Groove type atomic gas cavity and atomic clock physical system formed by same

A technology of atomic gas cavity and physical system, which is applied in the field of atomic clock and atomic optics, can solve the problems of low signal-to-noise ratio of CPT signal, short interaction space between laser and alkali metal atomic gas, and reduce the frequency stability of CPT atomic clock, etc., to achieve high The effect of signal-to-noise ratio, CPT atomic clock output frequency signal stability, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Directly bonded and sealed double-layer structure trough-type atomic gas cavity and its constructed atomic clock physical system:

[0034] Figure 4In order to directly bond and seal the double-layer structure groove-type atomic gas cavity, select a silicon wafer with a thickness of 1-3 mm, use silicon dioxide or silicon nitride as a mask, and pass potassium hydroxide or other anisotropic wet The prism-shaped silicon groove structure on the silicon substrate is formed by etching process using the method, and the side wall of the silicon groove structure is the {111} crystal plane. Using evaporation or sputtering technology, using hard mask or lift-off technology, the silicon groove side wall Make a metal film mirror on the surface, and then move the alkali metal element or the compound that reacts to form an alkali metal into the silicon pit in an anaerobic environment, or directly fill it with excess alkali metal vapor, and then fill it with a buffer gas mixed accordi...

Embodiment 2

[0038] The double-layer structure trough-type atomic gas cavity with gas channel sealing and the atomic clock physical system constructed by it:

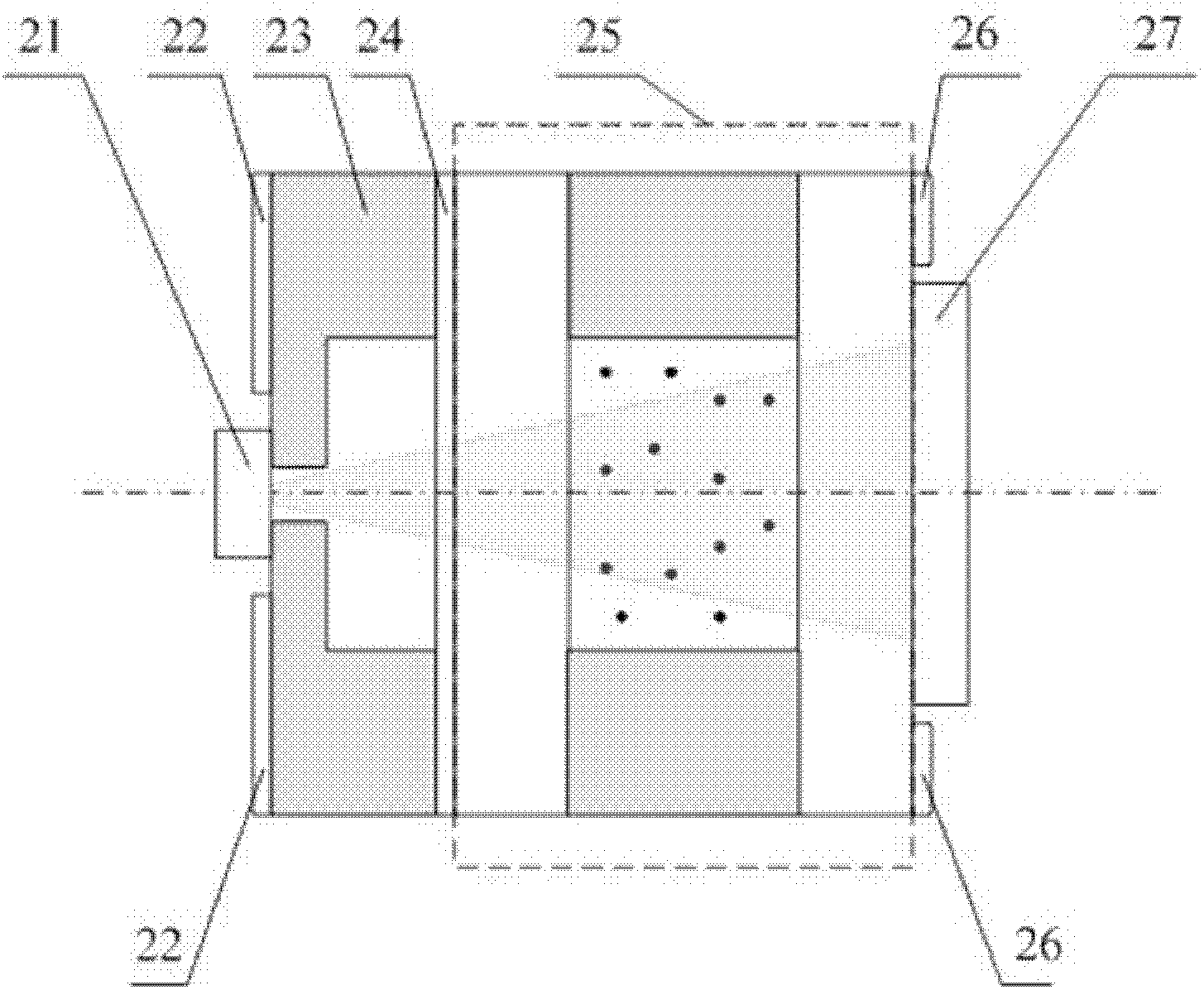

[0039] Figure 5 ~ Figure 7 The double-layer groove-type atomic gas cavity structure is sealed for three kinds of gas channels. The silicon grooves are etched out first in the three structures, and the gas channels are made on the edge of the cavity. The side wall of the silicon groove structure is the {111} crystal plane , use evaporation or sputtering process, use hard mask or lift-off technology, make metal film mirror on the side wall of silicon tank, and then carry out silicon-glass anode bonding, and then pour alkali metal gas and Buffer gas, and finally the cavity is sealed by blocking the gas channel. Figure 5 The form of the gas channel is to make a channel on silicon; Figure 6 The form of the gas channel is to make a channel on the glass, Figure 7 The gas channels in the middle are in the form of through holes on the...

