Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

107results about How to "Unlimited thickness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Timber wood hot pressing charing intensification method

ActiveCN101214675AUnlimited thicknessGood dimensional stabilityDrying using combination processesWood compressionCarbonizationVolumetric Mass Density

The present invention discloses a hot-pressing carbonization strengthening method of timbers, which includes drying, planing, hot-pressing carbonization, cooling and other steps. The present invention applies a hot press as a timber-carbonizing device, and the timbers under the state of compression are processed by hot-pressing carbonization. The present invention is characterized in that the investment on carbonization devices is less, the carbonization process is simple, the production is safe, the production efficiency is high, the consumption of heat energy is little, and the production cost is low; moreover, the thickness of the carbonized timbers is not limited, the defects of the timbers, such as deformation, cracking, stiker stain, color difference, knot fall-off, etc., do not occur in the process of production, so the quality of products is high; not only is the size stability and noncorrodibility of the carbonized timbers improved, but also the density and mechanical property of the timbers is increased.

Owner:广州豪沃仕家具有限公司

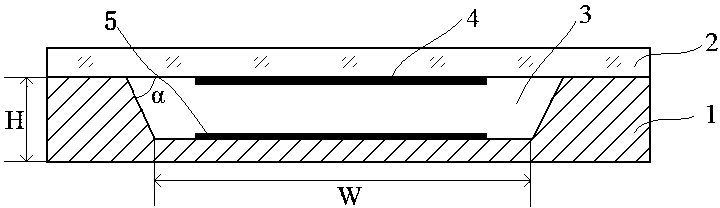

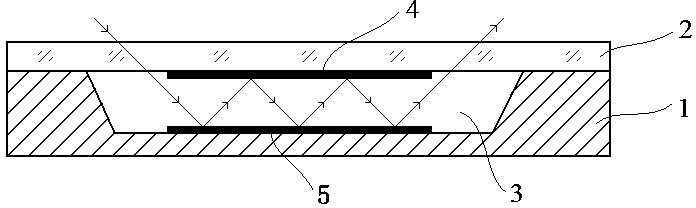

Groove type atomic gas cavity and atomic clock physical system formed by same

ActiveCN102323738ALower working temperatureUnlimited thicknessApparatus using atomic clocksCrystal planeParticle physics

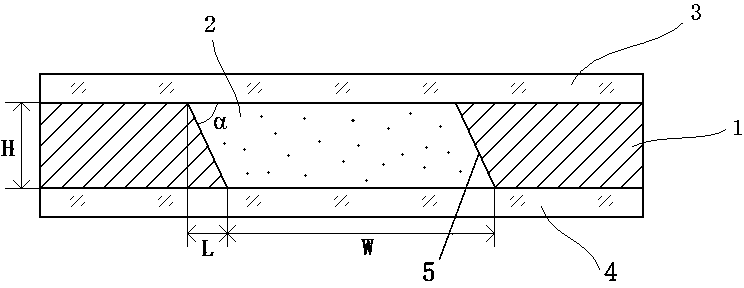

The invention relates to a groove type atomic gas cavity produced by applying MEMS technology and an atomic clock physical system formed by the same. The cavity is characterized in that the cavity is formed in such a manner that a silicon wafer with a groove and Pyrex glass sheets define a cavity structure through bonding; the cavity structure is used for alkali metal atom vapor and buffer gases to fill in; the cross section of the groove is in a shape of inverted trapezoid; and the groove comprises a bottom surface and side walls forming included angles with the bottom surface. The cavity is manufactured based on MEMS (micro-electro-mechanical system) technology. The silicon groove is formed through anisotropic etching of the (100) monocrystalline wafer. The groove type cavity is manufactured through silicon-glass anode bonding. The side walls of the cavity are {111} crystal planes of the silicon wafer. The cavity and the system have the following beneficial effects: by utilizing the cavity, the distance between two reflectors in the cavity is easy to enlarge through atomic cavity dimension design, thus increasing the length of the interaction space between laser and atomic gas, enhancing the signal to noise ratio of the CPT (coherent population trapping) signal and being beneficial to improvement of the frequency stability of the micro CPT atomic clock.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

