Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

37results about How to "Long material" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

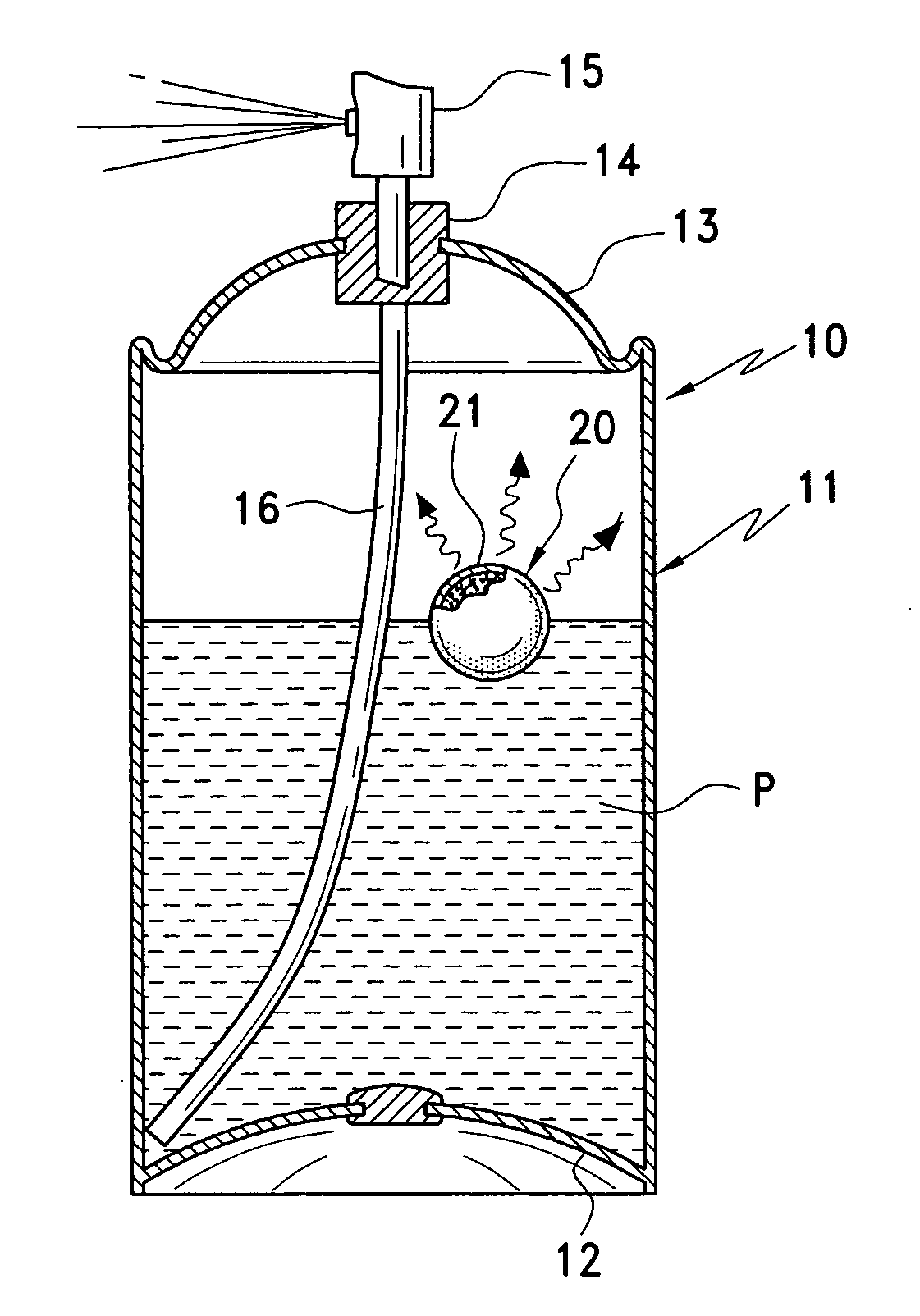

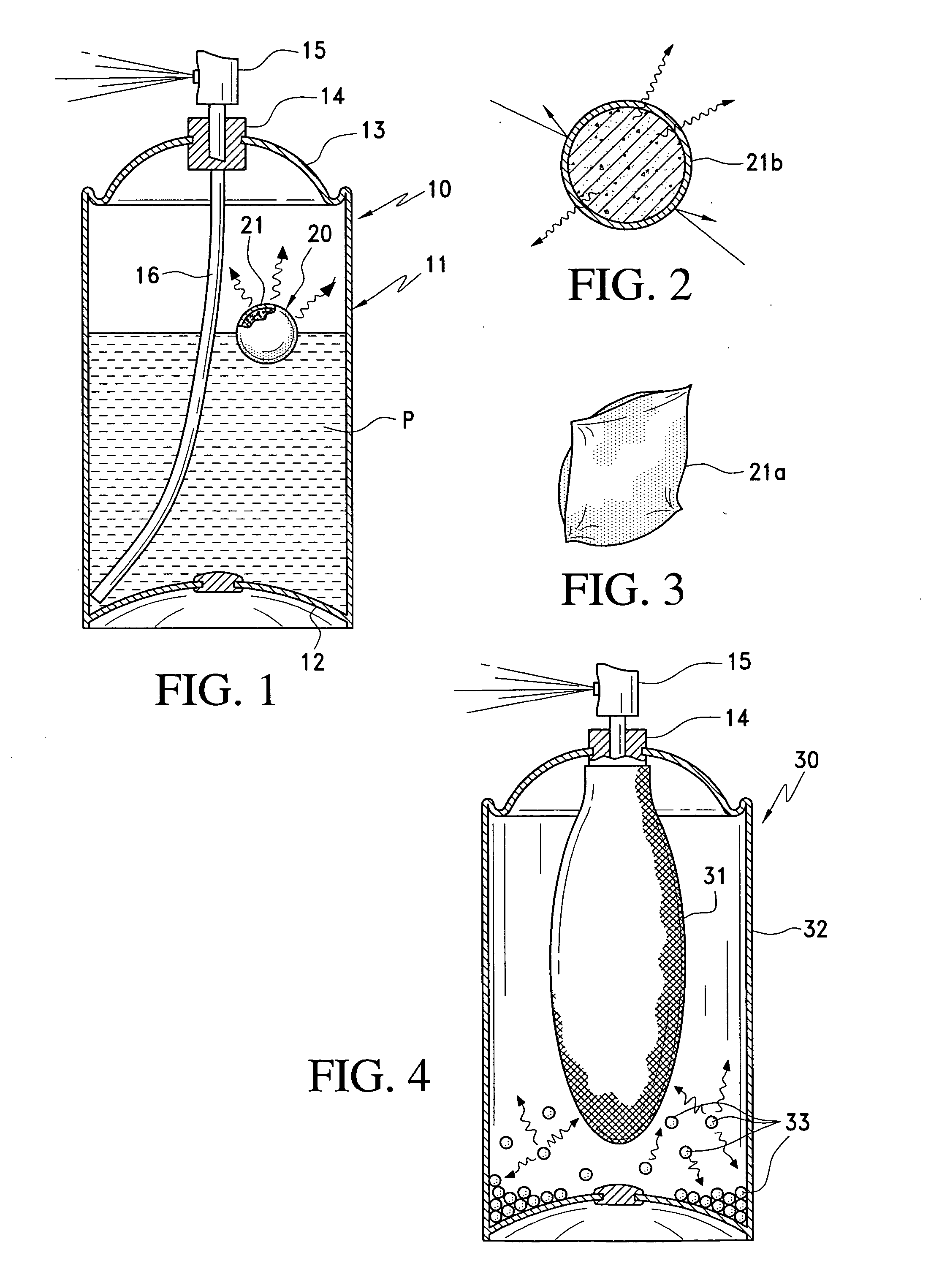

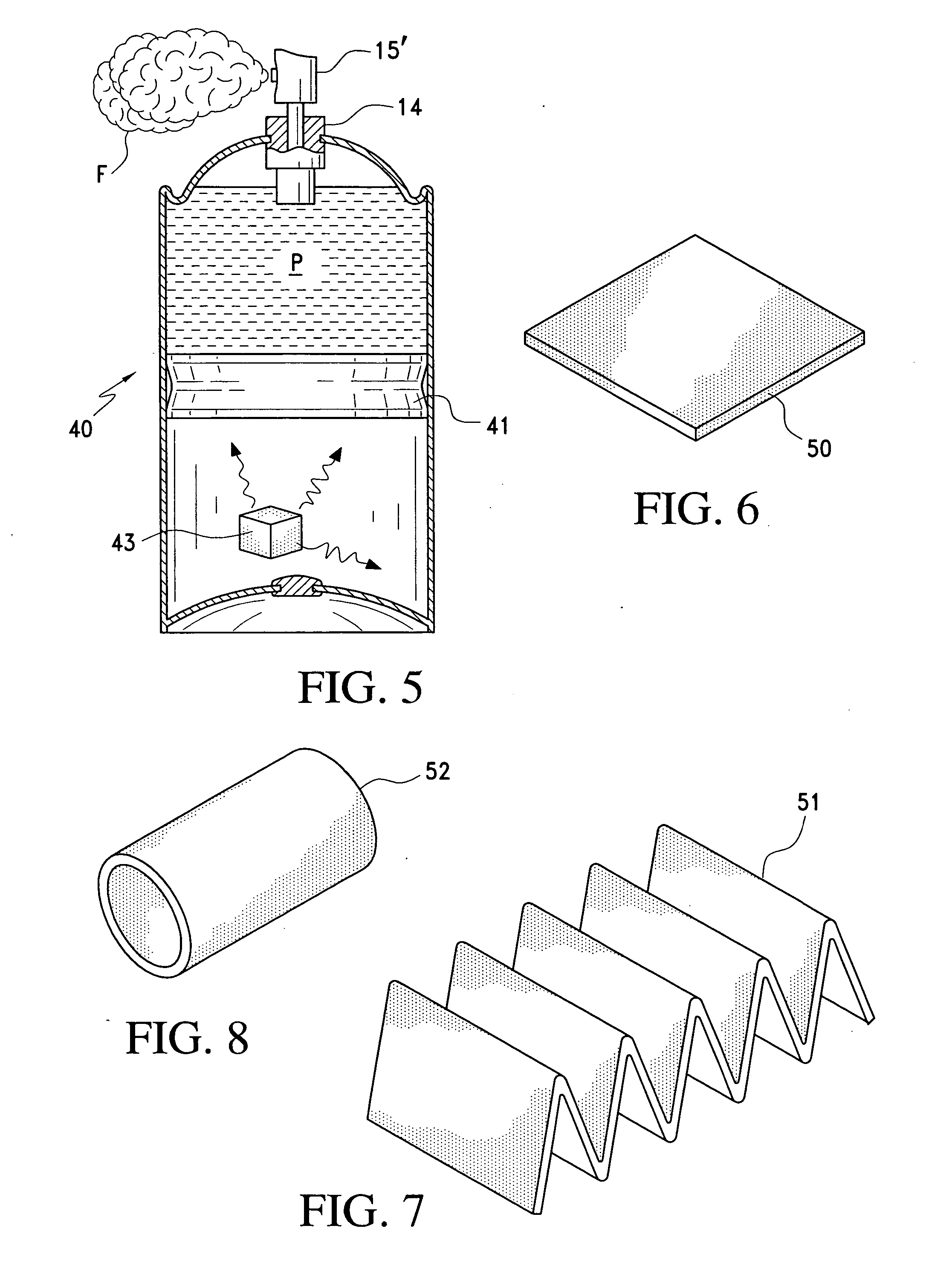

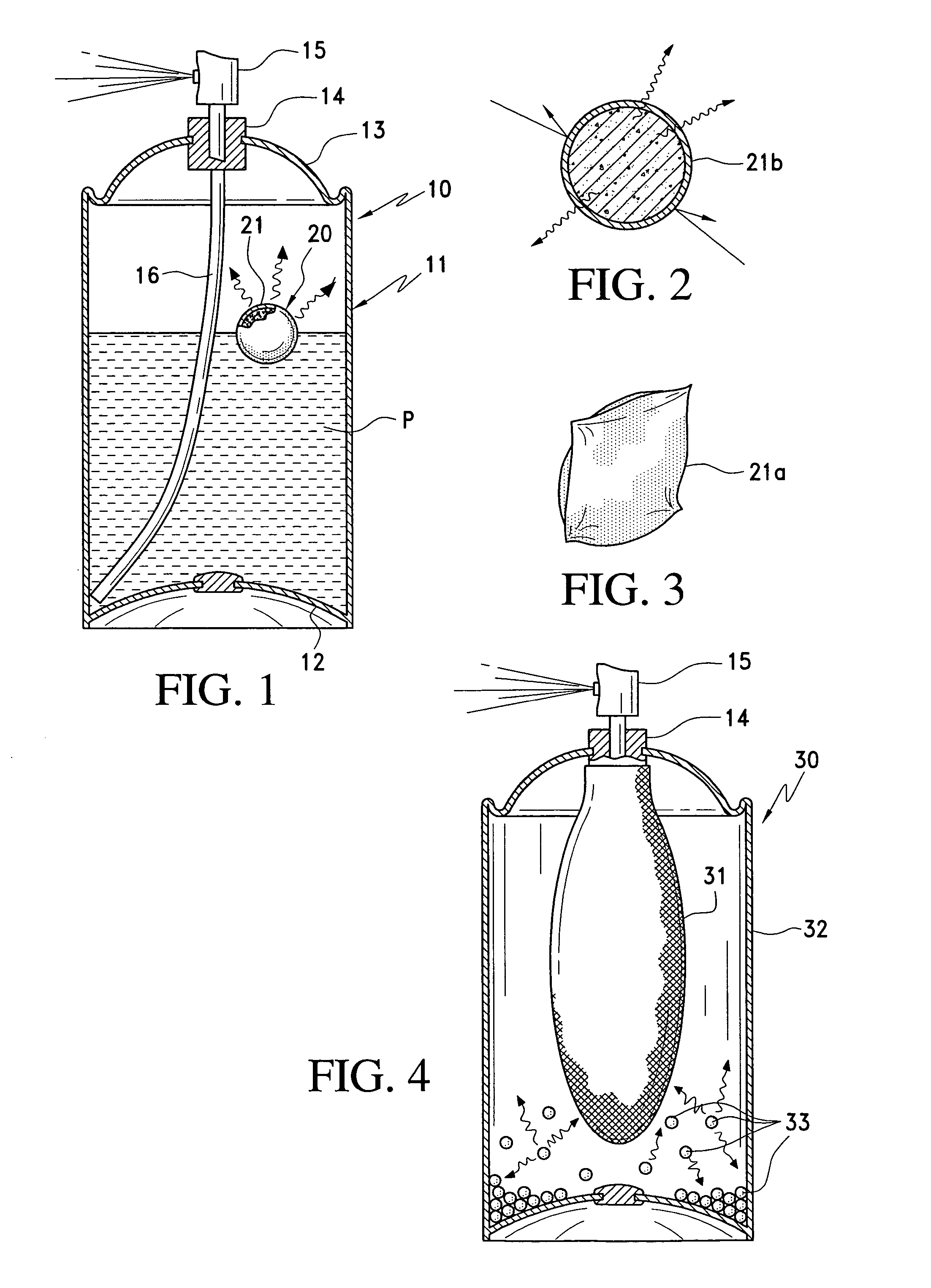

System and method for providing a reserve supply of gas in a pressurized container

InactiveUS20060049215A1Economic securityFacilitated releaseLiquid flow controllersLiquid transferring devicesMechanical engineeringDelivery system

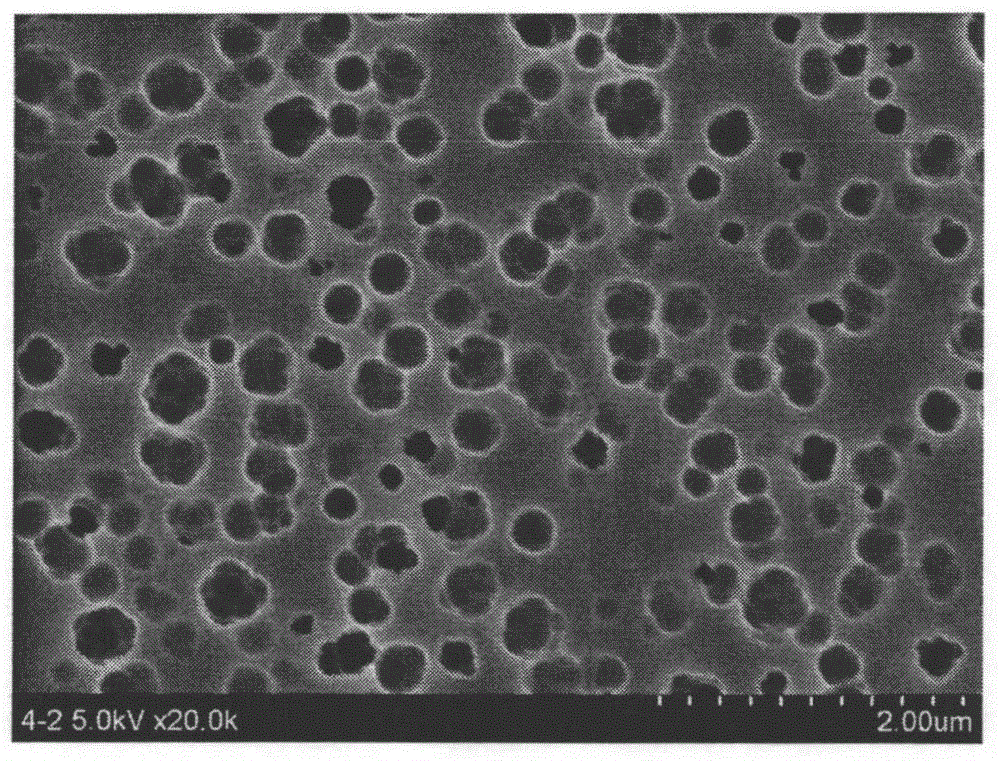

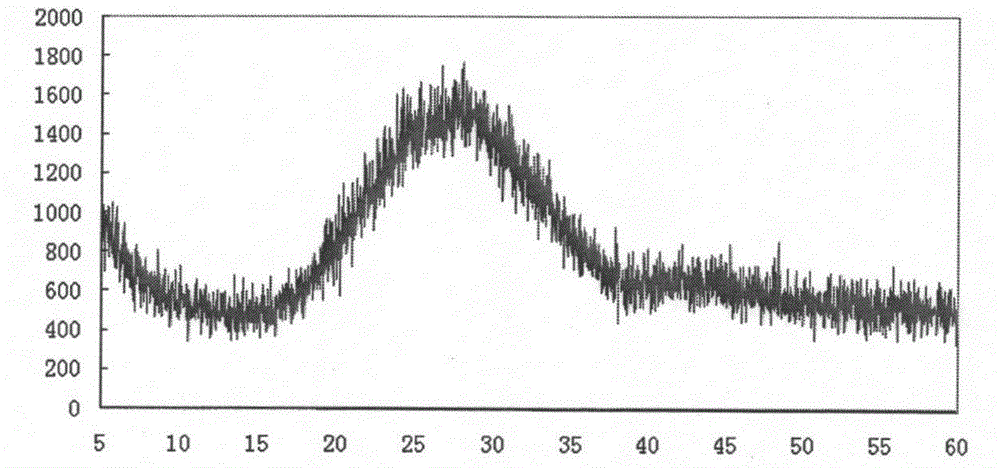

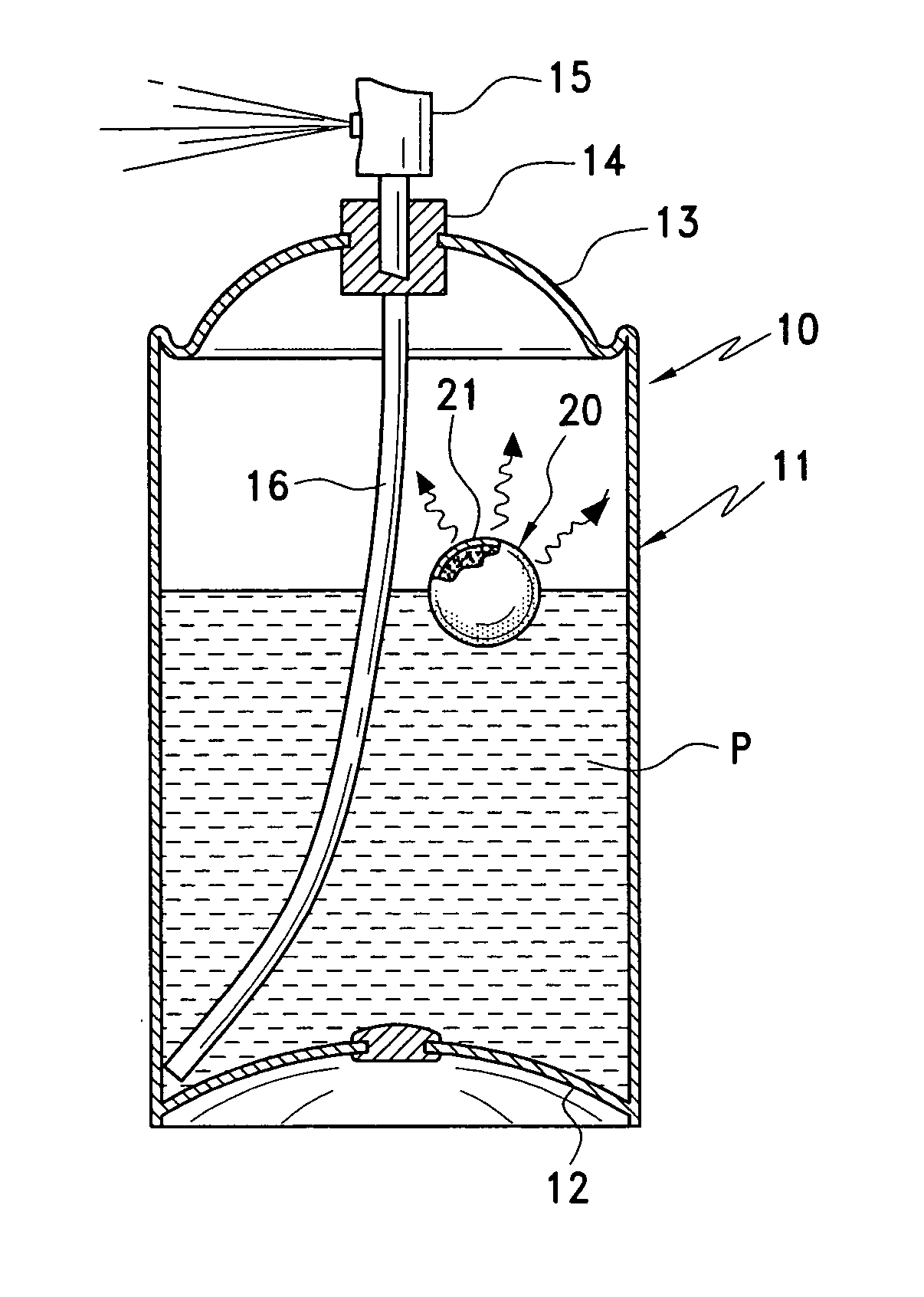

A gas storage and delivery system for restoring pressure as it is depleted from a pressurized container, includes a container holding a product under pressure to be dispensed from the container, a quantity of gaseous material under pressure, occupying a space in the container and applying to the product a predetermined pressure of from about 30 to about 180 psig, and a quantity of gas-adsorbing material, storing under pressure a quantity of the gaseous material and releasing it into the container in response to a decrease in pressure in the container, thereby restoring and maintaining a predetermined pressure in the container as product is depleted from the container, wherein the gas-adsorbing material is wetted with a release-promoting agent to promote release of the sorbed gas from the gas-adsorbent material. A process of filling the container is also disclosed.

