Rolling forming method of metal plate component

A technology of roll forming and metal plate, which is applied in the field of roll forming of metal plate components with large step ratio and variable thickness, to achieve the effects of improving manufacturing accuracy and fatigue strength, efficient and precise forming and manufacturing, and avoiding pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] Hereinafter, a preferred embodiment of the method for roll forming a metal plate member with a large step ratio and a variable thickness according to the present invention will be described in detail with reference to the accompanying drawings.

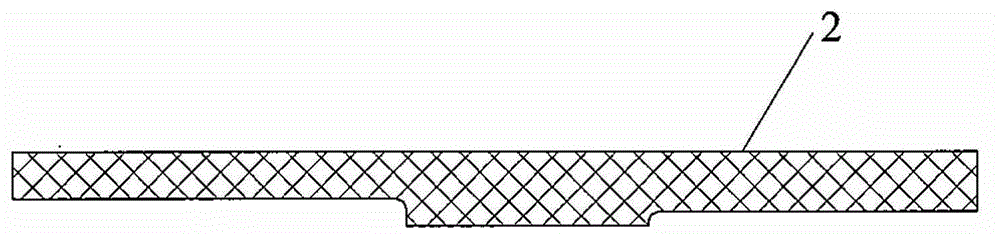

[0041] The technical scheme of the present invention is used to form and process the skin components of the fuselage door frame, such as Figure 5 As shown, the skin material is aluminum alloy 2024-T3, and the thickness of the parts varies from 6mm to 1.4mm. The elastic pad used in this embodiment is an engineering plastic sheet PA6-G with a thickness of 8 mm.

[0042] (1) Unfold the fuselage panel parts. According to the actual three-dimensional geometric structure of the fuselage door frame skin and the requirements of aluminum alloy 2024-T3, the CAE software Dynaform is used to expand the fuselage door frame skin parts into a flat structure.

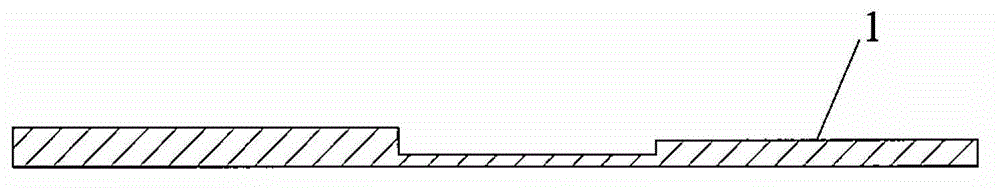

[0043] (2) Preparation of metal slabs with large step ratio and variable thickness stru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com