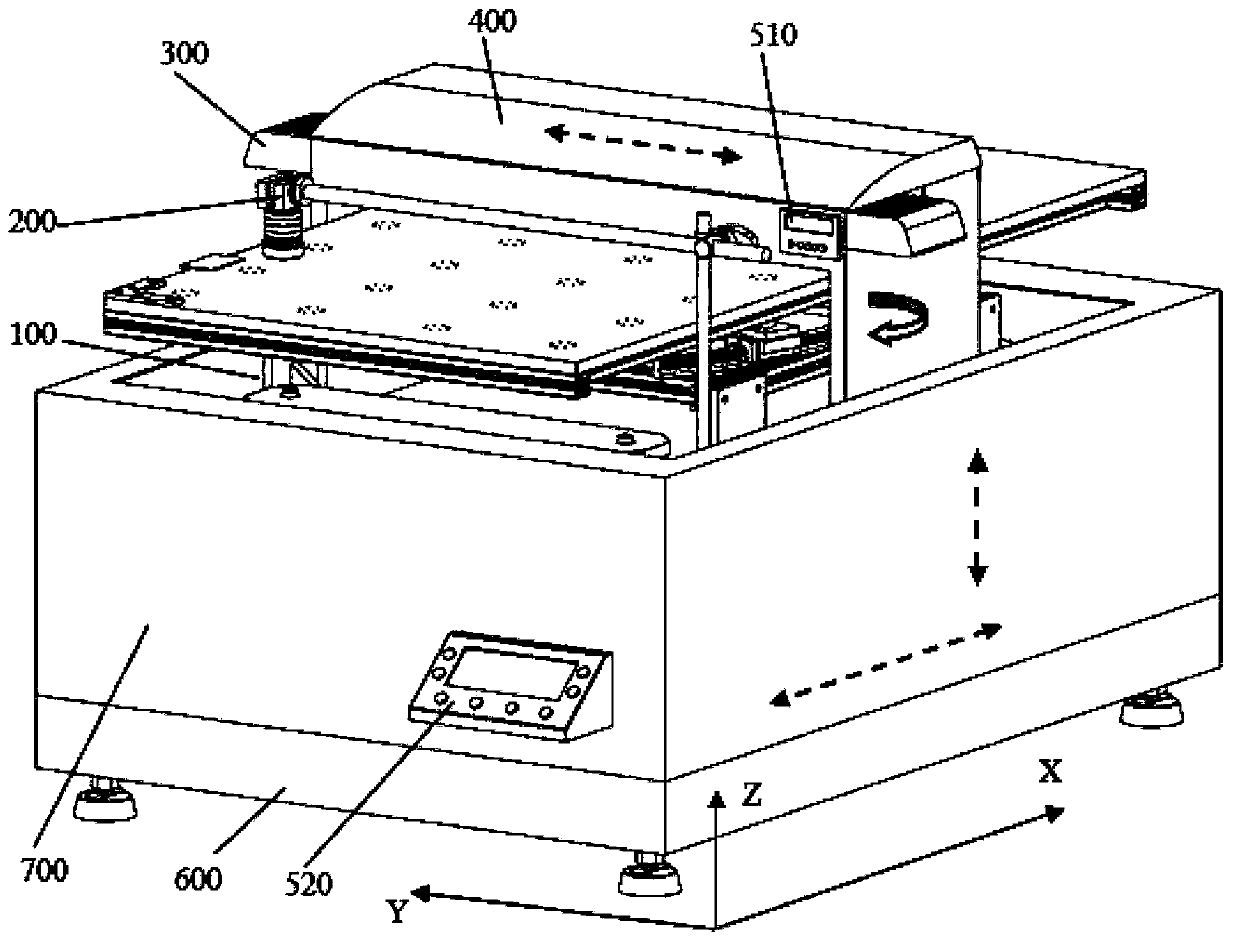

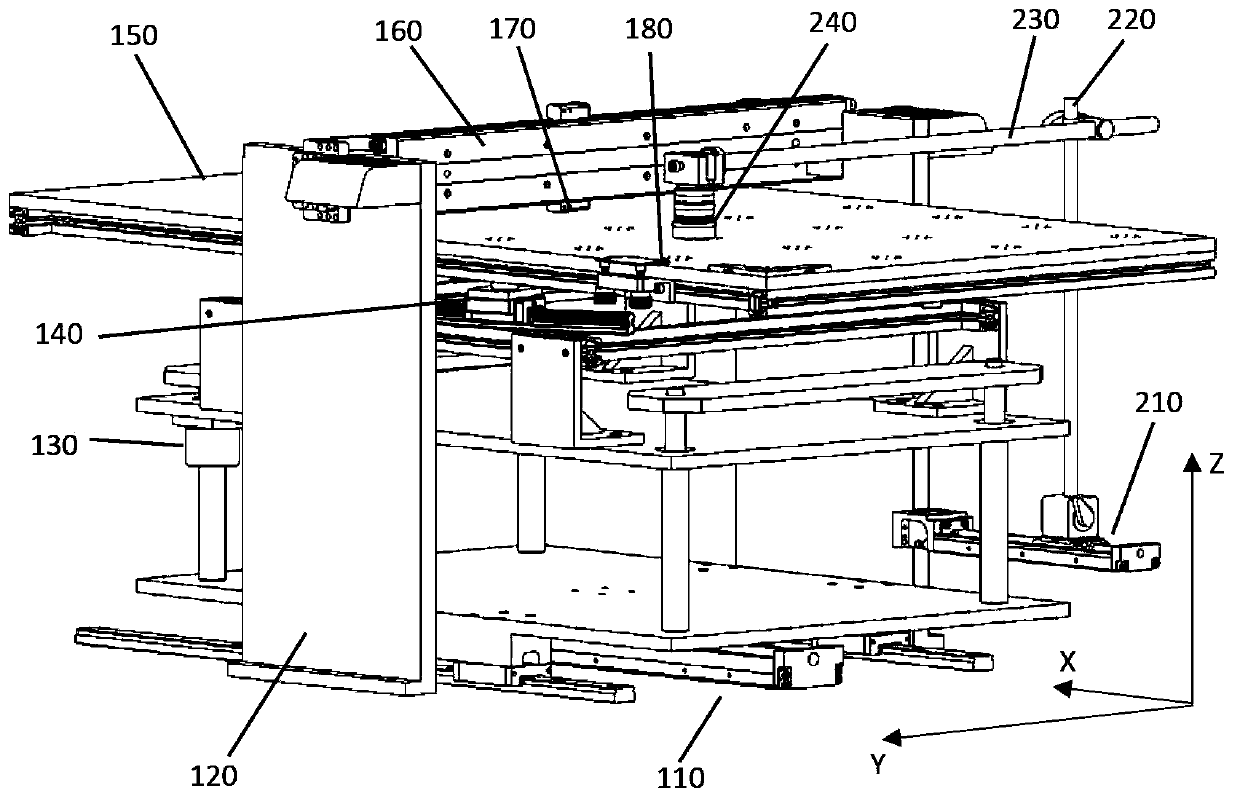

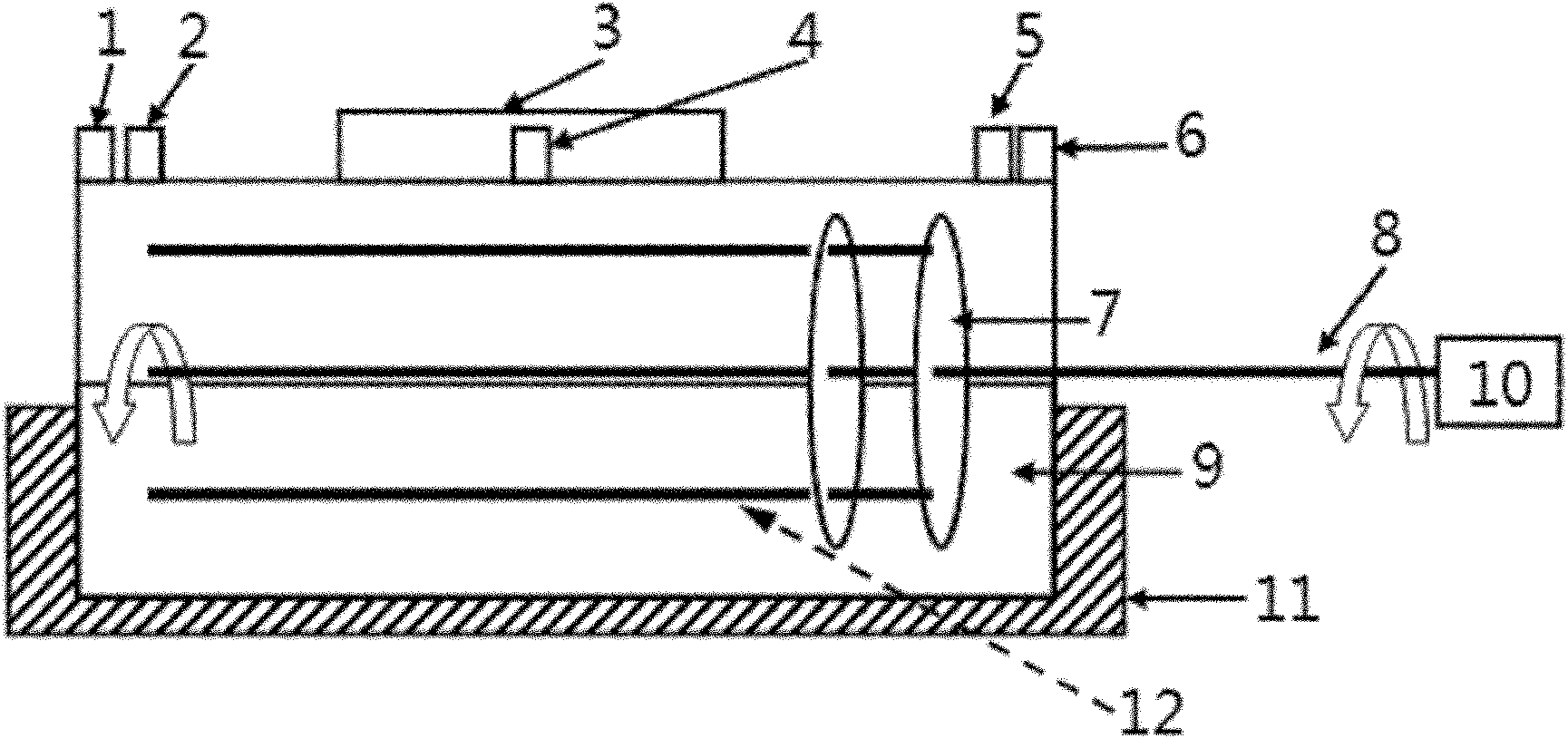

Machine-vision-based raster stereo image flat printer and method

The invention discloses a machine-vision-based raster stereo image flat printer for realizing stereo printing on a raster plate matrix. The printer comprises a printing system, a visual sense measuring system and an error correction processing system, wherein the visual sense measuring system is used for obtaining the image of a raster plate on the printing system and detecting a position and an angle; the error correction processing system calculates the position deviation of the raster plate and the printed image according to the position and the angle and controls the printing system to perform corresponding position error correction according to the deviation so that a stereo image can be obtained by printing at an accurate position. By using the printer and the method provided by the invention, the problems of low printing precision, complicated operation, difficult automation realization and the like in a conventional raster stereo image printing process can be overcome, a method of machine visual sense measuring positioning and mechanical and visual sense auxiliary error correction is adopted so that the stereo image printing based on the raster plate can be realized, the material adaptability can be improved, the operation is convenient, and the printing precision is high.

Owner:HUAZHONG UNIV OF SCI & TECH

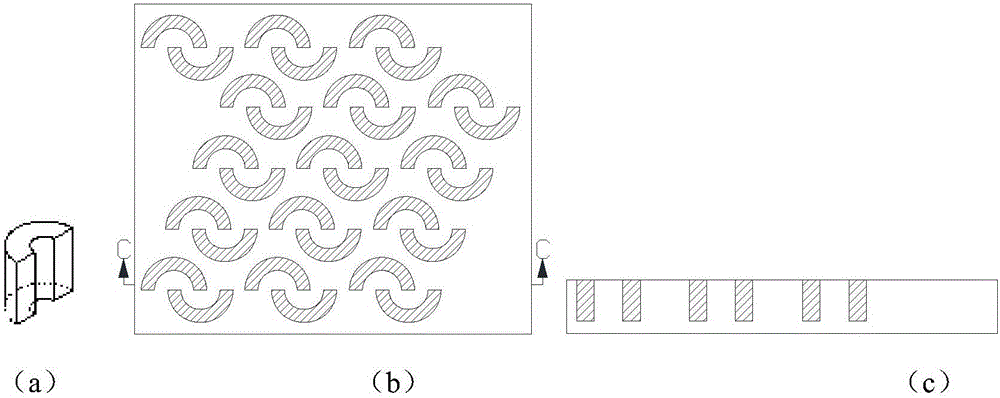

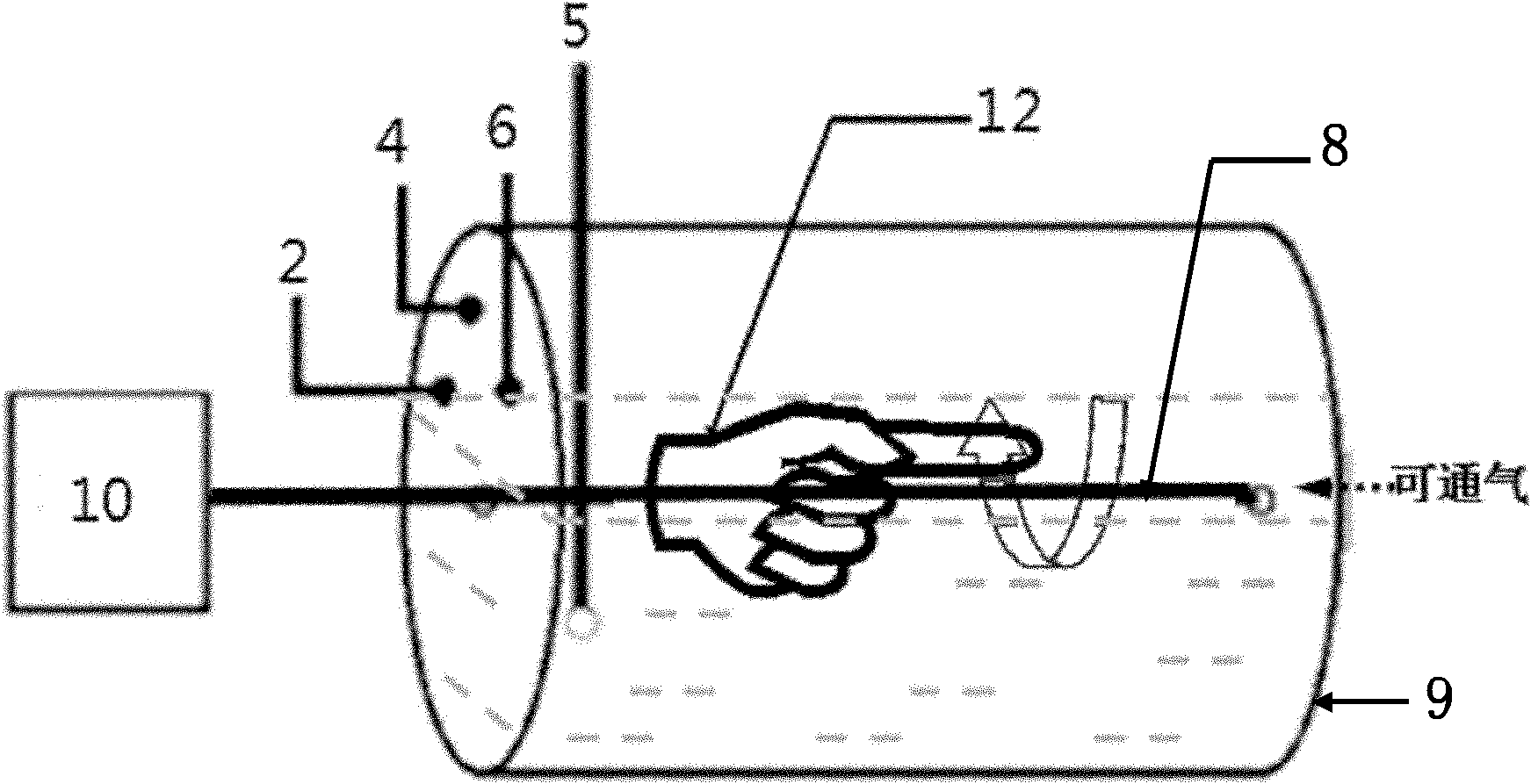

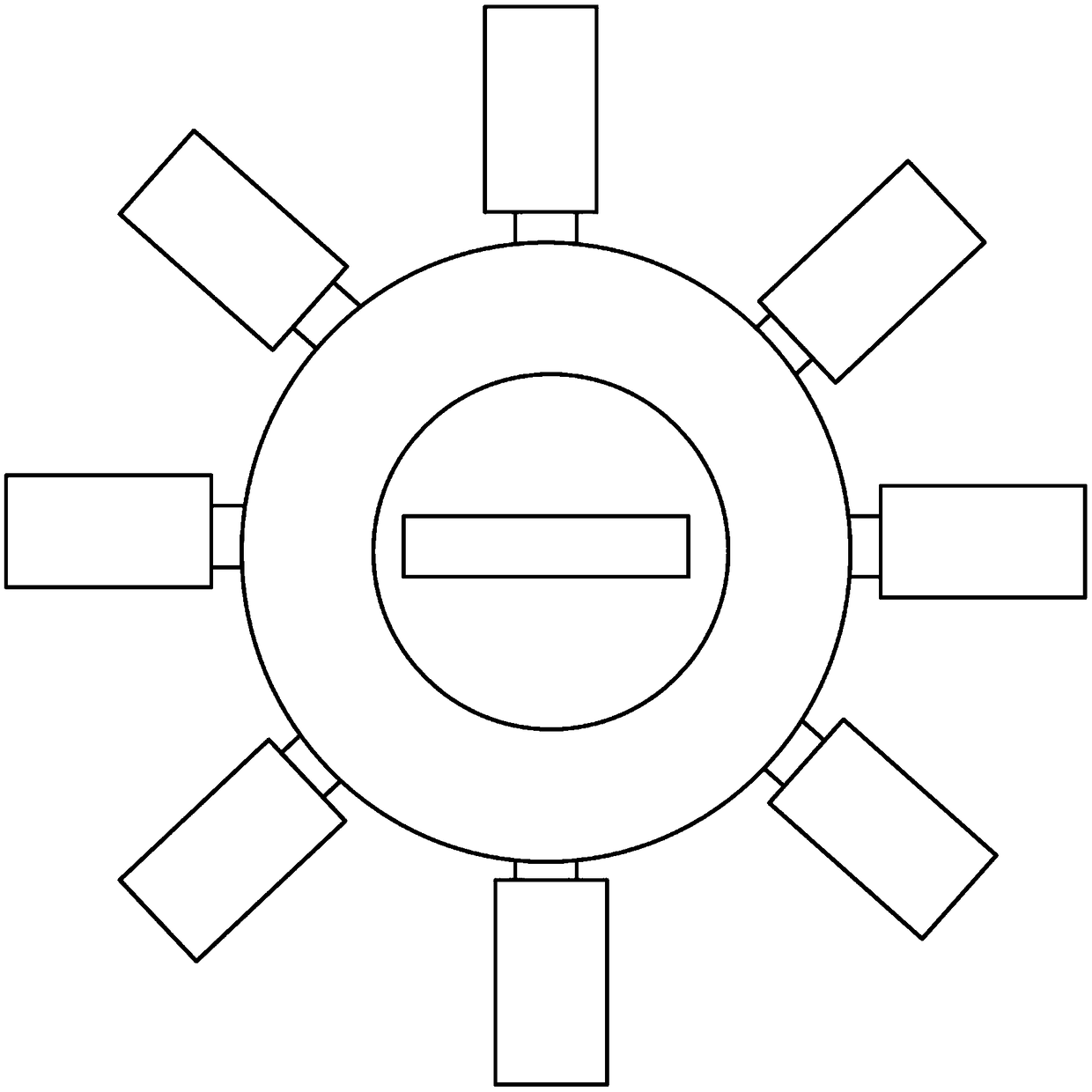

Device and method for dynamically preparing heterocavity bacterium cellulose materials

ActiveCN101914434AUnique three-dimensional network nanostructureHigh chemical purityBioreactor/fermenter combinationsBiological substance pretreatmentsFiberNerve fiber bundle

The invention relates to a device and a method for dynamically preparing heterocavity bacterium cellulose materials. The device comprises a thermometer hole, an acid liquor and alkali liquor adding hole, a handle, a venting hole, a pH meter hole, a nutrition supplement hole, a rotating shaft, a fermentation tank, a motor, a water bath device and a mould. The preparation method comprises the following steps of: inoculating bacterium cellulose strains into a fluid nutrient medium to be propagated and then transferring to a fermentation device provided with specific shape moulds for later dynamic disturbance cultivation, and then obtaining the heterocavity cellulose materials after the cultivation step. The size and the shape of the heterocavity BC (Bacterium Cellulose) materials prepared by utilizing the invention are controllable, and the moulds of the fermentation device can be detached to be reused. The preparation method has the advantages of simple and convenient implementation, low cost and high production efficiency, and is suitable for industrialization production. The heterocavity BC materials can be widely applied to cavity organ succedaneums of artificial vessels, nerve fiber conduits and the like, and can be used as food packing materials, such as meat sausage wrappers, jelly wrappers and the like.