Owner:LIM WALTER K

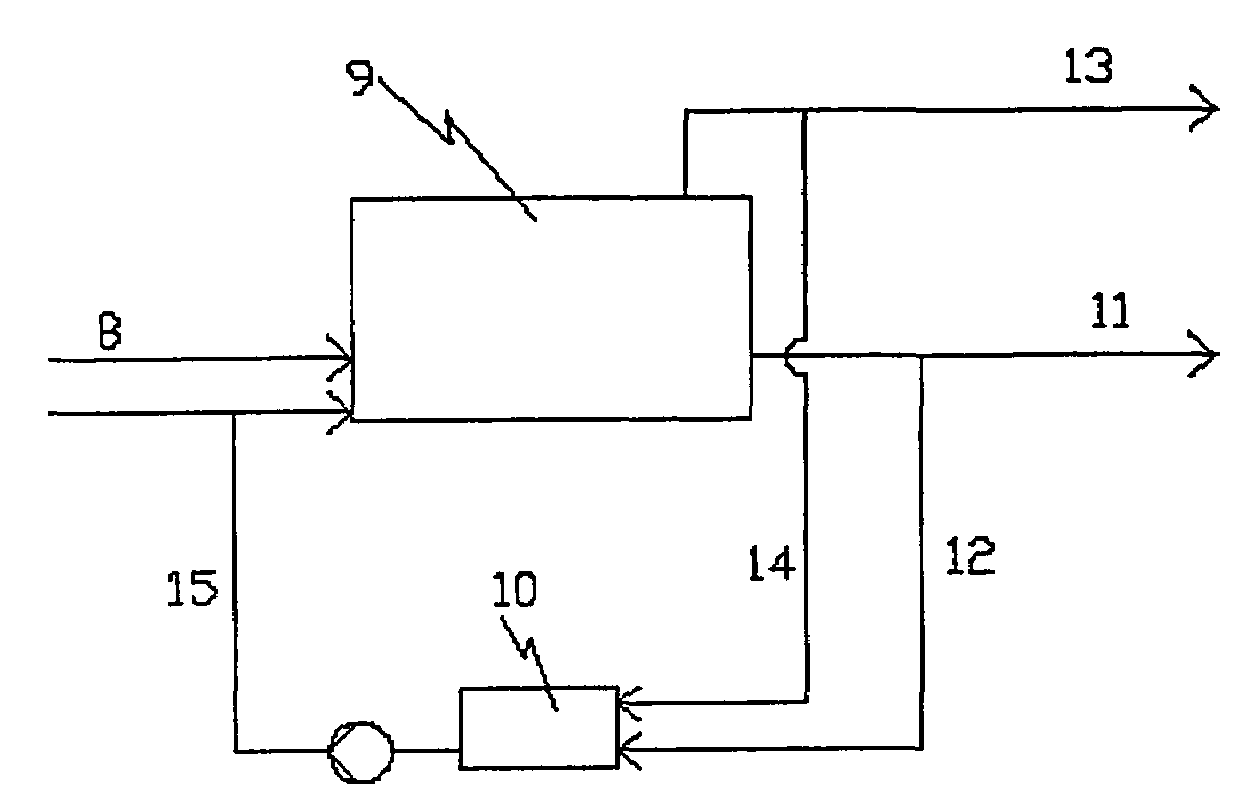

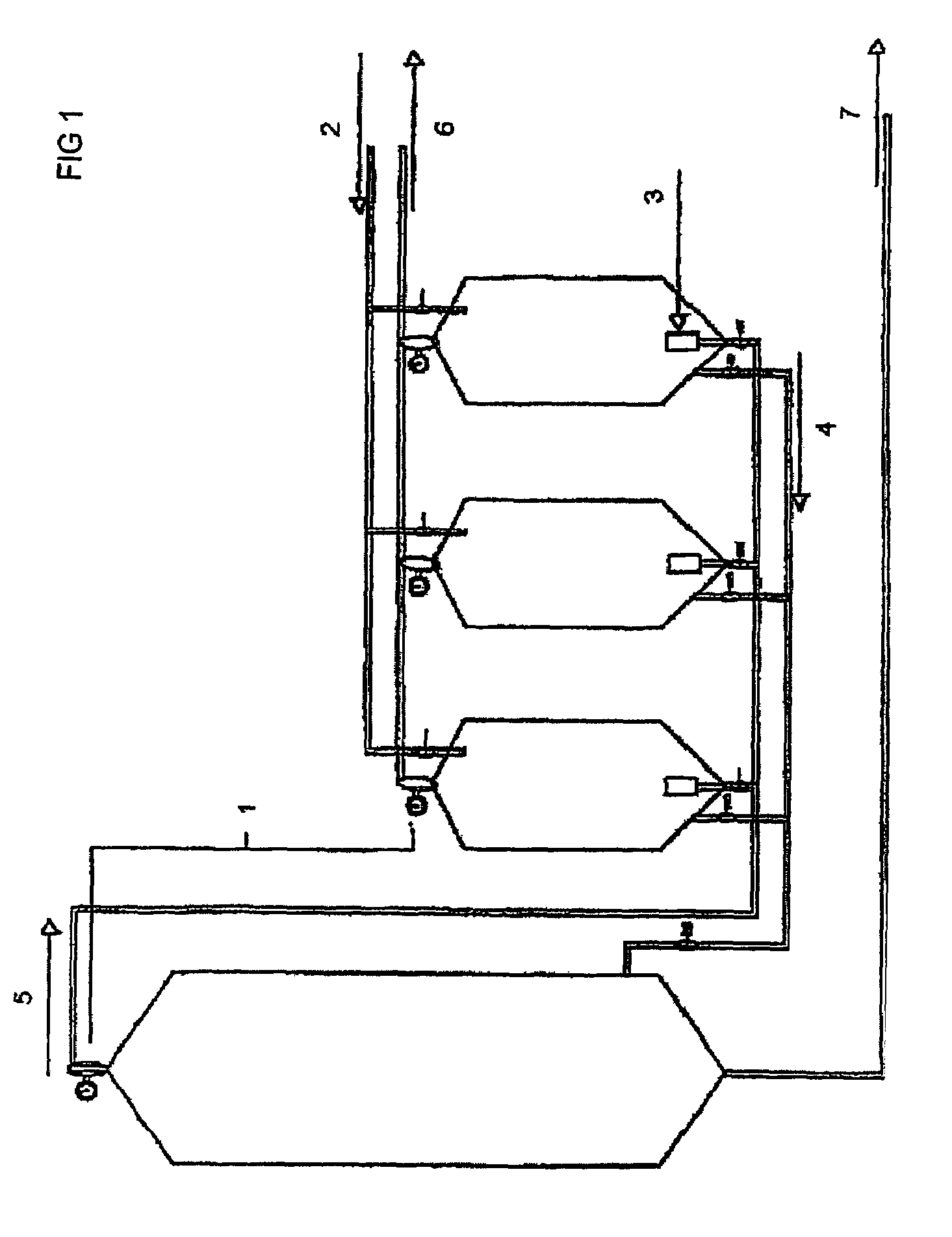

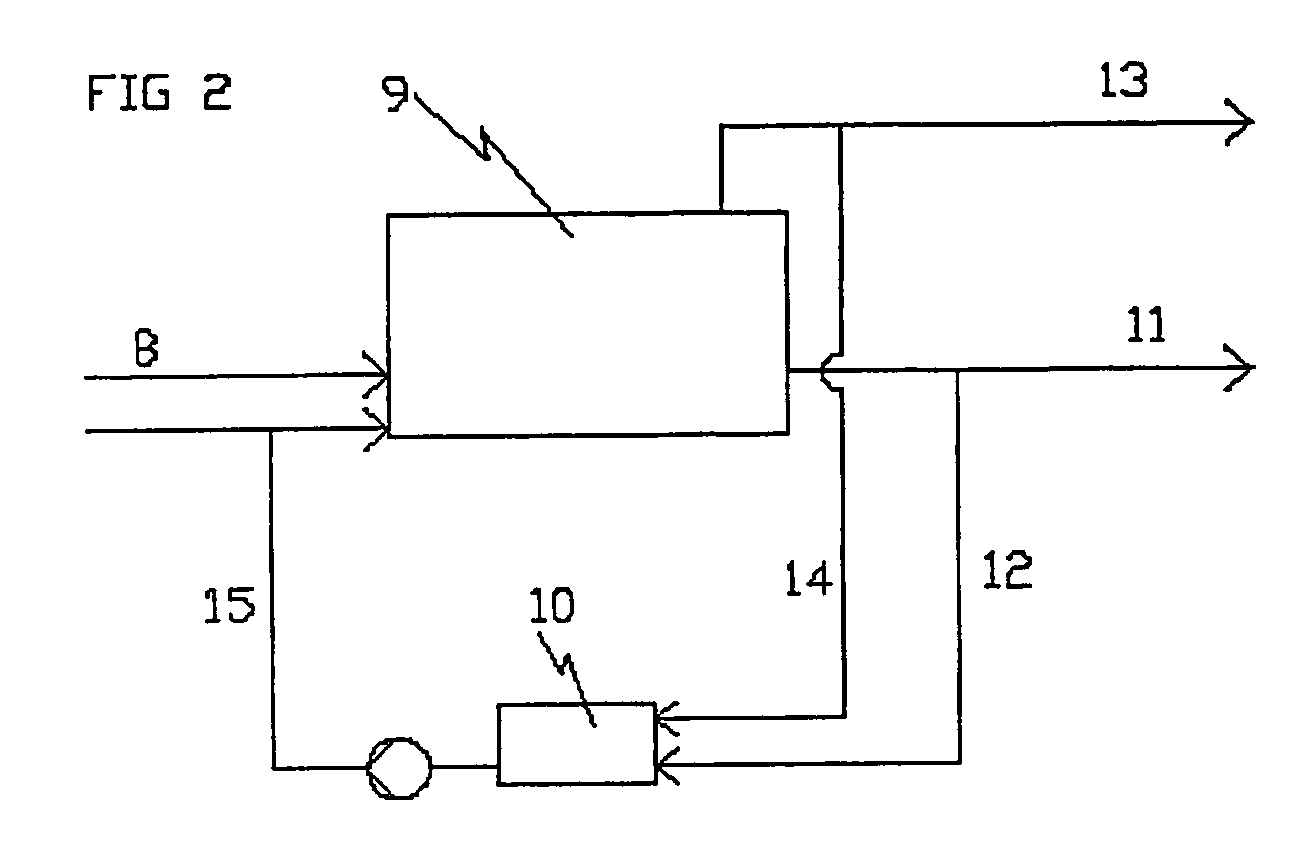

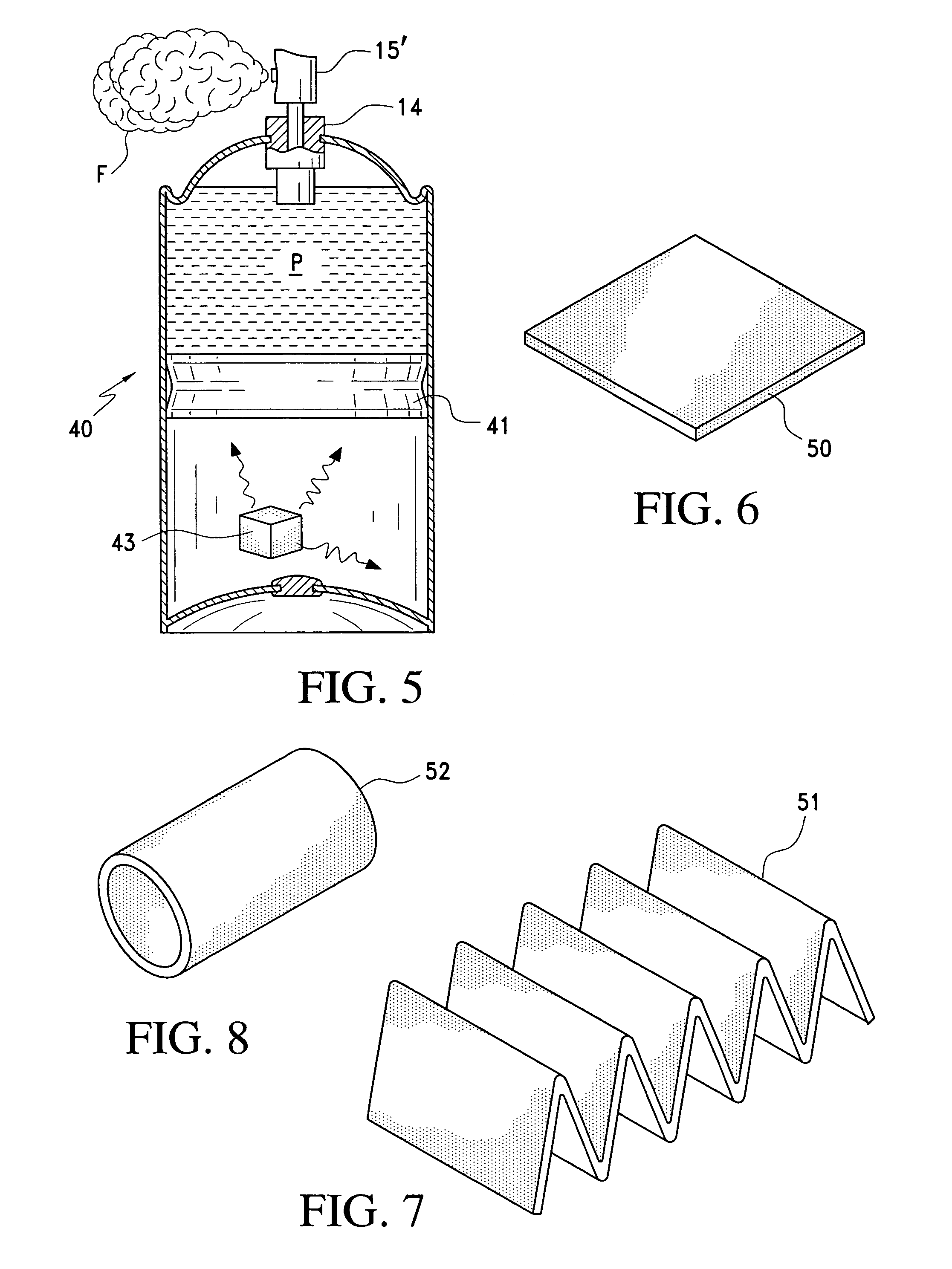

Method and equipment for processing organic material

InactiveUS7160456B2Organic material longerEasy to storeBio-organic fraction processingAnimal corpse fertilisersBuffer solutionAmmonia

A method for processing organic material, in which method bioconversion is performed on the organic material in at least one first reactor, the biogas formed in the bioconversion is treated with ammonia in at least one second reactor and buffer solution produced in the second reactor is recycled to the bioconversion in the first reactor. Thus, the carbon dioxide of the mixed methane / carbon dioxide gas reacts with the ammonia and forms a buffer compound, such as ammonium bicarbonate and / or ammonium carbonate.

