Production method of totally-coated metal composite pipe

A metal composite pipe and production method technology, applied in the direction of pipe, rigid pipe, pipeline protection, etc., can solve the problems of difficult industrialized production, low production and yield, difficult production process, etc., to achieve convenient product use and controllable production scale , the effect of reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

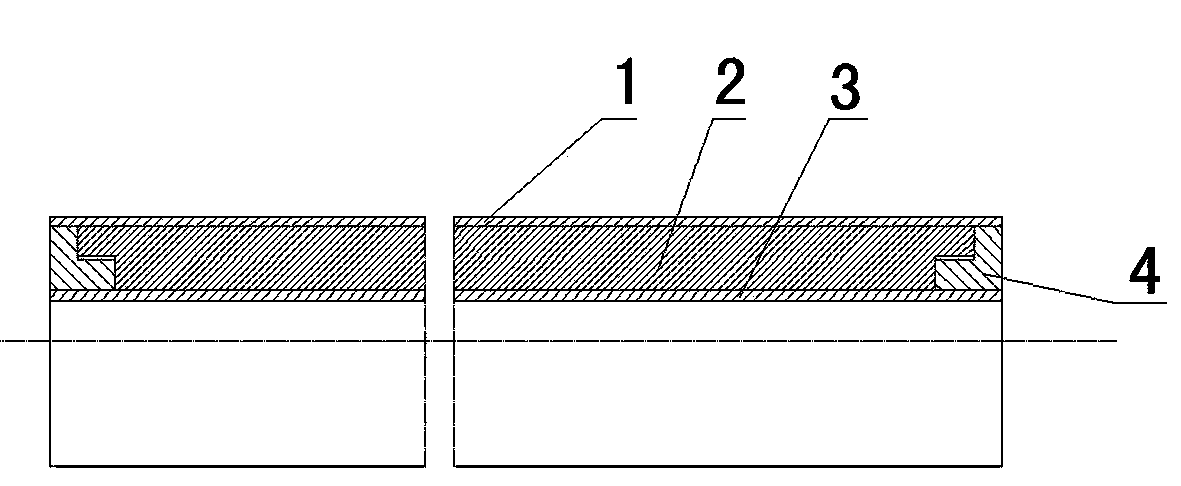

[0037] according to figure 1 The structure and production method of the fully clad metal composite tube blank of the present invention are described in detail. The production method of the fully clad metal composite pipe comprises the following steps:

[0038] Processing of composite tube billet structure: separately process or select Q235 steel pipe material 2 with connecting threads at both ends, pure titanium TA0 outer layer titanium tube 1 material and pure titanium TA0 inner layer titanium tube 3 material matching the inner and outer dimensions of Q235 steel pipe material , and the pure titanium TA0 metal pipe head 4 threaded with the two ends of the low-carbon steel pipe material. Then, from the outside to the inside, the inner pure titanium TA0 pipe material 3, the Q235 steel pipe material and the outer pure titanium TA0 pipe material 1 are combined together to form a composite pipe blank, in which the inner layer pure titanium TA0 pipe material The two ends of the ou...

Embodiment 2

[0042] According to the needs of the application field of the present invention, the titanium pipe materials are selected: pure titanium TA0, pure titanium TA1, pure titanium TA2; the materials of the low carbon steel pipe materials are selected: Q235, 16Mn, No. 20 steel, 20g boiler steel.

[0043] The structure of the fully clad metal composite tube blank in this embodiment is the same as in Example 1; and the production method of the fully clad metal composite tube of the present invention is as follows:

[0044] First select pure titanium TA2 titanium tube and 20g boiler steel steel tube for blanking (radial size: titanium tube D84 / d82--steel tube D82 / d72--titanium tube D72 / d70, length 1000)——Used at both ends of the steel tube The threaded connection method is matched with two titanium metal pipe heads - the joint surface is treated to ensure that the metal is fresh and clean - the billet is assembled (the radial dimension of the composite pipe blank is D84 / d70, and the len...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com