) genetic parameter estimation; (4) individual-based Genome-wide selection of breeding values. Compared with the prior art, the beneficial effects of the present invention are: a) Compared with the model hypothesis of GBLUP, the model hypothesis proposed by the application is more in line with the law of biological inheritance and has higher predictive power, that is, has a higher genome Selection accuracy; b) The present invention is based on a mixed linear model, which has great flexibility and facilitates model expansion.

Owner:ZHEJIANG UNIV

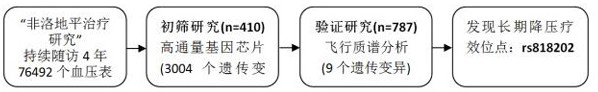

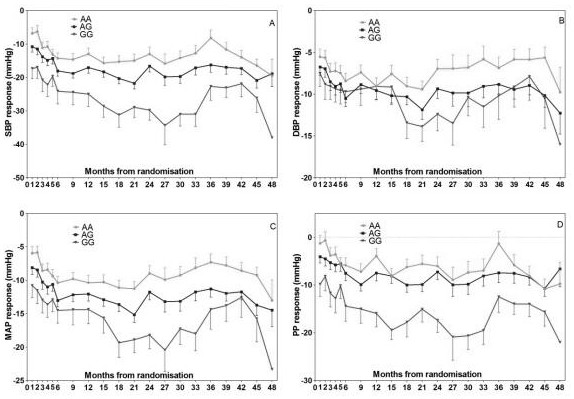

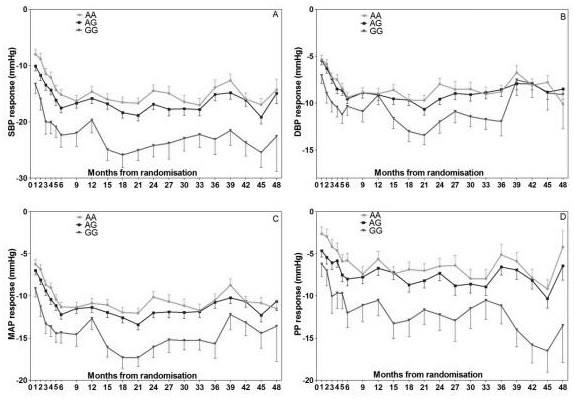

Application of SNP locus of CDA gene

ActiveCN112322727AThe efficacy of treatment is clearStrong specificityMicrobiological testing/measurementMedicineMedication effects

The invention relates to the technical field of biology, in particular to application of an SNP locus of a CDA gene. Researches show that the SNP locus rs818202 of CDA can significantly affect the long-term antihypertensive effect of felodipine, and a genetic model constructed on the basis of rs818202 can better predict the antihypertensive effect. A kit prepared by taking the SNP locus of the CDAas a marker can achieve a good prediction effect on the medication effect of an antihypertensive drug.

Owner:THE SECOND XIANGYA HOSPITAL OF CENT SOUTH UNIV

Method for discovering wild rice beneficial gene using convertible large fragment genome library

InactiveCN1277924CEasy to operateShort cycleFermentationVector-based foreign material introductionOryzaAgricultural science

The invention discloses a method for exploring wild rice advantageous gene using transformable large fragment genome library, the steps including: constructing wild rice transformable large fragment genome library, inducing large fragment clone into cultivated rice through transgene technology, establishing full genome gene knock in mutant library, after field screening about character and genetic model controlled by large fragment clone in mutant, obtaining gene transferred mutant rice dramatically improved in yield ,resistance and quality etc. Once large fragment clone containing advantageous gene is authenticated, it can be utilized in other cultivated rice variety, which modifies the existing rice varieties and can be the same with exploring other plant gene resource.

Owner:HUNAN WEST CITY HYBRID RICE GENE TECH

A restricted two-stage genome-wide association analysis method based on snpldb markers

InactiveCN104651517BShorten the attenuation distanceMultiple allelic variationMicrobiological testing/measurementProteomicsMulti siteRegression analysis

The invention discloses a restrictive two-stage genome-wide association study (GWAS) method based on an SNPLDB mark, and aims at solving the problems that a traditional method cannot be used for estimating multiple allele information, and is high in false positive rate and low in efficiency of detection on inbreeding crops. By combination of the SNPLDB mark constructed on the basis of a haplotype block, correction of deviation of an inbreeding population relation analysis model and a two-stage relation analysis strategy under a multi-site model, the GWAS method suitable for conventional breeding of inbreeding crops is built; the SNPLDB mark is applied to GWAS, so that a method is provided for multiple allele estimation; candidate sites are screened on the basis of a single-site model in the first stage, and are further screened on the basis of a progressive regression analysis method in the multi-site model in the second stage, so as to balance the problems of missing of heritability and over-high heritability estimation. Therefore, the interpretation ratio of a final genetic model is controlled at trait heritability. The positioning accuracy and efficiency are improved by a feature vector and an appropriate significant level of a similarity coefficient matrix estimated by the SNPLDB mark by GWAS.

