Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

175results about "Blow machines" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Flexible 3D Freeform Techniques

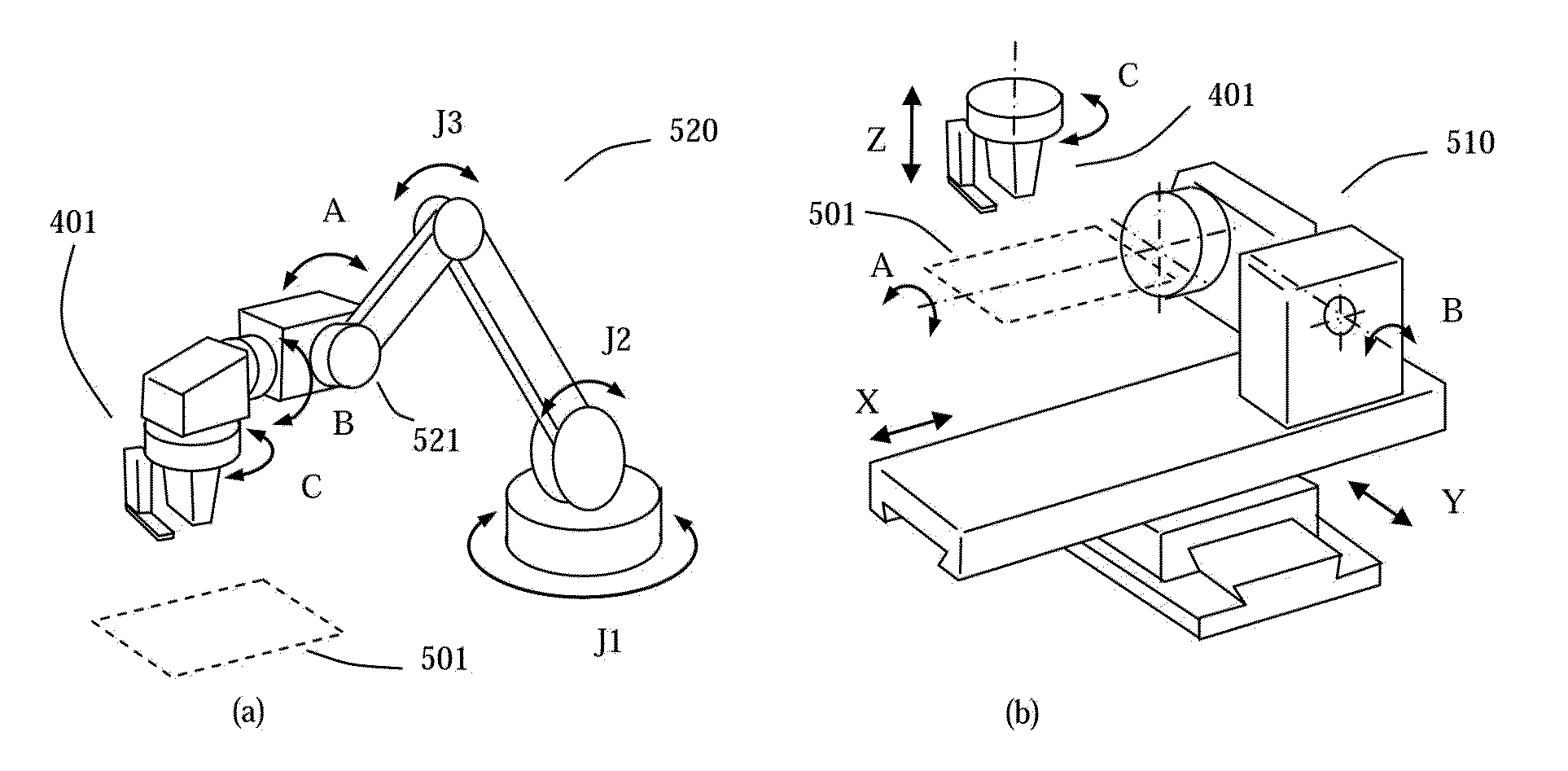

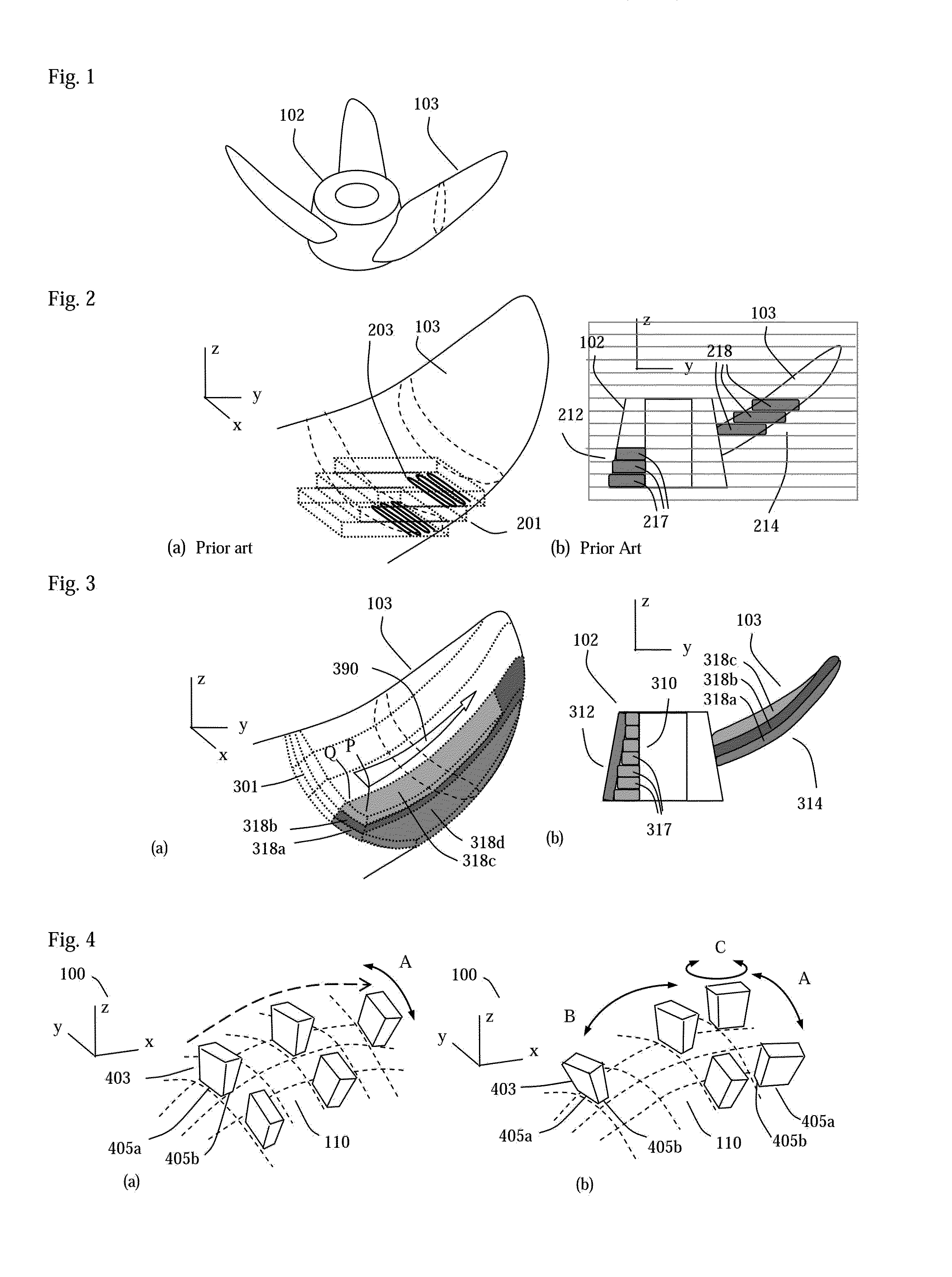

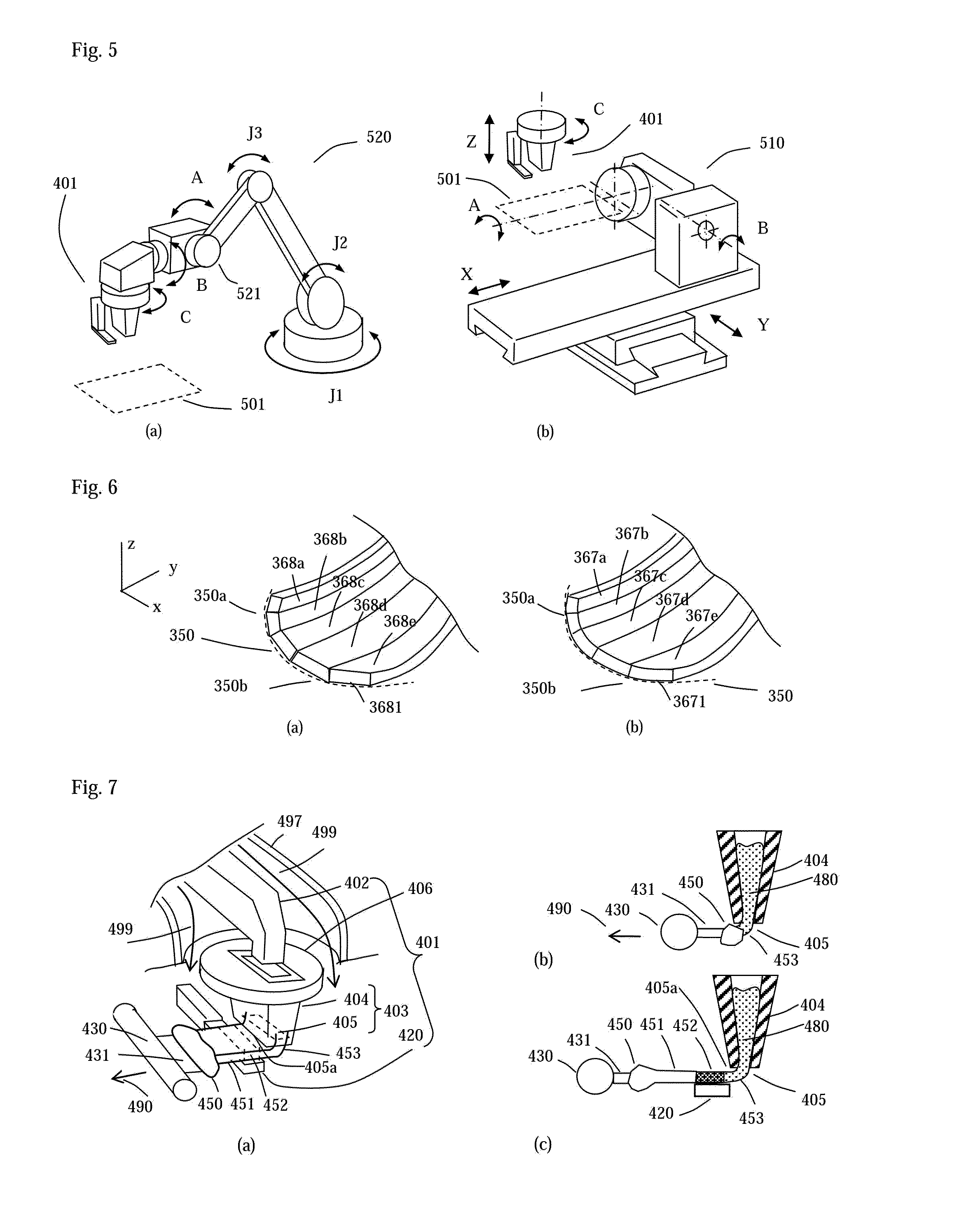

ActiveUS20160151833A1Improve manufacturing speedBuild fine and complexConfectioneryGlass forming apparatusEngineeringInjection molding machine

This invention relates to processes and systems of rapid prototyping and production. Its features includes flexible material deposition along tangential directions of surfaces of a part to be made, thereby eliminating stair-shape surface due to uniform horizontal layer deposition, increasing width of material deposition to increase build up rate, applying the principles of traditional forming / joining processes, such as casting, fusion welding, plastic extrusion and injection molding in the fabrication process so that various industrial materials can be processed, applying comparatively low cost heating sources, such as induction heating and arc-heating. Additional features include varying width and size of material deposition in accordance with geometry to be formed and applying a differential molding means for improved shape formation and surface finishing.