Owner:PRESECO

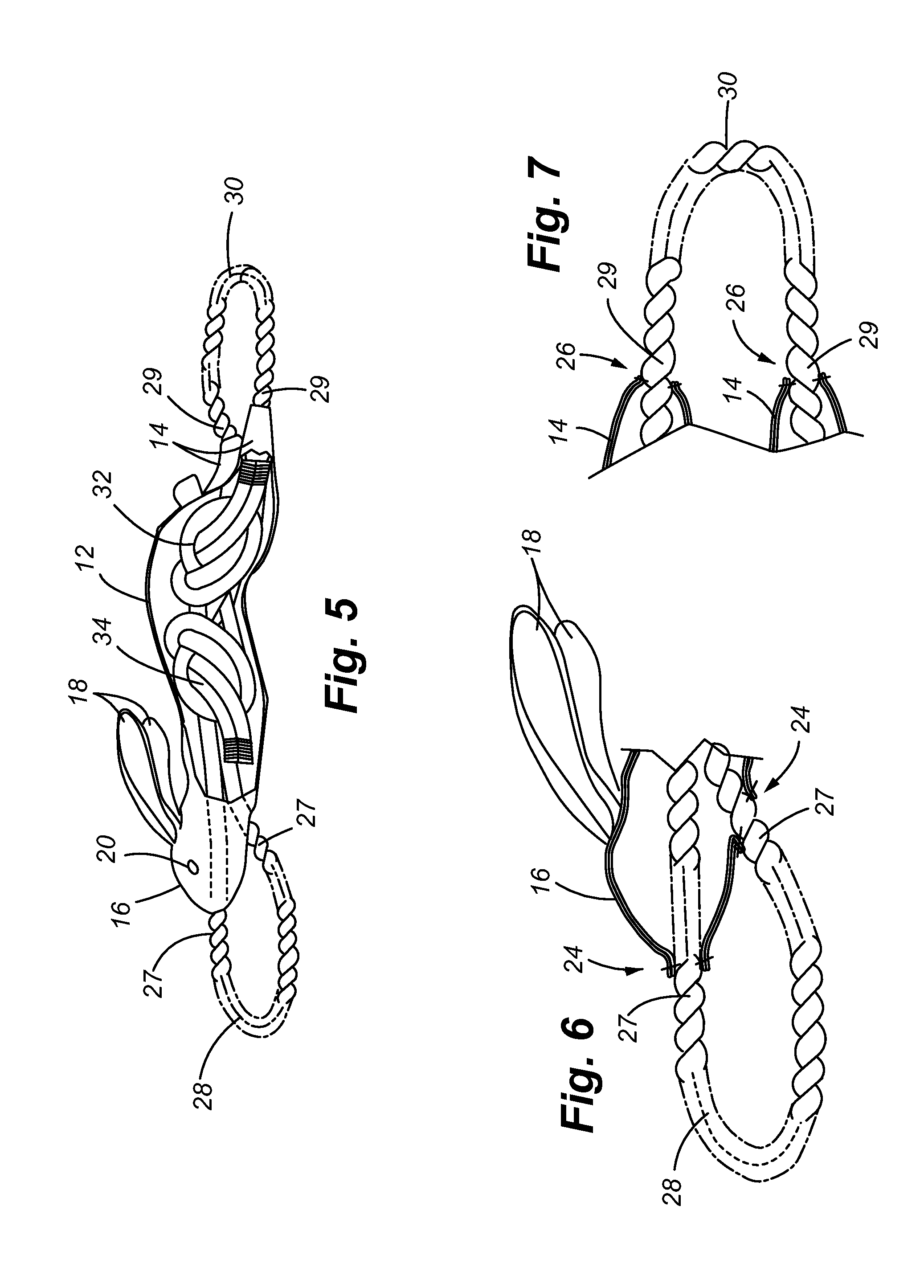

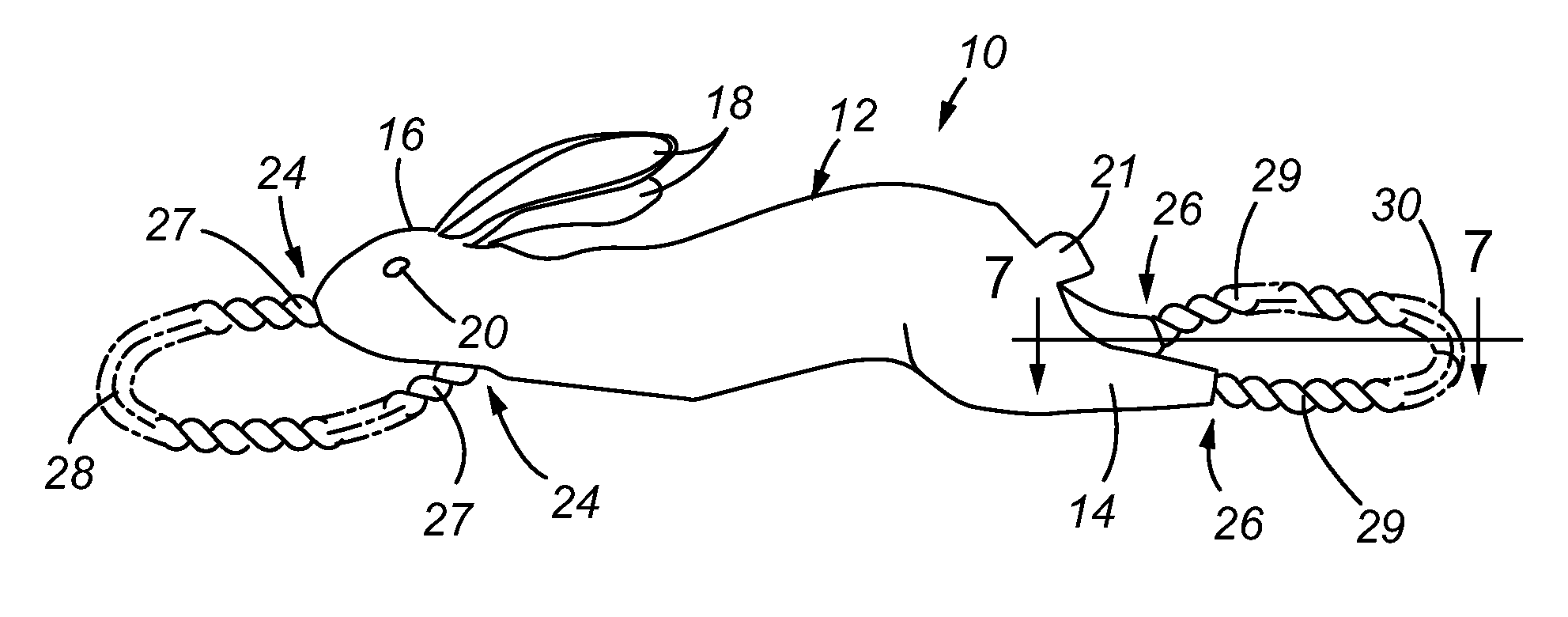

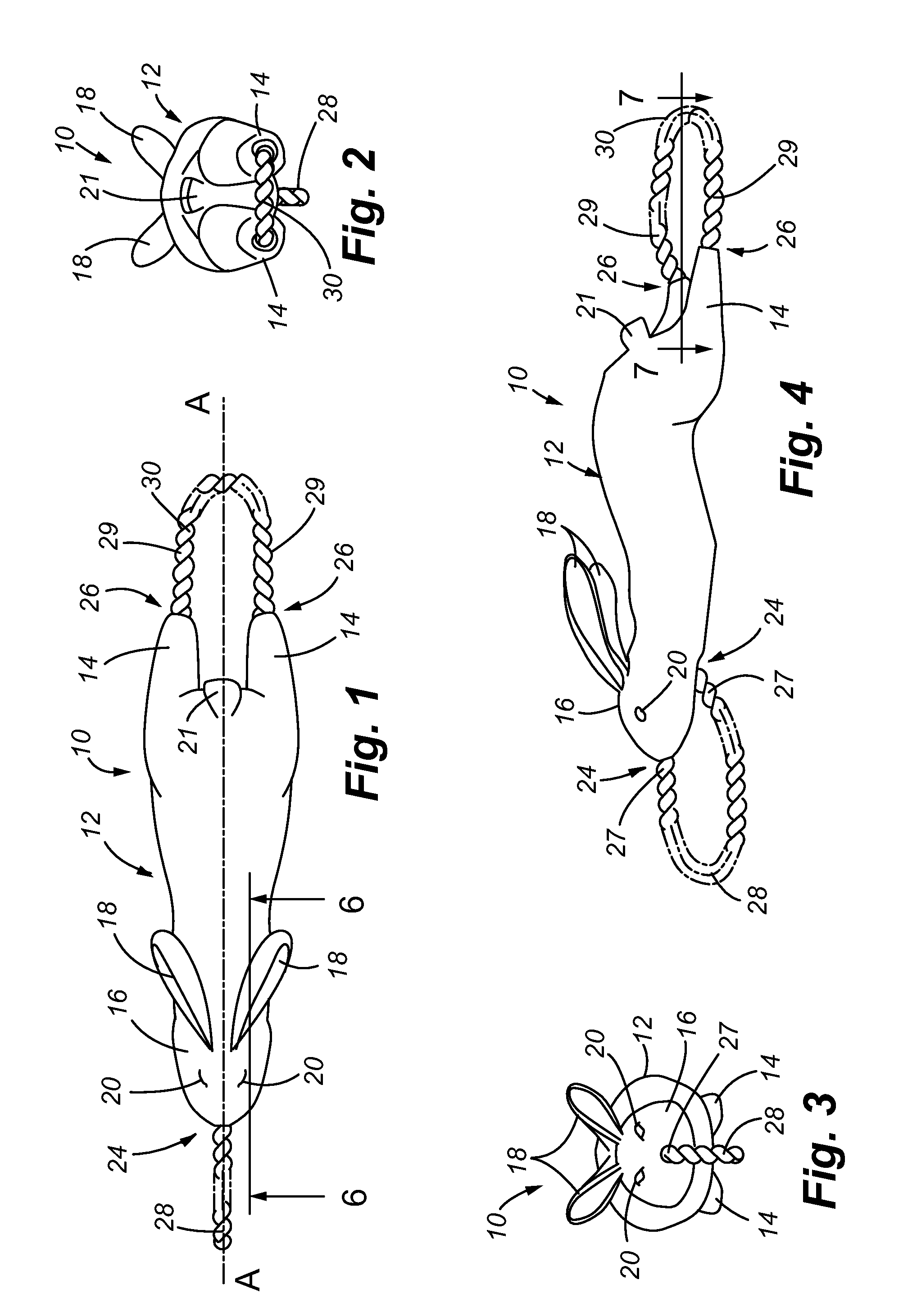

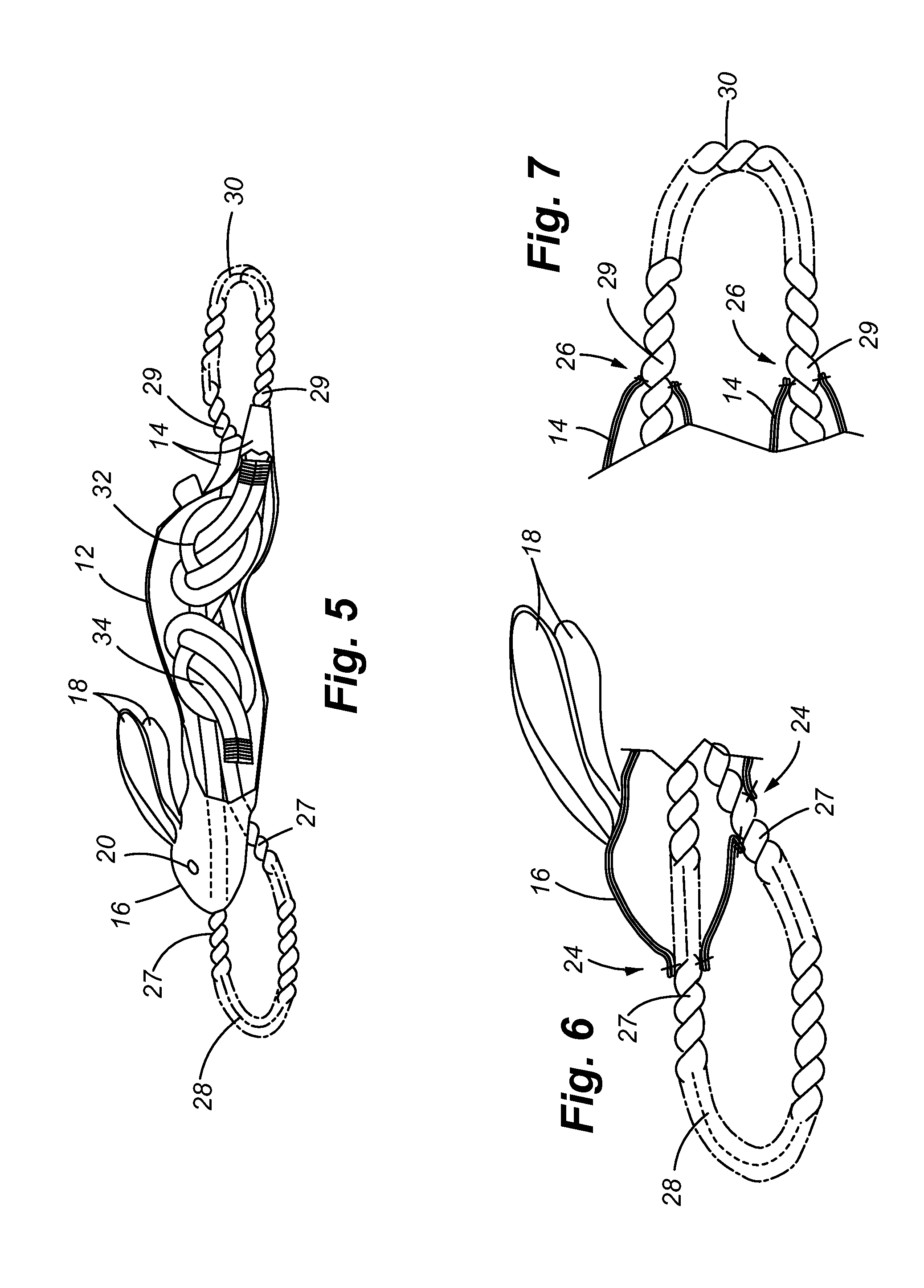

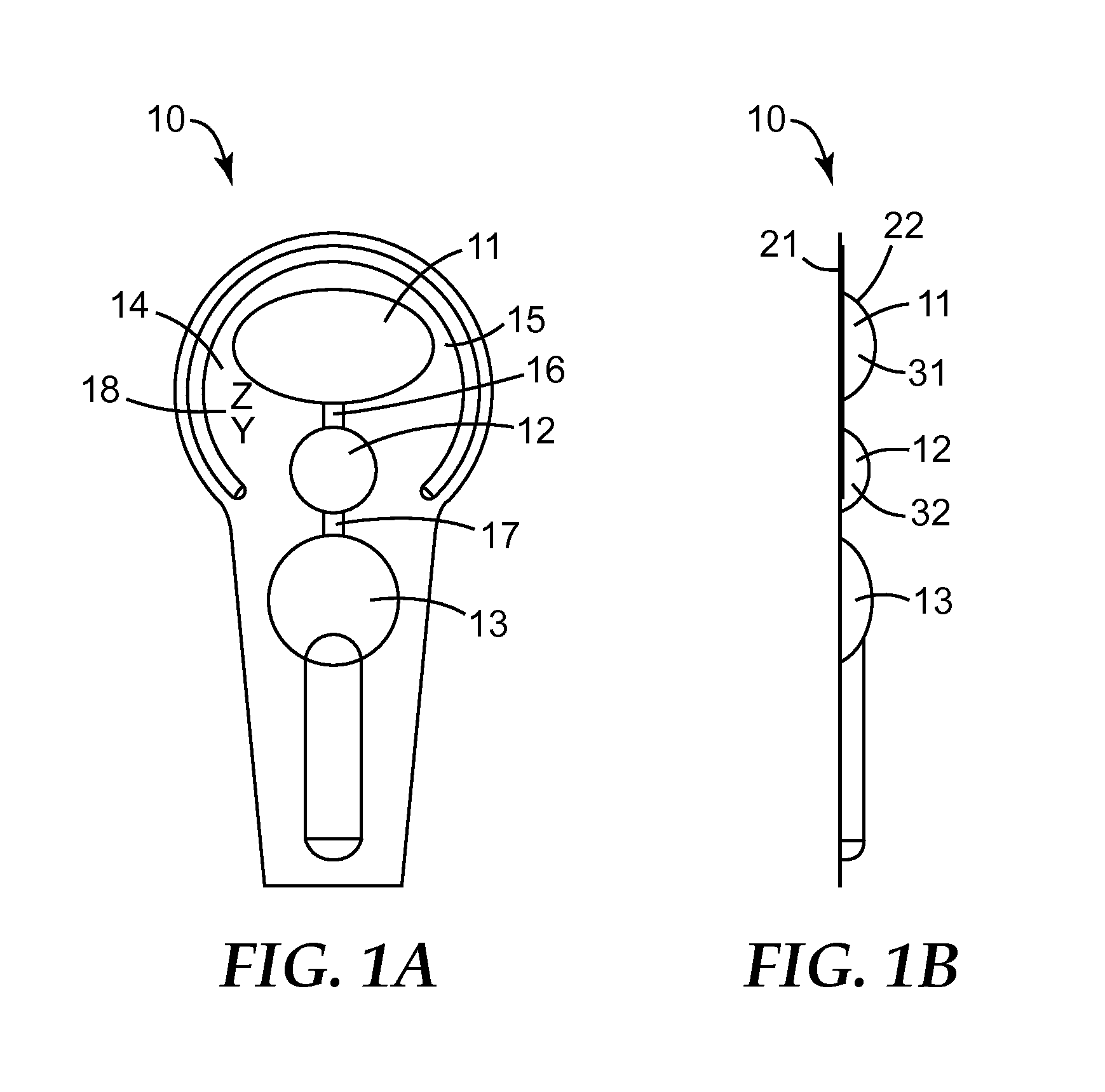

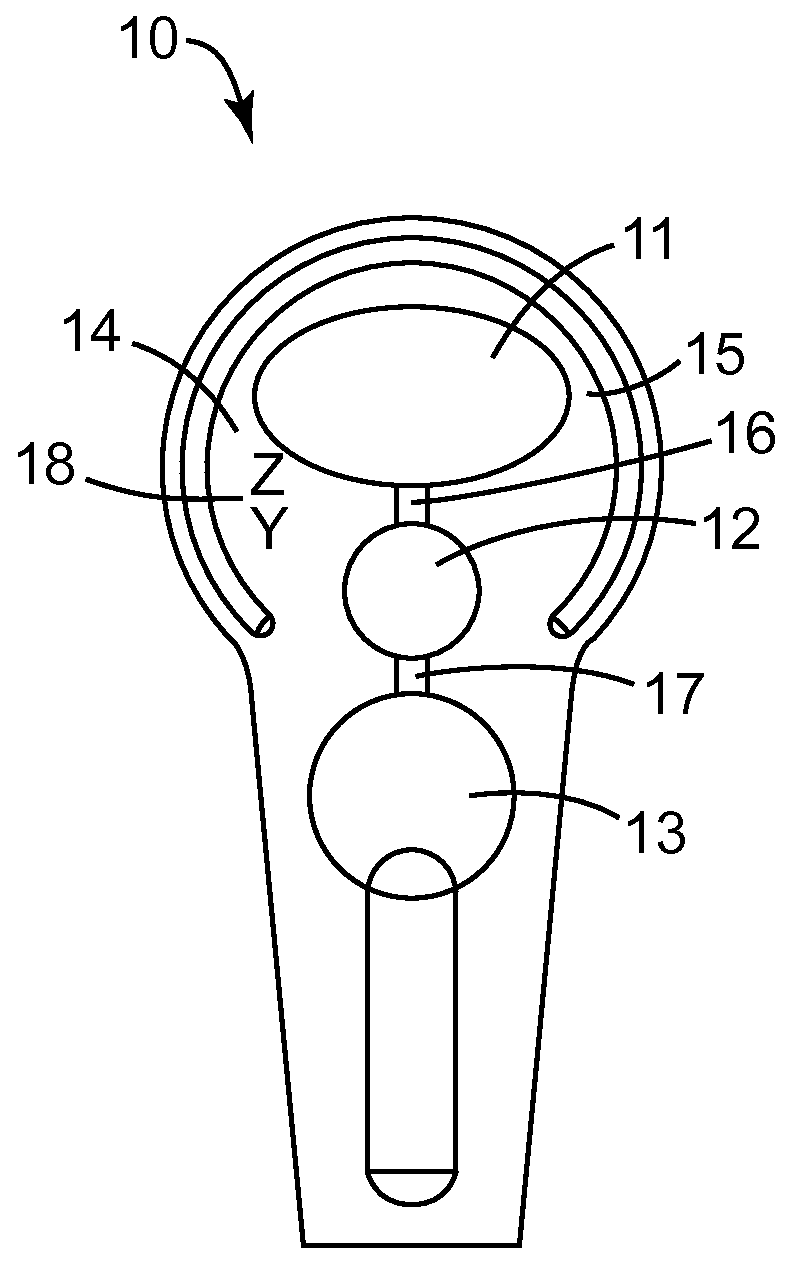

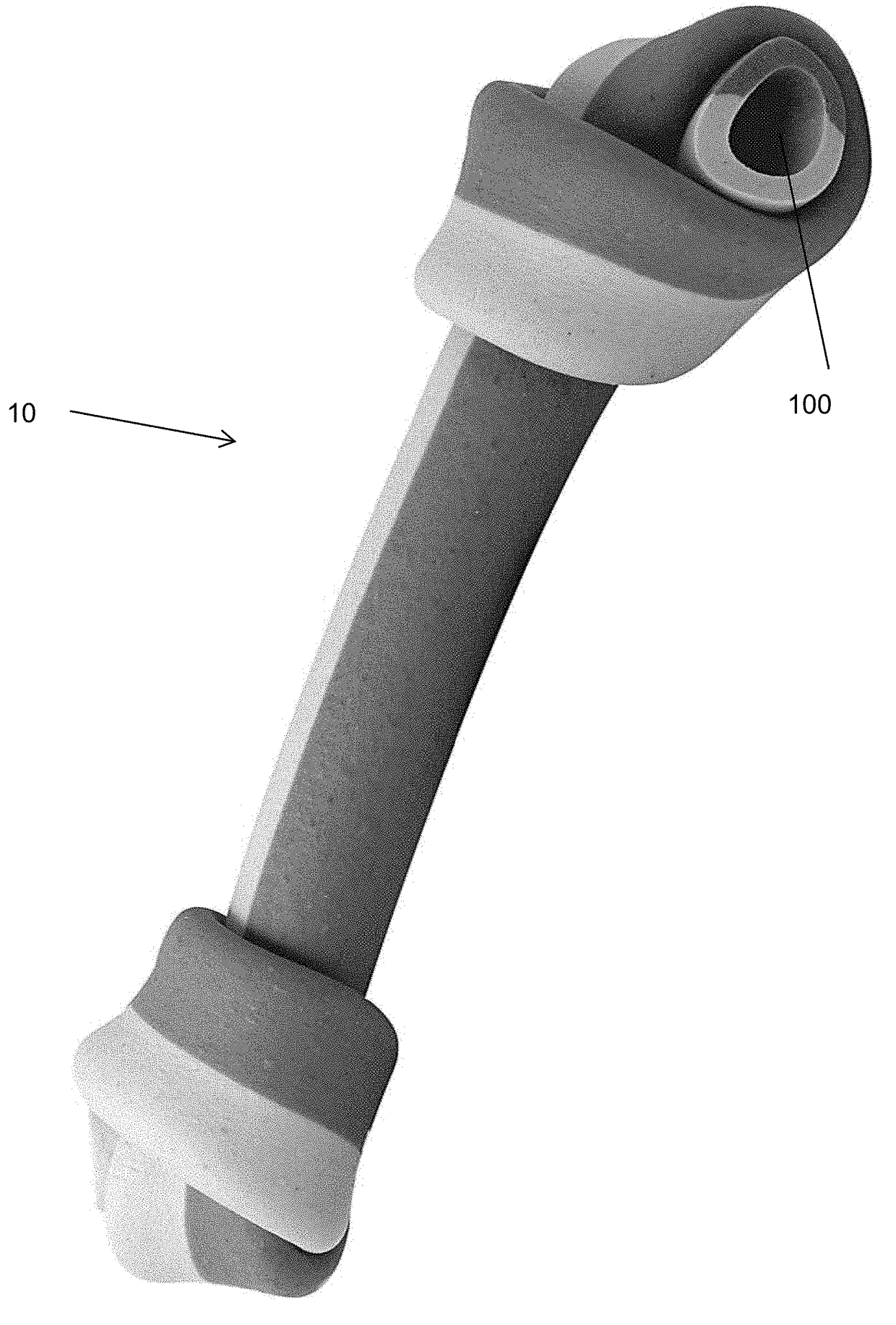

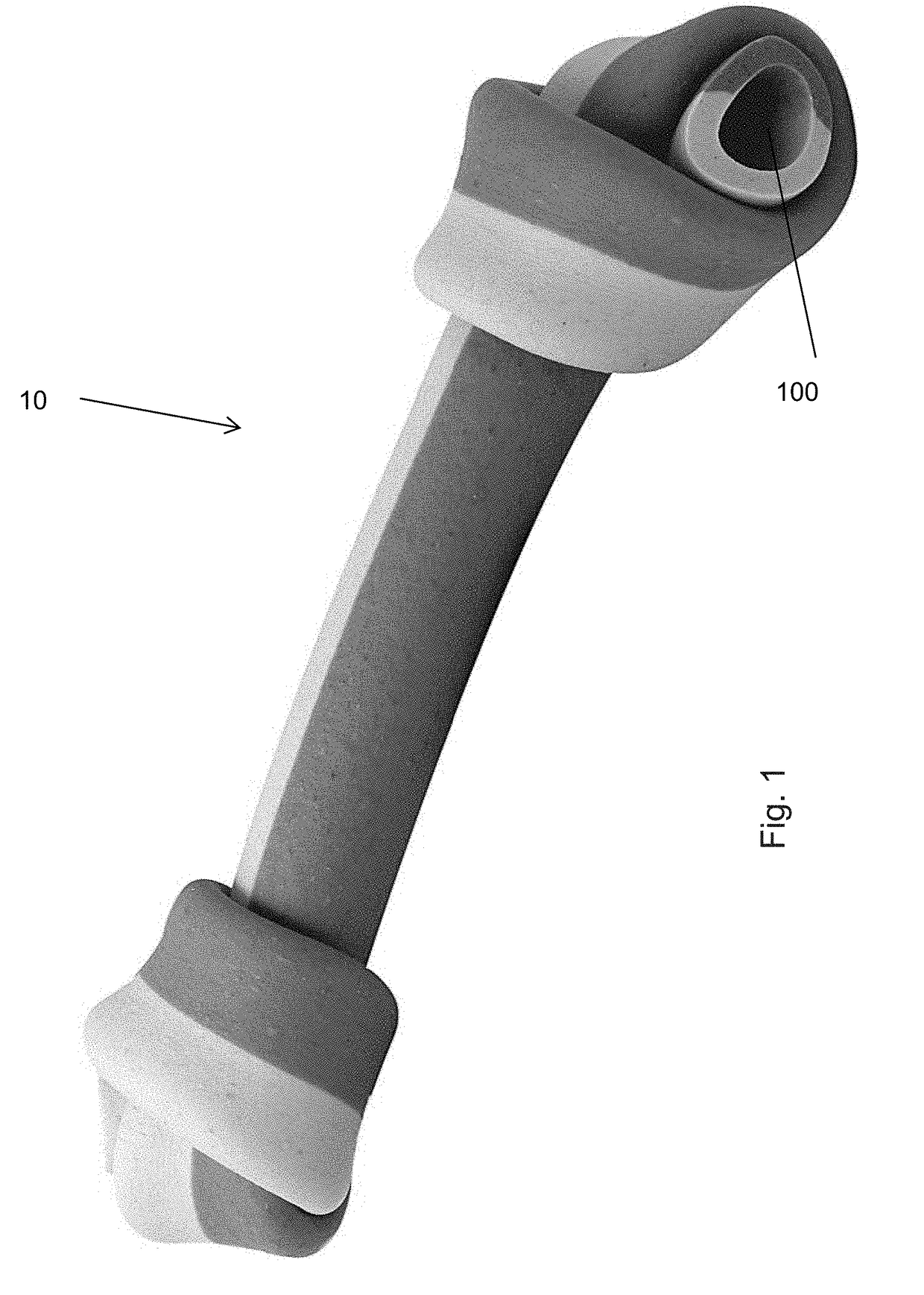

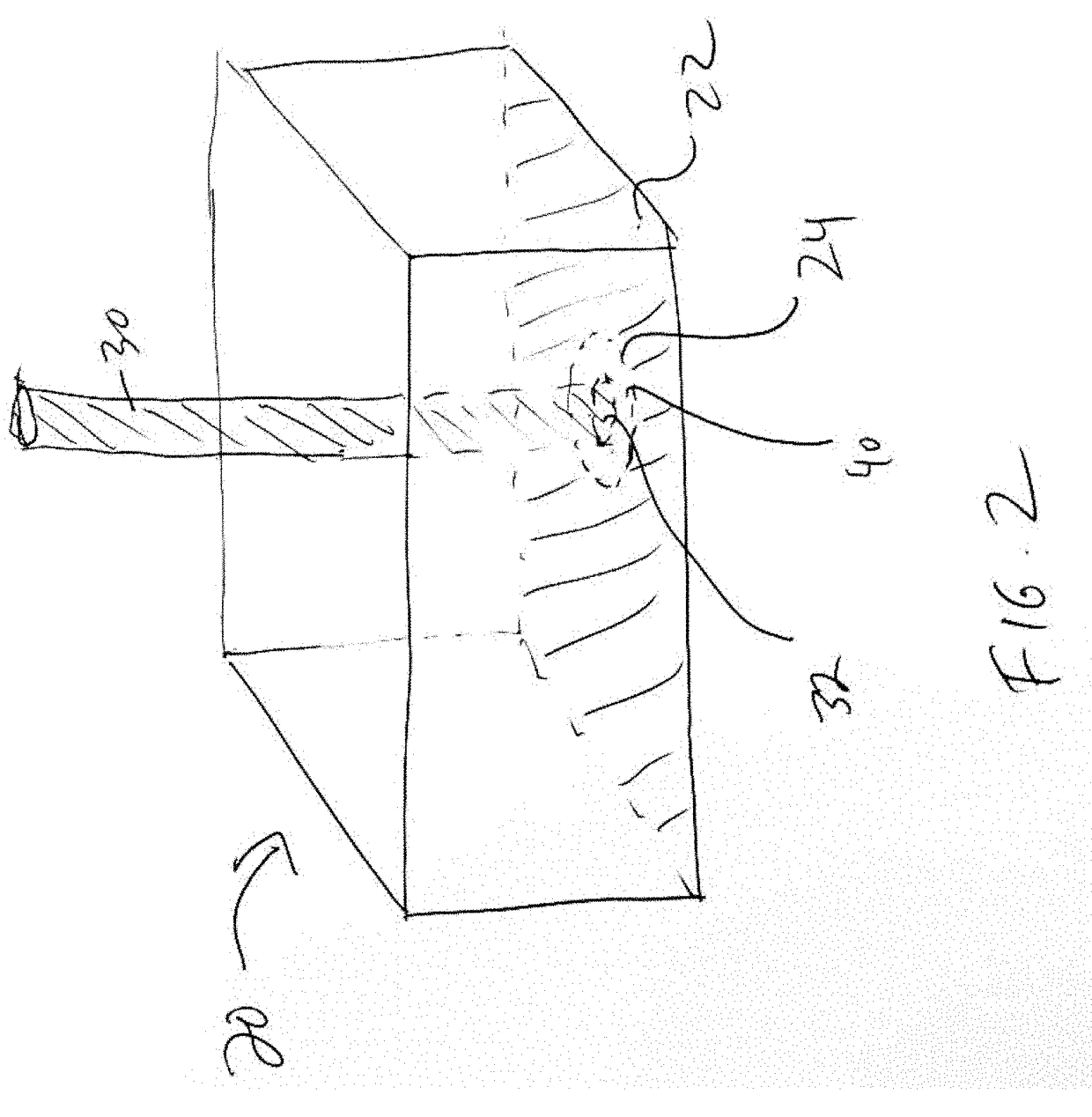

Pet toy with flexible body and rope support configurations

ActiveUS8393300B2Less stressRobust constructionFilament handlingOther apparatusEngineeringCompanion animal