Owner:DONGHUA UNIV

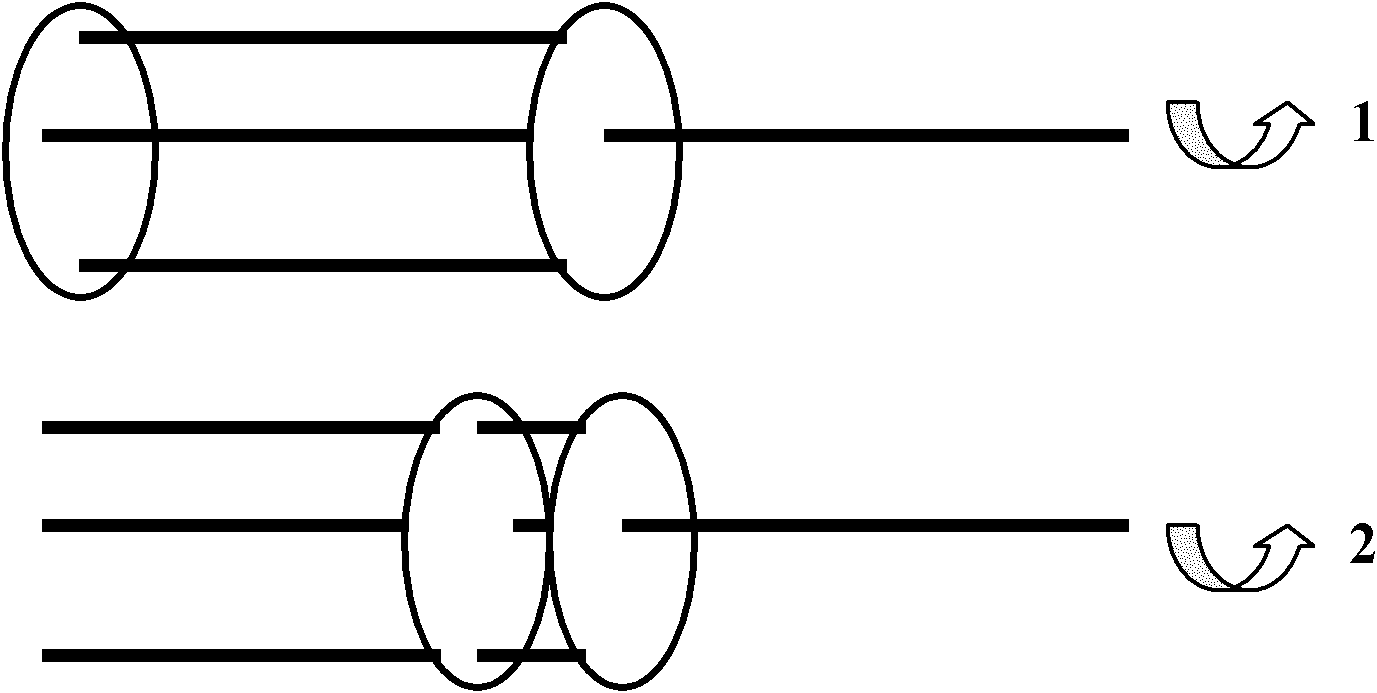

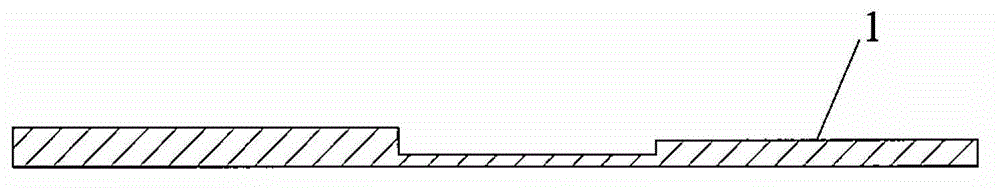

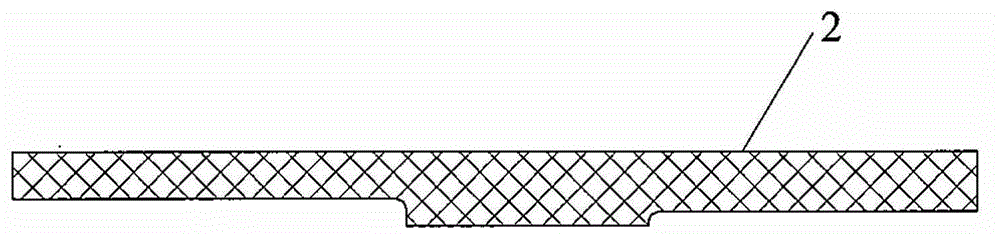

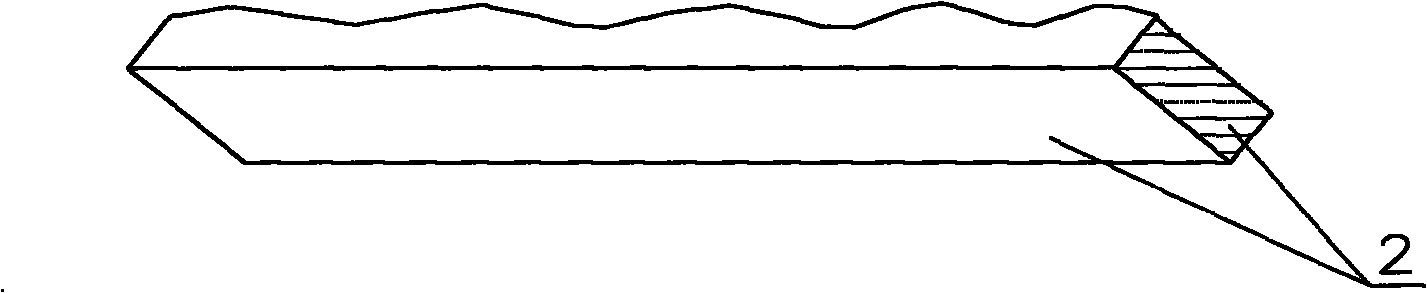

Rolling forming method of metal plate component

The invention discloses a rolling forming method of a metal plate component. The rolling forming method comprises the steps that (1) a wall plate part of a machine body is unfolded into a flat plate structure, and one side of the part is provided with a step; (2) a metal plate blank is prepared according to the unfolded flat plate structure; (3) a padding structure is designed, and the padding structure and the metal plate blank are complementary structures; (4) an elastic padding plate is prepared according to the designed padding structure; (5) the metal plate blank and the elastic padding plate are assembled, and a combined plate blank is formed; (6) rolling parameters of the combined plate blank are determined; (7) the combined plate blank is subjected to numerical control rolling forming; and (8) the metal plate component is extracted. The rolling forming method has the advantages that the precise forming of the component in the great-step-ratio and variable thickness structure can be realized, in addition, the limitation of the thickness and the intensity of processed parts is avoided, meanwhile, the rolling forming method can be utilized for replacing the traditional manufacture method of carrying out chemical milling after forming on the wall plate part of the machine body, the manufacture precision of products is improved, and the environment pollution caused by the chemical milling is also avoided.

Owner:SHANGHAI AIRCRAFT MFG

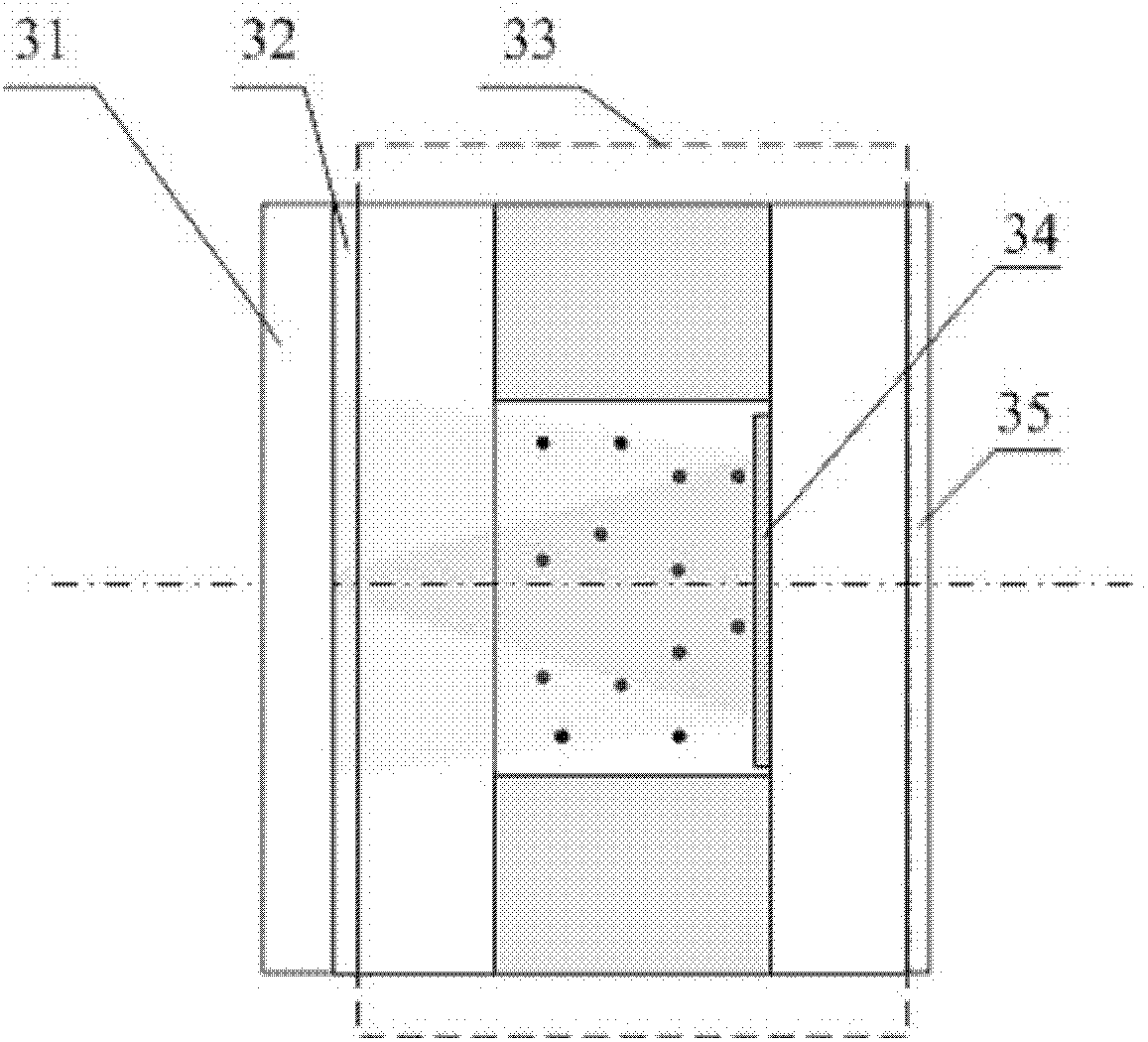

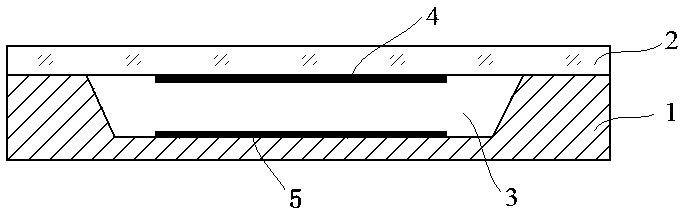

Atom gas cavity device based on MEMS technology and manufacturing method thereof

InactiveCN103941576AUnlimited thicknessIncrease the length of the interaction spaceApparatus using atomic clocksVolume/mass flow by thermal effectsEtchingParticle physics

The invention relates to an atom gas cavity device based on an MEMS technology and a manufacturing method thereof. The atom gas cavity device has a typical sandwich structure and is of a cavity structure formed by defining a silicon wafer with through holes and two glass sheets in a bonding mode. The cross section of each through hole is a parallelogram and is formed by a monocrystalline silicon slice of an N(100) type through silicon anisotropism wet etching, and the side walls of each through hole are crystal faces{111} of the silicon wafer. The two glass sheets and the silicon wafer with the through holes form an atom gas cavity after silicon-glass anodic bonding. The atom gas cavity device can be used for systems of atomic clocks, magnetometers and the like, the distance between two reflectors in the cavity can be increased easily through changing of size design of the atom gas cavity, accordingly, the interaction space lengths between lasers and atom gas are increased, the signal to noise ratio of coherent layout imprisoned effect signals is enhanced, and improvement of stability of a system is facilitated.

