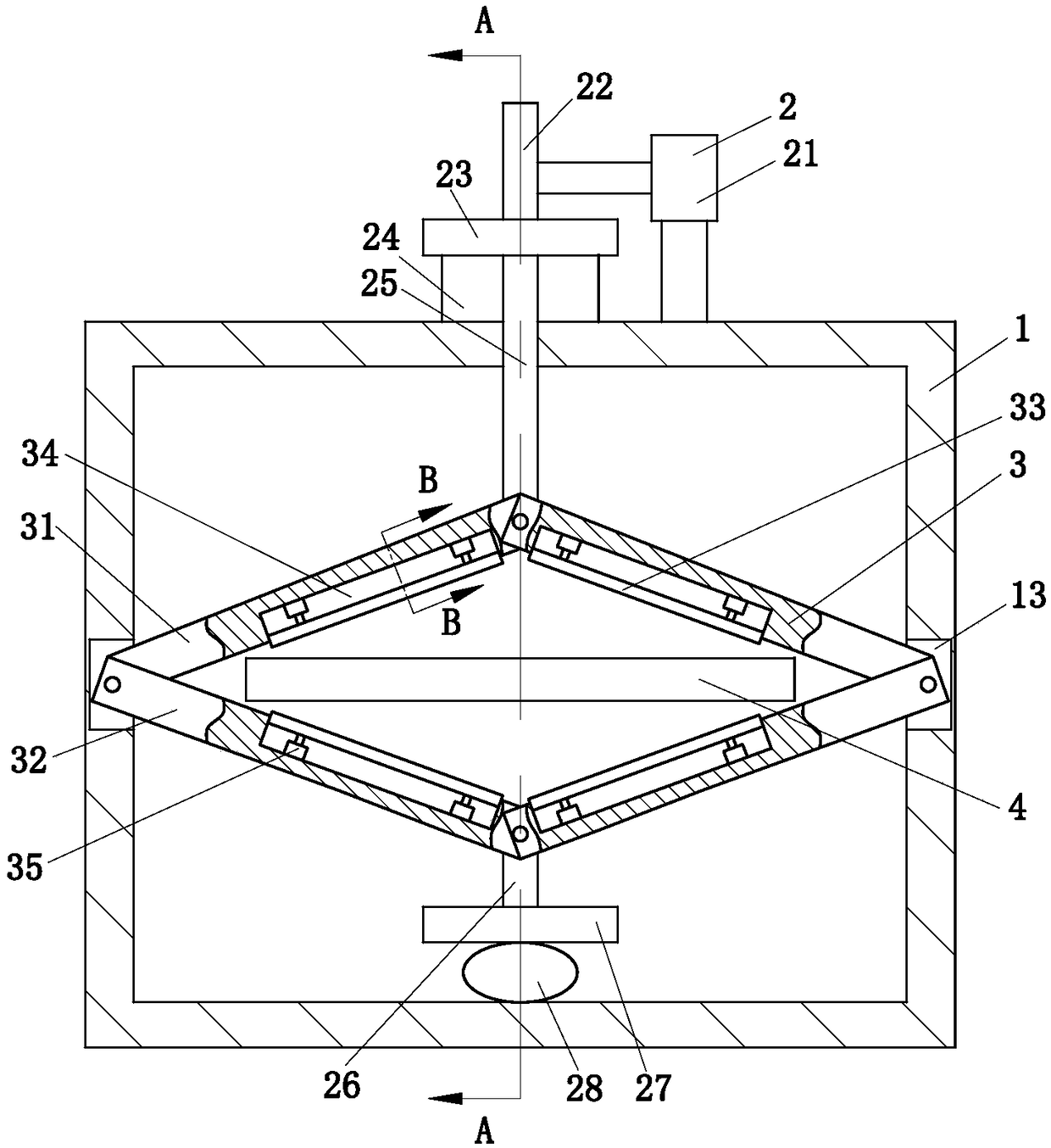

Garment fabric cutting device

A cloth and cutting technology, which is applied in the cutting of textile materials, textiles and papermaking, etc., can solve the problems of affecting the efficiency of cloth cutting, increasing the labor intensity, and affecting the effect of cloth cutting, so as to improve the utilization rate and improve the Cutting efficiency, the effect of improving the cutting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