Owner:THE KONG

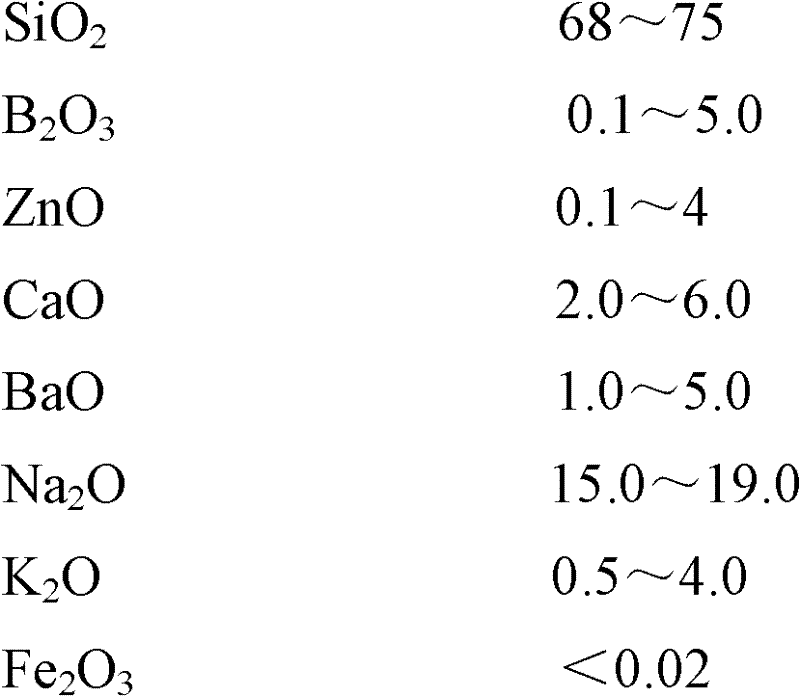

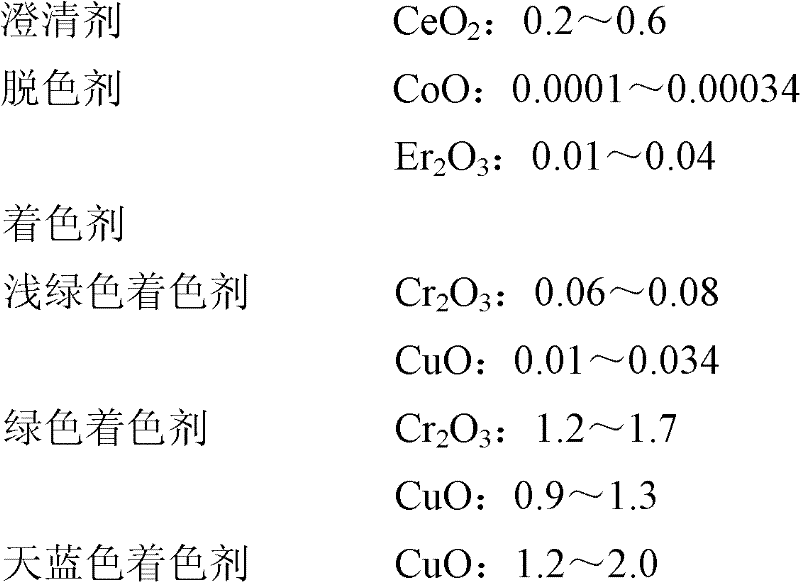

Leadless, cadmium-free and strontium-free glass and manufacture process thereof

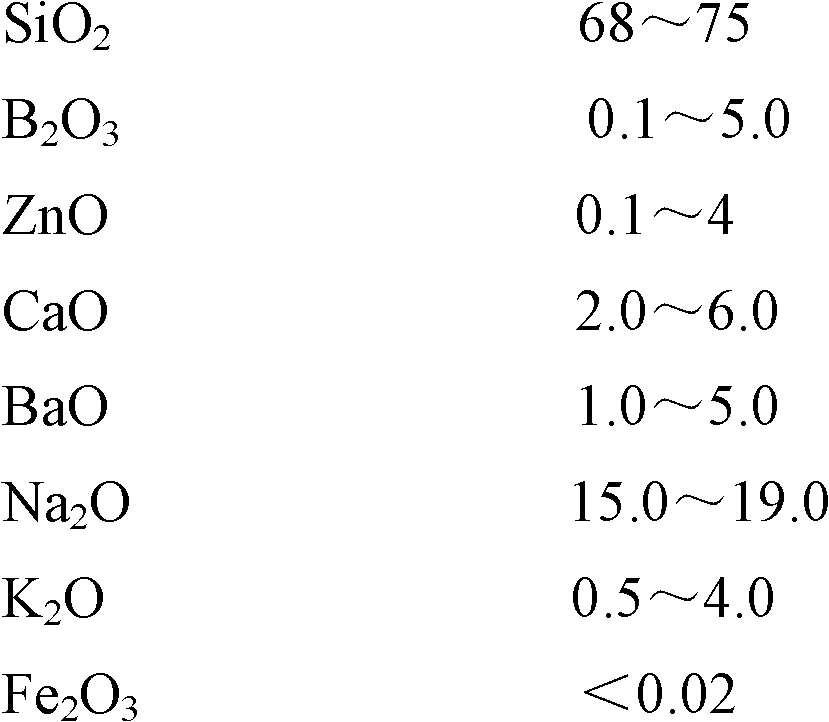

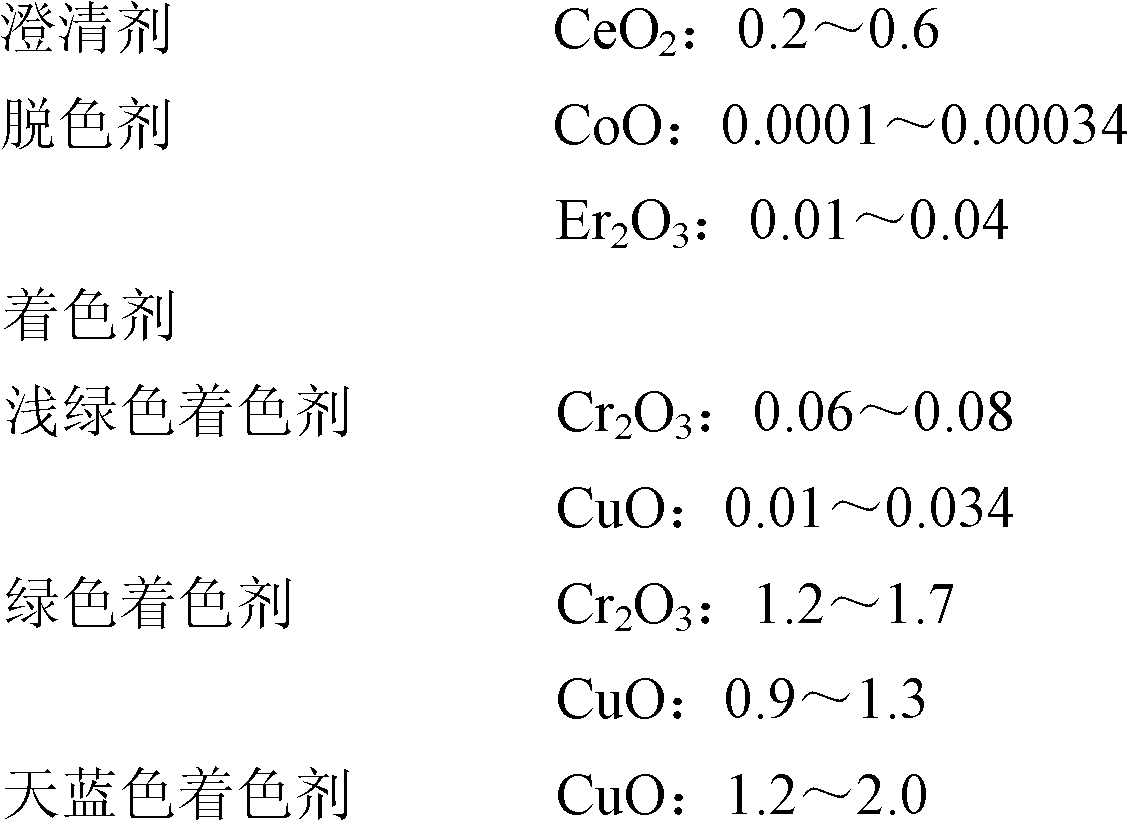

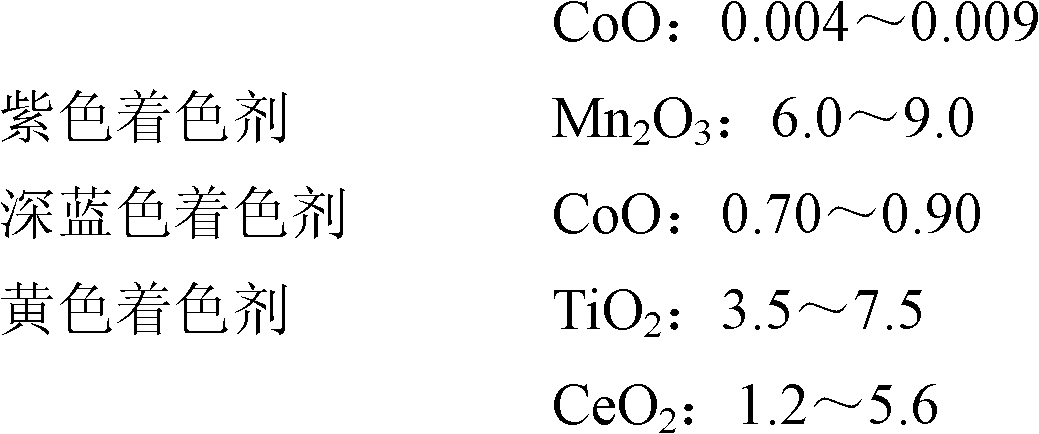

The invention belongs to the technical field of an inorganic amorphous material, and particularly relates to a leadless, cadmium-free and strontium-free transparent colored glass component and a manufacture process thereof. The transparent colored glass component is characterized by only containing conventional oxides, such as SiO2, B2O3, ZnO, CaO, BaO, Na2O, K2O and the like without containing lead, cadmium or strontium which has great toxic effect. The invention has the advantages that: a decolorizing agent is added into the leadless, cadmium-free and strontium-free basic component to prepare a colorless transparent glass product; various coloring agents are added into the leadless, cadmium-free and strontium-free basic component to obtain the colored glass. Equipment or investment is not additionally increased, the glass product with good color, low softening point and long material property can be produced only by adopting existing raw material treatment, melting furnaces, hot melting furnaces, annealing furnaces, cold machining and other equipment, and the cost of the transparent colored glass is reduced by 2 to 4 times than that of conventional medium-lead and high-lead glass. The invention has wide application prospect.

Owner:DALIAN POLYTECHNIC UNIVERSITY

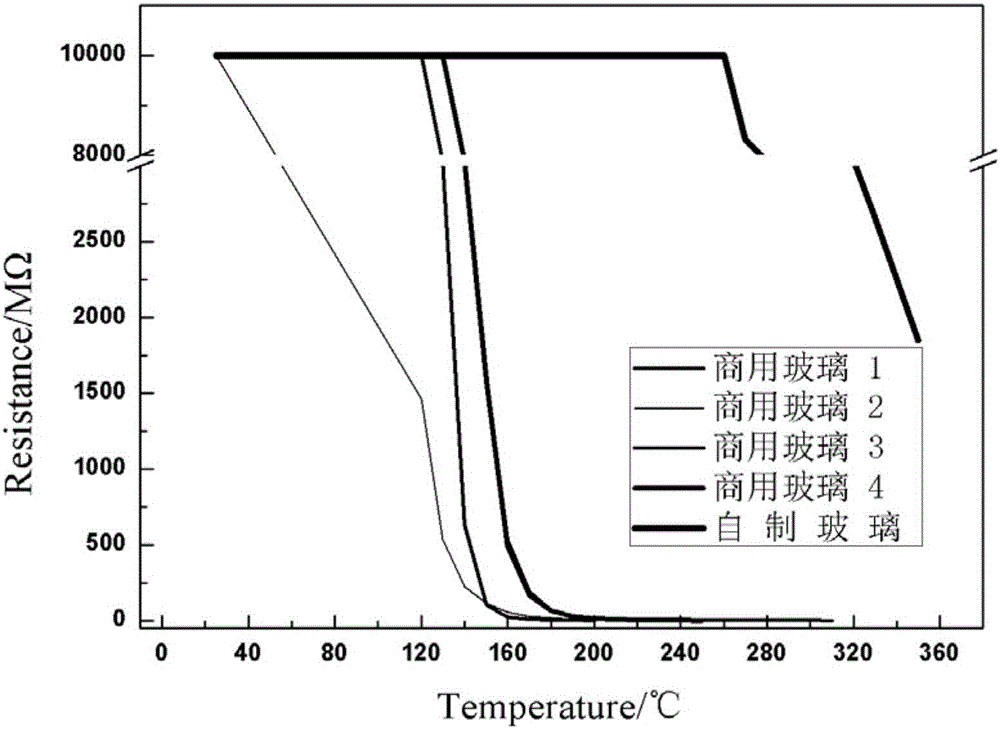

Sealing glass powder for electric connectors, preparation method for sealing glass powder and sealing process of sealing glass powder

ActiveCN105859144ALower melting temperatureHigh expansion coefficientContact member assembly/disassemblyMixed alkali effectOxide

The invention discloses sealing glass powder for electric connectors. According to the sealing glass powder, silicon dioxide serves as a skeleton structure and serves as a network forming body of glass, and an extremely small amount of alkali metal element is used, so that the melting temperature is lowered, the coefficient of expansion is increased, and the influence on high-temperature insulating properties of the glass is relatively low; alkaline-earth metal oxides such as MgO, CaO, SrO and BaO are added, and network gaps are filled with cations, i.e., Mg<2+>, Ca<2+>, Sr<2+> and Ba<2+> of MgO, CaO, SrO and BaO and a mixed base effect and a depressing effect are generated, so that the movement of alkali metal ions is hindered, and thus the insulating properties of the glass is improved; due to relatively high content of BaO, the material properties of the glass can be improved, and the high-temperature insulating properties of the glass is greatly improved; due to the addition of Al2O3, an AlPO4 unit can be formed in the glass, and a straight chain is changed into a network structure, so that the structure of the glass is stabilized, and the chemical stability is improved; in addition, by adding oxides such as ZnO, TiO2, ZrO2 and V2O5, the improvement on the chemical stability and electrical insulating performance of the glass is facilitated.

Owner:XIAN SEAL ELECTRONICS MATERIAL TECH CO LTD

Glass protection lubricant powder used for titanium alloy die forging forming and paint

InactiveCN105132103AWide temperature rangeNo flowCoatingsLubricant compositionCelluloseWater soluble

The invention belongs to the technical field of paint, and relates to glass protection lubricant powder used for titanium alloy die forging forming and paint. The glass protection lubricant powder comprises silicon dioxide (SiO2), sodium oxide (Na2O), calcium oxide (CaO) and boric oxide (B2O3). Brush coating is conducted through suspension prepared from heat-resistant type water-soluble cellulose and water, wherein the grain size of glass powder is 200 meshes or below. The use temperature range of the glass protection lubricant is wide and is between 700 DEG C and 1000 DEG C, melting begins at the temperature of 700 DEG C, and no flowing happens at the temperature of 1000 DEG C. the forging process temperature of titanium alloy is 945+ / -15 DEG C. The high temperature viscosity change range of the glass protection lubricant is narrow, and melting coverage can be achieved within the short time of 8 minutes or less. The flowing and protection deficiency phenomena do not happen within the heat preservation time of 8 hours. In addition, the high-temperature contact angle of the prepared glass protection lubricant on the surface of TC4 titanium alloy is small, the temperature is 40 degrees lower than the temperature of 945+ / -15 DEG C, and in other words, the titanium alloy surface wettability is good. The friction coefficient measured through a circular ring test is lower than 0.01.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

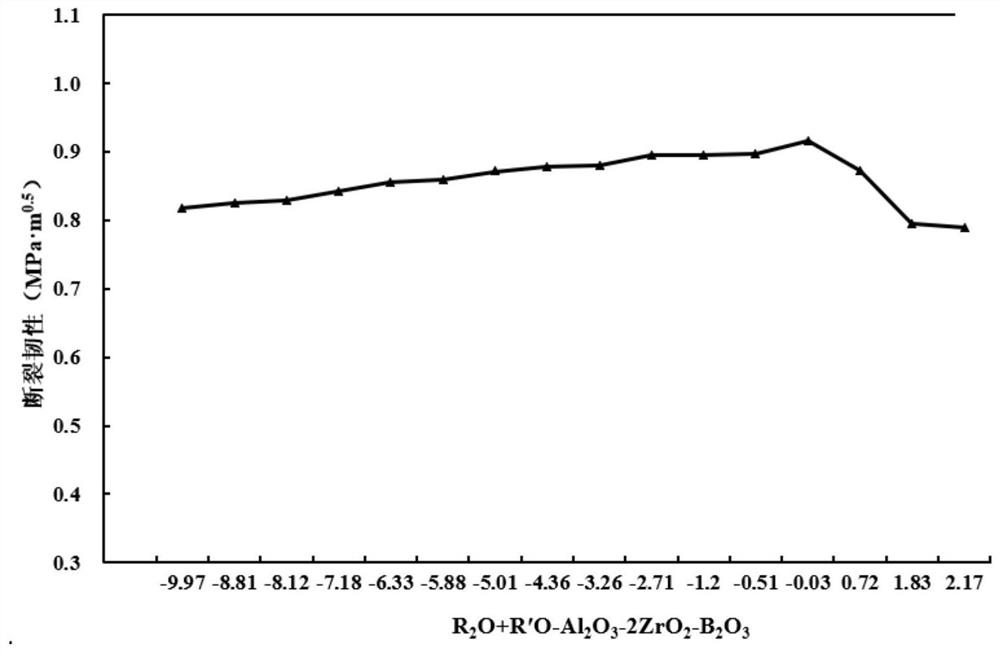

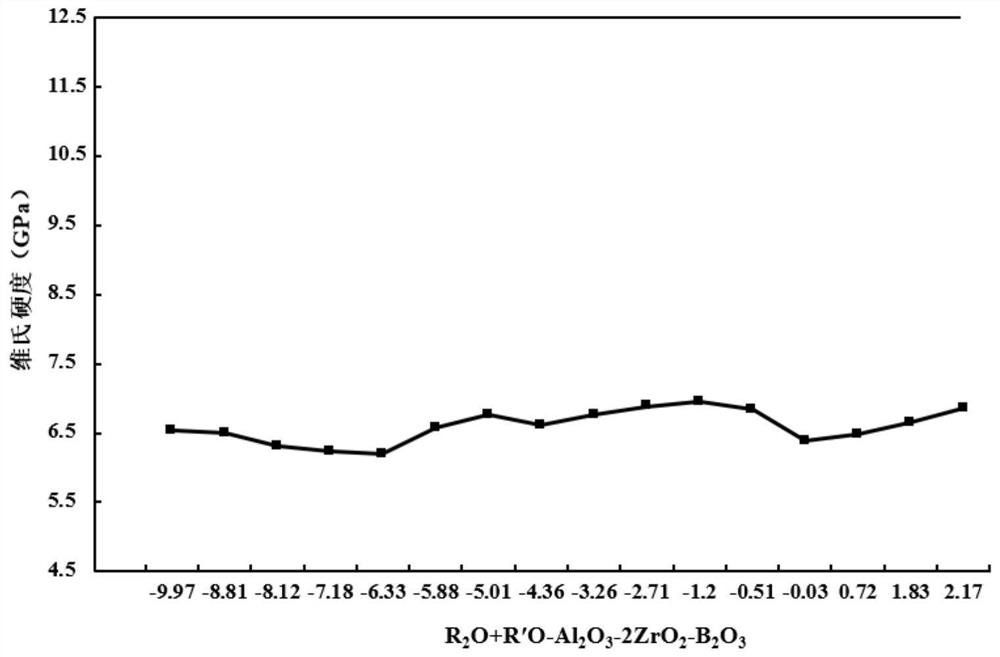

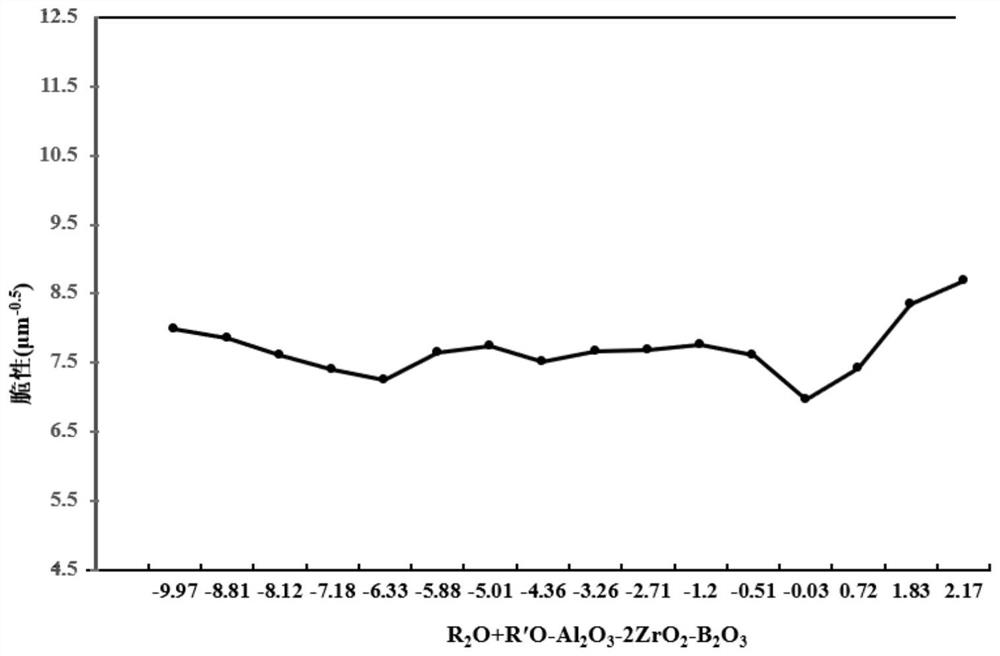

High-strength and low-brittleness aluminosilicate glass as well as strengthening method and application thereof

The invention provides high-strength and low-brittleness aluminosilicate glass as well as a strengthening method and an application thereof. The glass is prepared from the following components in percentage by mole; 56%-70% of SiO2, 8%-25% of Al2O3, 1%-10% of B2O3, 0-15% of Li2O, 6%-20% of Na2O, 0-10% of K2O, 0-5% of MgO, 1%-5% of ZrO2 and 0.1%-1% of SnO2. The strengthening method comprises the following steps: preparing raw materials according to the components of the glass, melting and clarifying the raw materials, and forming the glass; and carrying out ion exchange on the glass in a salt bath of potassium nitrate and sodium nitrate at 360-450 DEG C to obtain the chemically strengthened aluminosilicate glass which can be applied to mobile device protection and fixed device protection.

Owner:CAIHONG GRP SHAOYANG SPECIAL GLASS CO LTD

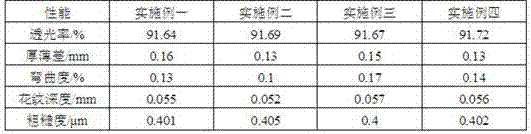

Ultrathin photovoltaic rolled glass

InactiveCN107162407AReduce glass expansion coefficientIncrease glass refractive indexExpansion factorOxide

The invention discloses ultrathin photovoltaic rolled glass. The ultrathin photovoltaic rolled glass comprises the following oxides by mass percentage: 71.0-73.18% of SiO2, 8.0-8.50% of CaO, 3.50-4.50% of MgO, 1.35-2.8% of Al2O3, 13.30-14.0% of Na2O, 0.6-1.0% of B2O3, 0.05-0.18% of Sb2O3, 0.05-0.1% of CeO2 and 0.01-0.012% of Fe2O3. According to the content of the oxides, the raw materials are compounded, and the photovoltaic rolled glass of which the thickness is less than 2.0 mm is prepared by founding, rolling forming and annealing processes; a glass component system is optimized, the B2O3 is introduced to reduce the glass expansion factor and increase the glass refractive index so as to play the fluxing action; the CeO2 and nitrate perform the combined action, so the clarification and decoloration effects are improved, the drawability of the glass is enhanced, and the plasticity of the photovoltaic rolled glass is improved; and the content of the Al2O3 and MgO is high, and the frit performance is improved. The final performance can satisfy the high-transparent and high-speed formability requirements of the industrial production of the photovoltaic glass of which the thickness is less than 2.0 mm, the production cost is saved, and the industrial production of the light and thin photovoltaic glass is realized.