Owner:CHINA ELECTRONIC TECH GRP CORP NO 38 RES INST

Collagen fiber regenerated leather surface treatment method

InactiveCN103231576BAvoid the decrease of bond strengthAvoid defects that are not highly simulatedLamination ancillary operationsSynthetic resin layered productsFiberSurface layer

The invention related to a collagen fiber regenerated leather surface treatment method. According to the treatment method, a layer of wet-method resin buffering layer is manufactured on the surface of one side of a substrate cloth with a polyurethane wet method; a dry-method resin surface layer is manufactured with a polyurethane dry method; when the resin buffering layer and the resin surface layer on the surface of one side of the substrate cloth are molded, the surface of the other side of the substrate cloth is subjected to a hot lamination adhesion treatment with collagen fiber regenerated leather. Therefore, a composite leather bonding strength reduction phenomenon caused by a sequence that the substrate cloth is first bonded with the collagen fiber regenerated leather and then subjected to polyurethane wet treatment is avoided. Also, according to the treatment method, polyurethane is directly coated on the substrate cloth, and printing and texture rubbing treatments are then carried out, such that a defect of poor imitation performance of surface manufacturing by using a conventional release paper medium on the substrate surface is avoided. Further, with roughening treatment and the like, the composite leather obtained with the method has an effect closer to that of first-layer genuine leather. The product can be used for manufacturing high-end handbags and sofa materials.

Owner:JIANGYIN JUNHUA TEXTILE TECH

Linear motor, telescopic camera assembly and mobile phone

PendingCN109088964AUnlimited thicknessReduce lagTelevision system detailsColor television detailsLinear motionCamera module

The invention provides a linear motor, a telescopic camera assembly and a mobile phone. A linear motor comprise a bracket, a mover, a stator and an elastic member, wherein the stator is fixed on the bracket, the mover is movably arranged on the bracket and an elastic member is arranged between the mover and the bracket, the stator can drive the mover to perform linear motion, and the elastic member has an elastic force driving the mover away from the stator. A telescopic camera assembly is applied to an electronic device, includes camera module, the camera module is provided with a connectingrod, the mover of the linear motor is provided with a connecting part, the connecting part of the linear motor can be driven to be engaged with or separated from the connecting rod, the elastic driving part is arranged between the electronic equipment and the camera module, and when the connecting part is separated from the connecting rod, the elastic driving part drives the camera module to be telescopic relative to the electronic equipment. The mobile phone comprises a mobile phone body and a telescopic camera assembly, which is a linear motor, a telescopic camera assembly and a mobile phonewith lightweight thickness, good telescopic characteristics and more energy-saving.

Owner:SHENZHEN ZHAOWEI MACHINERY&ELECTRONICS CO LTD

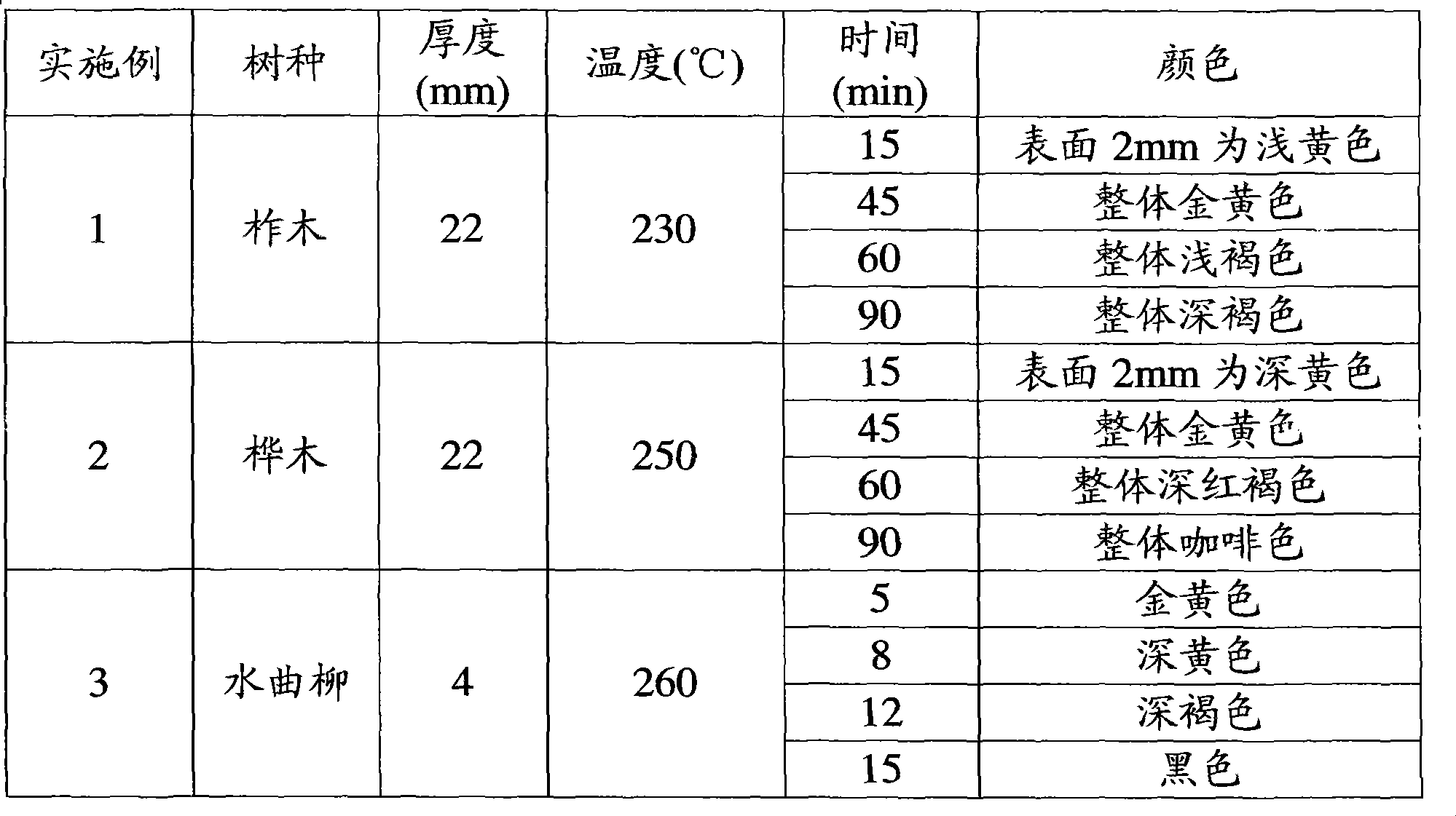

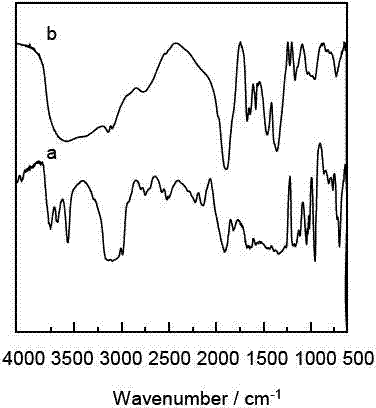

Physical dyeing method for lumber

InactiveCN101367222AWill not cause pollutionNo consumptionWood treatment detailsWater vaporWood machining

The invention provides a method for physically dyeing wood, which belongs to the technical field of wood processing. The method for physically dyeing the wood is to heat the wood and control temperature and time for heating to dye the wood. The method for physically dyeing the wood has the characteristics of small equipment investment, small production field, simple process and short treatment period; moreover, no pollution is generated during dyeing treatment, with safe production and high production efficiency; besides, the dyeing process does not require water vapor, so that the method has the advantages of no water consumption, small heat energy consumption, energy conservation, low production cost and the like during the process of dyeing treatment. Furthermore, the thickness of dyed wood is not restricted, and the method overcomes the defects of deformation, cracking, color difference and the like for the wood during production process, and has high product quality; and dyed wood has dimension stability, improved noncorrosibility and wide application range.

Owner:广西贺州恒达板业股份有限公司

Method for preparing metal organic framework (MOF) membrane

ActiveCN102773025AEasy to manufactureLow costSemi-permeable membranesPolymethyl methacrylateMetal-organic framework

The invention belongs to the field of the preparation of an MOF membrane on a novel membrane growth substrate, and concretely relates to a method for preparing the MOF membrane on an acidified polymethyl methacrylate membrane substrate. The method has the advantages of membrane formation on surfaces of various carriers, expandable application range of the MOF material and the like.

Owner:KEY LAB OF INORGANIC SYNTHESIS & PEPARATIVE CHEM AT JILIN UNIV IN ZHUHAI

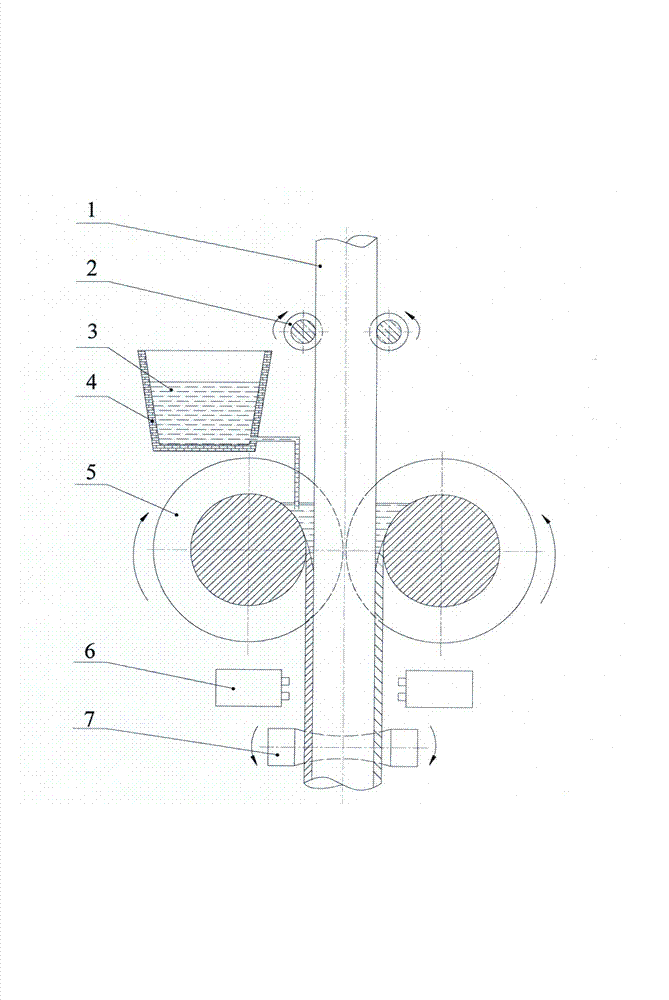

Method for producing bimetal composite material by adopting cold core continuous casting and rolling process

ActiveCN102825067ALow requirements for billet size and shape accuracyHigh yield and metal utilizationMetal rolling arrangementsManufacturing engineeringPipe

The invention relates to a method for producing a bimetal composite material by adopting a cold core continuous casting and rolling process. The method is characterized by comprising the following steps of: using an inlet pinch and guide device to feed a cold core base material into a groove of a casting and rolling roller, continuously pouring a molten-state covering material in a ladle into an annular crystallizer constituted by the base material and the groove of the casting and rolling roller, driving the casting and rolling roller, continuously and uniformly coating the molten-state covering material on the surface of the cold core base material, and arranging a secondary cooling device and an outlet pinch and guide device on the outlet side so as to realize cold core continuous casting and rolling composite molding of a bimetal composite pipe or rod. The method has the advantages that the bimetal composite pipe or rod produced by the technological method has the advantages of low requirements on size and shape precision of a stock, no need of pre-assembly, high finished product rate, high metal utilization rate, no limitations on length and thickness of a covering layer of a product, a wide range of specifications of the product and the like, and the method is of a high-efficient production technological method. The product can be directly used as a finished product or be used as the stock for pipe rolling, cold drawing and other process steps.