Embodiment 3

[0042] Three-layer structure trough atomic gas cavity and its atomic clock physical system:

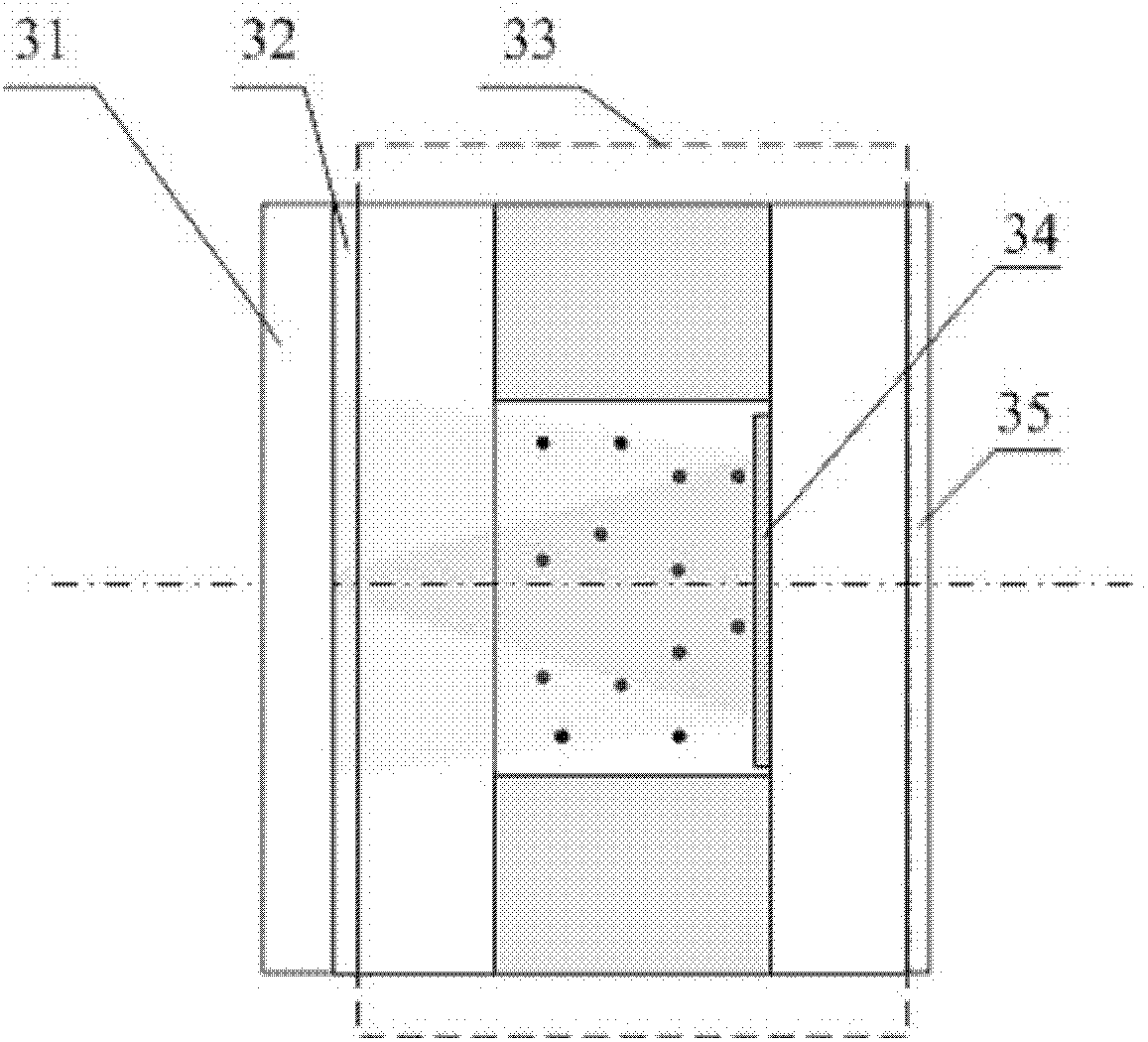

[0043] Similar to the two-layer structure trough-type atomic gas cavity, the three-layer structure trough-type atomic gas cavity also includes a direct bonding sealing structure and a gas channel sealing structure. Figure 8 It is a schematic diagram of the structure of a three-layer groove-type atomic gas cavity with direct bonding and sealing. Select a silicon wafer with a thickness of 1 to 3mm, use silicon dioxide or silicon nitride as a mask, and use potassium hydroxide or other anisotropic wet etching processes to etch the silicon wafer on one side to form a silicon substrate The through-hole structure on the through-hole, the side wall of the through-hole is the {111} crystal plane, and the post-corrosion surface of the silicon wafer is anodically bonded to a piece of Pyrex glass to form a half-cavity structure, using evaporation or sputtering technology, using a hard mask Or ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com