Owner:CNBM YIXING NEW ENERGY CO LTD

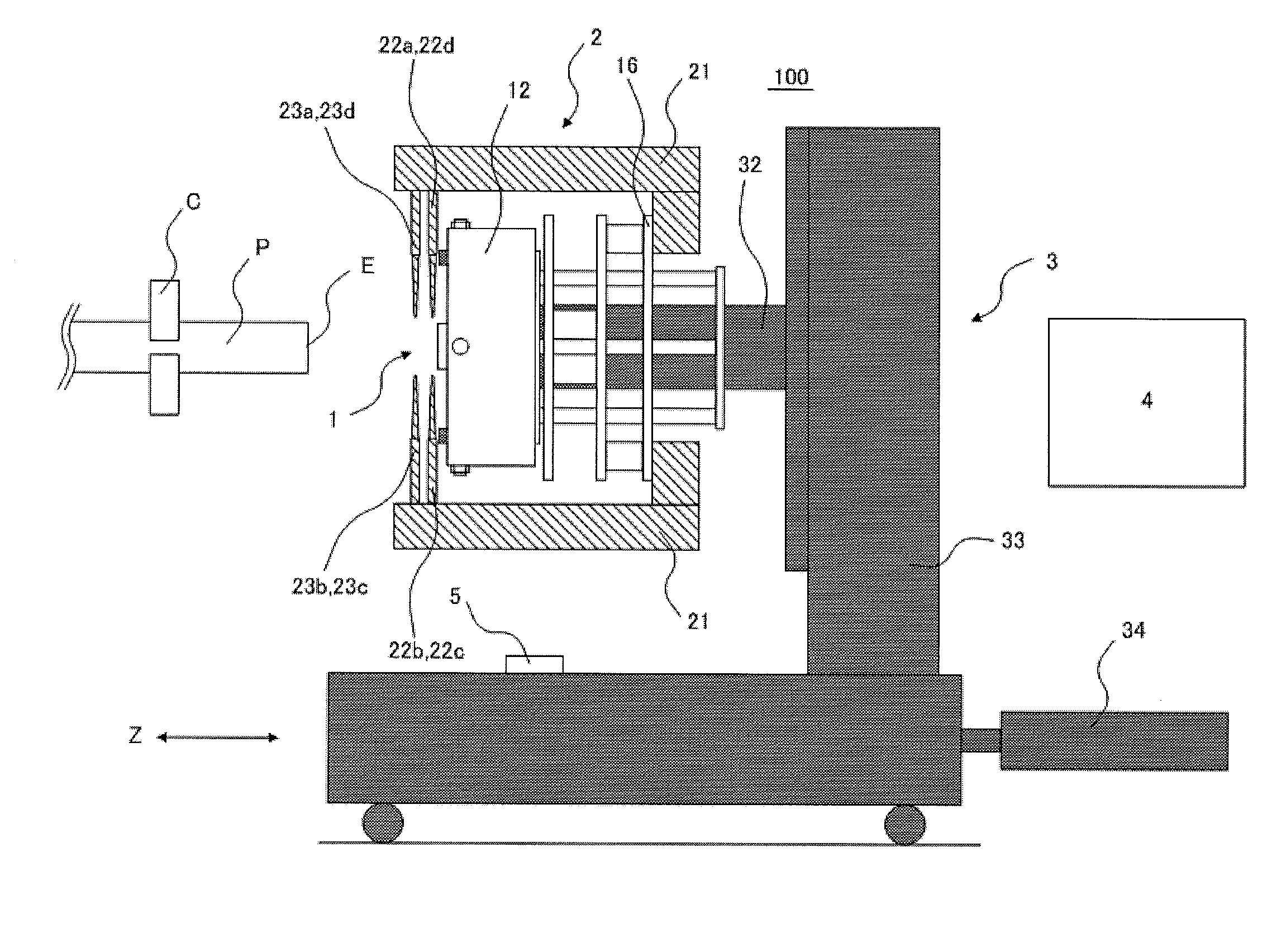

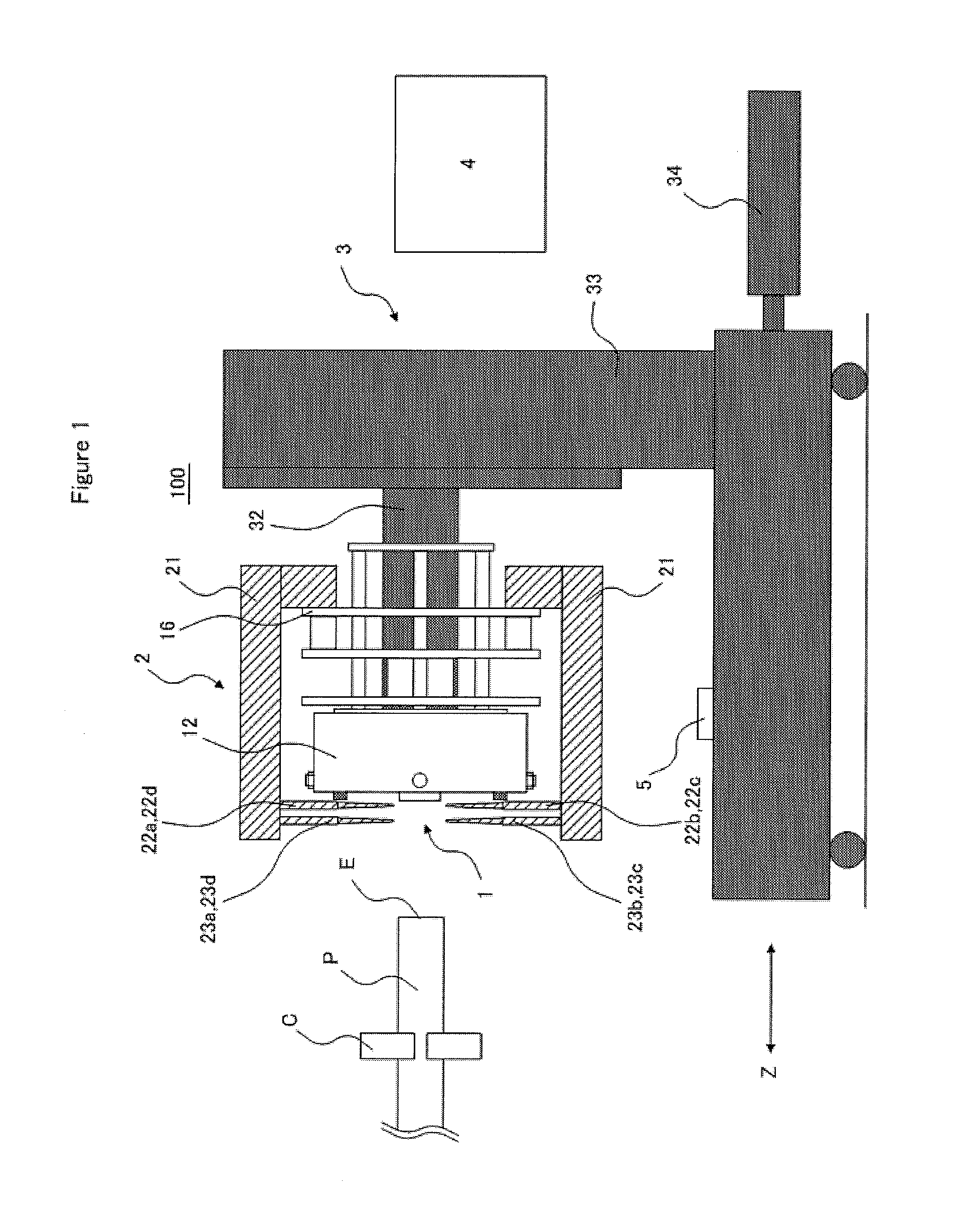

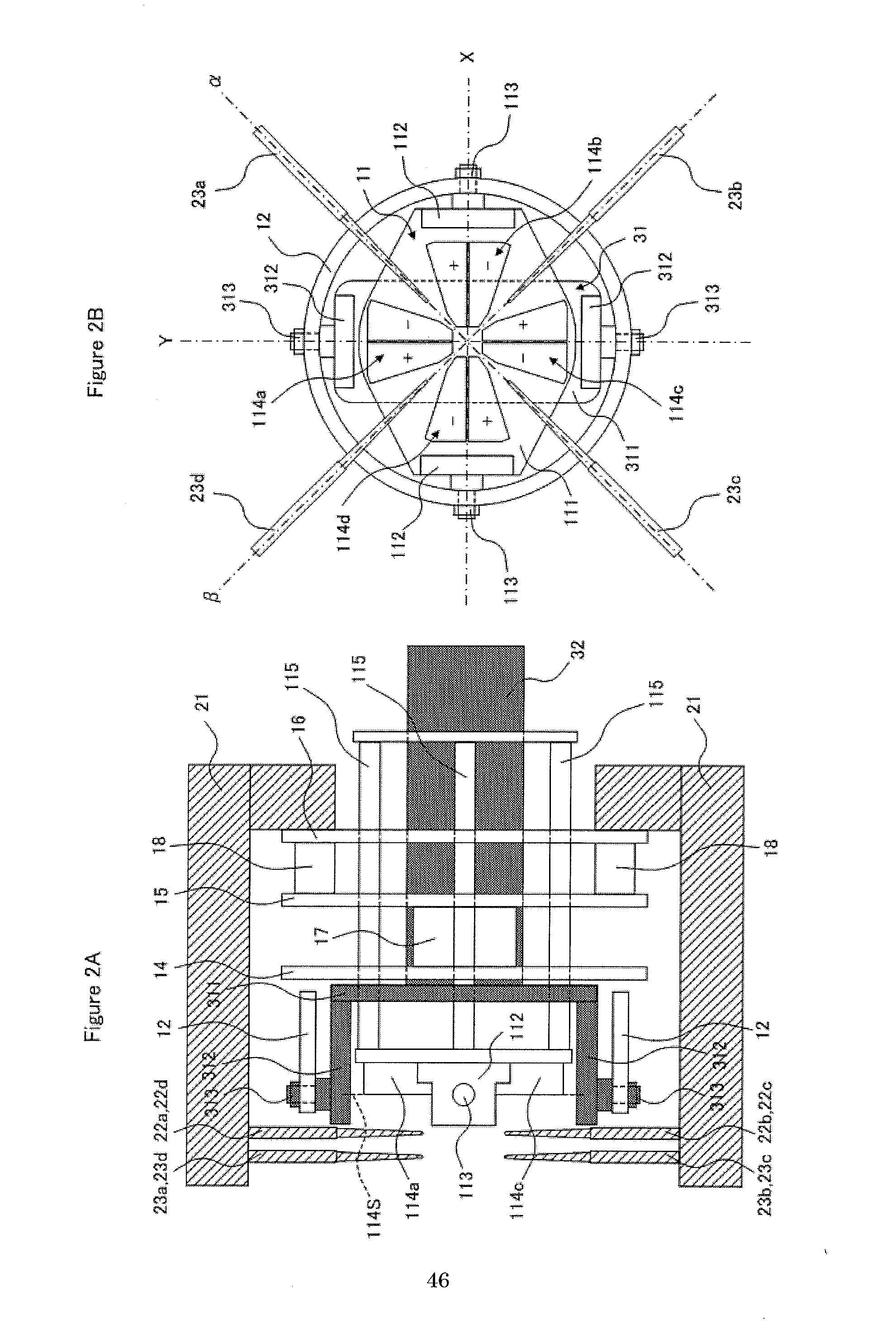

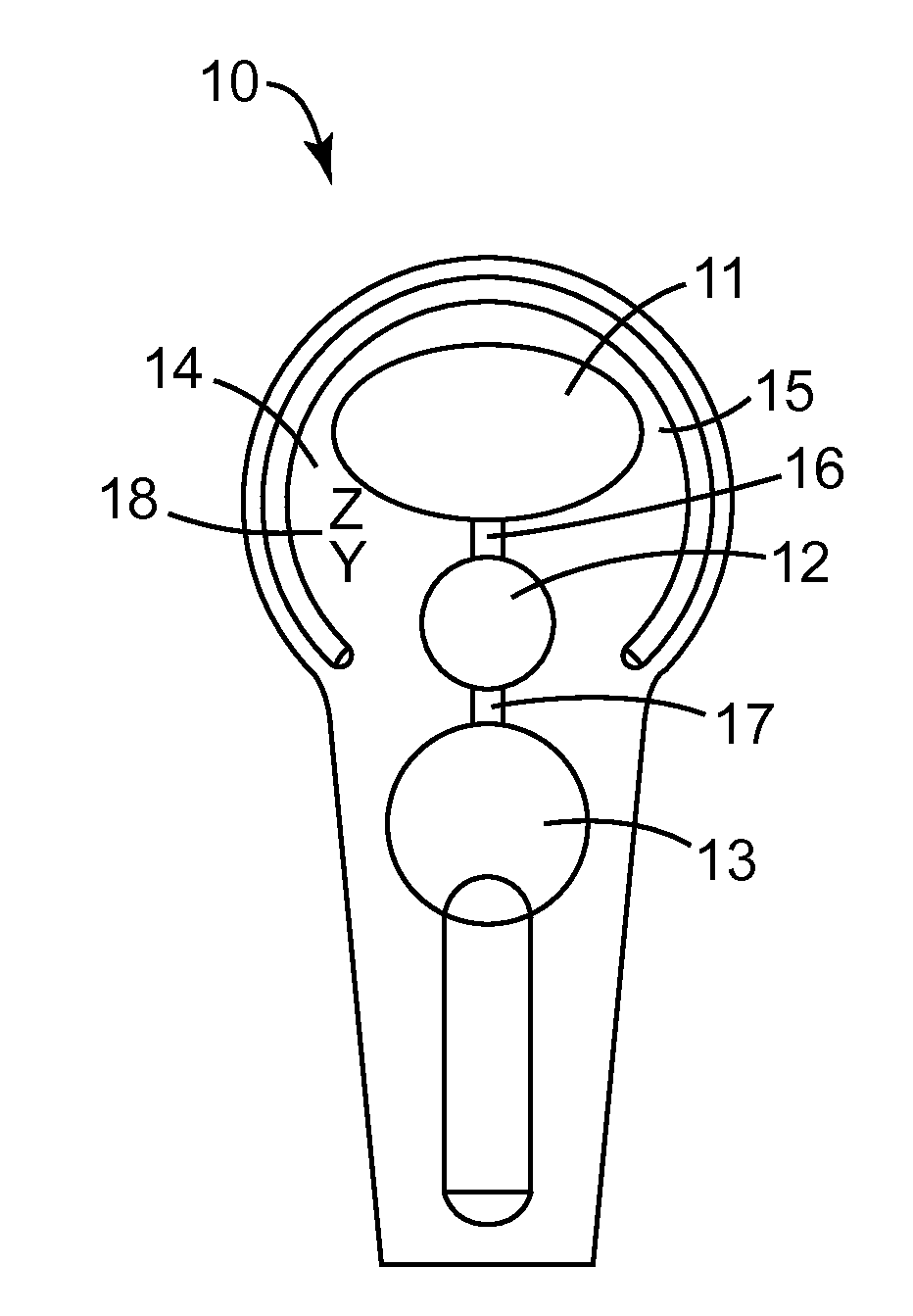

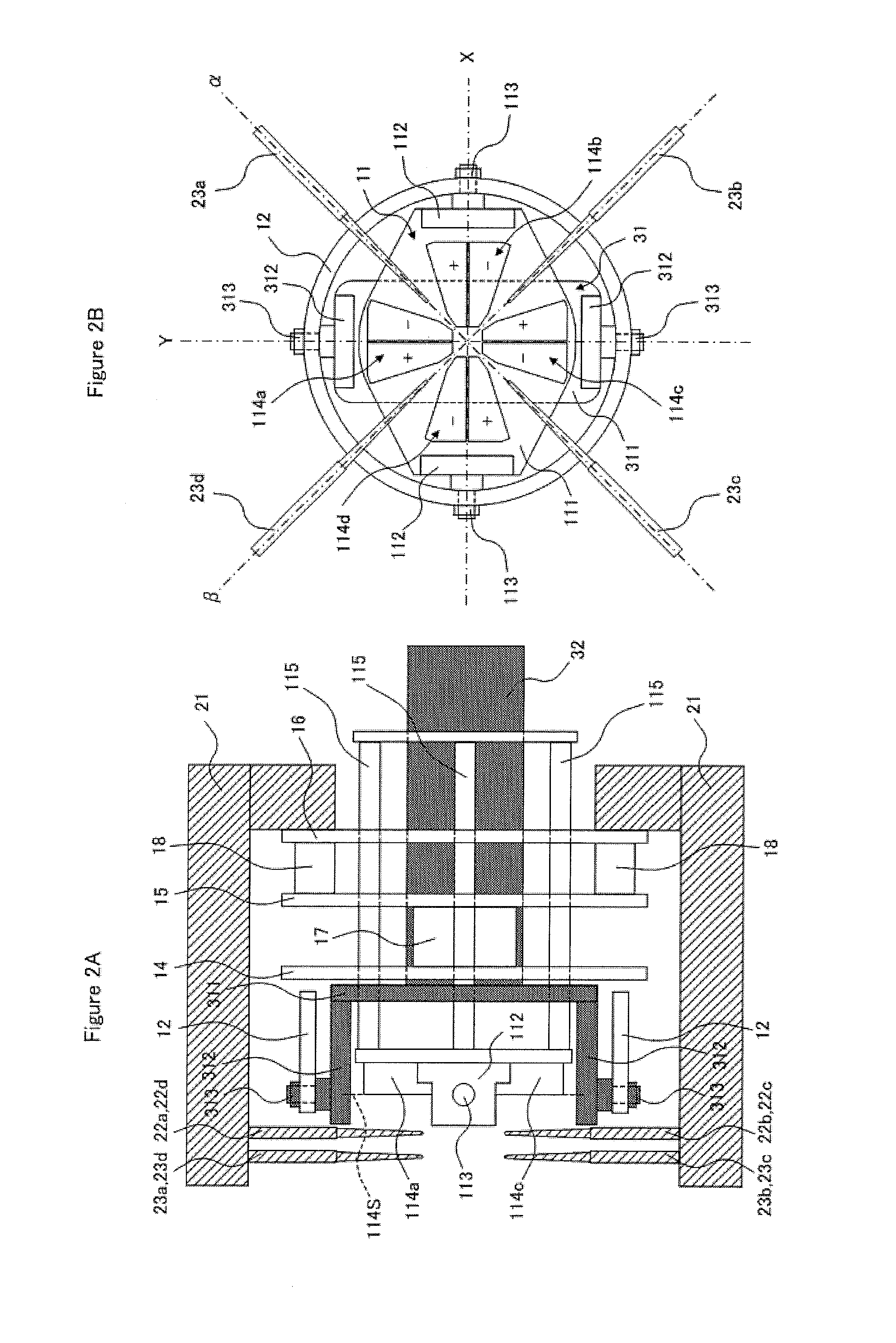

Dimension measuring device for long material

ActiveUS20110146095A1Improve accuracyReduce production efficiencyMechanical diameter measurementsMeasurement deviceSize measurement

Owner:NIPPON STEEL CORP

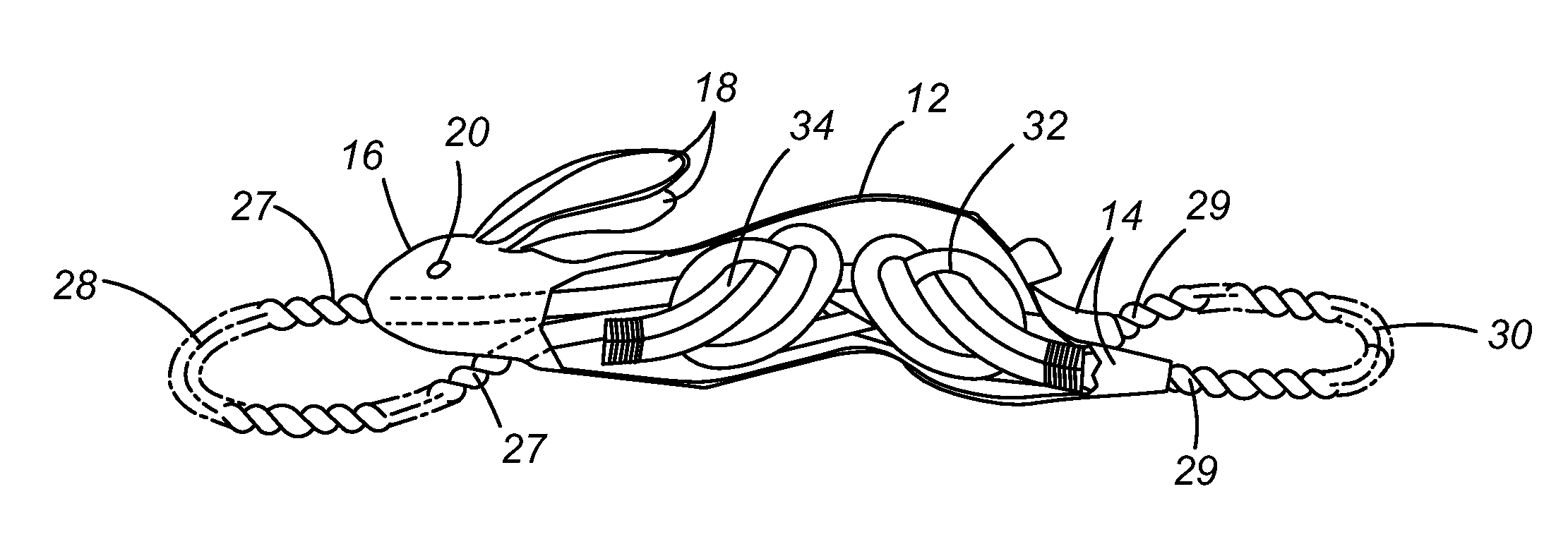

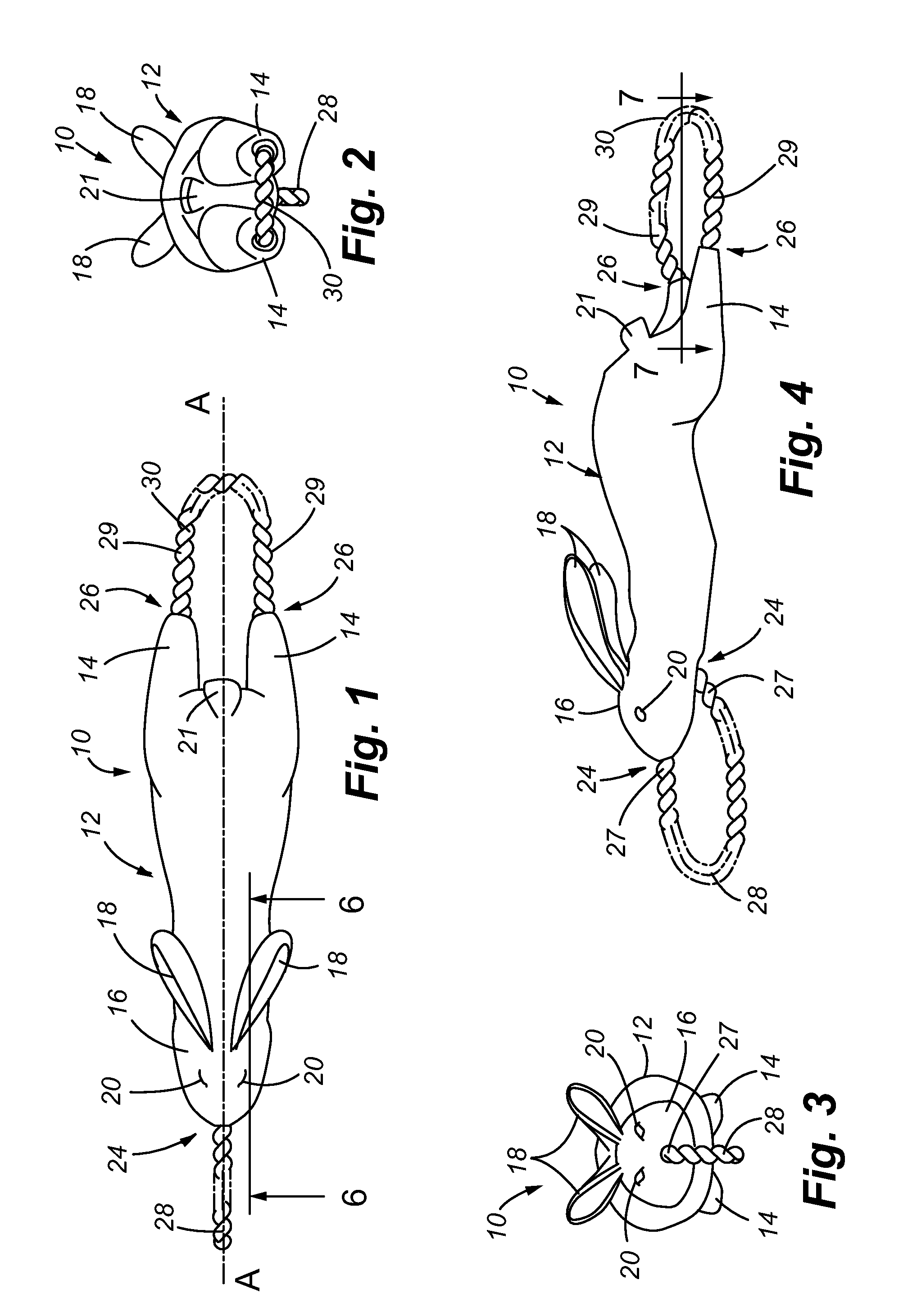

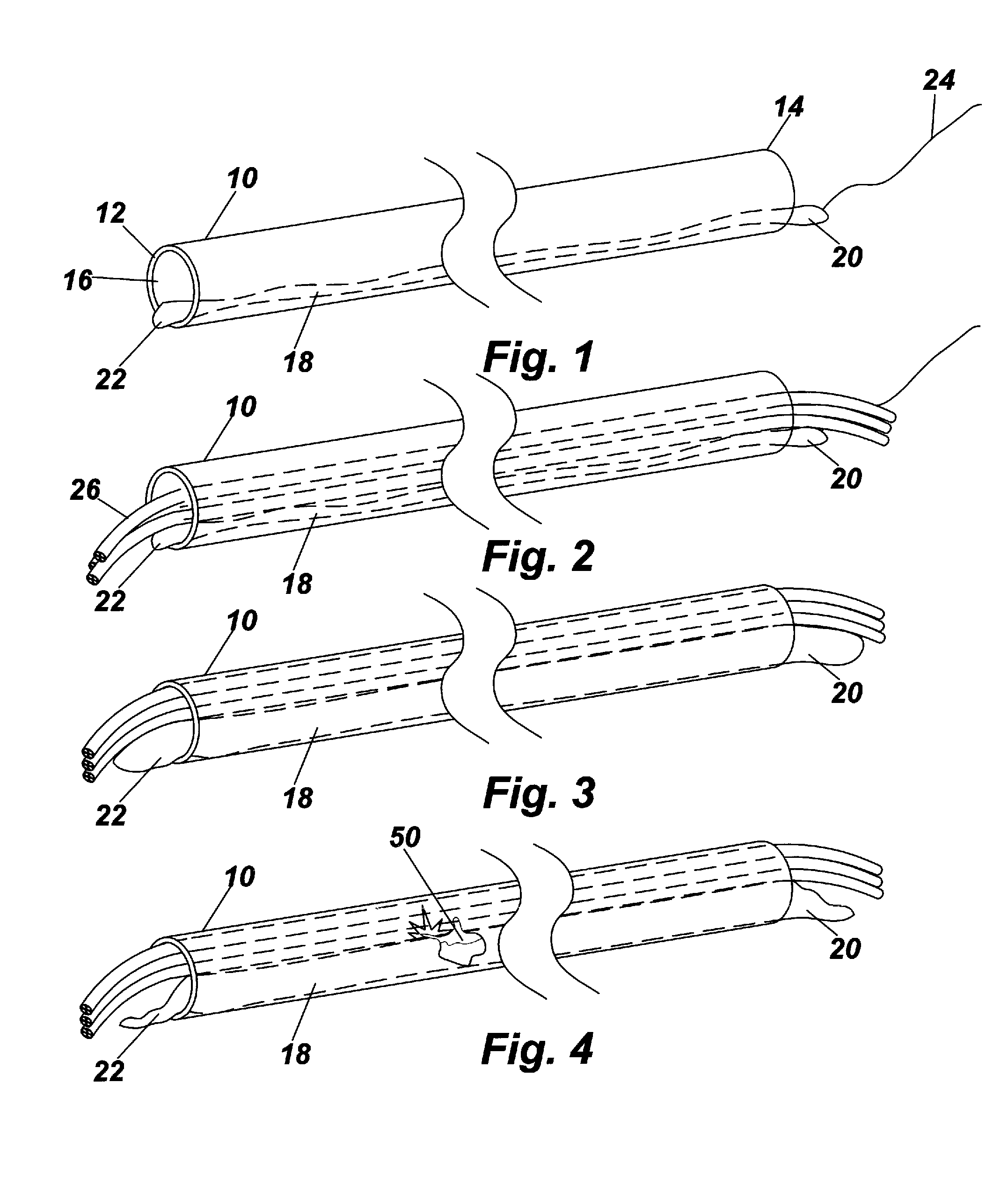

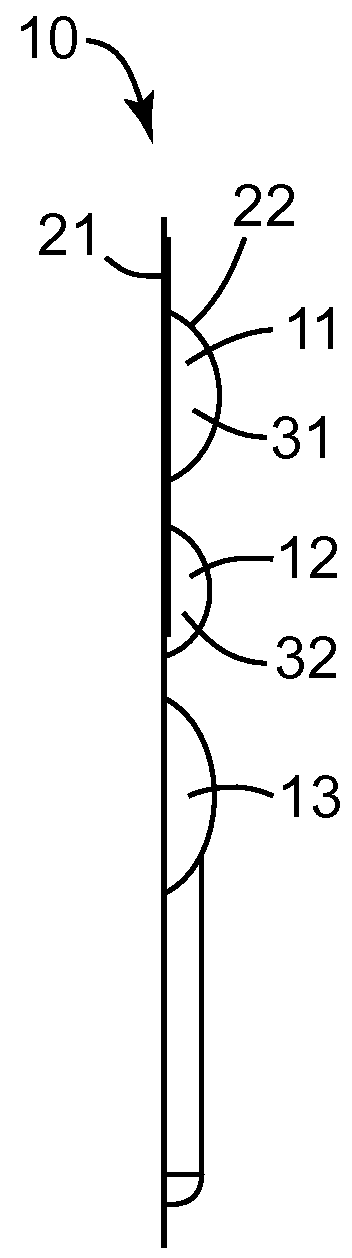

Pet toy with flexible body and rope support configurations

ActiveUS20120145089A1Robust constructionLess stressFilament handlingOther apparatusEngineeringCompanion animal

A pet toy includes a flexible body with rope support configurations. In one embodiment, the rope configurations include one or more loops that are exposed and one or more knots that are covered by an exterior plush component of the pet toy. In another embodiment, two or more strands of rope material are tied in a series of knots, and an additional strand of rope material may be tied to the other strands in a transverse fashion. Preferably, the exterior plush component includes fabric. One or more of the free ends of the strands of rope material may also protrude beyond the plush component. The fabric material is sewn over the exposed portions of the rope material. Enough fabric material is used such that twisting, extending and retracting the rope material does not transfer force directly to the exterior fabric, thereby preserving the exterior plush component. The knots provide internal bulk to the body of the toy eliminating the need for stuffing. The knots also provide a robust structure for biting and tugging that can aid in dental cleaning. The exposed loops or free ends of the rope material act as handles for grasping by the pet owner or animal.