Owner:YANSHAN UNIV

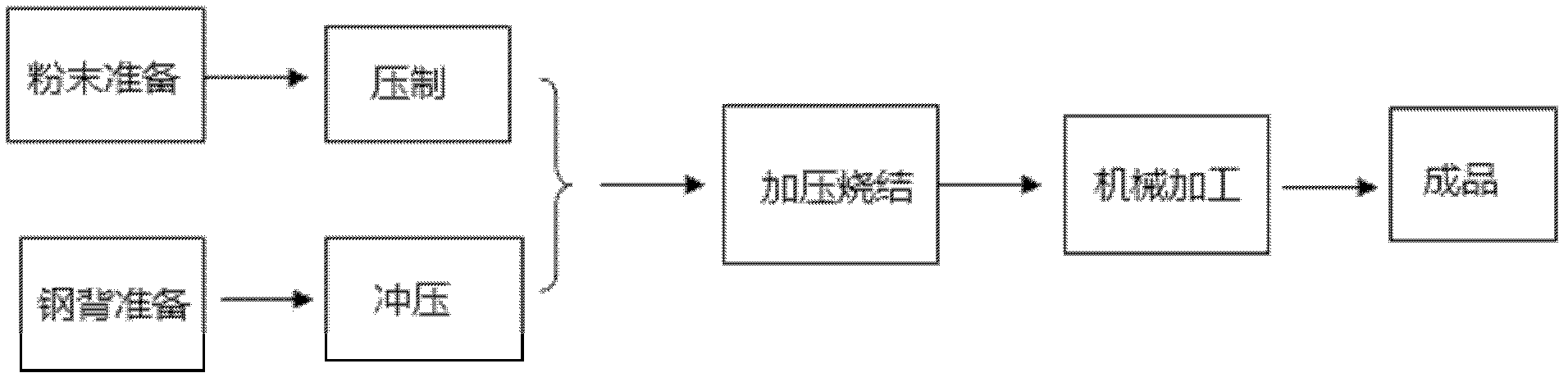

Sintered metal matrix friction sheet and deep processing production technology thereof

The invention discloses a deep processing production technology of a sintered metal matrix friction sheet and a sintered metal matrix friction sheet prepared by the production technology. The sintered metal matrix friction sheet comprises a steel backing layer and one or two friction layers. The production technology includes the steps of powder spread, primary sintering, primary rolling, secondary sintering, secondary rolling, annealing treatment, and stamping to obtain the sintered metal matrix friction sheet. The defects that prior sintered metal matrix friction materials are large in production technology investment, complicated in processing, low in production efficiency, unstable in product quality, uncontrollable and the like are overcome, the method can be applicable to the production of iron-based and copper-based friction materials, the thicknesses of the steel layer and the friction layers can be controlled respectively, the control accuracy is high, the finished product qualities of the friction sheets are stable, the device investment is small, the operation is simple, and the production efficiency is high.

Owner:SHANGHAI HEWEI IND

Radiation-resisting composite dope

The invention belongs to the inorganic non-metallic material field, disclosing a radiation proof composite paint formulation. The radiation proof composite paint of the invention is formed by the following compositions, 15-25wt% ferric oxide whose grain size is 0.1mm-1.3mm, 2.7-8wt% tungsten ore powder whose grain size is 0.1mm-0.3mm, 4-10wt% rectorite ore whose grain size is 100-200 mesh, 40-50wt% barium sulfate whose grain size is 0.1mm-2.0mm, 0.7-1.3wt% ferric sulfate whose grain size is 1.0mm-1.5mm, 20-50wt% cement and 0.5-0.9wt% borax. The radiation proof composite paint of the invention has the advantages of environmental protection, convenient construction and firm bonding.

Owner:刘文

Non-plate gold blocking method

InactiveCN105216468AEasy transferImprove efficiencyDuplicating/marking methodsOther printing apparatusBlock effectBase oil

The invention relates to and provides a non-plate gold blocking method. The non-plate gold blocking method comprises the following steps that firstly, the surfaces of various package materials are coated with base oil through a printer; and secondly, alumite is attached to the surfaces of the materials, the alumite is transferred after passing a hot pressing roller, and gold blocking is finished. The non-plate gold blocking method has the beneficial effects that the base oil can be printed into various high-precision patterns, the printing coating weight can be adjusted, and therefore a protruding emboss effect can be formed; compared with traditional gold blocking, plate making is not needed, and gold blocking patterns are finer; a special gold blocking machine is not needed, and pattern transferring can be easily finished through an ordinary film laminating machine; too long plate correcting time is not needed, and the concept of local pressure supplementing is avoided; the method is not influenced by the breadth or the batch, efficiency is extremely high, and the gold blocking effect is better; and the thickness of gold blocking emboss manufacturing materials is not limited, and the non-plate gold blocking method is suitable for the gold blocking effect of various materials.

Owner:SHANGHAI JIELONG ART PRINTING +1

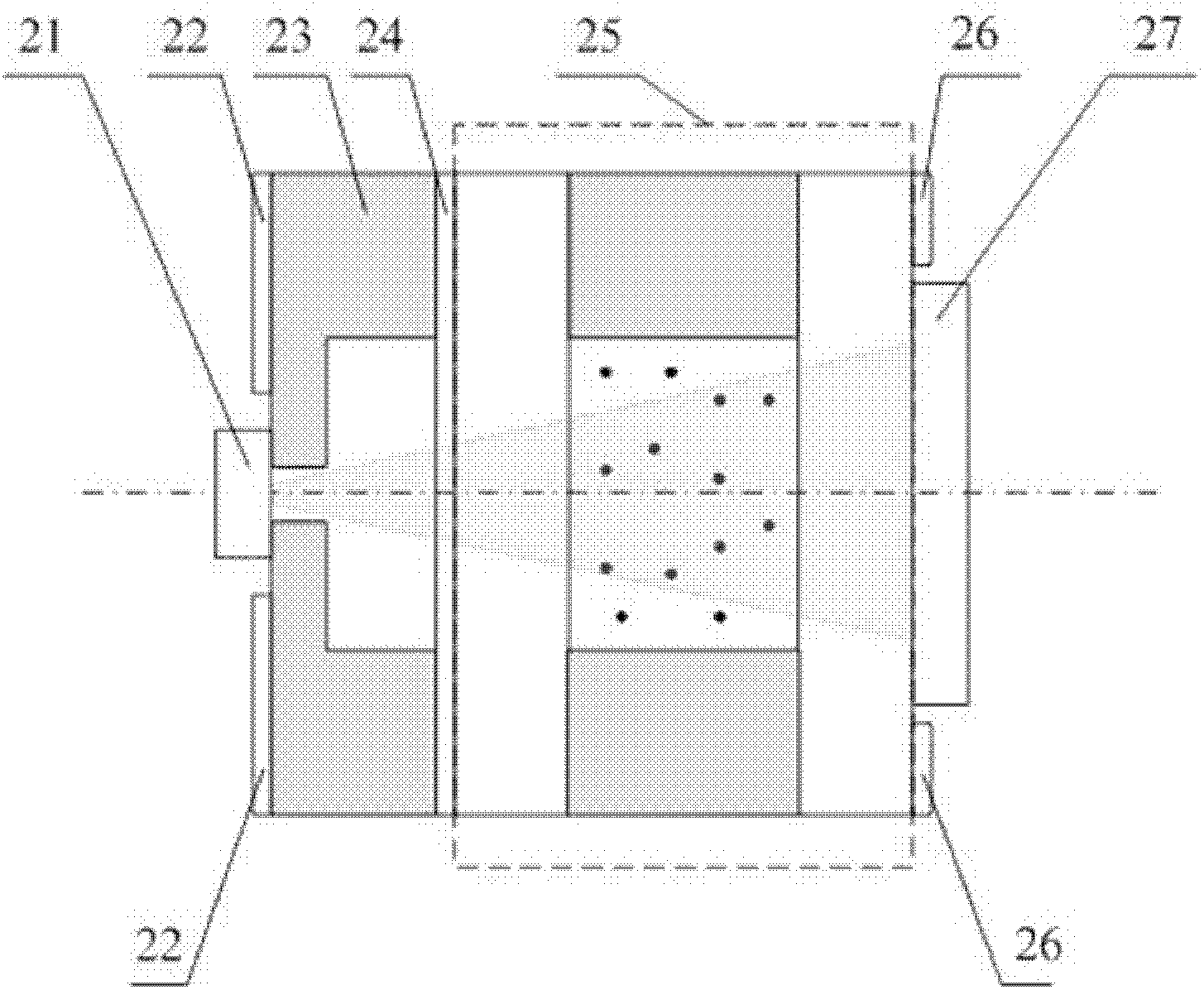

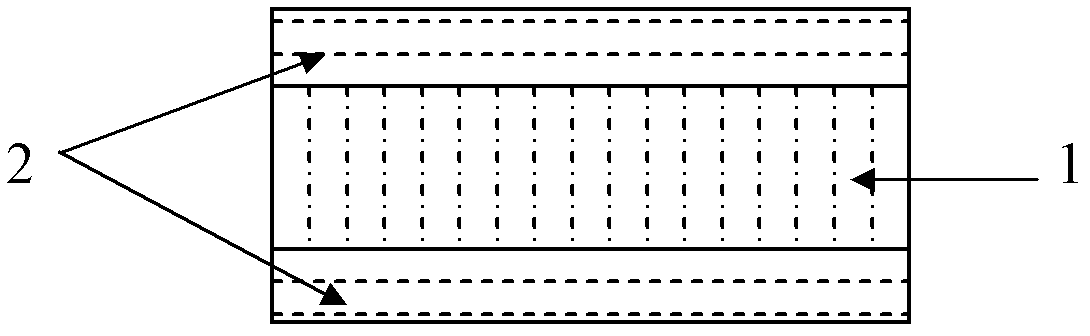

Atom gas cavity device with double reflectors and groove-shaped structure and manufacturing method thereof

InactiveCN103941577AUnlimited thicknessIncrease the length of the interaction spaceApparatus using atomic clocksVolume/mass flow by thermal effectsEngineeringMechanical engineering

The invention relates to an atom gas cavity device with double reflectors and a groove-shaped structure and a manufacturing method of the atom gas cavity device. The atom gas cavity device is composed of a cavity body structure defined by a silicon wafer and a glass sheet in a bonding mode, wherein the bottom of the silicon wafer is provided with one reflector, the silicon wafer is provided with a groove, and the other reflector is arranged inside the glass sheet. The cross section of the groove is of an inversed trapezoidal shape structure, and is formed by a 100-type monocrystalline silicon wafer in a silicon anisotropic wet etching mode. The side walls of the groove are 111-type crystal faces of the silicon wafer. The interior of the glass sheet and the bottom of the groove of the silicon wafer are respectively provided with one reflector, and the reflectors are used for reflecting laser many times. The atom gas cavity device can be used for atomic clocks, magnetometers and other systems, laser is reflected many times between the double reflectors, the space length of interaction between laser and atom gas is increased, the signal-to-noise ratio of coherent population trapping signals is increased, and system stability can be improved.

Owner:CHINA ELECTRONIC TECH GRP CORP NO 38 RES INST

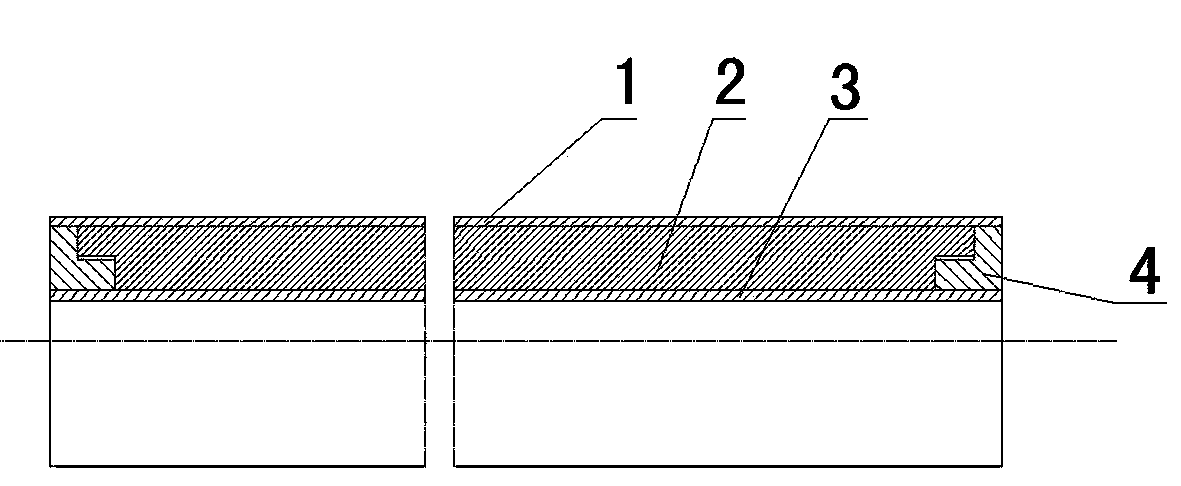

Prefabricated reinforced concrete composite heat-preservation outer wall plate and manufacturing and installation method thereof

PendingCN106836526ADoes not affect strengthReduce weightHeat proofingReinforced concreteArchitectural engineering

The invention provides a prefabricated reinforced concrete composite heat-preservation outer wall plate and a manufacturing and installation method thereof. The prefabricated reinforced concrete composite heat-preservation outer wall plate comprises a heat-preservation plate body and a prefabricated reinforced concrete wall plate body which is installed on the heat-preservation plate body; and a plurality of installation protruded blocks are installed on the end face, facing the prefabricated reinforced concrete wall plate body, of the heat-preservation plate body, and installation grooves matched with the protruded blocks are formed in the prefabricated reinforced concrete wall plate body. The installation method comprises the following steps that a steel plate is welded onto an upper wing and a lower wing of a steel girder on a to-be-constructed wall face correspondingly; and the prefabricated reinforced concrete heat-preservation wall plates are fixed to the upper wing and / or lower wing of the steel girder through bolts. According to the prefabricated reinforced concrete composite heat-preservation outer wall plate and the manufacturing and installation method thereof, the prefabricated reinforced concrete wall plate body is combined with the heat-preservation plate body, and part of the heat-preservation plate body is embedded into the concrete wall plate body, so that the weight of the concrete wall plate body is reduced, the strength, the rigidity and the using function of the concrete wall plate body are not lowered, the installation technique is simple, and operation is convenient.