Owner:NANJING AGRICULTURAL UNIVERSITY

Non-functional pituitary adenoma detection device and application

ActiveCN108707548BHigh clinical application valueSimple and reliable diagnostic methodBioreactor/fermenter combinationsBiological substance pretreatmentsFunctioning pituitary tumorNucleotide

Owner:BEIJING TIANTAN HOSPITAL AFFILIATED TO CAPITAL MEDICAL UNIV

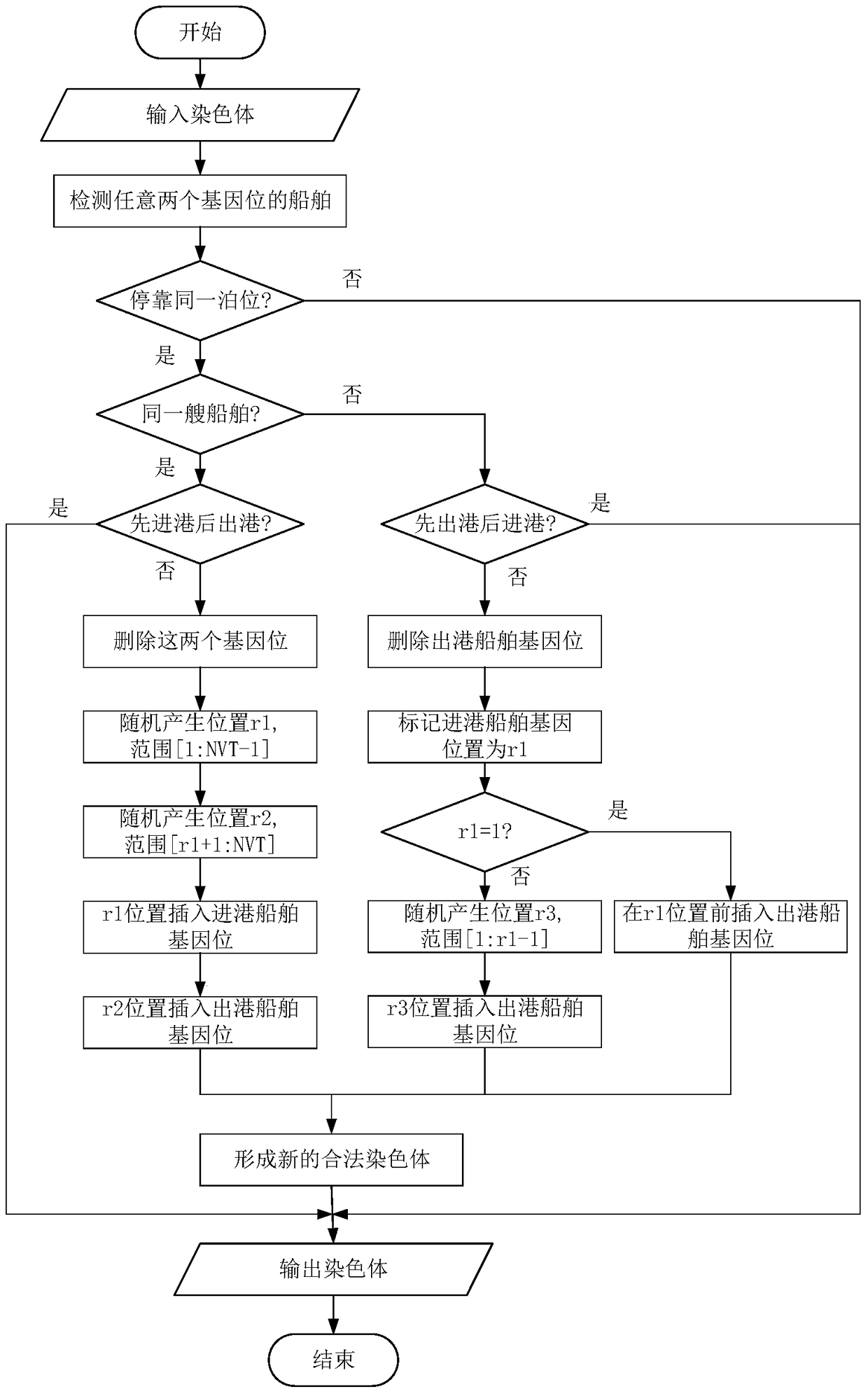

A two-way navigable port ship scheduling optimization method

ActiveCN105117793BImplement schedulingImprove scheduling efficiencyGenetic modelsForecastingShip safetyEngineering

An embodiment of the invention provides a two-way navigable port ship scheduling optimization method. The method comprises the following steps of according to a one / two-way navigable conversion characteristic, establishing a mode conversion constraint; according to continuity of harbor operation of a ship, establishing a continuity constraint; according to a vertical ship safety spacing and a transverse safety spacing, establishing a safety constraint; according to the mode conversion constraint, the continuity constraint and the safety constraint, establishing a multi-objective genetic model; initializing the multi-objective genetic model, wherein chromosome corresponding to the multi-objective genetic model after decoding is combined with the continuity constraint and the safety constraint so as to obtain a ship scheduling scheme; the scheduling scheme comprises ship scheduling beginning time, time of sailing to other key positions, a speed after adjustment and time of waiting for putting in or leaving. By using the method of the invention, two-way navigable port ship scheduling is realized and efficiency of the two-way navigable port ship scheduling is increased.

Owner:DALIAN MARITIME UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com