Owner:THE KONG

Device for dispensing a dental material and method of dispensing

ActiveUS20140299624A1Low expandabilityMinimizing total elasticityOpening closed containersBottle/container closureBiological activationBiomedical engineering

A device for dispensing a dental material comprises first compartment and the second compartment formed between interconnected sheet-like layers. The compartments encapsulate a first flowable component and a second flowable component of the dental material. The device has a first seal and a second seal for sealing the first compartment and the second compartment in the device. Each seal is adapted to automatically open in consequence of forcing a component of the dental material toward the seal. The capacity of the first compartment and the second compartment relative to each other is dimensioned such that squeezing out the first component from the first compartment by compressing the first compartment causes the first seal and the second seal to open. The device preferably allows easy and quick activation for use of the stored components.

Owner:3M INNOVATIVE PROPERTIES CO

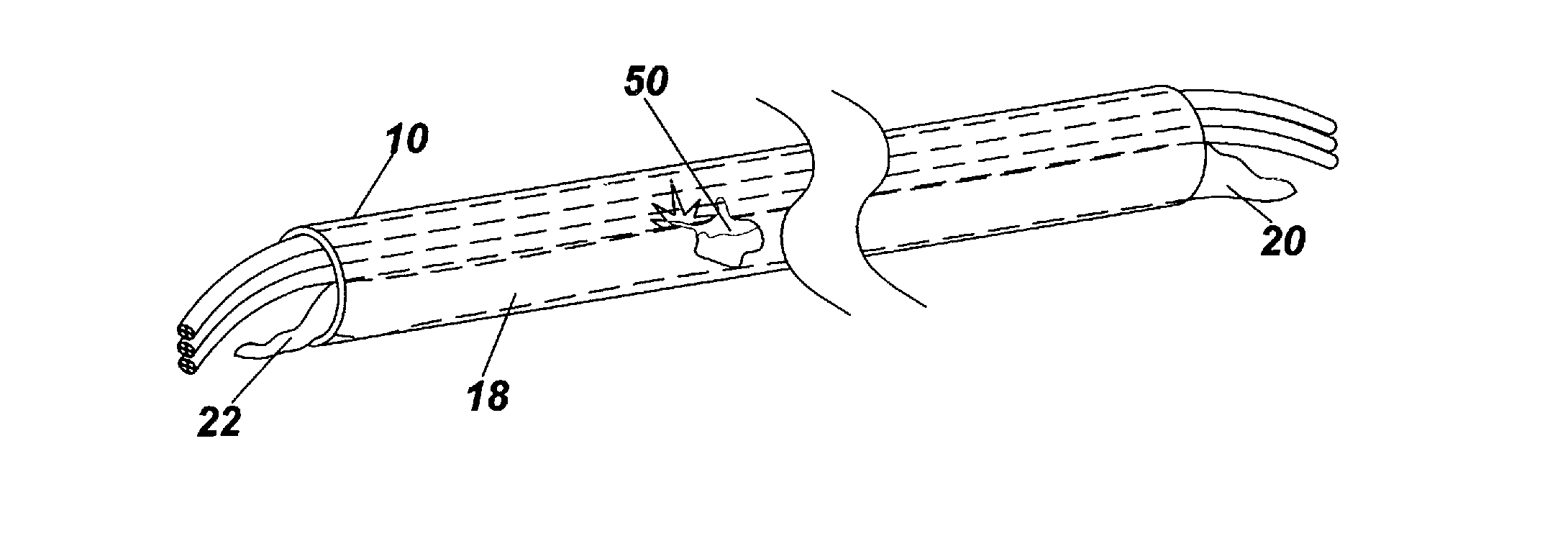

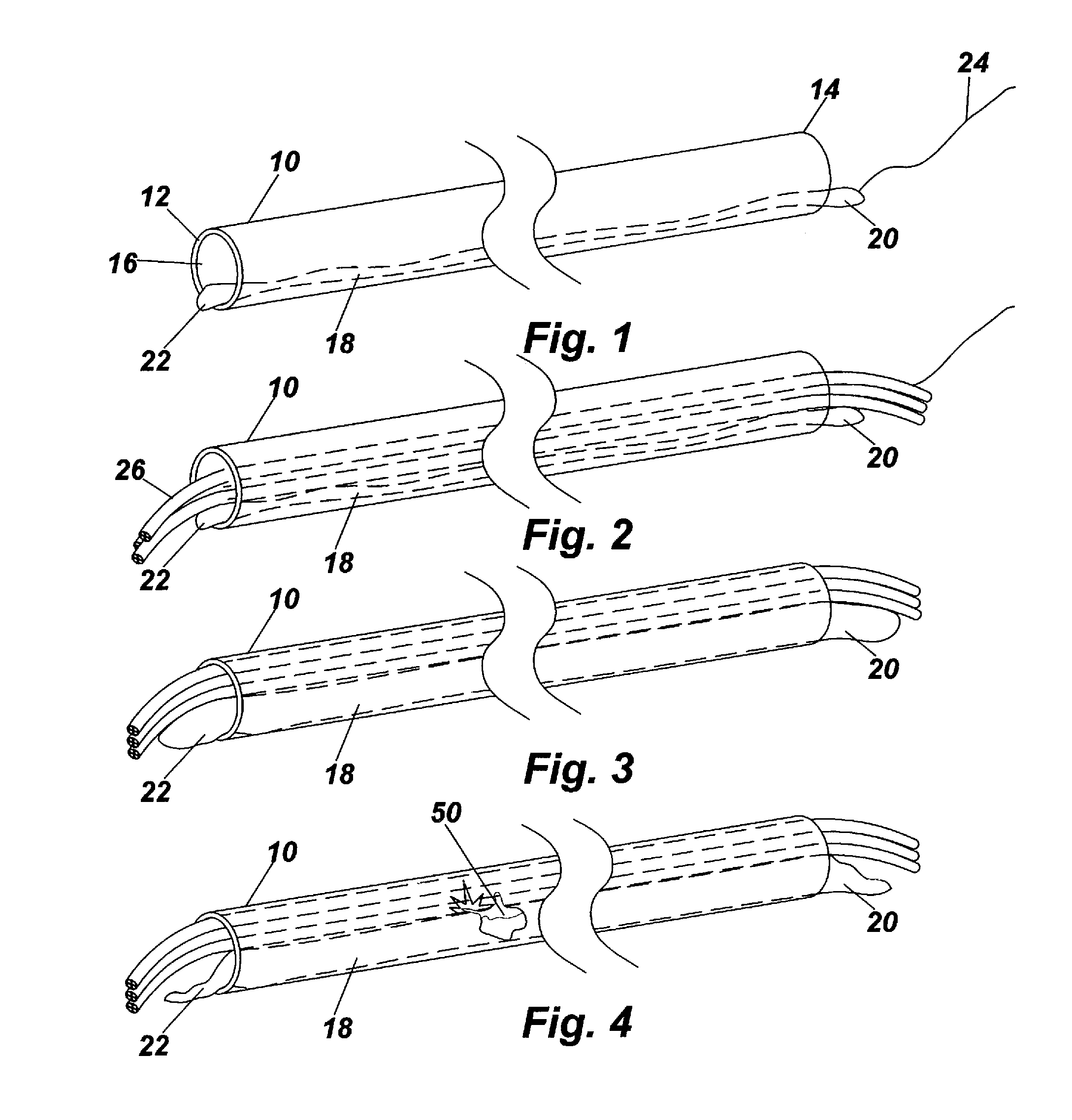

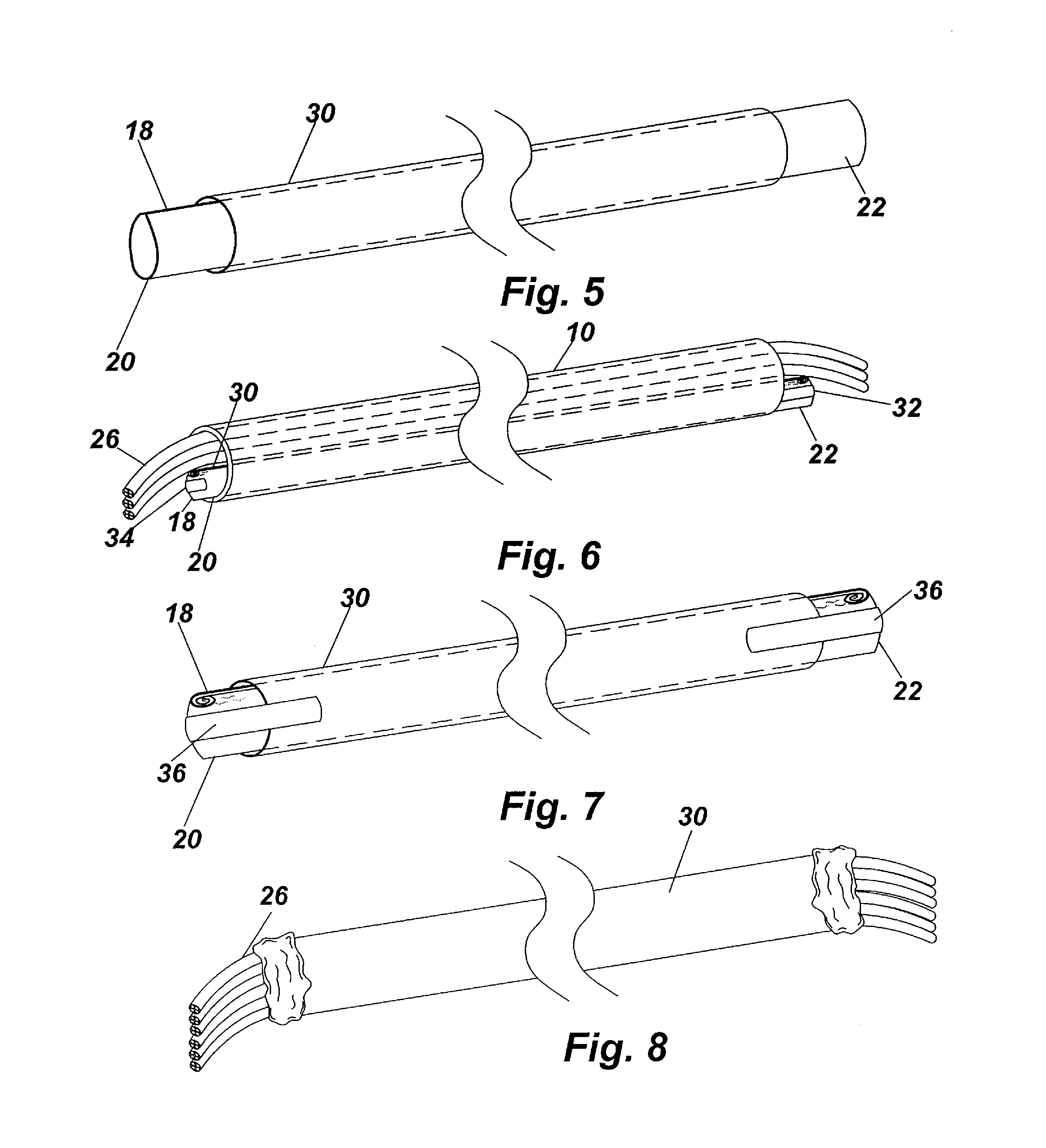

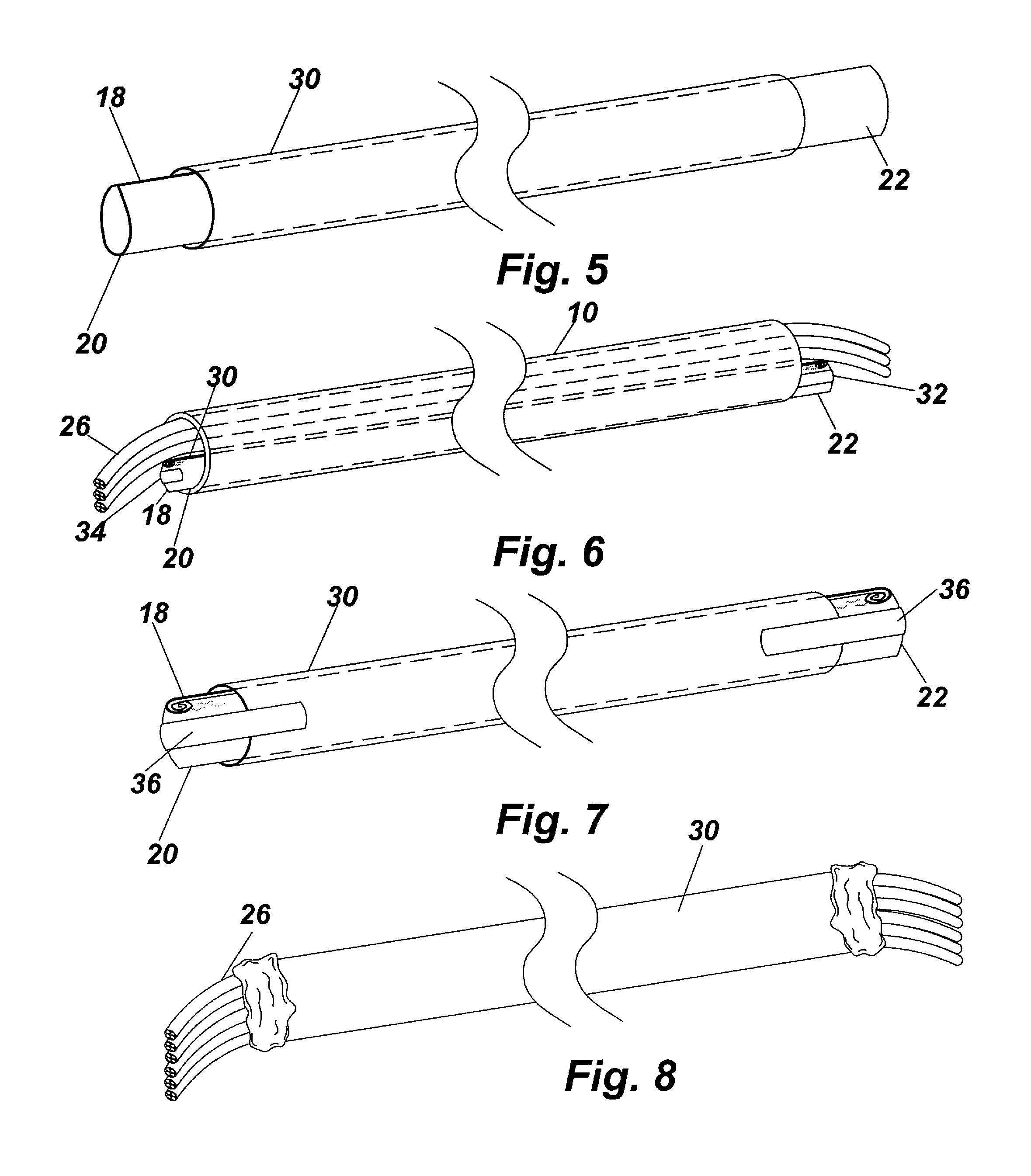

Method and Device for Suppressing Electrical Fires in Underground Conduit

ActiveUS20140305666A1Solve the quick positioningLong materialFire rescueBoring toolsToxic gasSuper absorbent

A method and device for suppressing an electrical fire within an electrical wire carrying conduit. The device is a flexible receptacle containing an admixture of super absorbent polymer and water having substantially superior fire suppression and extinguishing properties that does not provide an electrically conductive environment. The receptacle is drawn though a conduit either before or after wires have been placed in the conduit, and the filled with the admixture. A sleeve may be placed over the receptacle to prevent breaching of the receptacle during installation. Once the receptacle and admixture is positioned within the conduit, should arcing or a buildup of heat occur, the receptacle will rupture and the admixture will cover the specific area. These particular properties and ratios of the admixture will enable electrical fires to be extinguished more rapidly and not flare back up. The admixture further encapsulates noxious and toxic gases associated with electrical fires.

Owner:REGER MICHAEL L

Semitransparent high haze opal glass for LED and preparation method thereof

The invention provides semitransparent high haze opal glass for an LED and a preparation method thereof. The semitransparent opal glass for the LED provided by the invention is characterized by comprising the following components by weight percent: 60-68% of SiO2, 0-4% of Al2O3, 6-10% of B2O3, 1-5% of ZnO, 0-3% of CaO, 0-2% of MgO, 6-13% of alkali metal oxide, 2-5% of fluoride and 1-5% of P2O5. The preparation method comprises the following steps: mixing all the components according to the proportion to prepare glass batch; fusing at 1450-1550 DEG C; casting for formation or drawing for formation; naturally cooling or naturally cooling after annealing, so as to obtain the semitransparent opal glass for the LED. According to the semitransparent opal glass series prepared through the preparation method, the light transmittance is guaranteed, and the problems that the LED light is dazzling and blue ray overflows are avoided; for a glass sheet with the thickness of 3 mm, the light transmittance is 2-10%, the haze value is 30-95, and the brightness is 60-80.

Owner:DONGHUA UNIV

System and method for providing a reserve supply of gas in a pressurized container

InactiveUS8746503B2Economic securityFacilitated releaseLiquid flow controllersLiquid transferring devicesEngineeringMechanical engineering

A gas storage and delivery system for restoring pressure as it is depleted from a pressurized container, includes a container holding a product under pressure to be dispensed from the container, a quantity of gaseous material under pressure, occupying a space in the container and applying to the product a predetermined pressure of from about 30 to about 180 psig, and a quantity of gas-adsorbing material, storing under pressure a quantity of the gaseous material and releasing it into the container in response to a decrease in pressure in the container, thereby restoring and maintaining a predetermined pressure in the container as product is depleted from the container, wherein the gas-adsorbing material is wetted with a release-promoting agent to promote release of the sorbed gas from the gas-adsorbent material. A process of filling the container is also disclosed.

Owner:LIM WALTER K

Method and Device for Suppressing Electrical Fires in Underground Conduit

InactiveUS20140202720A1Solve the quick positioningLong materialFire rescueBoring toolsToxic gasSuper absorbent

A method and device for suppressing an electrical fire within an electrical wire carrying conduit. The device is a flexible receptacle containing an admixture of super absorbent polymer and water having substantially superior fire suppression and extinguishing properties that does not provide an electrically conductive environment. The receptacle is drawn though a conduit either before or after wires have been placed in the conduit, and the filled with the admixture. A sleeve may be placed over the receptacle to prevent breaching of the receptacle during installation. Once the receptacle and admixture is positioned within the conduit, should arcing or a buildup of heat occur, the receptacle will rupture and the admixture will cover the specific area. These particular properties and ratios of the admixture will enable electrical fires to be extinguished more rapidly and not flare back up. The admixture further encapsulates noxious and toxic gases associated with electrical fires.

Owner:REGER MICHAEL L

Device for dispensing a dental material and method of dispensing

ActiveUS9375292B2Providing some amountMinimizes numberLiquid transferring devicesAmalgam presses/mixersBiological activationBiomedical engineering

A device for dispensing a dental material comprises first compartment and the second compartment formed between interconnected sheet-like layers. The compartments encapsulate a first flowable component and a second flowable component of the dental material. The device has a first seal and a second seal for sealing the first compartment and the second compartment in the device. Each seal is adapted to automatically open in consequence of forcing a component of the dental material toward the seal. The capacity of the first compartment and the second compartment relative to each other is dimensioned such that squeezing out the first component from the first compartment by compressing the first compartment causes the first seal and the second seal to open. The device preferably allows easy and quick activation for use of the stored components.

Owner:3M INNOVATIVE PROPERTIES CO

High-light-transmittance and high-refraction-index crystalline glass and production process thereof

InactiveCN109942184AHigh mechanical strengthGood chemical stabilityGlass shaping apparatusLithium oxideRefractive index

The invention discloses high-light-transmittance and high-refraction-index crystalline glass and a production process thereof. The high-transmittance and high-refraction crystalline glass is preparedfrom, by weight, 30-60% of silicon dioxide, 1-3% of aluminum oxide, 5-25% of titanium dioxide, 1-10% of calcium oxide, 3-10% of magnesium oxide, 3-10% of zinc oxide, 10-20% of barium oxide, 1-3% of lithium oxide, 0.01-0.05% of a decolorizing agent and 0.1-1% of a clarifying agent. The production process comprises the following steps that step 1, the raw materials are classified according to different types; step 2, the classified component raw materials are crushed by a crusher; step 3, the crushed component materials are put into a grinder for grinding. The high-light-transmittance and high-refraction-index crystalline glass and the production process thereof have the advantages that the high-light-transmittance and high-refraction-index crystalline glass can be provided, the lead elementin the crystalline glass is removed, the volatilization of the lead is reduced, the damage to the human body is reduced, the light transmittance and refraction index of the glass are also improved, and the product has stronger market competitiveness and brings higher earnings for enterprises.

Owner:安徽晶晶玻璃制品有限公司

Dimension measuring device for long material

ActiveUS8393087B2Improve accuracyReduce production efficiencyMechanical diameter measurementsMeasurement deviceDimension measurement

Owner:NIPPON STEEL CORP

Comfortable eaglewood pillow

InactiveCN104473521AConforms to natural physiological curvatureEven by forcePillowsAromatherapyHigh density

The invention relates to an eaglewood pillow. The eaglewood pillow comprises a wood body, wherein the wood body is semielliptical eaglewood; the wood body 1 is formed by wrapping the upper surface of an arc 2 of the wood body 1 with a layer of high-density high-quality sponge 3. Neck and shoulders bear comfortable supporting force; a bulge part of the pillow completely bears the neck, so that cervical vertebrae are protected and are stressed uniformly, and an effect of natural traction is achieved. The eaglewood has the effects of aromatherapy, healthcare, and health preservation, and has certain treatment effects on removing wind and water poison and swelling, removing filthy substance, removing heart and abdominal pain, treating cholera and noxious pathogen attack, removing pathogenic factor and chronic infectious disease, refreshing spirit, regulating middle energizer, tonifying the five internal organs, benefiting the spirit and tonifying Yang.