Owner:DAYUAN CONSTR GRP

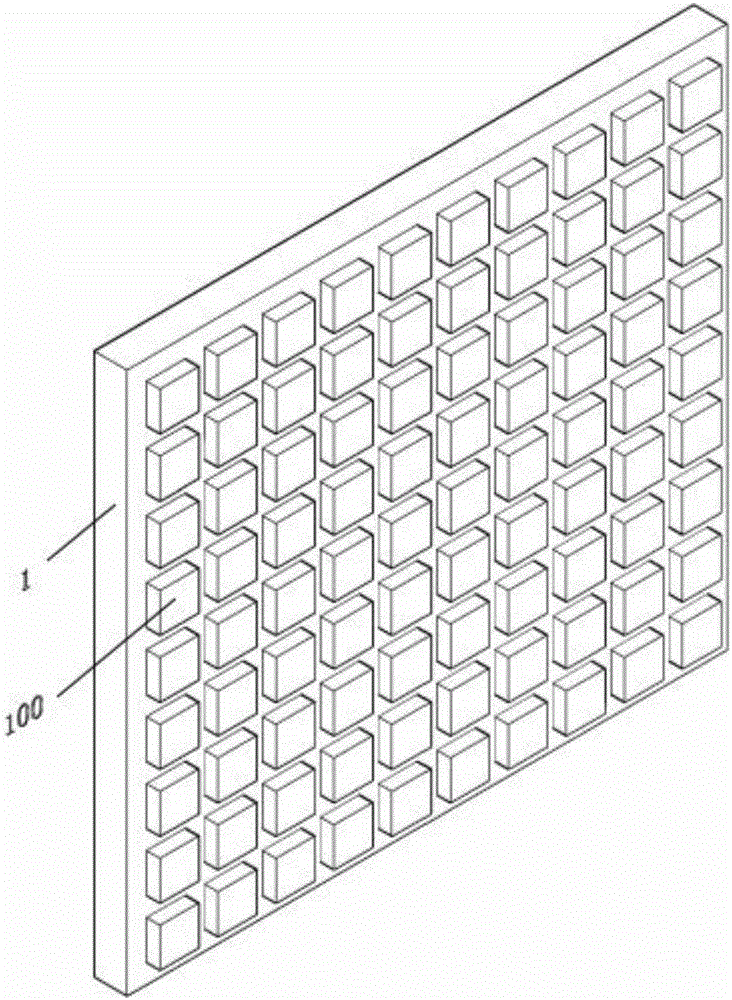

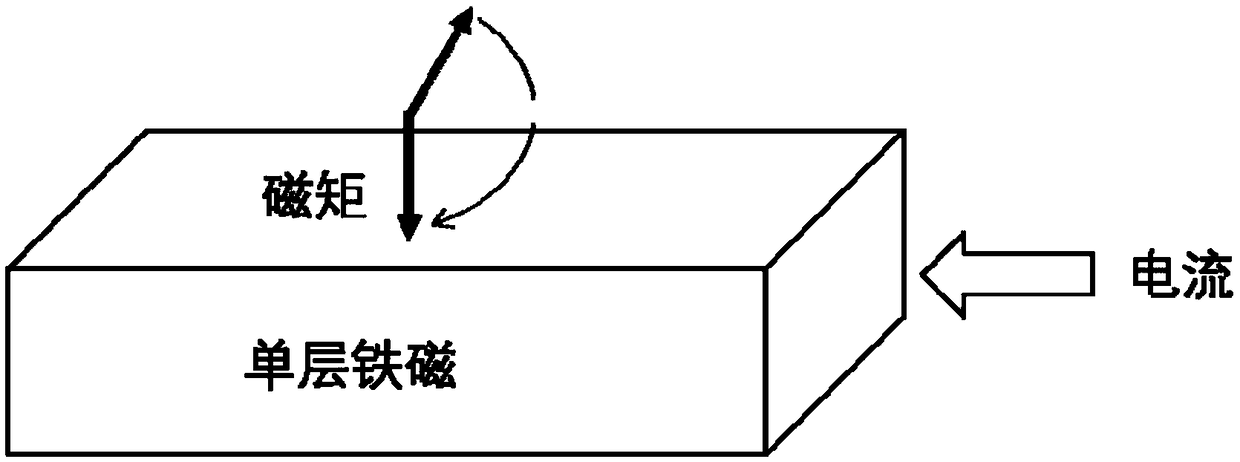

Single-layer ferromagnetic materials with current-driven magnetic moment flipping and their applications

ActiveCN109273593ANot easy to damageUnlimited thicknessMagnetic-field-controlled resistorsGalvano-magnetic material selectionSpin momentCoupling

The invention relates to a single-layer ferromagnetic material with magnetic moment flipping driven by current and application thereof. The single-layer ferromagnetic material is a thin film with thickness of 1-100nm, has strong spin-orbit coupling action, generates spin moment after current is introduced, and flips self-magnetic moment of the single-layer ferromagnetic material by spin moment. The invention utilizes current to generate spin moment in monolayer ferromagnetism, and inverting the magnetic moment of the single-layer ferromagnetism by using the spin moment, The device can be applied to magnetic random access memory and spin logic device, and the device based on the technology of the invention can have unlimited thickness so as to have higher thermal stability, that is, nonvolatility, and simplify the structure and preparation process of the device in application, and has great cost advantage.

Owner:TONGJI UNIV

Production method of lead-coated copper plate grid of lead acid storage battery and special combined mould

InactiveCN102629689BReduce usageIncrease profitElectrode carriers/collectorsCopper wireMechanical engineering

The invention discloses a production method of a lead-coated copper plate grid of a lead acid storage battery. The specific production method comprises the following steps of: closing and fixing a mould A and a mould C; heating to 120-140 DEG C; casting for the first time to form a lead layer with a groove; after cooling molten lead and the moulds, removing the mould C from the mould A; holding a copper wire serving as a copper plate grid in the groove of the copper layer; heating a mould B with the groove to 120-140 DEG C; closing and fixing the mould A and the mould B; and casting for the first time to construct the lead-coated copper plate grid of which the surface is completely covered by lead. The special combined mould of the production method is provided with the mould A and the mould B which are mutually corresponding to each other, and has the special points of being provided with the mould C which is matched with the mould A for use, wherein the inner surface of the mould C is provided with a convex edge which is matched with the groove on the mould A; the size of the cross section of the convex edge is less than that of the cross section of the groove on the mould A; and the diameter of the cross section of the convex edge is the same as that of the copper wire of the copper plate grid.

Owner:隋明奎 +1

Inertial sensor and production method thereof

The present invention provides an inertial sensor and a production method thereof, wherein electrochemical etching is performed on a first silicon substrate to form a porous silicon layer, then a monocrystalline silicon layer, a sacrificial layer, a through hole, a wiring layer and a buried layer are sequentially formed, a second silicon substrate and the first silicon substrate are bonded, the porous silicon layer is etched so as to separate the first silicon substrate and the second silicon substrate, and finally the monocrystalline silicon layer is patterned and the sacrificial layer exposed on the monocrystalline silicon layer is removed through an etching manner so as to form the movable structure layer. According to the present invention, the inertial sensor production method is compatible with the conventional IC manufacturing method so as to easily achieve integration of the micro-structure and the IC, and the monocrystalline silicon layer growing on the porous silicon layer in the epitaxial manner has advantages of low stress small, no limitation on the movable structure thickness and the like so as to easily reduce the pipe core area and reduce the cost.

Owner:HANGZHOU SILAN MICROELECTRONICS +1

Production method of totally-coated metal composite pipe

InactiveCN104191182ALow costCorrosion resistantCorrosion preventionPipe protection against corrosion/incrustationChemical industryTitanium metal

A production method of a totally-coated metal composite pipe is technically characterized by including the steps of hermetically nesting a titanium tube, a steel tube and another titanium tube, connecting titanium heads to two ends of the steel tube in a threaded manner, and welding the inner titanium tube and the outer titanium tube on the titanium heads to ensure the steel tube is completely coated with titanium integrally; performing rolling, combining, rounding, straightening, deheading and sizing to obtain a finished product. According to the method, the totally-coated metal composite pipe is manufactured by a cold-rolling method. In terms of oil exploitation, chemical industry, fine chemicals, heat exchangers and marine pipelining, the composite pipe is completely coated with the titanium to keep properties of the titanium, product strength is guaranteed by using a low-cost base steel tube as a structural portion, the titanium heads at two ends can be connected by welding, and a screw thread can also be made for mechanical connection. The totally-coated metal composite pipe has the advantages such that the performance is high, the cost is low, the service life is long, and applicable range is wide. The production method is insusceptible to seasons and free of environmental pollution, and production scale and product specification are controllable.

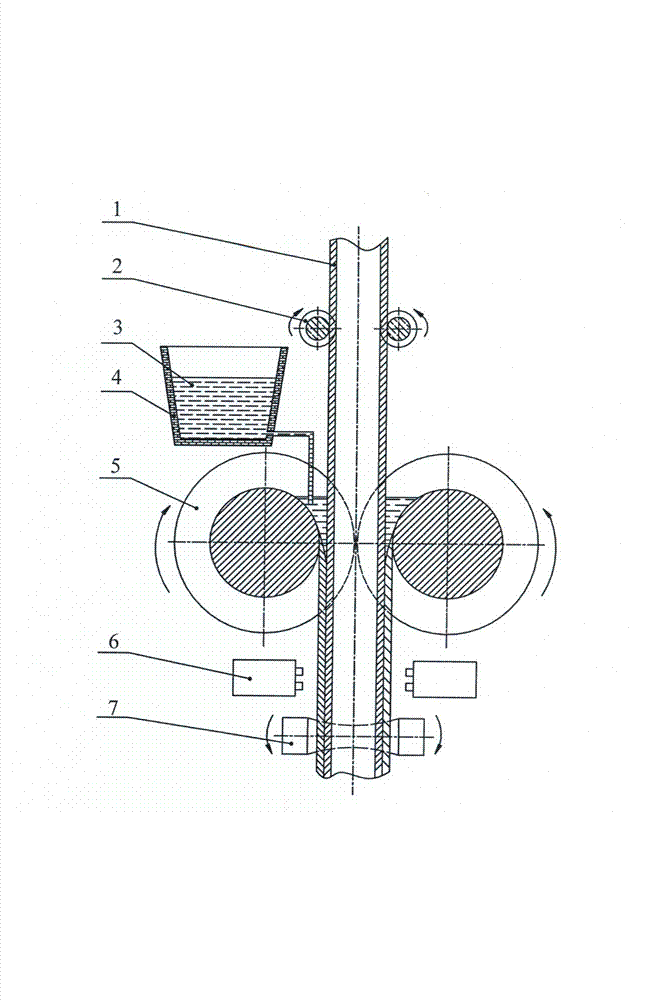

Timber wood hot pressing charing intensification method

ActiveCN101214675BUnlimited thicknessGood dimensional stabilityDrying using combination processesWood compressionCarbonizationMechanical property

The present invention discloses a hot-pressing carbonization strengthening method of timbers, which includes drying, planing, hot-pressing carbonization, cooling and other steps. The present invention applies a hot press as a timber-carbonizing device, and the timbers under the state of compression are processed by hot-pressing carbonization. The present invention is characterized in that the investment on carbonization devices is less, the carbonization process is simple, the production is safe, the production efficiency is high, the consumption of heat energy is little, and the production cost is low; moreover, the thickness of the carbonized timbers is not limited, the defects of the timbers, such as deformation, cracking, stiker stain, color difference, knot fall-off, etc., do not occur in the process of production, so the quality of products is high; not only is the size stability and noncorrodibility of the carbonized timbers improved, but also the density and mechanical property of the timbers is increased.

