Special cross-linked polyethylene material for rotational molding and preparing process thereof

A technology of cross-linked polyethylene and special material, applied in the field of cross-linked polyethylene special material for rotomolding and its preparation, can solve the problem of poor processability of LLDPE, heat resistance, creep resistance, low temperature impact resistance and swelling resistance, limiting LLDPE Application range and other issues, to achieve the effect of good permeability and chemical resistance, good rotomolding performance and good fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

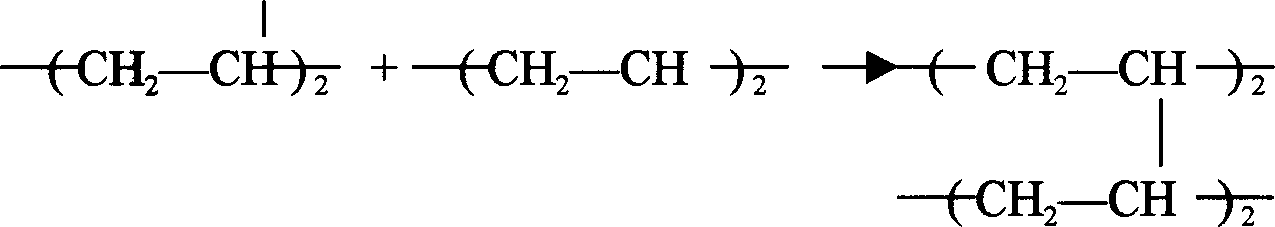

Method used

Image

Examples

example 1

[0018] formula:

[0019] LLDPE 7042 70 kg

[0020] LDPE 1F7A 30 kg

[0021] Dicumyl peroxide 4.5kg

[0022] Antioxidant 1010 500g

[0023] Preparation: Mix the raw materials prepared according to the formula evenly in a high-speed mixer, and then blend on a double-roll mill, and the blending temperature is 130-140°C. The next piece was crushed.

example 2

[0025] formula:

[0026] LLDPE 7042 90 kg

[0027] LDPE 1F7A 10kg

[0028] 2,5 dimethyl-2,5 di-tert-butyl hexane 1 kg

[0029] Dilauryl Thiodipropionate 900g

[0030] Preparation: The method is the same as the preparation method of Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com