Owner:刘彩凤

Edible dog chew with hollow cylindrical tube and method for making such dog chew

InactiveUS20180116249A1Raise the possibilityLong materialAnimal feeding stuffWorking-up animal fodderEngineeringHollow core

An edible dog chew includes a hollow cylindrical tube of edible plant or animal material, the hollow cylindrical tube knotted at both ends. A method is also provided.

Owner:CHEN XIANG +1

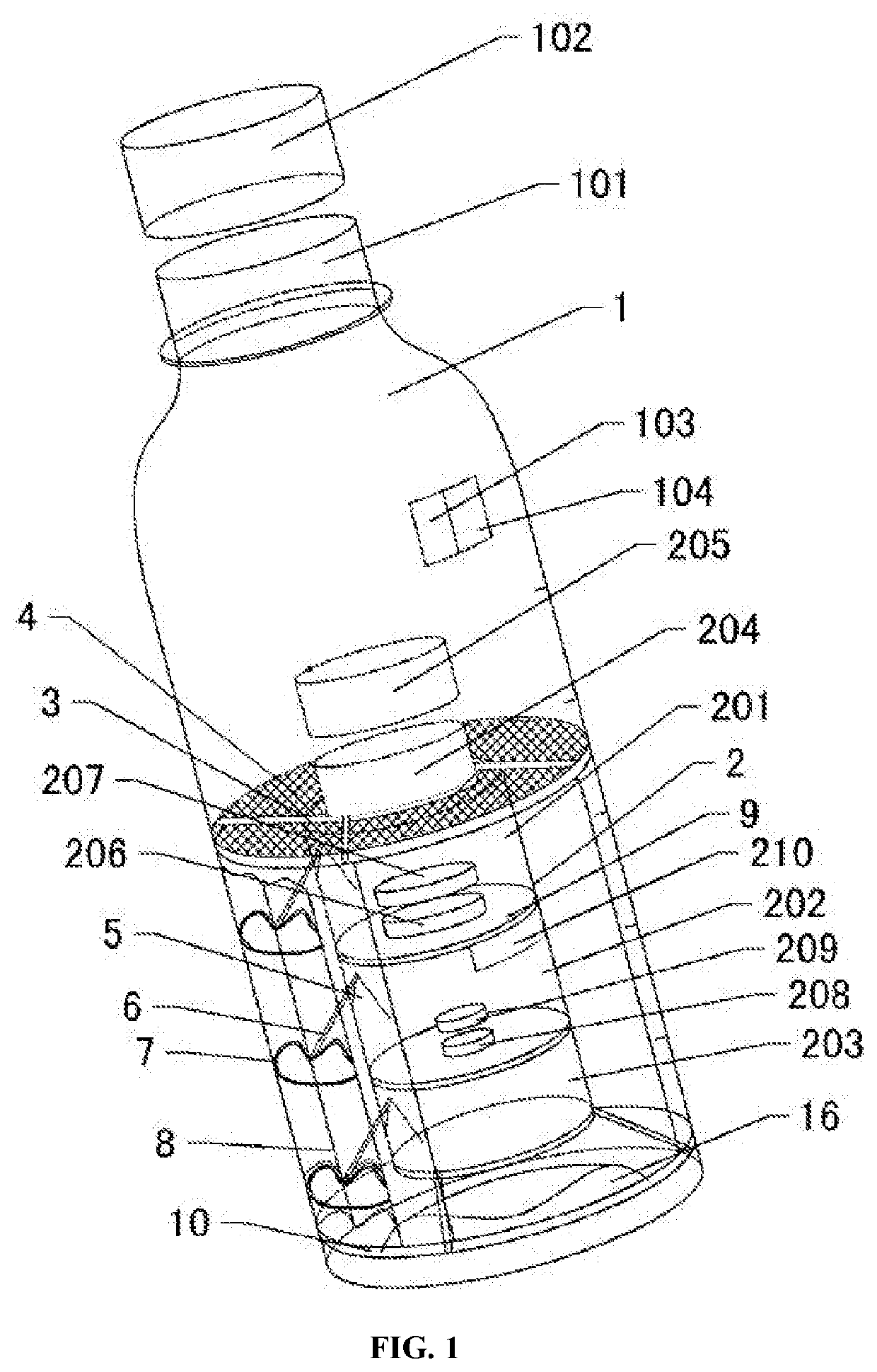

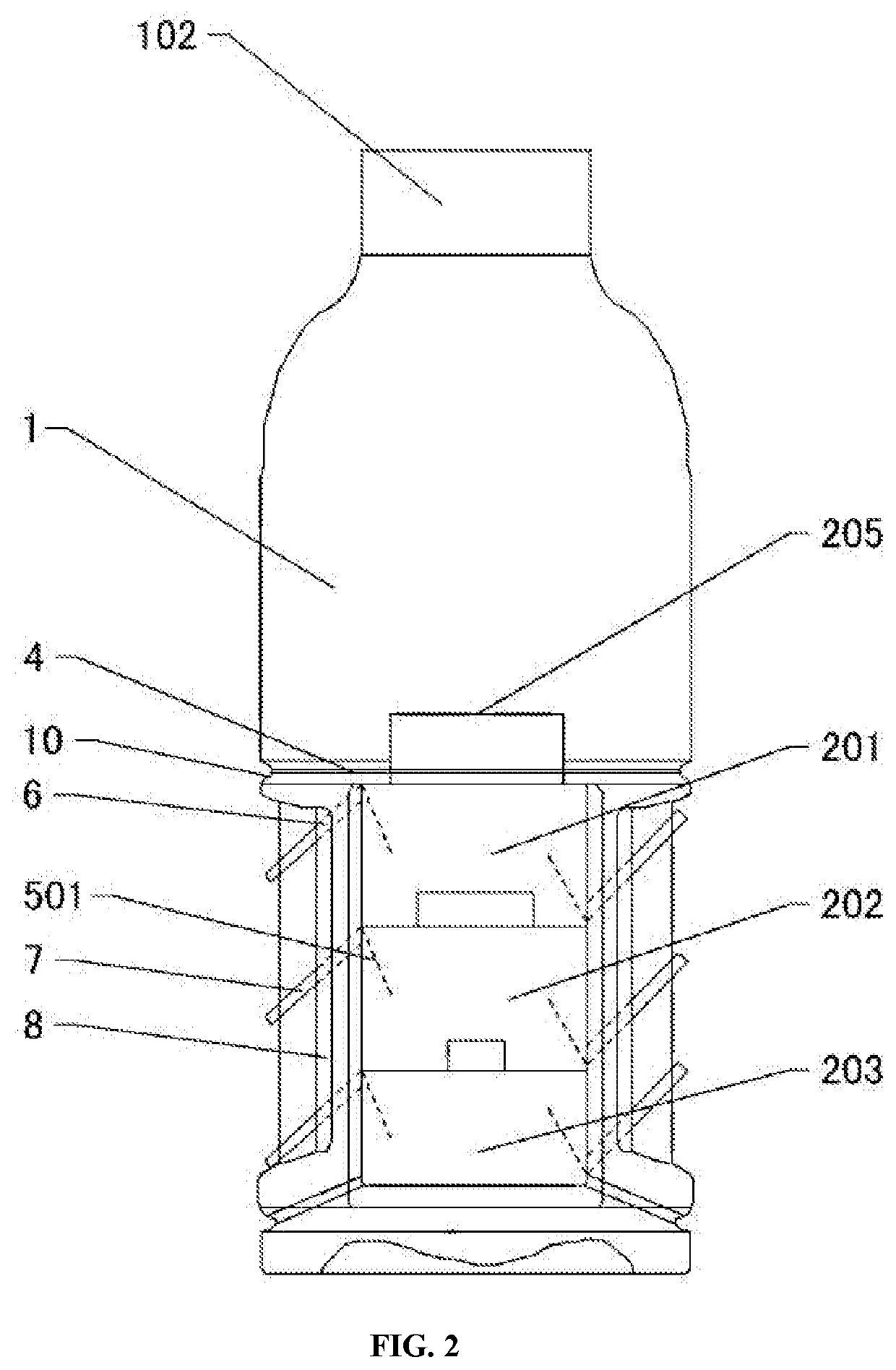

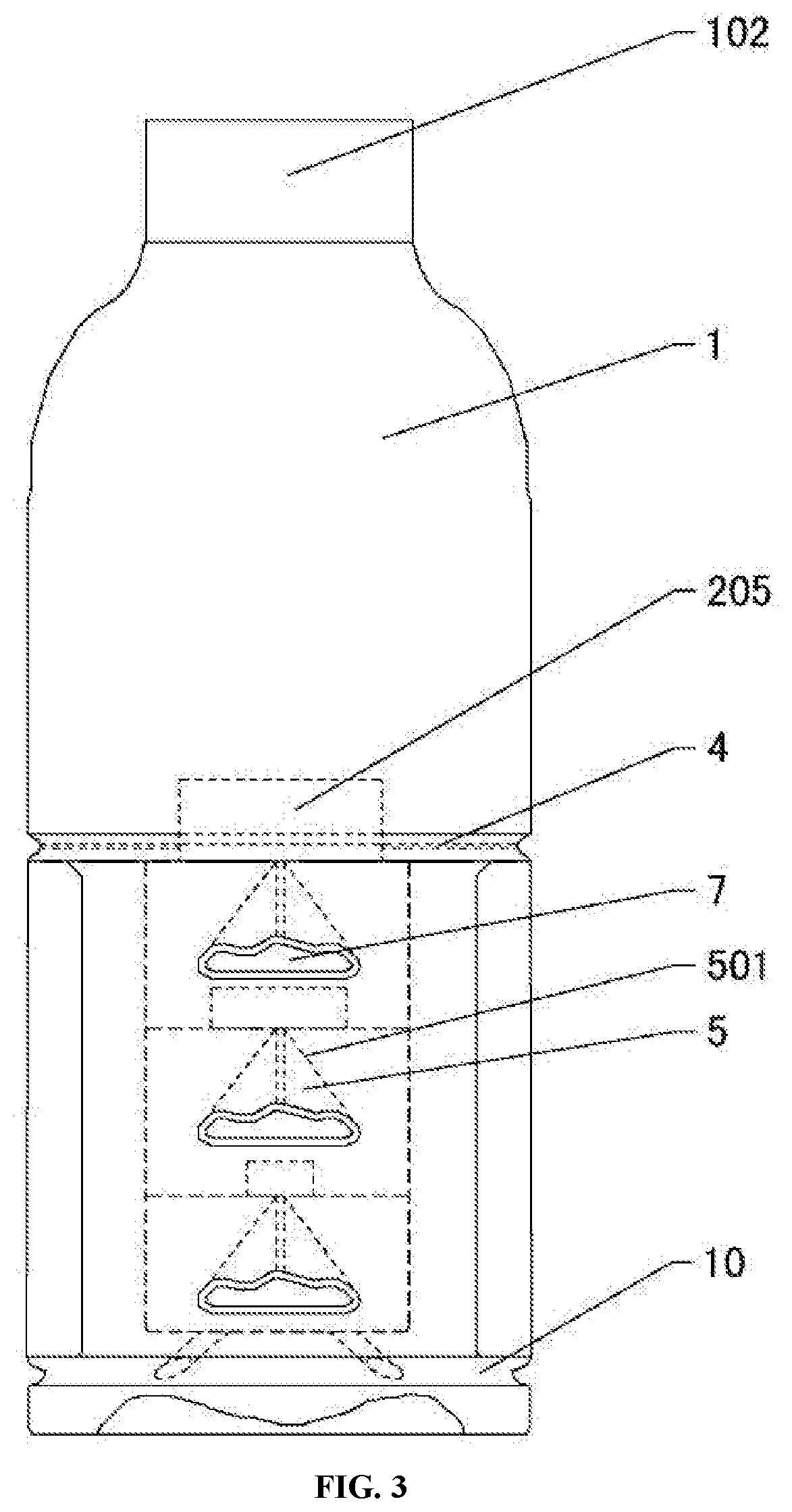

Instant mixing container and product

ActiveUS11203480B2Difficult to repairEasy to useContainer decorationsLevel indicationsMulti materialEngineering

Owner:ZHANG GUANGMING

Method for preparing colored glaze with waste flint glass as raw material

The invention discloses a method for preparing colored glaze with waste flint glass as a raw material. The waste flint glass not only wastes the lead resource, but also has potential threats to human health and ecological environment, but no better method for treating the water flint glass exists. The method comprises the following steps of generally smashing the waste flint glass and grinding; then regulating the chemical components of the grinded waste flint glass; melting for 2-6 hours at high temperature of 750-980 DEG C; carrying out manual forming or mechanical forming according to a designed shape; sending the formed product into an annealing furnace for annealing, wherein the annealing temperature is 450-550 DEG C and the annealing time is 2-10 hours; and cooling to normal temperature so as to obtain the colored glaze. According to the method, the waste flint glass is taken as the main raw material for preparing the colored glaze, so that the method has the advantages that technological process is simple, raw material source is wide, energy consumption is low and the like, can be used for preparing colored glaze product with good gloss, low softening point and long material property, is applicable to the existing various colored glaze product factories in north and south and is beneficial to large-scale industrial production.