Owner:NATIONAL TSING HUA UNIVERSITY

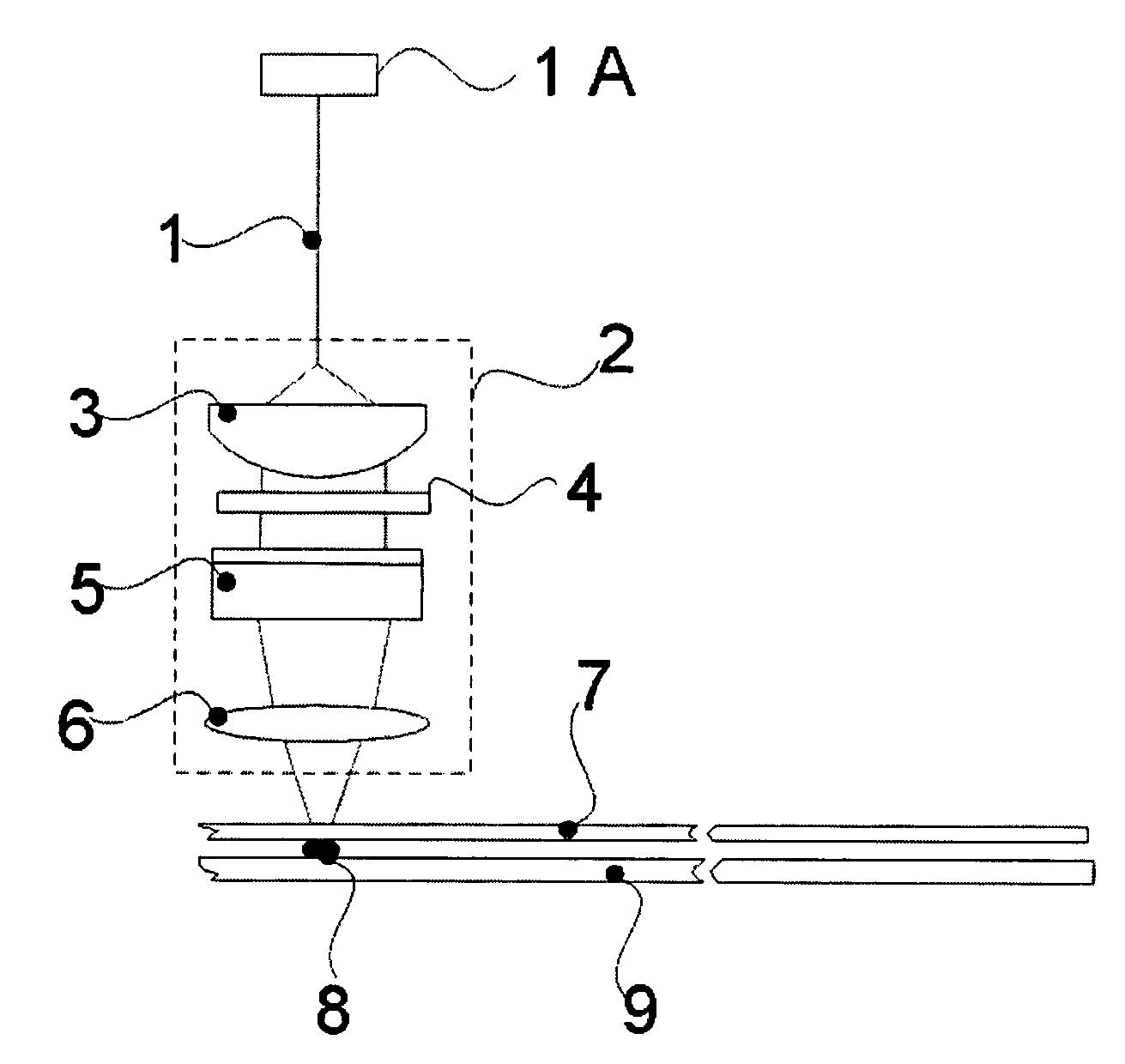

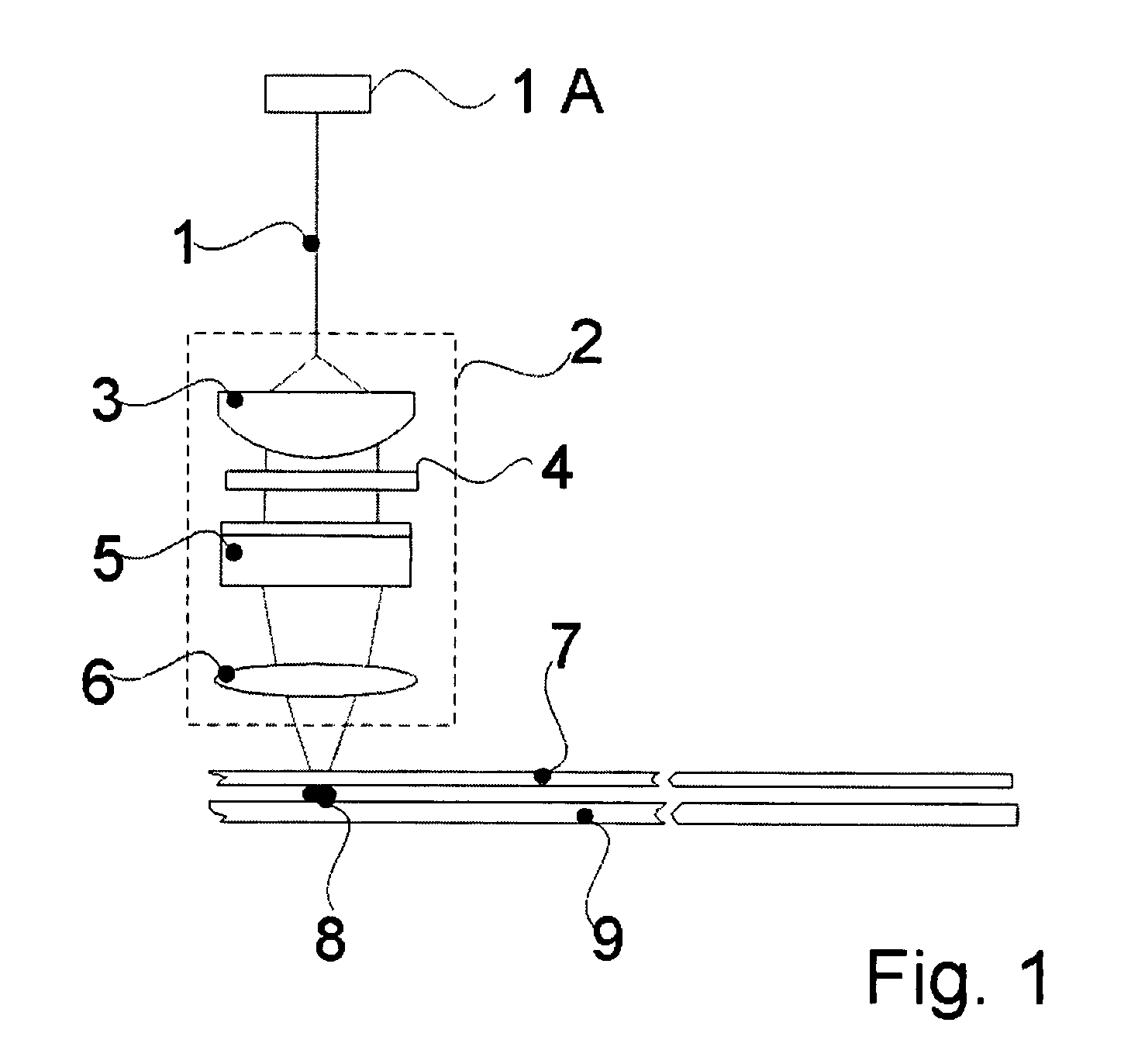

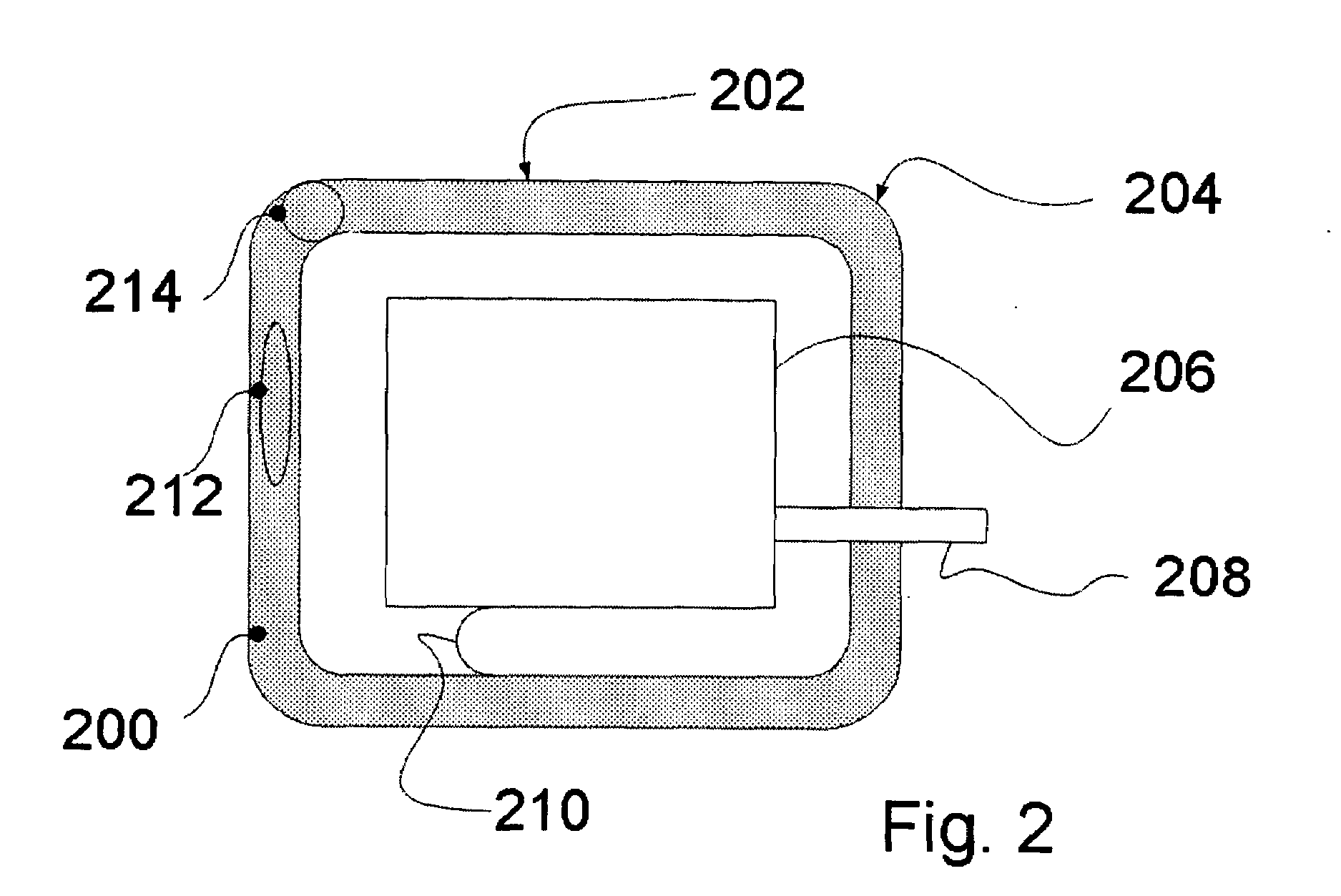

