Fiber-reinforced resin heat-resistant high-speed abrasive cutting wheel and processing method thereof

A fiber-reinforced resin and cutting grinding wheel technology, which is applied in the field of grinding wheels, can solve the problems of poor wear resistance, small cutting ratio, and poor heat resistance, and achieve good wear resistance, high cutting ratio, and good heat resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

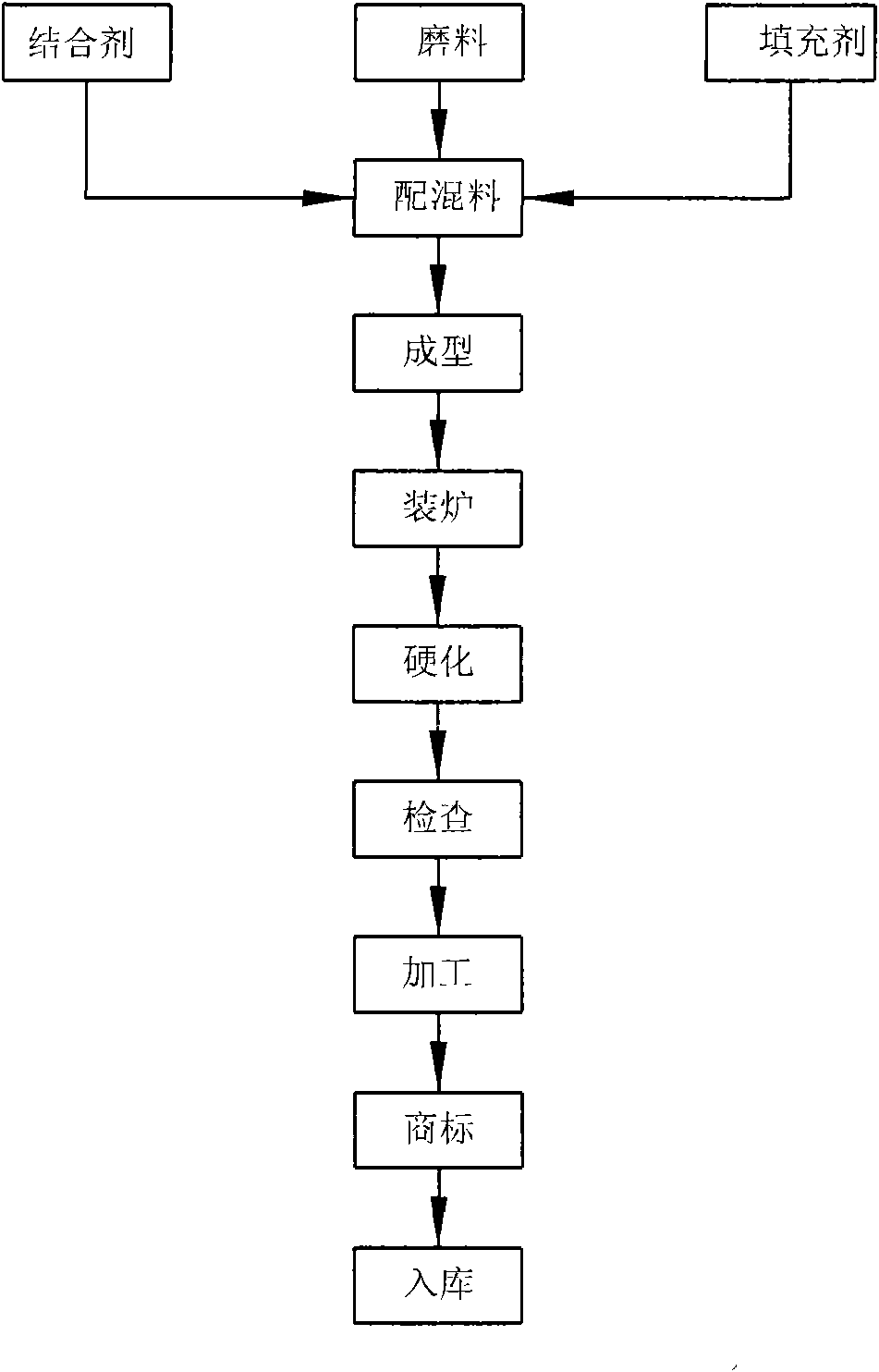

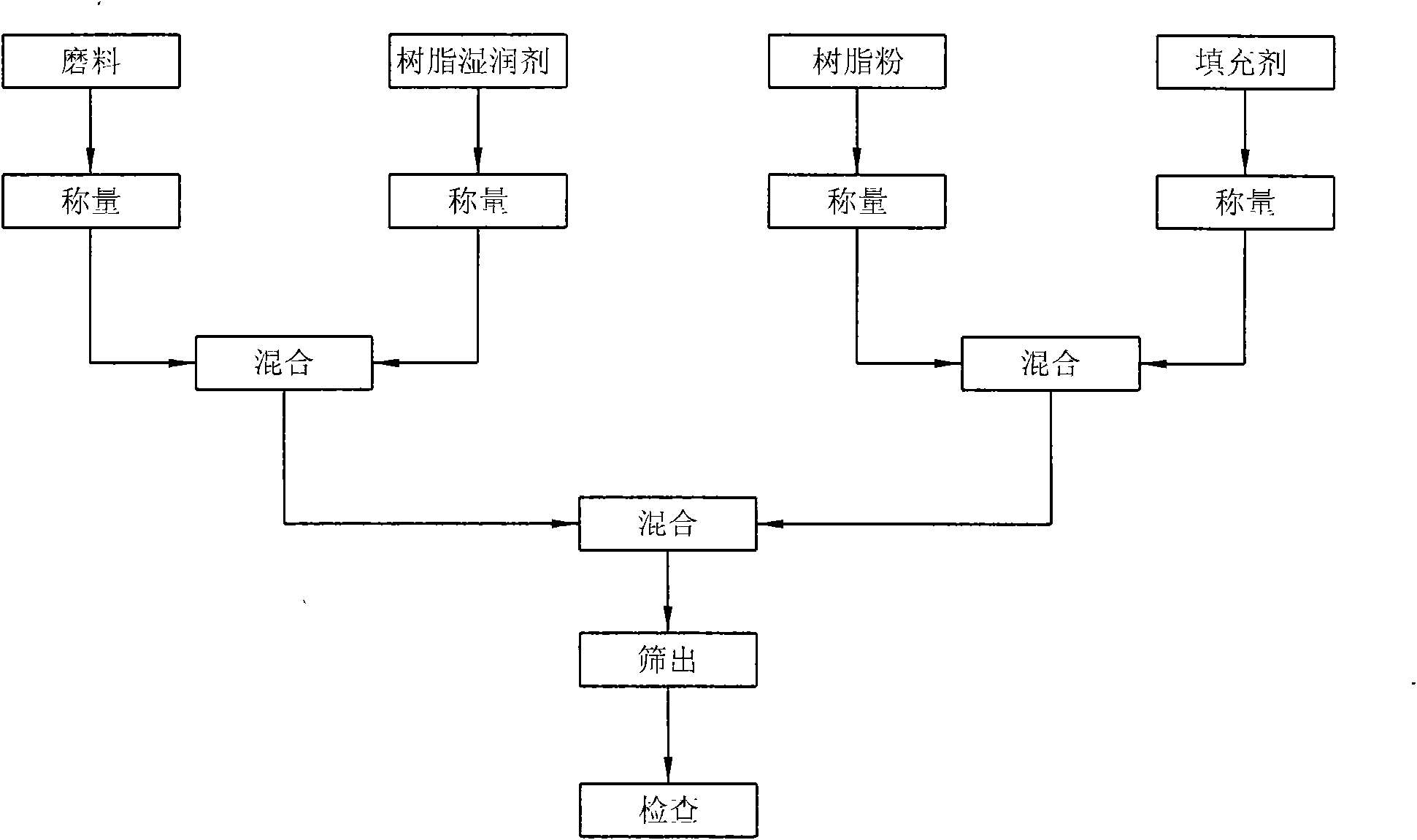

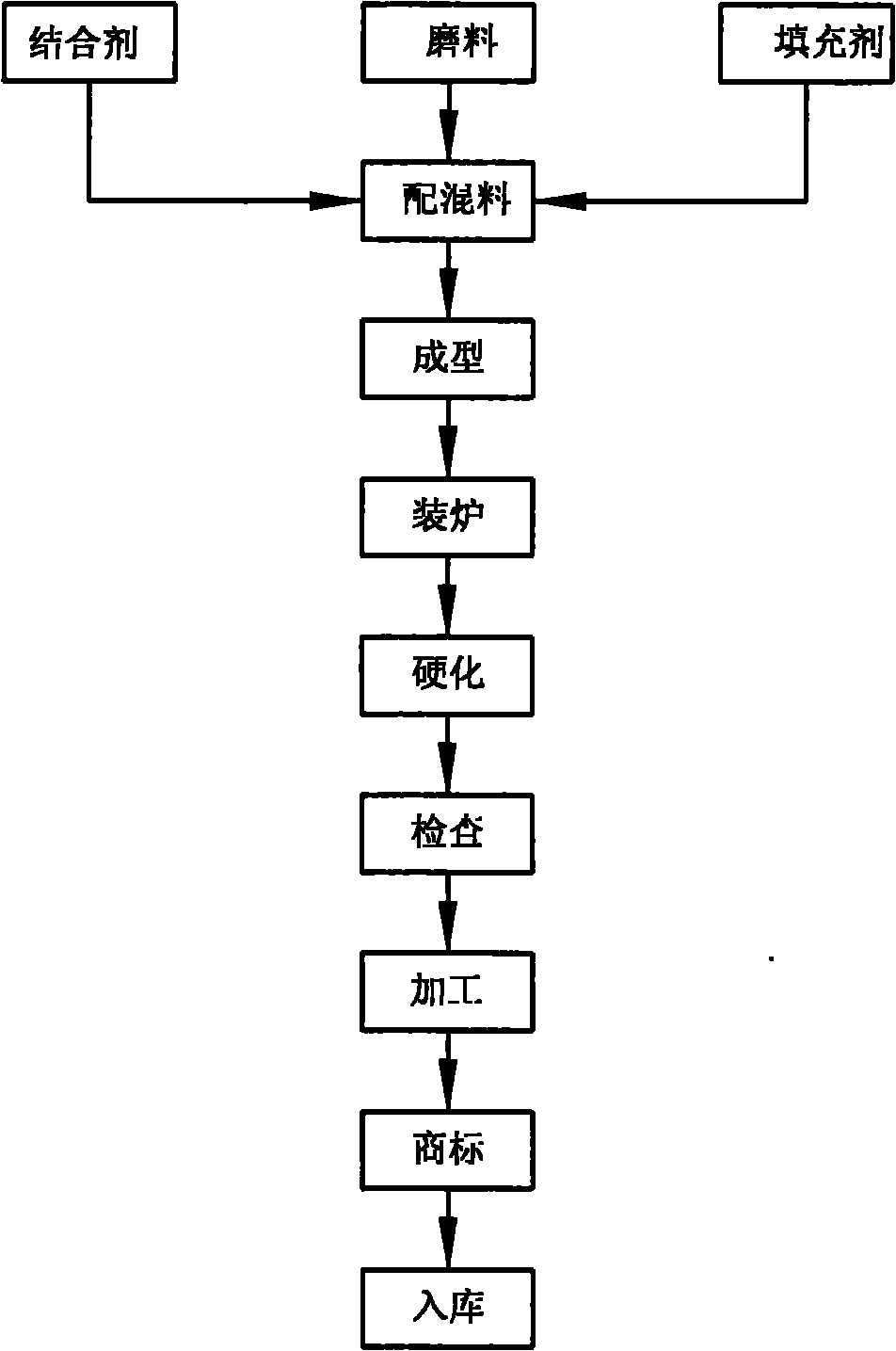

Method used

Image

Examples

Embodiment 1

[0038] The emery wheel of the present invention comprises a central reinforcement part and a cutting use part, and the parts by weight of each component of the central reinforcement part are:

[0039] A24# 25 copies

[0040] A36# 65 copies

[0041] A150# 10 copies

[0042] 8 parts phenolic resin powder

[0043] 4.5 parts of phenolic resin wetting agent

[0044] Silane coupling agent: 0.3 parts

[0045] Hemihydrate gypsum powder: 3.5 parts.

[0046] The weight fraction of each component of described cutting use part is:

[0047] ZA16# 18 parts

[0048] ZA20# 12 parts

[0049] A20# 30 copies