Owner:HUAWEI TEHCHNOLOGIES CO LTD

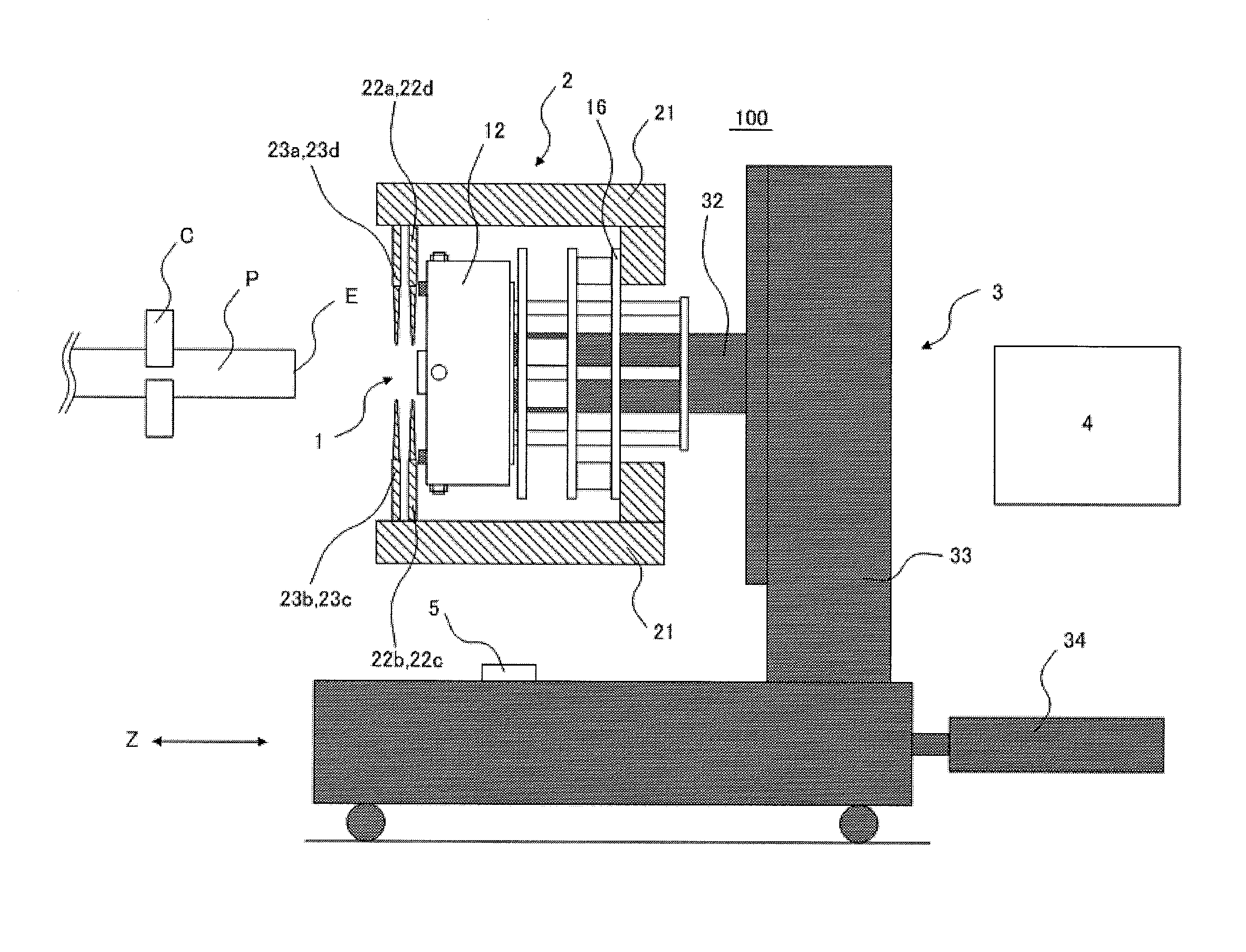

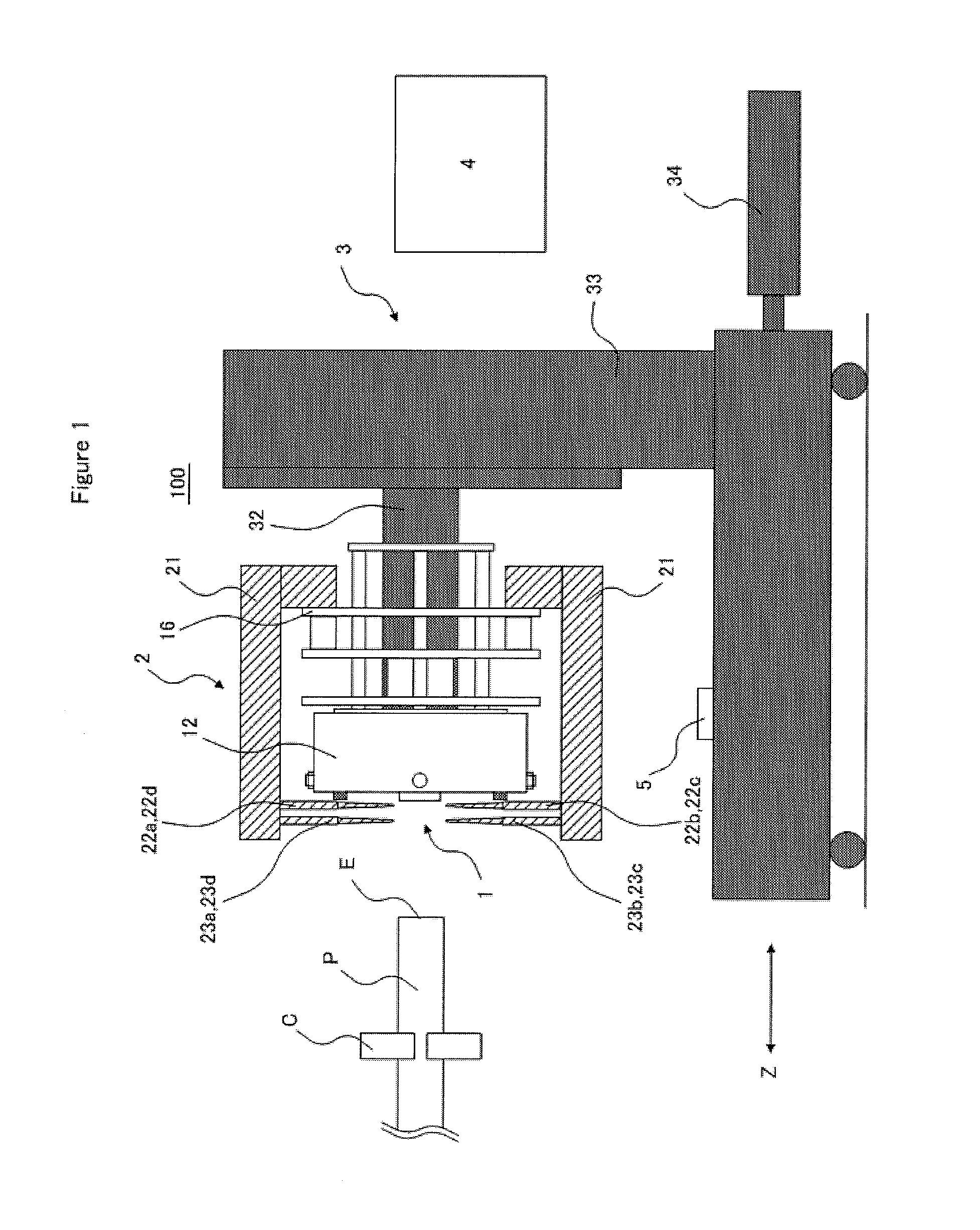

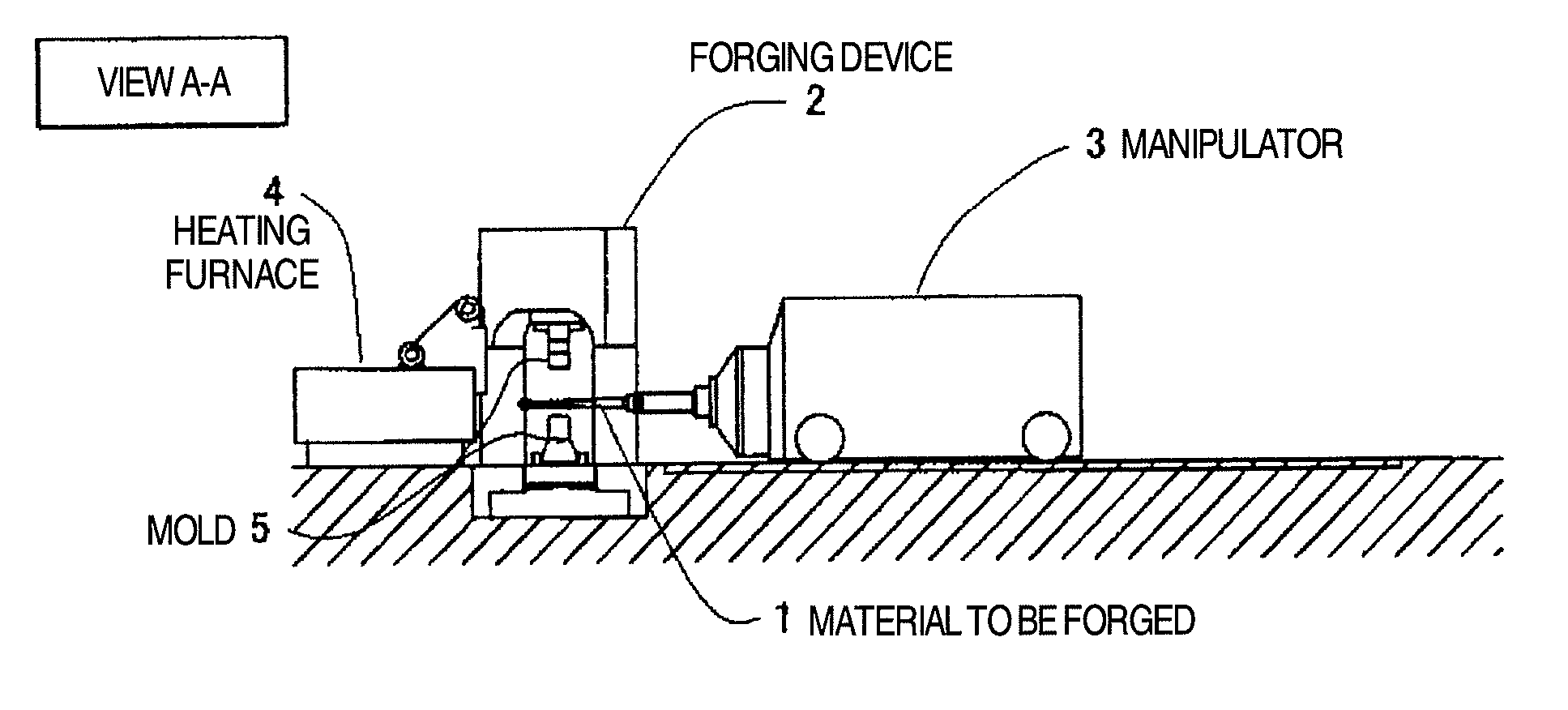

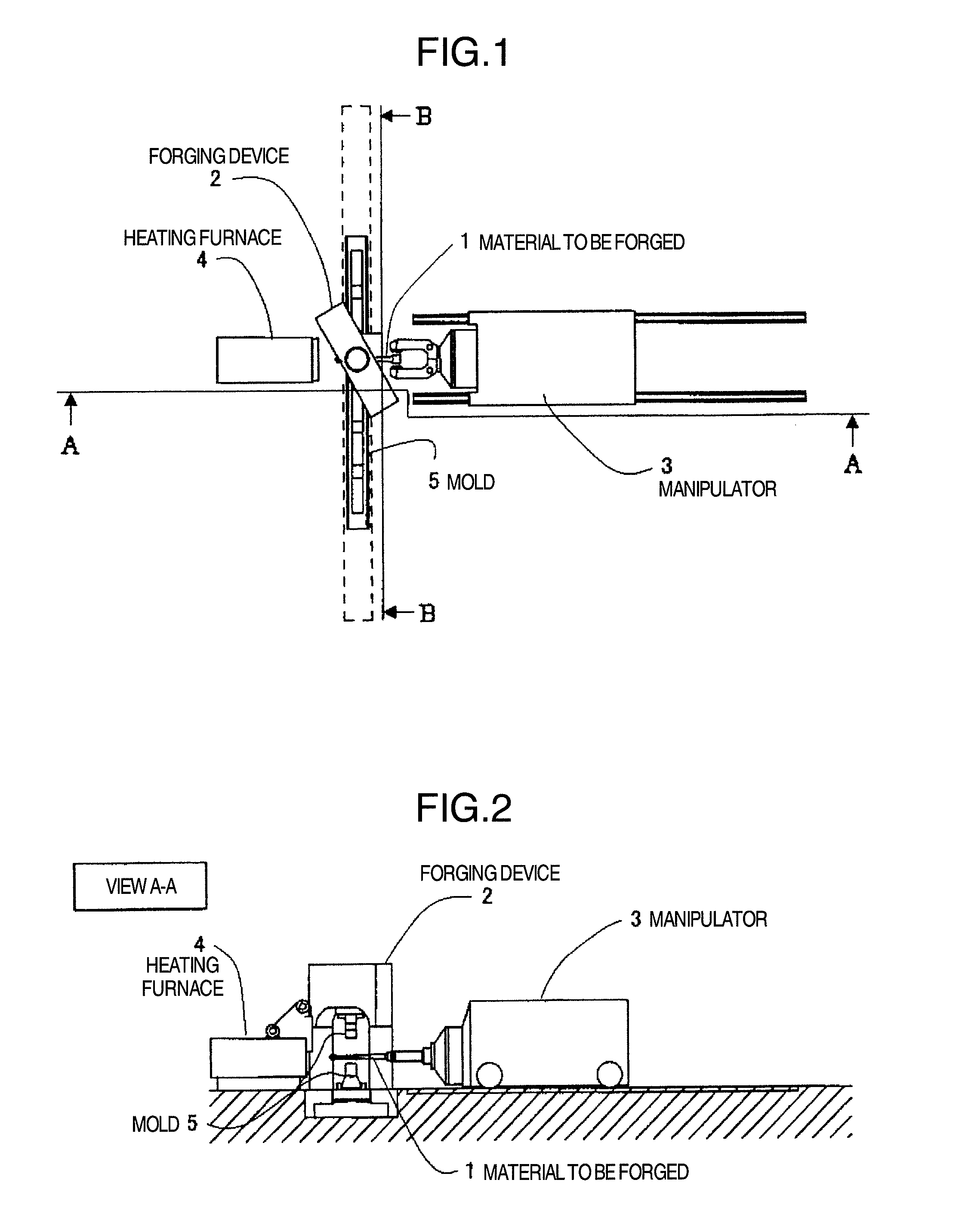

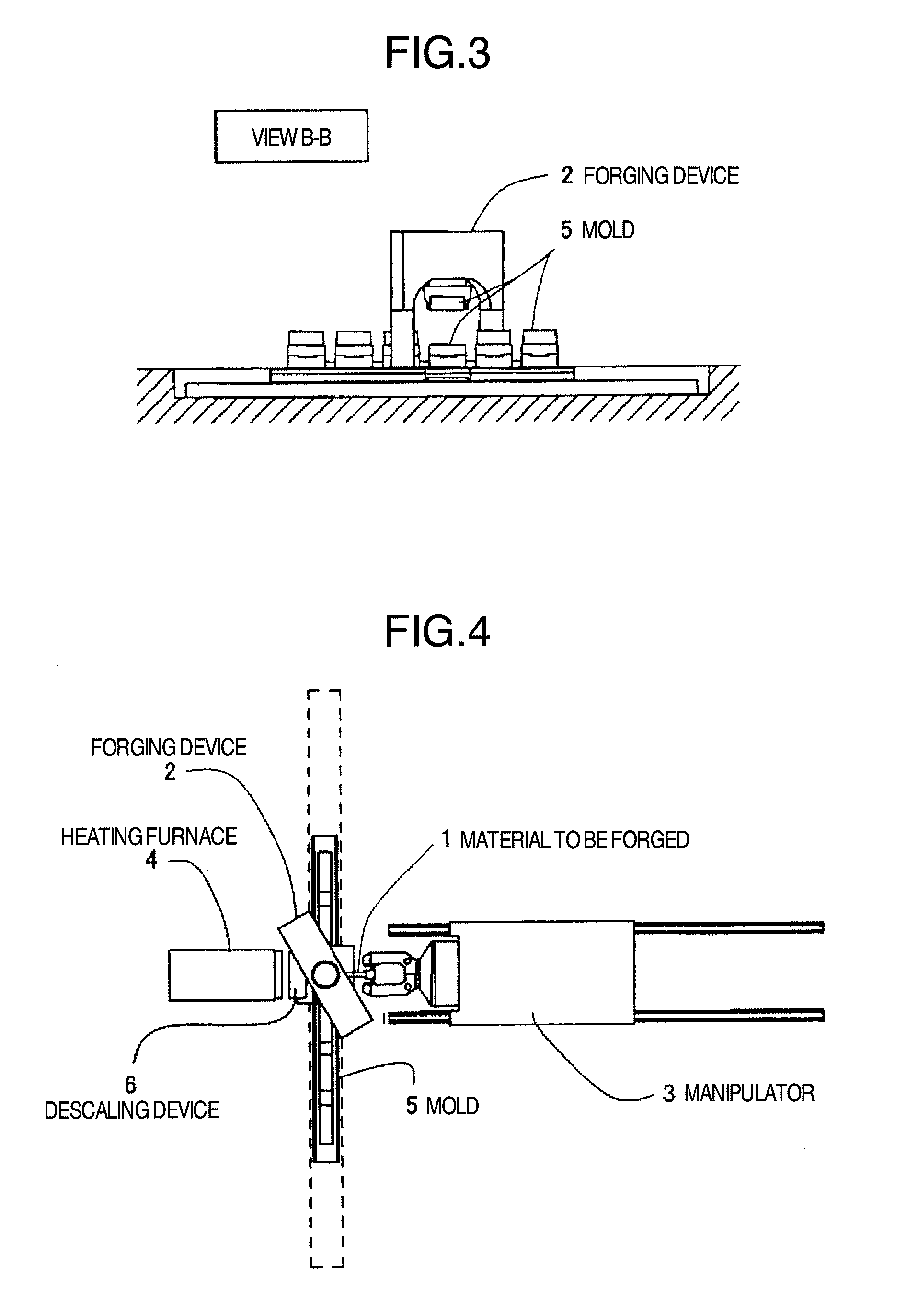

Manufacturing method for a blade material

ActiveUS9221095B2Long materialAircraft componentsForging/hammering/pressing machinesKnife bladesManufacturing engineering

Provided are a manufacturing method for a blade material and a manufacturing device for a blade material, by which a long blade material can be manufactured without using a large-sized press forging machine. A manufacturing method for a blade material, in which hot forging is sequentially performed by molds from the root side to a blade (vane) tip, wherein when a root-side portion is grasped and a material to be forged is restrained by a mold, twisting is performed on a region between the grasped portion and the restrained portion. A manufacturing method for a blade material, in which hot forging and twisting are repeated, is preferable, and a manufacturing method for a blade material, in which hot forging is performed while molds are sequentially changed, is more preferable.

Owner:HITACHI METALS LTD

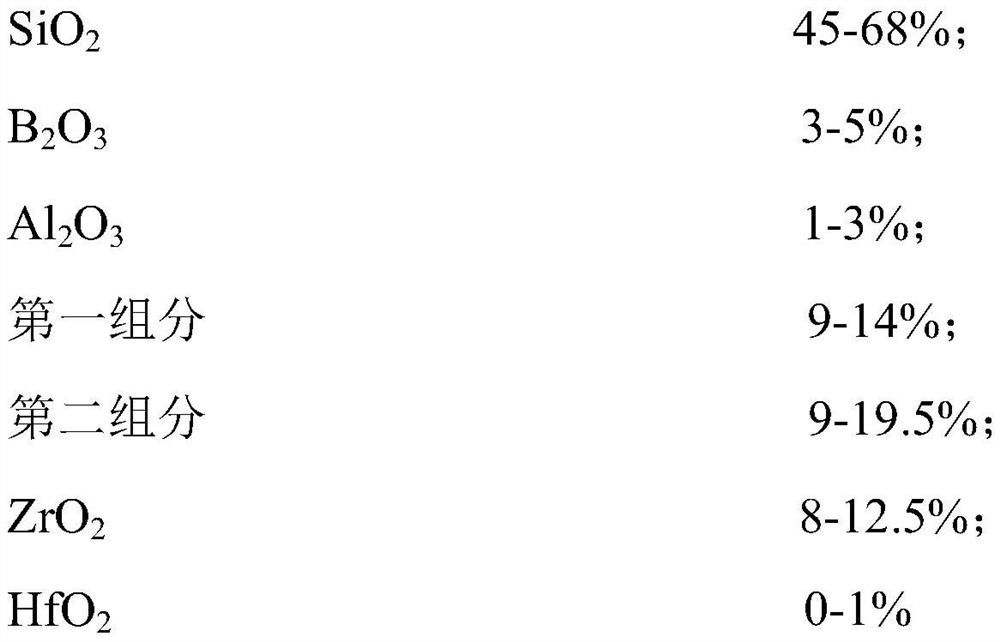

Alkali-resistant glass and preparation method thereof

The invention relates to alkali-resistant glass and a preparation method thereof. The alkali-resistant glass is prepared from the following components by mass percentage: 45-68% of SiO2; 3-5% of B2O3;1-3% of Al2O3; 9-14% of first component; 9-19.5% of second component; 8-12.5% of ZrO2; 0-1% of HfO2; The preparation of the glass comprises the following steps: mixing the raw materials according tothe formula ratio to obtain a first mixture; adding a clarifying agent into the first mixture and then mixing to obtain a second mixture; melting and mechanically stirring the second mixture, supplemented by bubble clarifying, seeping moulding or compression moulding. The alkali-resistant glass has excellent resistance to corrosion from alkali metal and from aqueous alkali, and also has great optical transmittance and long workability, indicating outstanding processing performance of the glass.

Owner:CHINA BUILDING MATERIALS ACAD

Leadless, cadmium-free and strontium-free glass and manufacture process thereof

The invention belongs to the technical field of an inorganic amorphous material, and particularly relates to a leadless, cadmium-free and strontium-free transparent colored glass component and a manufacture process thereof. The transparent colored glass component is characterized by only containing conventional oxides, such as SiO2, B2O3, ZnO, CaO, BaO, Na2O, K2O and the like without containing lead, cadmium or strontium which has great toxic effect. The invention has the advantages that: a decolorizing agent is added into the leadless, cadmium-free and strontium-free basic component to prepare a colorless transparent glass product; various coloring agents are added into the leadless, cadmium-free and strontium-free basic component to obtain the colored glass. Equipment or investment is not additionally increased, the glass product with good color, low softening point and long material property can be produced only by adopting existing raw material treatment, melting furnaces, hot melting furnaces, annealing furnaces, cold machining and other equipment, and the cost of the transparent colored glass is reduced by 2 to 4 times than that of conventional medium-lead and high-lead glass. The invention has wide application prospect.

Owner:DALIAN POLYTECHNIC UNIVERSITY

A kind of long-material large bottle glass and preparation method thereof

ActiveCN110282873BSolve the problem that cannot be mechanically formed at one timeLong materialBlow machinesPolymer scienceManufactured material

Owner:QILU UNIV OF TECH +1

Chemical ingredient component of lead-free special glass for energy-saving lamp

InactiveCN106430955ASmall expansion coefficientLow softening pointProduction lineManufacturing technology

The invention relates to a chemical ingredient component of lead-free special glass for an energy-saving lamp, in particular to a chemical ingredient component of lead-free special glass for manufacturing the energy-saving lamp and belongs to the technical field of energy-saving lamp manufacturing. The chemical ingredient component contains SiO2, AL2O3, B2O3, B2O, K2O, Na2O, CaO, MgO, S2O and Li2O and is characterized in that the SiO2 accounts for 69-70%, the AL2O3 accounts for 1-2%, the B2O3 accounts for 1-1.5%, the B2O accounts for 8-9%, the K2O accounts for 2-3%, the Na2O accounts for 9-10%, the CaO accounts for 1-1.5%, the MgO accounts for 0-1%, the S2O accounts for 1.5-3%, and the Li2O accounts for 1.5-2%. The chemical ingredient component has the advantages that the chemical ingredient component saves energy, is environmentally friendly and can adapt to high-speed lamp-manufacturing production lines, a manufacturing softening point is low, linear expansion coefficients are small, and the properties of the materials are long.

Owner:武汉广宏利机电设备有限公司

A kind of large bottle glass suitable for artificial molding and preparation method thereof

Owner:QILU UNIV OF TECH +1

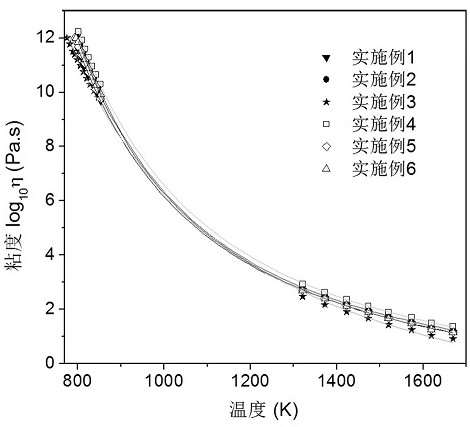

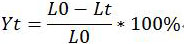

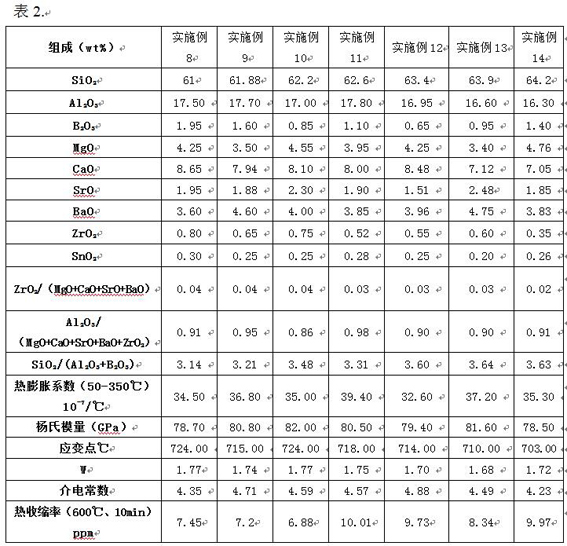

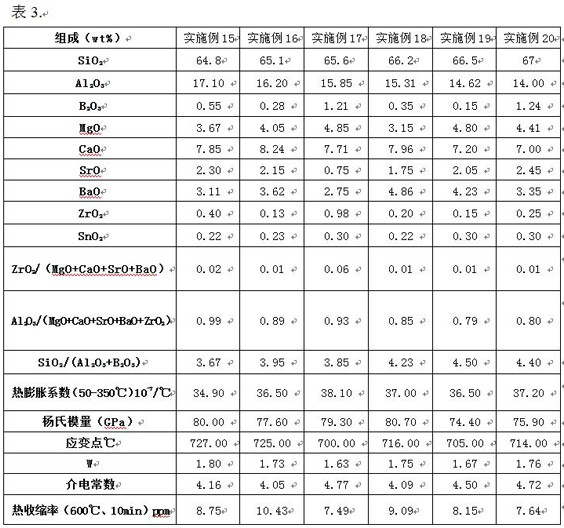

A kind of long material alkaline earth aluminosilicate glass for display

The invention relates to a long-material alkaline earth aluminosilicate glass for displays, which is characterized in that it is made of the following raw materials by weight: 58-67% SiO 2 , 14‑19% Al 2 O 3 , 0.15‑2%B 2 O 3 , 3.15‑5%MgO, 7‑9%CaO, 0.75‑2.5%SrO, 2.75‑5%BaO, 0.1‑1%ZrO 2 , 0.15‑0.3% SnO 2 . The advantages of the invention are: suitable for large-scale industrial production, suitable for overflow method, float method, etc., and more suitable for manufacturing 8.5-generation and above high-generation glass substrates; the glass has good surface flatness, high mechanical strength, low thermal shrinkage, Excellent properties such as high strain point and long material properties; the glass raw material is an environment-friendly glass system, which does not deform during high-temperature manufacturing processes. The prepared glass is suitable for optoelectronic display, photo, photovoltaic and other industries, especially for the preparation of flat panel display products. The substrate glass substrate material and / or the substrate glass substrate material of flexible display products.

Owner:BENGBU CHINA OPTOELECTRONIC TECH CO LTD +1

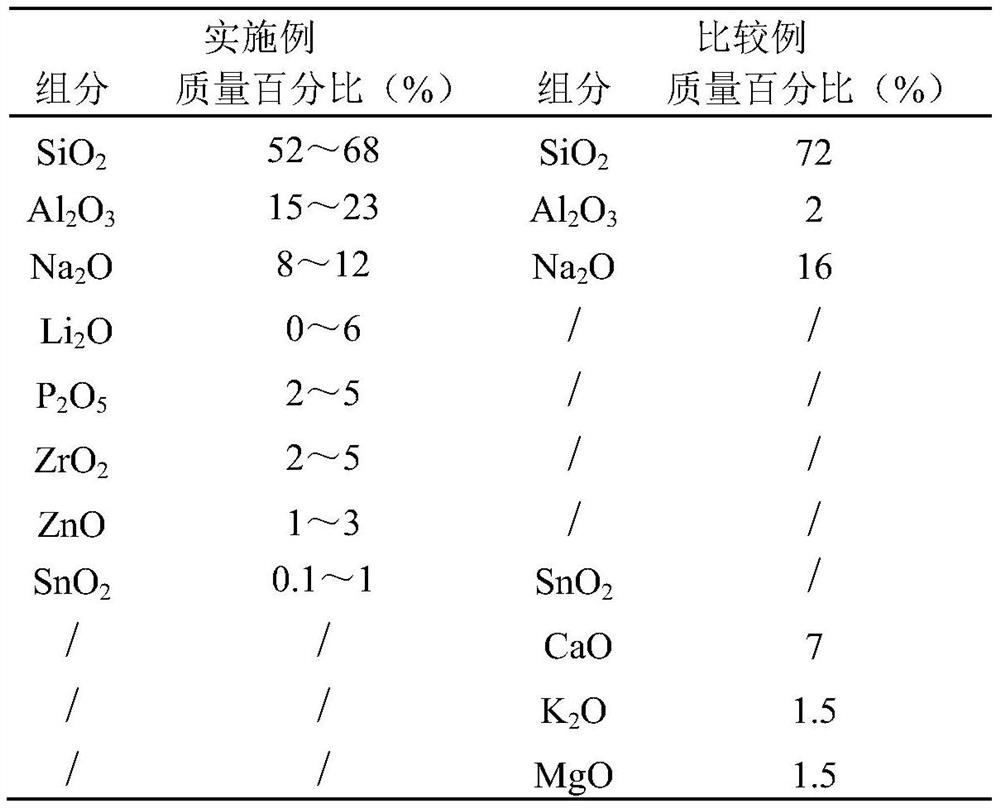

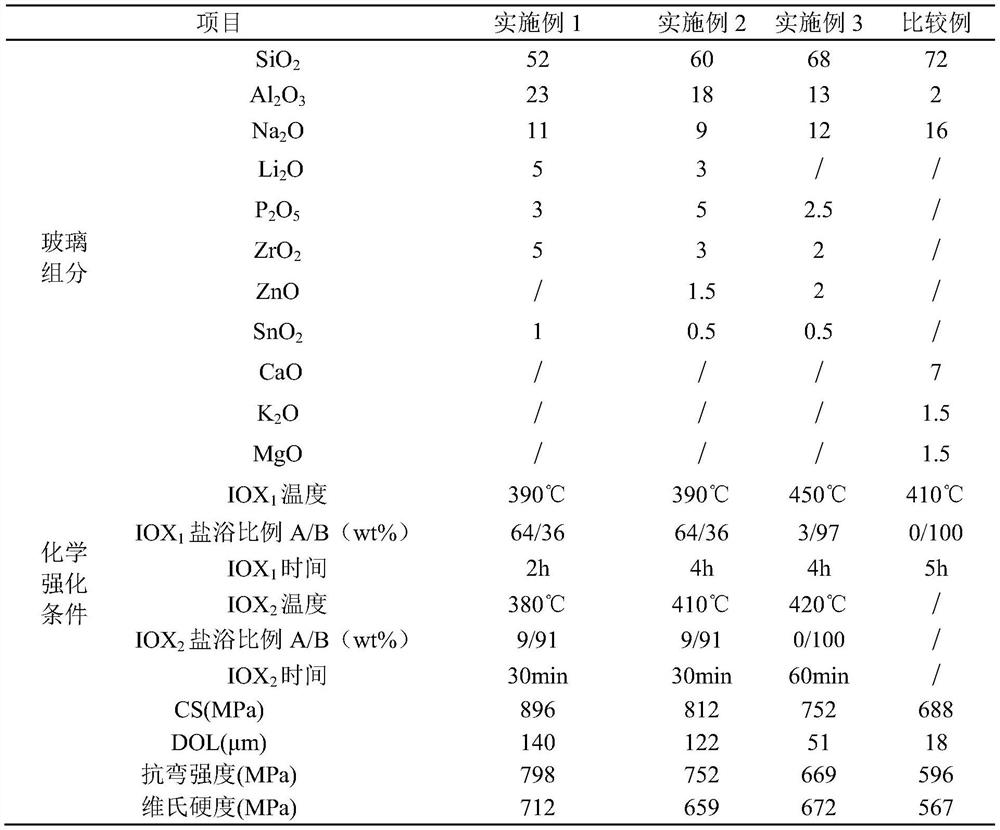

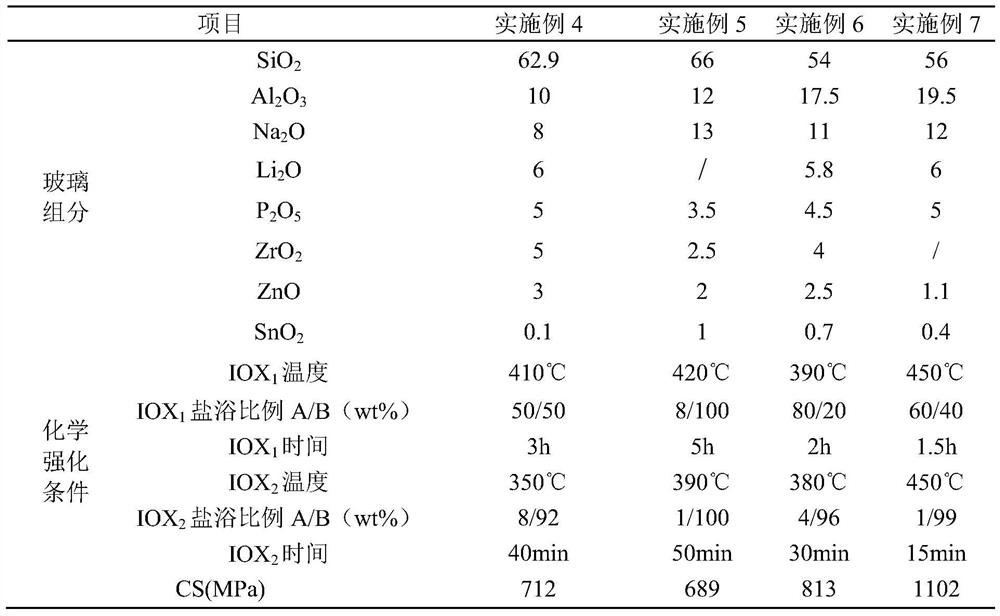

A kind of alkali-containing aluminosilicate glass and its product, strengthening method and application

The invention relates to an alkali-containing aluminosilicate glass and its products, strengthening method and application. In the method, the alkali-containing aluminosilicate glass is sequentially carried out twice in a salt bath of sodium nitrate and potassium nitrate at 350-450° C. Ion exchange to obtain a chemically strengthened aluminosilicate glass article; the composition of the glass includes, SiO 2 52%~68%, Al 2 o 3 10%~23%,Na 2 O 8%~13%, Li 2 O 0~6%, P 2 o 5 2%~5%, ZrO 2 0-5%, ZnO 0-3%; the surface compressive stress of the glass product after chemical strengthening is >600MPa, the compression depth of the stress layer is >50μm, the bending strength is >600MPa, and the Vickers hardness is >600MPa; in electronic devices In the application of the invention, the chemically strengthened alkali-containing aluminosilicate glass article of the present invention is included.

Owner:CAIHONG GRP SHAOYANG SPECIAL GLASS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com