Owner:广州豪沃仕家具有限公司

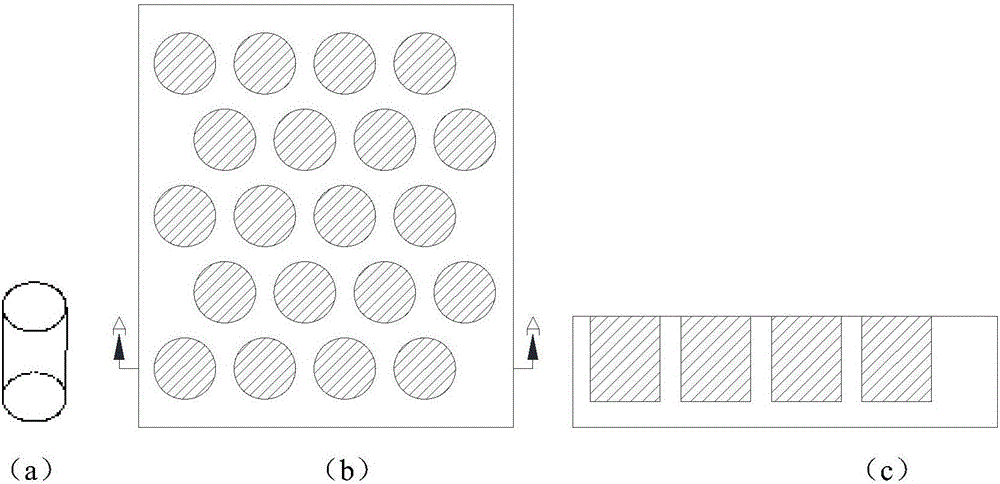

High-strength high-performance filter element

InactiveCN104190133AIncrease stiffnessEasy to processStationary filtering element filtersFinenessSteel belt

The invention belongs to the technical field of filter devices and discloses a high-strength high-performance filter element. The high-strength high-performance filter element comprises upper end covers, lower end covers, a central pipe and a filter cartridge arranged at the periphery of the central pipe; the upper end covers and the lower end covers are arranged on the upper and lower ends of the filter cartridge and the center pipe respectively; the filter cartridge comprises a waved filter layer and waved metal nets which are arranged on the inner and outer sides of the waved filter layer; the filter layer is formed by orderly stacking a glass fiber felt layer, a glass fiber filter paper layer and a non-woven cloth layer; the non-woven cloth layer is close to the central pipe; the body of the central pipe is formed by narrow steel strips which are spirally coiled in a staggered manner, wherein the narrow steel strip of the upper layer is fixedly connected with the narrow steel strip of the lower layer, and a squeezing hole is formed in the length direction of the narrow strips. The high-strength high-performance filter element is reasonable in design and simple in structure; the filter element has high strength and safety, and therefore, the filtering fineness of a filter is guaranteed, and moreover, the filtering efficiency of the filter is well improved and the service life of the filter is prolonged.

Owner:SOUTH CHINA UNIV OF TECH

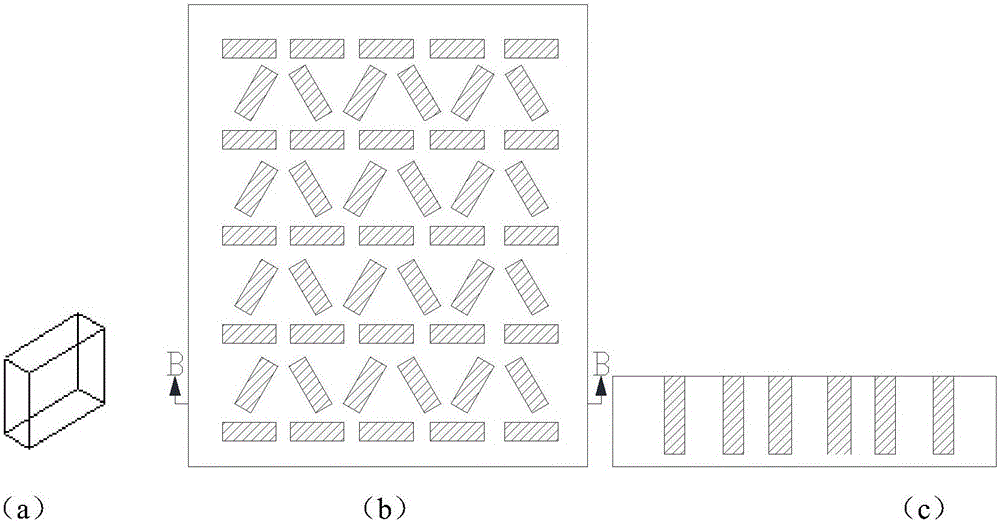

Method for preparing waved stripe bamboo board stuck by side bamboo strips

The invention relates to a method for preparing a waved stripe bamboo board stuck by side bamboo strips, comprising the following steps of: pretreating fresh bamboo, blanching, vulcanizing or dyeing, fixing width and thickness, drying after dipping gum or airing after coating gum, hot pressing, cooling, storing at constant temperature and cutting into finished products. The hot-pressing process comprises the following steps of: standing and stacking the bamboo strips with the fixed width and thickness into a bamboo board blank with needed width, feeding the bamboo board blank into a hot-press which pressurizes from above and supports the bamboo board blank by a waved curved-surface steel press strip from two side surfaces, and pressing the bamboo board blank stuck by side waved bamboo strips. The thickness of raw materials of the waved stripe bamboo board is not limited, various bamboo raw materials can be sufficiently used without beingcut into thin bamboo sheets. The method can save electricity of 20 percent and manpower of 20 percent; and the waved stripe bamboo board has high strength, resists abrasion and environment protection, can be applied to technical products of floors, furniture, outer shells of household appliances, vases, and the like, and can achieve the effect of using bamboo to replace wood, plastic and steel.

Owner:赵斌

Radiation-resisting composite dope

InactiveCN100588689CImprove the protective effectUnlimited thicknessCement coatingsSulfateMetallic materials

Owner:刘文

Lightweight flexible high-thermal-conductivity nanometer carbon composite film and preparation method thereof

ActiveCN106378984AOvercoming the problem of easy peelingImprove adhesionMaterial nanotechnologyLaminationCarbon compositesEarth observation

The invention provides a lightweight flexible high-thermal-conductivity nanometer carbon composite film and a preparation method thereof. The nanometer carbon composite film comprises a plurality of composite units, which are laid up in sequence. Each composite unit includes flexible bonding layers and a graphene film layer, wherein the flexible bonding layers are arranged at two sides of the graphene film layer. The nanometer carbon composite film is prepared by laying the composite units up in sequence and being subjected to thermocompression. The prepared nanometer carbon composite film has characteristics of high thermal conductivity, light weight and flexibility, and has an inside-surface thermal conductivity no less than 500 W / (m*K) and the density no more than 2.0 g / cm<3>. The nanometer carbon composite film has the thermal conductivity still no less than 500 W / (m*K) after being repeatedly bended at 180 degrees for 50 times, and no graphene is peeled off the surface. The nanometer carbon composite film has bright application prospects in the fields, such as satellite communications, earth observation, deep space exploration and civil electronic devices.

Owner:SHANGHAI COMPOSITES SCI & TECH CO LTD

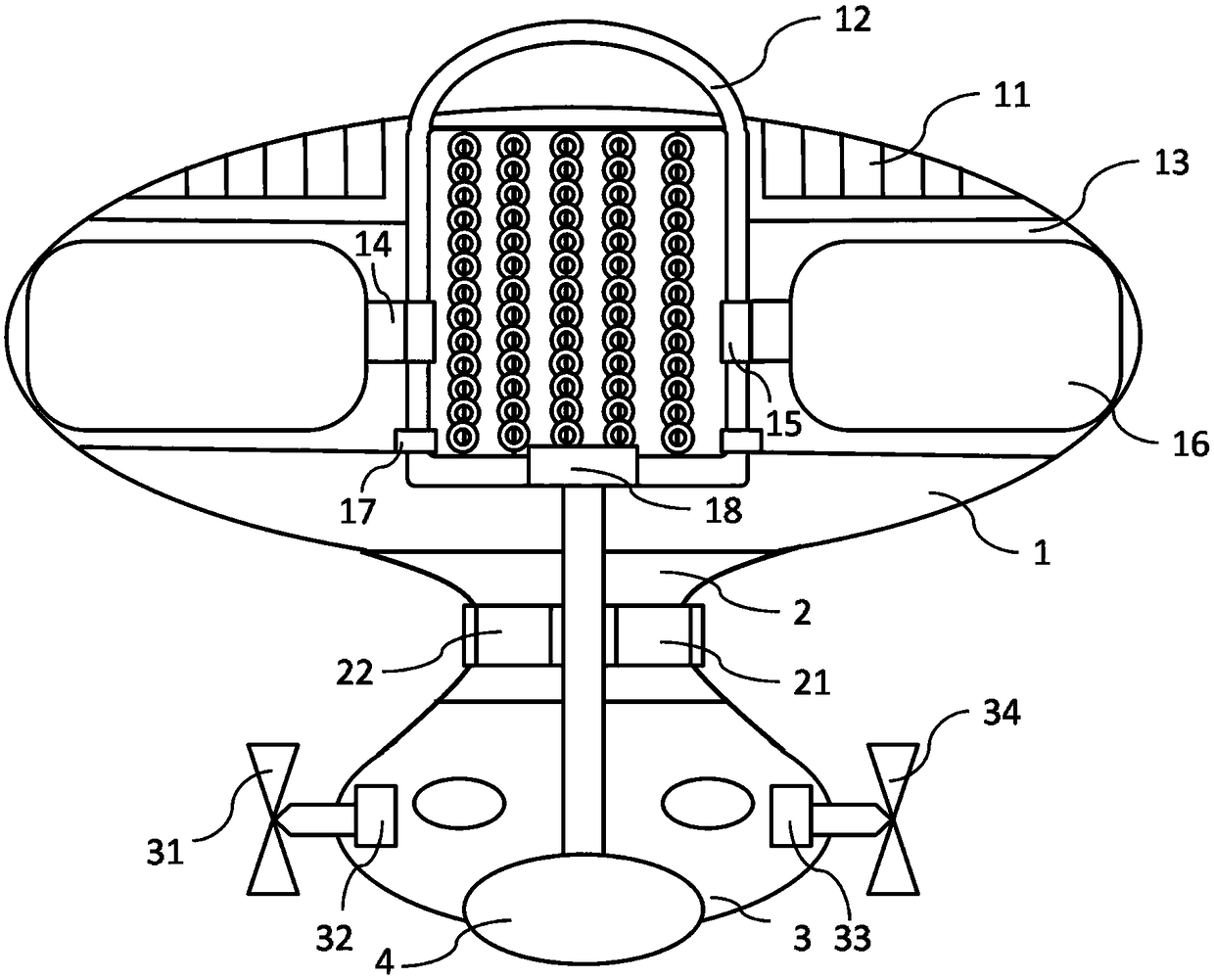

Intelligent petroleum machine for petroleum removal at sea

ActiveCN108867592AAutomation noTake advantage ofWater cleaningGeneral water supply conservationMaterial resourcesPetroleum

The invention provides an intelligent petroleum machine for petroleum removal at sea. Specifically, the intelligent petroleum machine comprises a petroleum removal machine body; the intelligent petroleum machine can achieve automatic and uninterrupted operation, is equipped with a solar storage battery and can fully utilize the characteristic of sufficient light at sea to reduce energy consumptionand make full use of environmental resources; a bioreactor can be periodically replaced and adjusted, the two modes of physical petroleum removal and biological petroleum removal are integrated, thepetroleum removal efficiency is high, and the thickness of a petroleum layer is not limited; the intelligent petroleum machine can replace a traditional petroleum containment treatment mode, the position of petroleum stains is judged through an optical sensor, the intelligent petroleum machine moves to the position of the petroleum stains, and the manpower and material resources are saved.

