Short carbon fiber modified high friction composite and preparing method and application thereof

A short carbon fiber and composite material technology, applied in friction linings, mechanical equipment, etc., can solve problems such as poor toughness, low room temperature and high temperature strength, toughening and forming difficulties, etc., to achieve high conductivity, low friction coefficient, The effect of stabilizing the coefficient of friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

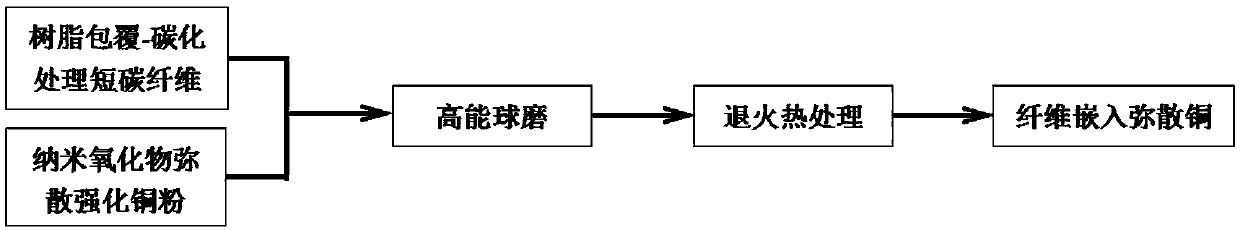

Method used

Image

Examples

Embodiment 1

[0095] The short carbon fiber modified high-friction composite material prepared in Example 1 comprises the following components in terms of mass percentage:

[0096] 2.0% short carbon fiber, 10% iron, 5% chromium, 3% silicon carbide, 3% zirconia, 2% granular graphite, 10% flake graphite, 8% iron-chromium alloy, 30% nano-alumina dispersion strengthened copper powder , Electrolytic copper powder 27%. The particle size of iron, chromium, silicon carbide, zirconia, and iron-chromium alloy is 100 microns, the particle size of granular graphite and flake graphite is 120 microns, the particle size of nano-alumina dispersed copper powder is 120 microns, and the electrolytic copper powder The particle size is 200 microns. The short carbon fibers have a diameter of 8 μm and a length of 2 mm. The difference from Comparative Example 2 and Comparative Example 3 is that the copper powder part is made of nano-alumina dispersion-strengthened copper powder, and the short carbon fibers are r...

Embodiment 2

[0102] The short carbon fiber modified high-friction composite material prepared in Example 2 comprises the following components in terms of mass percentage:

[0103] Short carbon fiber 2.0%, iron 10%, chromium 3%, silicon carbide 2%, granular graphite 2%, flake graphite 10%, iron-chromium alloy 9%, nanometer yttrium oxide dispersed copper powder 62%. The particle size of iron, chromium, silicon carbide and iron-chromium alloy is 100 microns, the particle size of granular graphite and flake graphite is 120 microns, and the particle size of nano-yttrium oxide dispersed copper powder is 100 microns. The short carbon fibers have a diameter of 8 μm and a length of 2 mm.

[0104] First, resin-coated-carbonized short carbon fibers are prepared. Dissolve the prepared phenolic resin in an organic solvent to obtain a phenolic resin alcohol saturated solution; then impregnate the short carbon fibers in an 80°C phenolic resin alcohol saturated solution for 2 hours; then dry at 120°C for...

Embodiment 3

[0109] The short carbon fiber modified high-friction composite material prepared in Example 3 comprises the following components in terms of mass percentage:

[0110] Short carbon fiber 1.5%, iron 10%, chromium 4%, silicon carbide 2%, zirconia 3.5%, granular graphite 2%, flake graphite 12%, iron-chromium alloy 6%, nano-alumina dispersed copper powder 25%, Electrolytic copper powder 34%. The particle size of iron, chromium, silicon carbide, zirconia, and iron-chromium alloy is 90 microns, the particle size of granular graphite and flake graphite is 120 microns, the particle size of nano-yttrium oxide dispersed copper powder is 100 microns, and the electrolytic copper powder The particle size is 150 microns. The short carbon fibers have a diameter of 8 μm and a length of 2 mm.

[0111] First, resin-coated-carbonized short carbon fibers are prepared. Dissolve the prepared phenolic resin in an organic solvent to obtain a phenolic resin alcohol saturated solution; then impregnat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com