[0050] A24# 25 copies

[0051] A36# 15 copies

[0052] 12 parts phenolic resin powder

[0053] 6.5 parts of phenolic resin wetting agent

[0054] 4.8 parts of iron disulfide powder

[0055] 4.5 parts cryolite powder

[0056] Ferrous oxide powder 1.2 parts

[0057] Titanium dioxide fine powder 0.8 parts

[0058] 0.6 parts of silane coupling agent

[0059] When the present i...

Embodiment 2

[0065] The emery wheel of the present invention comprises a central reinforcement part and a cutting use part, and the parts by weight of each component of the central reinforcement part are:

[0066] A24# 30 copies

[0067] A36# 60 copies

[0068] A150# 10 copies

[0069] 8.5 parts of phenolic resin powder

[0070] 4.5 parts of phenolic resin wetting agent

[0071] Silane coupling agent: 0.4 parts

[0072] Hemihydrate gypsum powder: 4 parts.

[0073] The weight fraction of each component of described cutting use part is:

[0074] ZA16# 25 parts

[0075] ZA20# 20 parts

[0076] A20# 20 copies

[0077] A24# 30 copies

[0078] A36# 5 copies

[0079] 10 parts of phenolic resin powder

[0080] 5.8 parts of phenolic resin wetting agent

[0081] Iron disulfide powder 5 parts

[0082] 5 parts cryolite powder

[0083] 1 part ferrous oxide powder

[0084] Titanium dioxide fine powder 0.8 parts

[0085] 0.4 parts of silane coupling agent

[0086] The key points of the pro...

Embodiment 3

[0089] The emery wheel of the present invention comprises a central reinforcement part and a cutting use part, and the parts by weight of each component of the central reinforcement part are:

[0090] A24# 35 copies

[0091] A36# 55 copies

[0092] A150# 10 copies

[0093] 9 parts phenolic resin powder

[0094] 5 parts phenolic resin humectant

[0095] Silane coupling agent: 0.3 parts

[0096] Hemihydrate gypsum powder: 4.3 parts.

[0097] The weight fraction of each component of described cutting use part is:

[0098] ZA16# 20 parts

[0099] ZA20# 15 parts

[0100] A20# 25 copies

[0101] A24# 25 copies

[0102] A36# 15 copies

[0103] 9 parts phenolic resin powder

[0104] 6 parts phenolic resin humectant

[0105] Iron disulfide powder 6 parts

[0106] 4 parts cryolite powder

[0107] 2 parts ferrous oxide powder

[0108] Titanium dioxide fine powder 1 part

[0109] Silane coupling agent 0.3 part

[0110] The key points of the process of this embodiment are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com