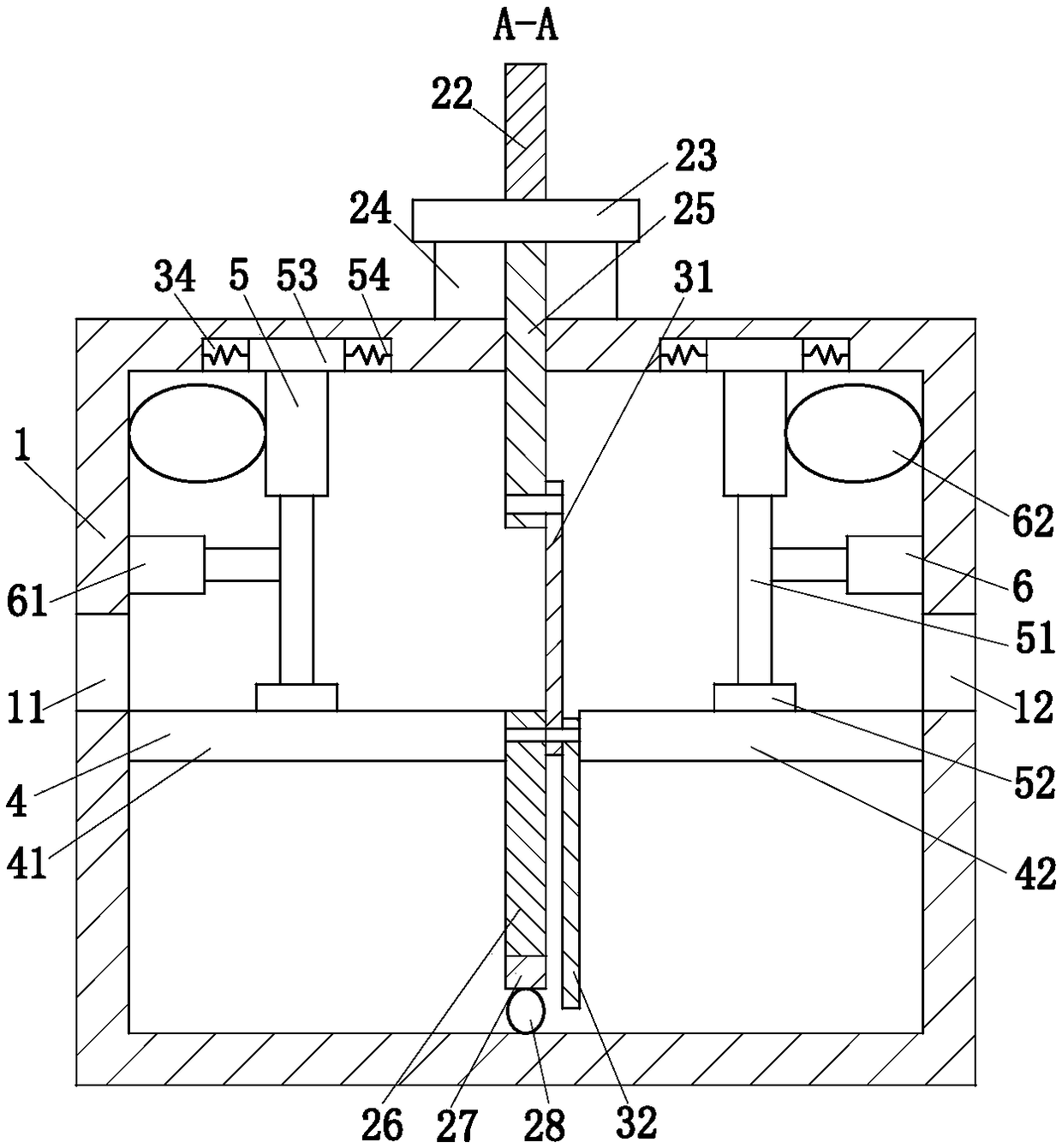

Embodiment approach

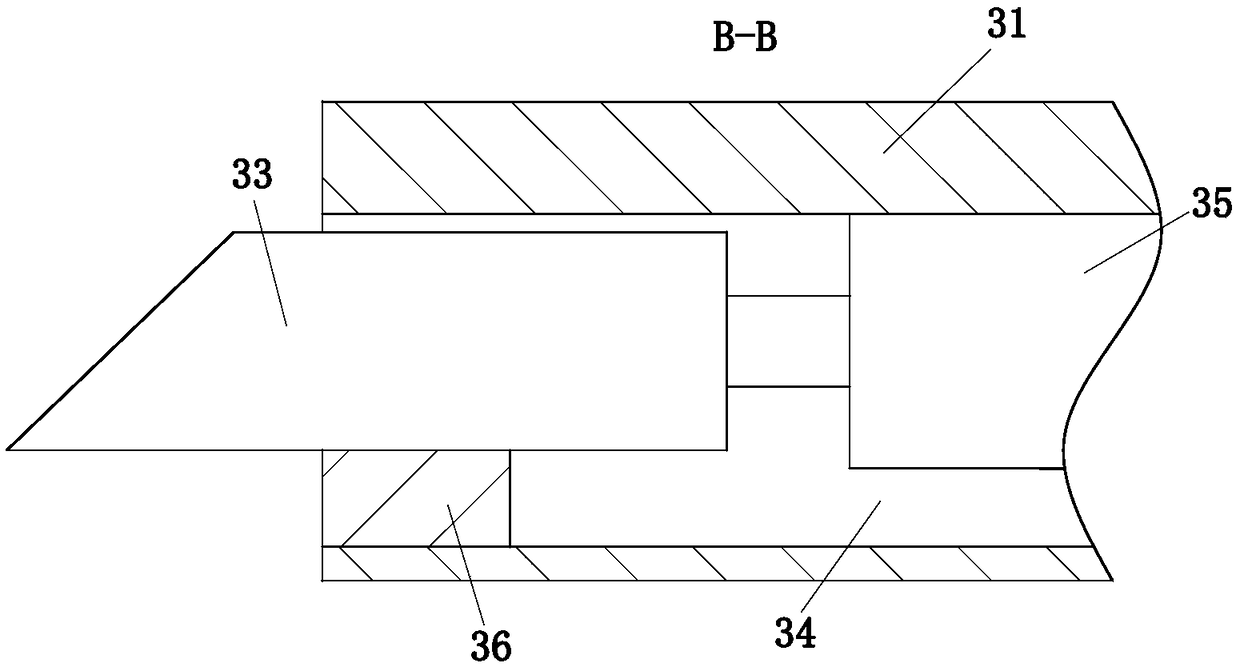

[0044] As an embodiment of the present invention, the No. 1 fixing plate 31 and the No. 2 fixing plate 32 are provided with a No. 3 groove 34; No. 3 cylinder 35 is arranged in the No. 3 groove 34; one end of the No. 3 cylinder 35 It is fixedly connected with the shearing tool 33, and the other end of the No. 3 cylinder 35 is connected with the No. 3 groove 34. The expansion and contraction of the No. 3 cylinder 35 is controlled by the air that the No. 3 air bag 62 blows out. By arranging the No. 3 cylinder 35, when the cloth is not shearing, the shearing tool 33 is retracted into the No. 3 groove 34 to avoid damage to the shearing tool 33, thereby improving the service life of the shearing tool 33.

[0045] When the shearing tool 33 is shearing, the gas blown out by the No. 3 airbag 62 acts on the No. 3 cylinder 35, and the movable plate in the No. 3 cylinder 35 is subjected to the action of the gas, and the movable rod in the No. 3 cylinder 35 drives the shearing process. Cut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com