Intelligent petroleum machine for petroleum removal at sea

A petroleum machinery and intelligent technology, which is applied in general water supply conservation, open-air water surface cleaning, water conservancy projects, etc. It can solve the problems of operators polluting the environment, taking a long time, and toxic chemical dispersants, so as to make full use of environmental resources and reduce energy. The effect of consuming and saving manpower and material resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

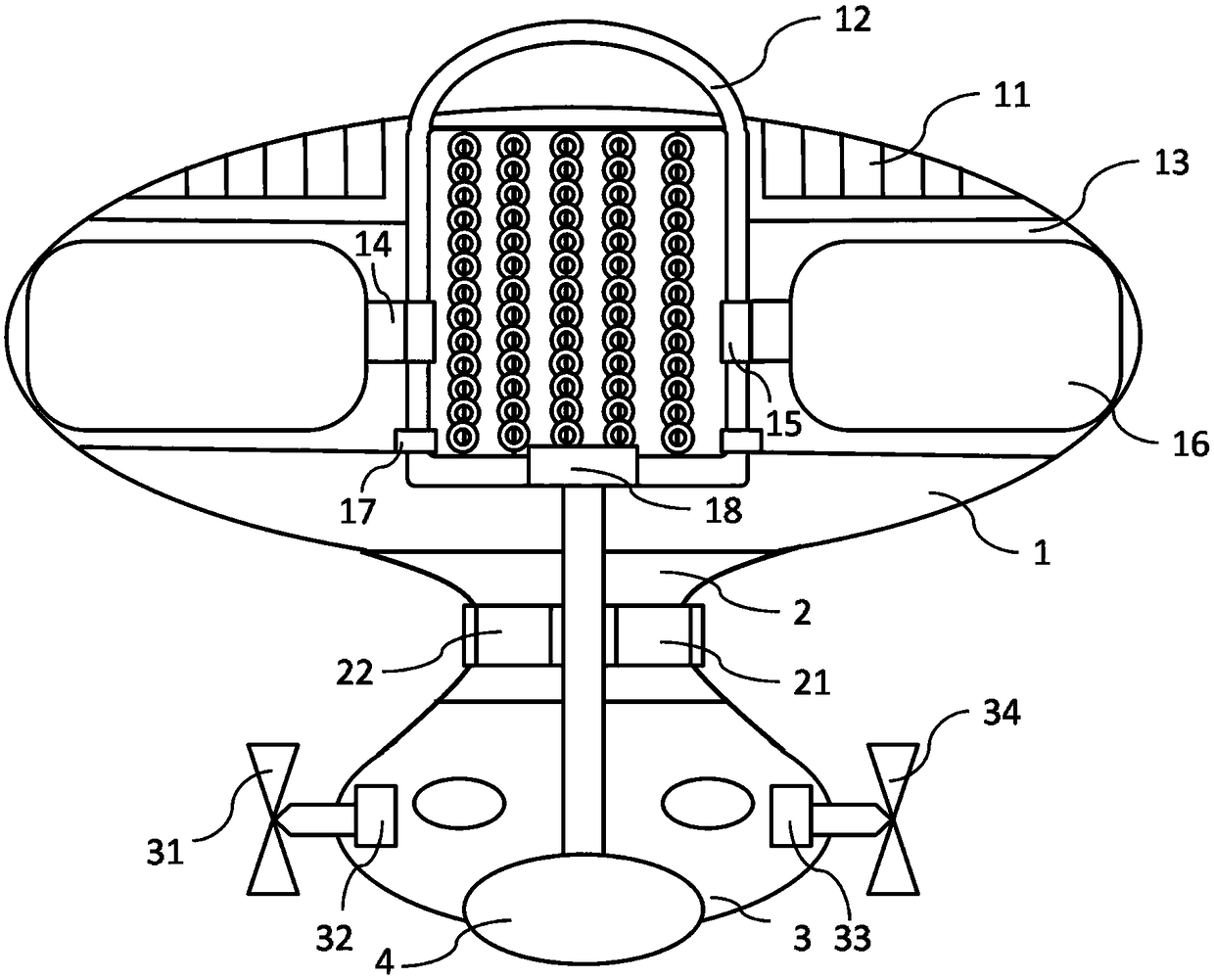

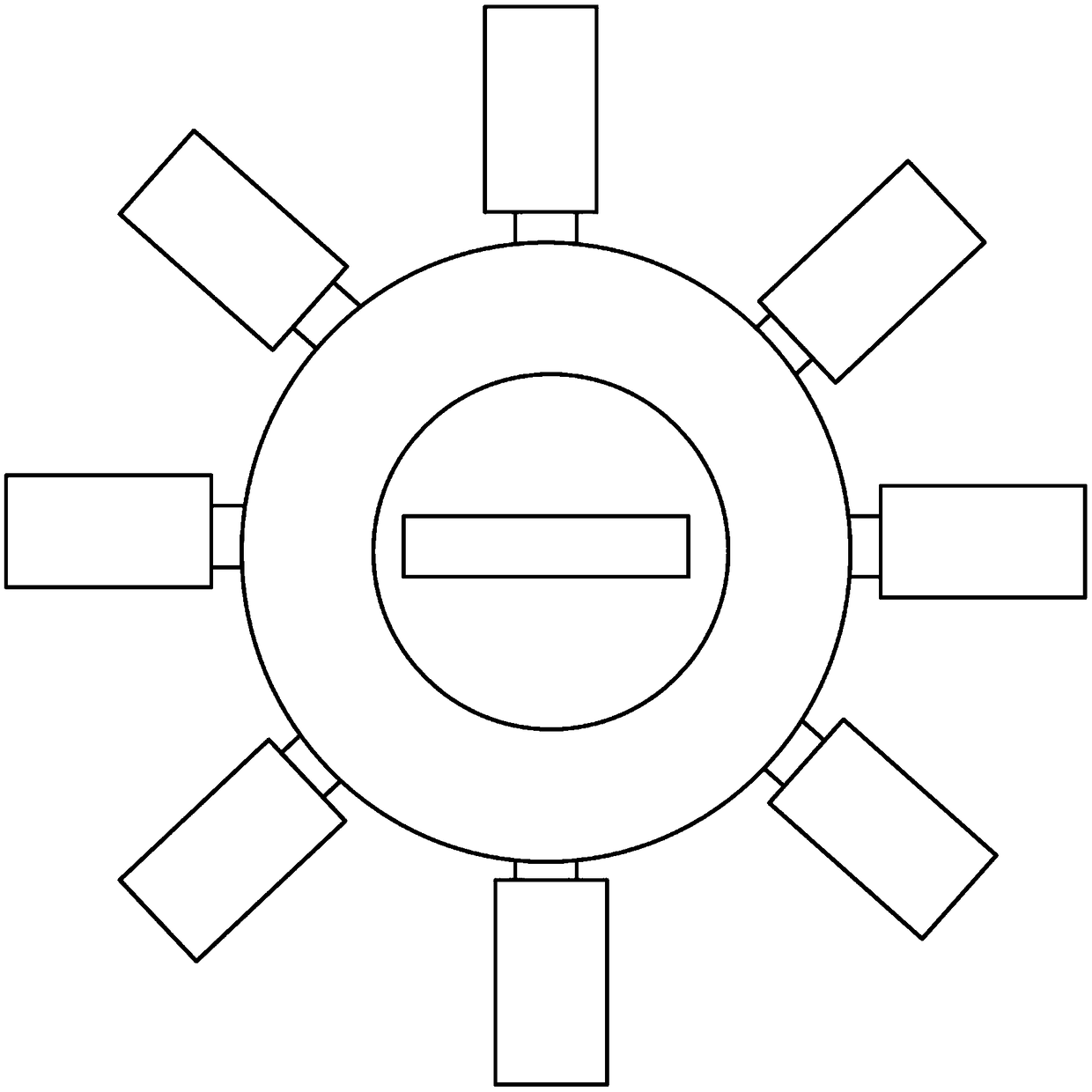

[0022] like figure 1 As shown, the intelligent petroleum machinery provided by the present invention includes an oil cleaning machine body, and the oil cleaning machine body is respectively provided with an oil absorption module 1, an intelligent module 2, a driving module 3 and a recovery tank 4 from top to bottom. The top of the oil absorption module 1 is provided with a solar battery 11, and a replaceable bioreactor 12 is arranged on the central axis direction. Eight groups of oil absorption chambers 13 are evenly arranged around the replaceable bioreactor 12, and each oil absorption chamber 13 There is an electric push rod 14 inside, and the end of the electric push rod 14 is connected with a rotating motor 15, which drives the new type of oil-absorbing cotton 16 to perform rotary motion, and the outer wall of the oil-absorbing chamber 13 is provided with an electric hatch. The replaceable bioreactor 12 is connected, and the replaceable bioreactor 12 includes the bioreacto...

Embodiment 2

[0024] like figure 1 , figure 2 As shown, the workflow of intelligent petroleum machinery is as follows:

[0025] First, the intelligent petroleum machinery is placed on the oil-polluted sea surface. In the initial state, the oil absorption module is in the retracted state. After entering the working state, the intelligent control system starts to send instructions to drive the eight groups of oil-absorbing chambers to open the electric hatch, and the electric push rod pushes the new oil-absorbing cotton out of the oil-absorbing chamber. Driven by the rotating motor, the new oil-absorbing cotton rotates at a low speed to protect Oil spill to clean up.

[0026] At the same time, under the feedback of the position sensor and the optical sensor, the intelligent control system controls the left electric motor and / or the right electric motor, drives the left propeller and / or the right propeller, drives the intelligent petroleum machinery to move to the adjacent polluted sea area...

Embodiment 3

[0029] Embodiment 3: Preparation of environment-friendly novel oil-absorbing cotton

[0030] Rice is the largest grain variety in my country, with an annual output of about 185 million tons, accounting for 42% of the country's total grain output. Rice production accounts for 37% of the total food production in the world. Rice bran is mainly processed from the seed coat, seed coat, outer endosperm, aleurone layer and embryo of rice, so a small amount of rice husk and a certain amount of dust and microorganisms will be mixed in during the processing, so it can only be used for Feed cannot maximize its economic benefits. The raw material used in the environmentally friendly new oil-absorbing cotton provided by the present invention is the rice bran eliminated in the rice processing process, and the specific steps are as follows:

[0031] Step 1. The magnetic carbon material uses paddy rice bran as the carbon silicon raw material. After crushing 100g of sterilized paddy rice bra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com