Owner:YANCHENG DEZHENG MACHINERY CO LTD

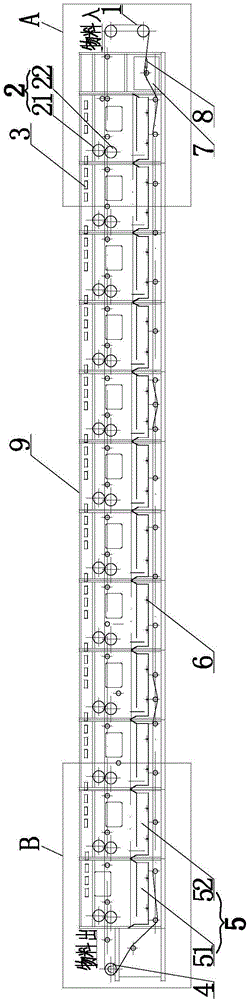

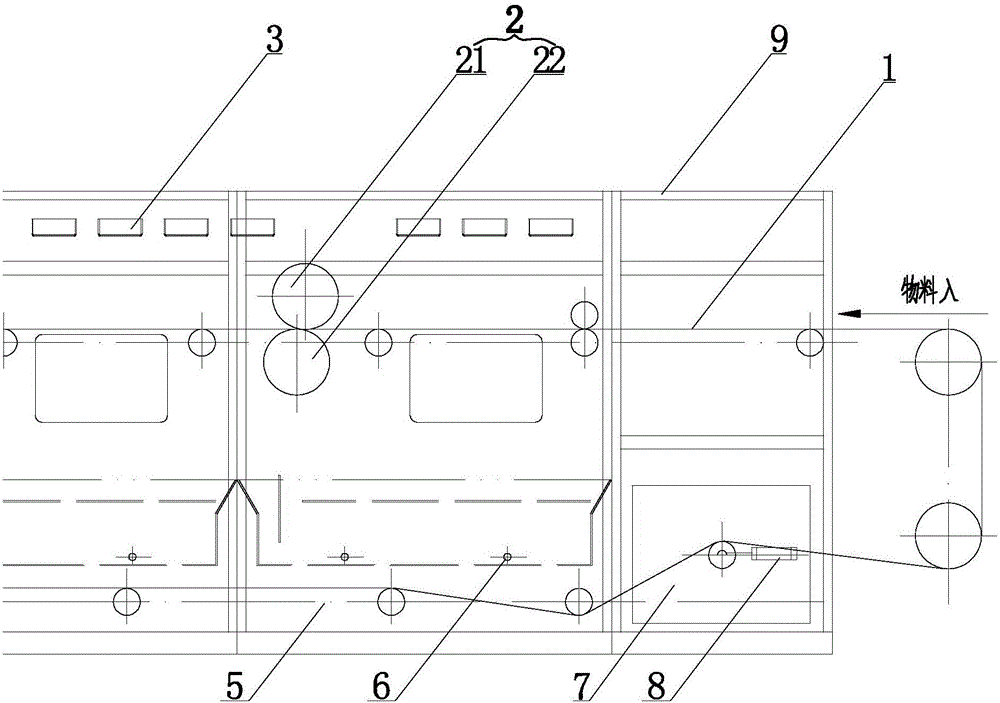

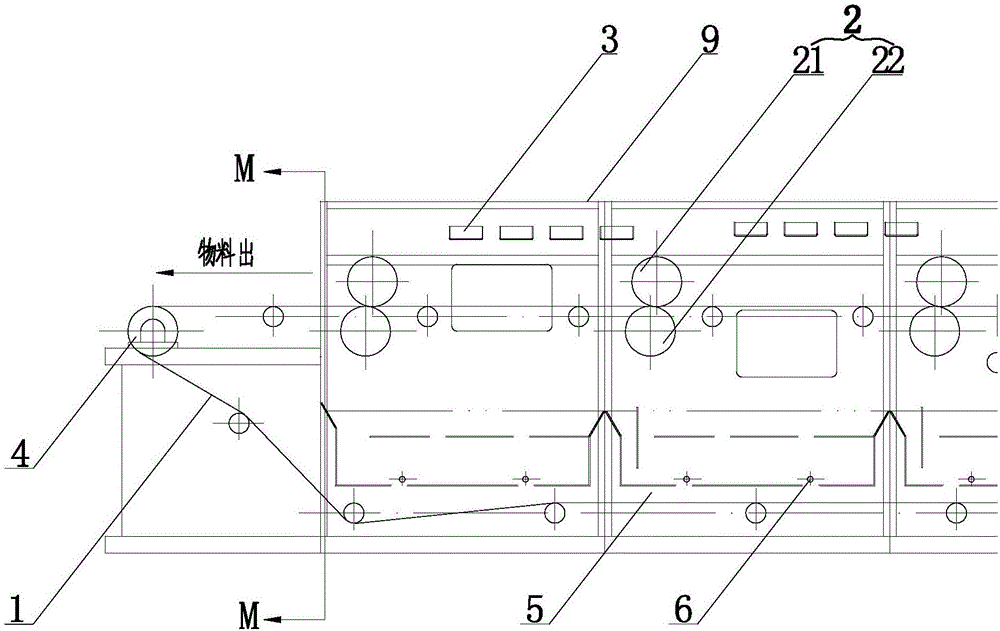

Spraying-type loose fiber treatment technology

ActiveCN106637754AGuaranteed treatment effectFully dyedTextile treatment containersTextile treatment machine arrangementsFiberTherapeutic effect

The invention relates to a spraying-type loose fiber treatment technology, and belongs to the technical field of loose fiber treatment. Loose fibers to be treated are placed on a treatment net, a plurality groups of rollers are arranged in the treatment net advancing direction, the rollers comprise the upper rollers and the lower rollers, the upper rollers and the lower rollers are arranged over and under the treatment net respectively, the central axes of the upper rollers and the central axes of the lower rollers are staggered, the central axes of the upper rollers penetrate through the lower rollers, the rotating direction of the upper rollers is opposite to that of the lower rollers, and then the loose fiber treatment net is dragged to advance; treatment liquid is sprayed downwards from the position over the upper rollers, and the loose fibers on the treatment net are delivered out after being treated. The spraying-type loose fiber treatment technology is applied to the processes of loose fiber dyeing, color fixing, cleaning, softening and the like and has the advantages of being low in energy consumption, large in treatment quantity, good in treatment effect and the like.

Owner:绍兴国周针织科技有限公司

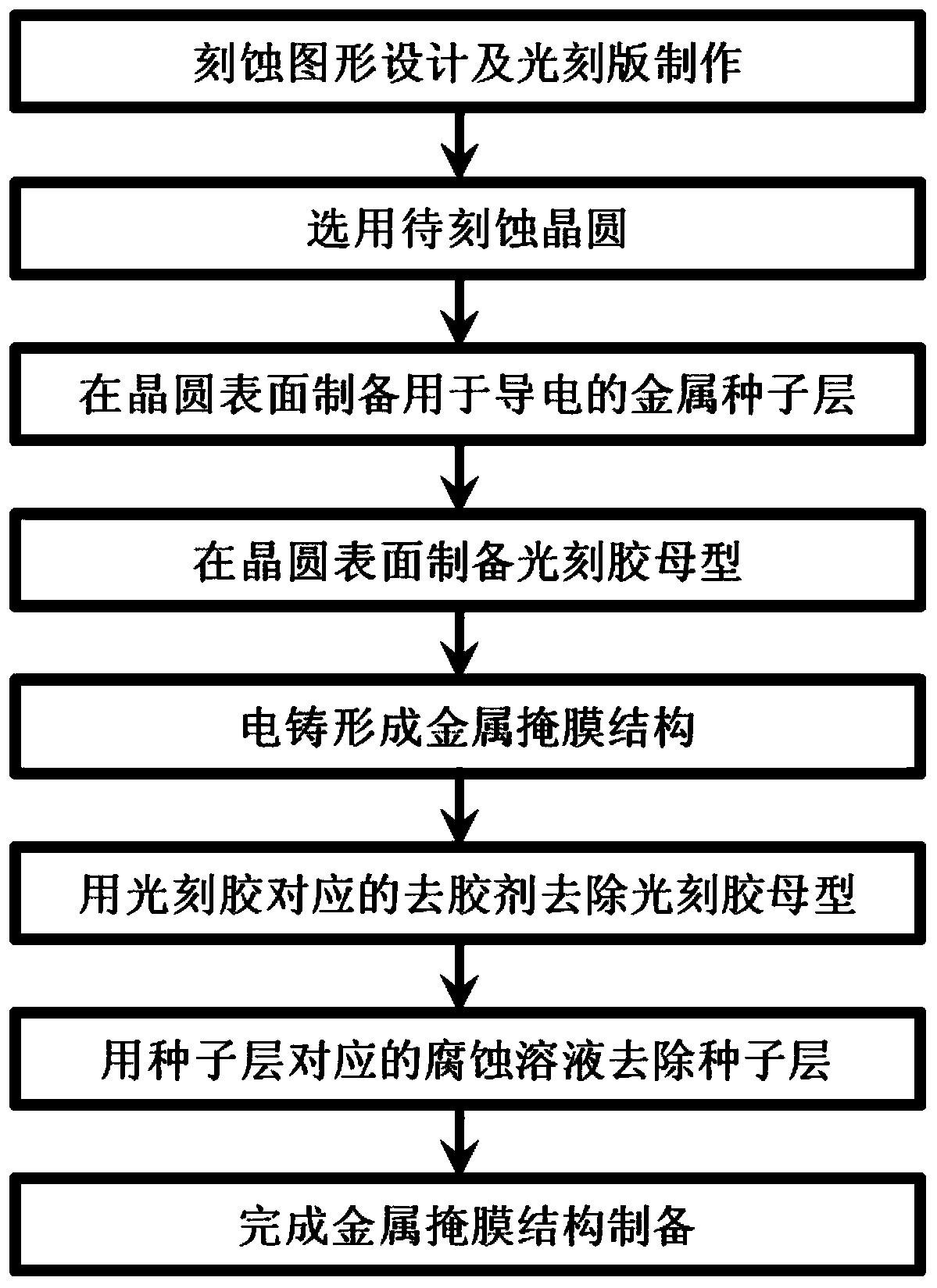

Metal mask forming method for wafer dry etching process

InactiveCN109712879AIncreasing the thicknessWide thickness rangeSemiconductor/solid-state device manufacturingElectroforming processesMicrometerPhotoresist

The invention discloses a metal mask forming method for a wafer dry etching process. The method is particularly suitable for a monocrystal silicon carbide or quartz wafer etching process, and comprises preparing a metal seed layer on a wafer surface; forming a photoresist model by a photoresist; and preparing an electroformed metal mask by an electroforming method. The thickness of the prepared metal mask is not limited, and can range from hundreds of nanometers to hundreds of micrometers. Thus, the method greatly expands the thickness range of the metal mask, avoids the poor lateral etching precision caused by the wet etching process of the metal mask, and in particular, can improve the pattern accuracy of metal masks for a thick etching process.

Owner:BEIJING RES INST OF TELEMETRY +1

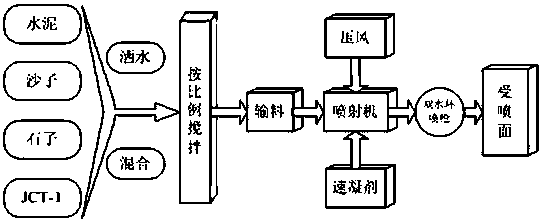

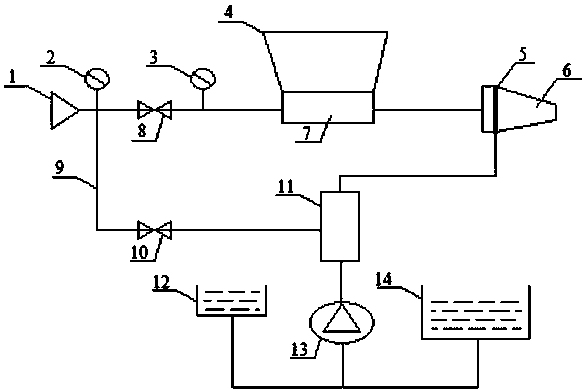

Heap sprayed concrete rapid wall constructing method for coal mine underground

The invention discloses a heap sprayed concrete rapid wall constructing method for coal mine underground, and belongs to the technical field of constructing a concrete wall and concrete spraying in the coal mine underground. The heap sprayed concrete rapid wall constructing method for the coal mine underground can solve the problems that an existing method for constructing the concrete wall in thecoal mine underground is low in speed, the final strength cannot meet the design requirements, no effective support is formed for a roof and the application range is small. A novel method for rapidlyconstructing a concrete wall for the coal mine underground comprises the steps that sand-gravel materials, cement, a JCT-1 shotcrete admixture and an accelerating agent are mixed uniformly in a certain proportion in a wet state and then loaded into an injection machine, and compressed air is used for transporting the wet mixture to a spray nozzle along a pipeline to be mixed with water and sprayed at a high speed to construct the wall. According to the heap sprayed concrete rapid wall constructing method for the coal mine underground, the wall is easy to form, initial setting time is short, initial strength of heap spraying forming is high, no slip and falling deformation is caused, and the thickness of the wall is not limited.

Owner:TAIYUAN UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com