High-strength and low-brittleness aluminosilicate glass as well as strengthening method and application thereof

An aluminosilicate glass, low brittleness technology, applied in the field of aluminosilicate glass preparation, can solve the problems of poor resistance to external impact and scratch resistance, inability to meet high strength, high hardness and low hardness, and achieve improved melting properties, improve chemical stability, and reduce the effect of thermal expansion coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described in detail below in conjunction with specific embodiments, which are explanations of the present invention rather than limitations.

[0032] The daily use of glass products usually requires glass to have high strength, and the strength of glass is essentially determined by the system and composition. Adding B to the glass composition 2 o 3 and ZrO 2 , By adjusting the composition of the glass, aluminosilicate glass with high strength and low brittleness can be obtained. The method of chemical strengthening can further improve the strength of glass. Chemical strengthening is realized by ion exchange process in a low temperature environment. Compressive stress and a compressive stress layer with a certain depth are formed on the surface of the glass, which can further prevent the expansion of micro-cracks, thereby Further obtain high-strength, low-brittle aluminosilicate glass.

[0033] The present invention is a high-stre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

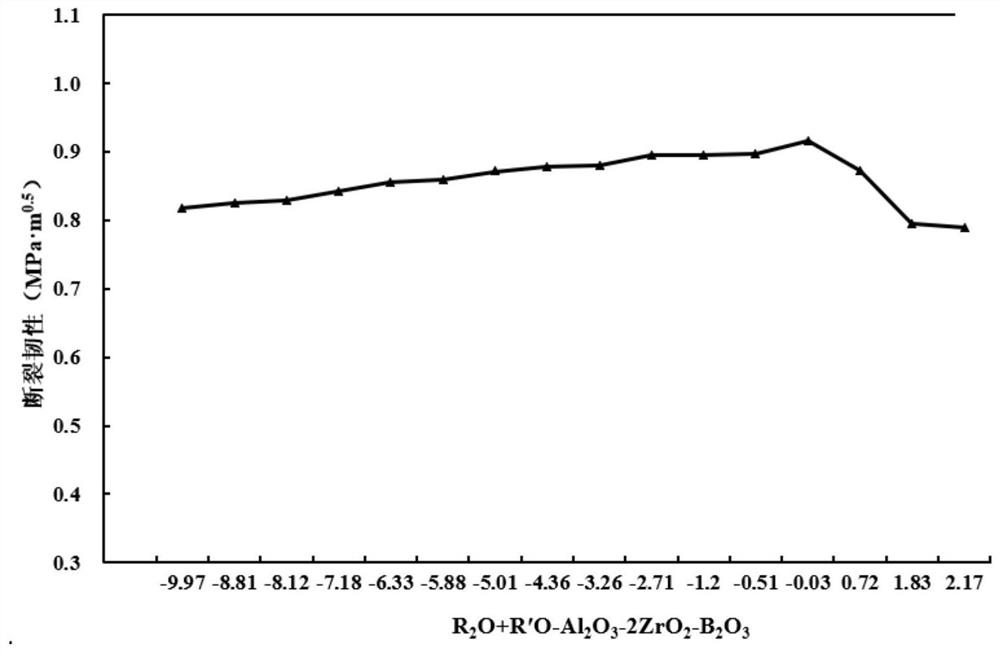

| fracture toughness | aaaaa | aaaaa |

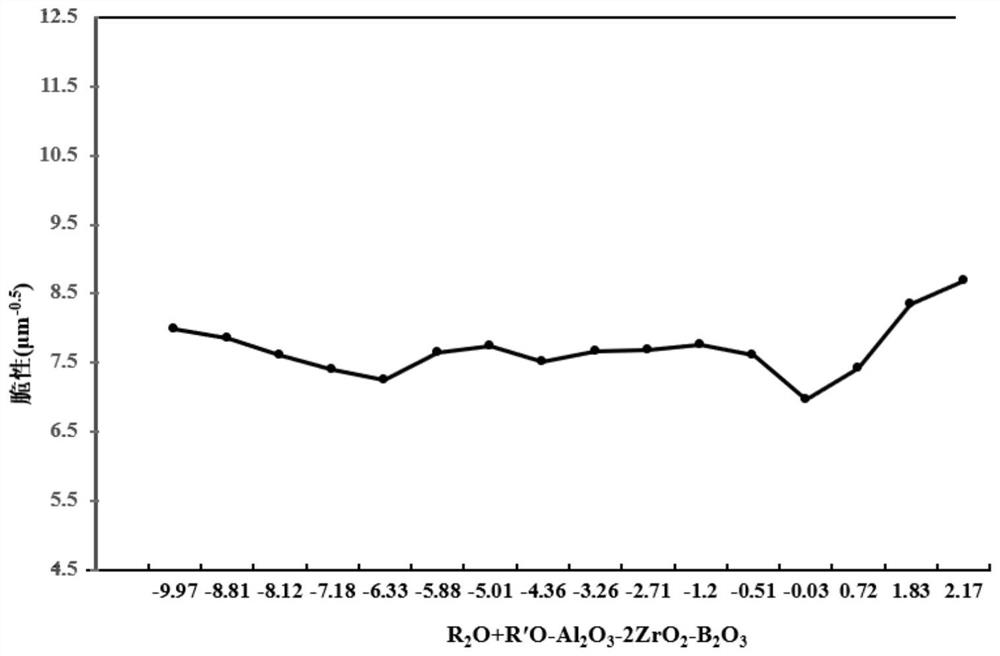

| brittleness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com