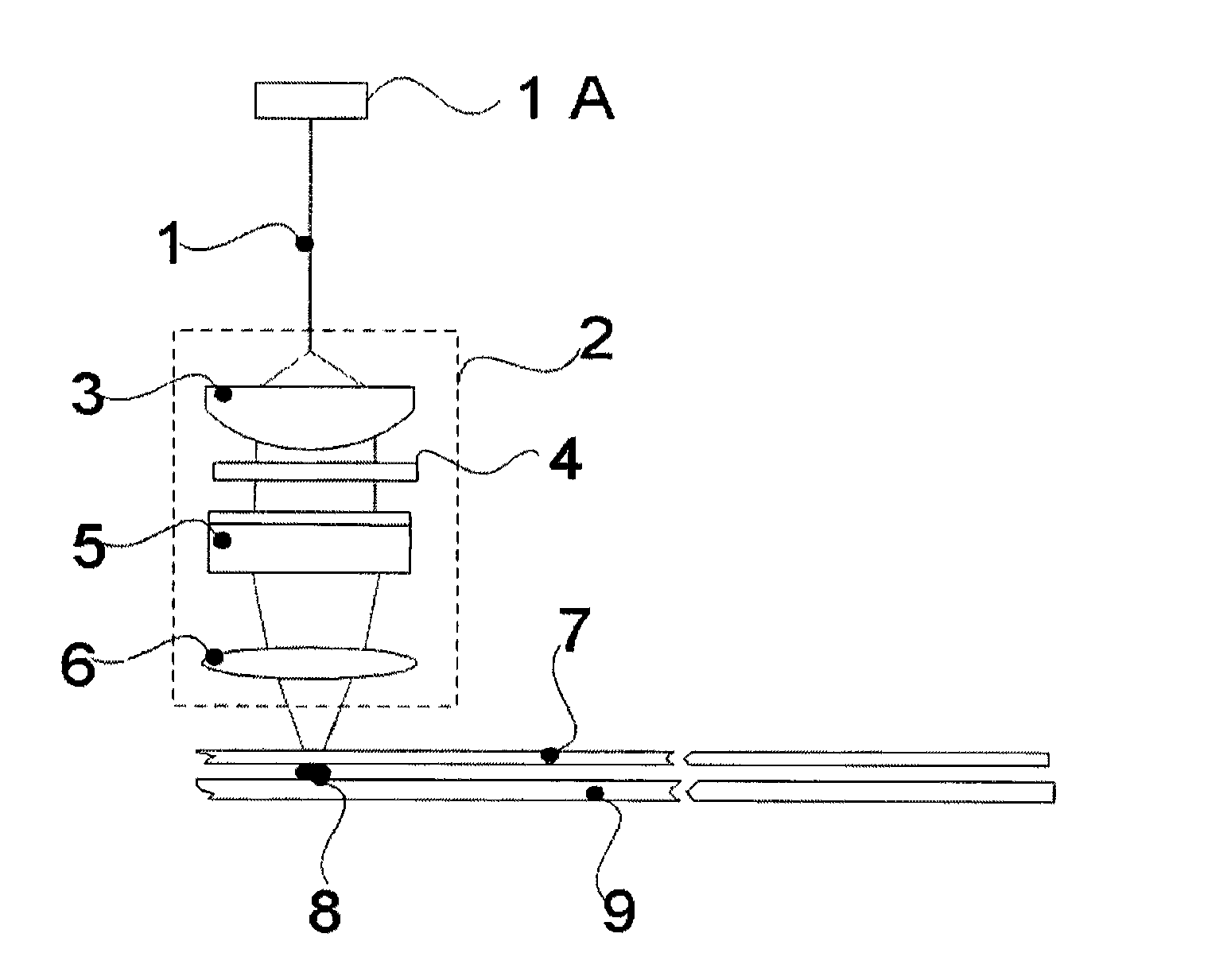

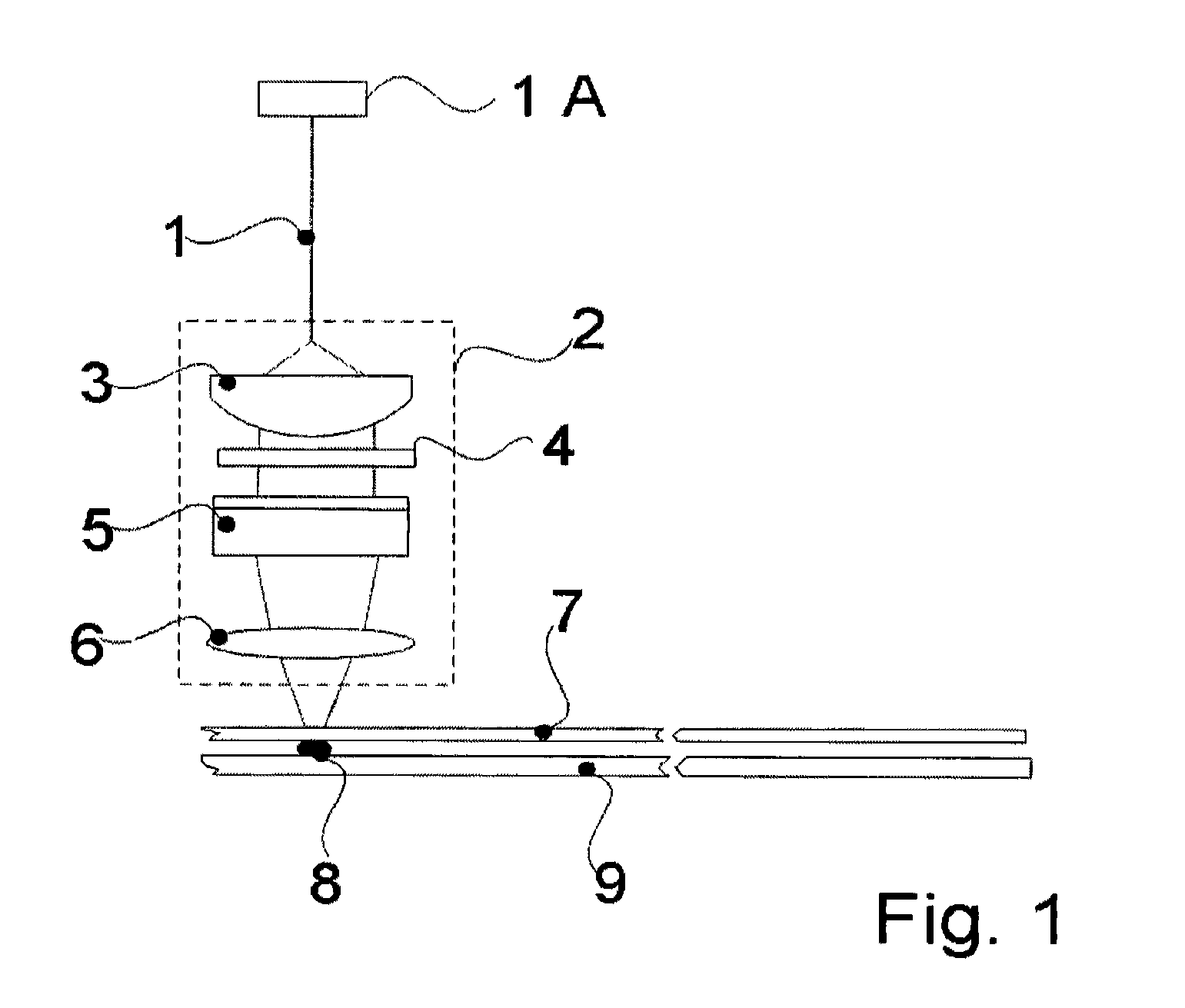

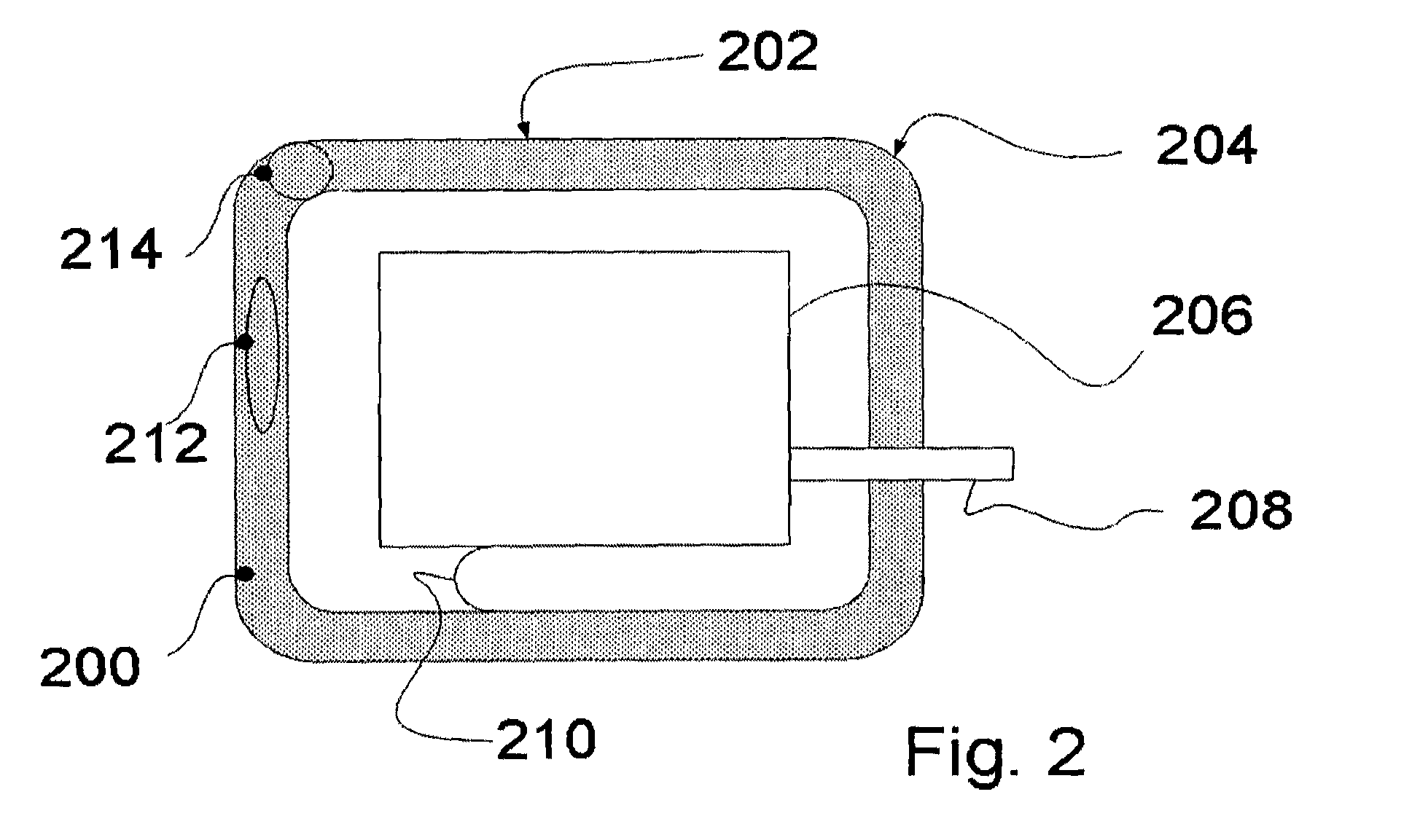

Method and apparatus for frit sealing with a variable laser beam

InactiveUS20090086325A1Uniform temperature distributionImprove overall utilizationDiffusing elementsElectroluminescent light sourcesFritLight beam

A beam shaper is implemented to seal an OLED. The beam shaper comprises a first and second lens and a beam shaper. Changing the relative position of the first, second lens and beam shaper relative to each other enables the beam shaper to generate laser beams with different shapes and intensity profiles.

Owner:CORNING INC

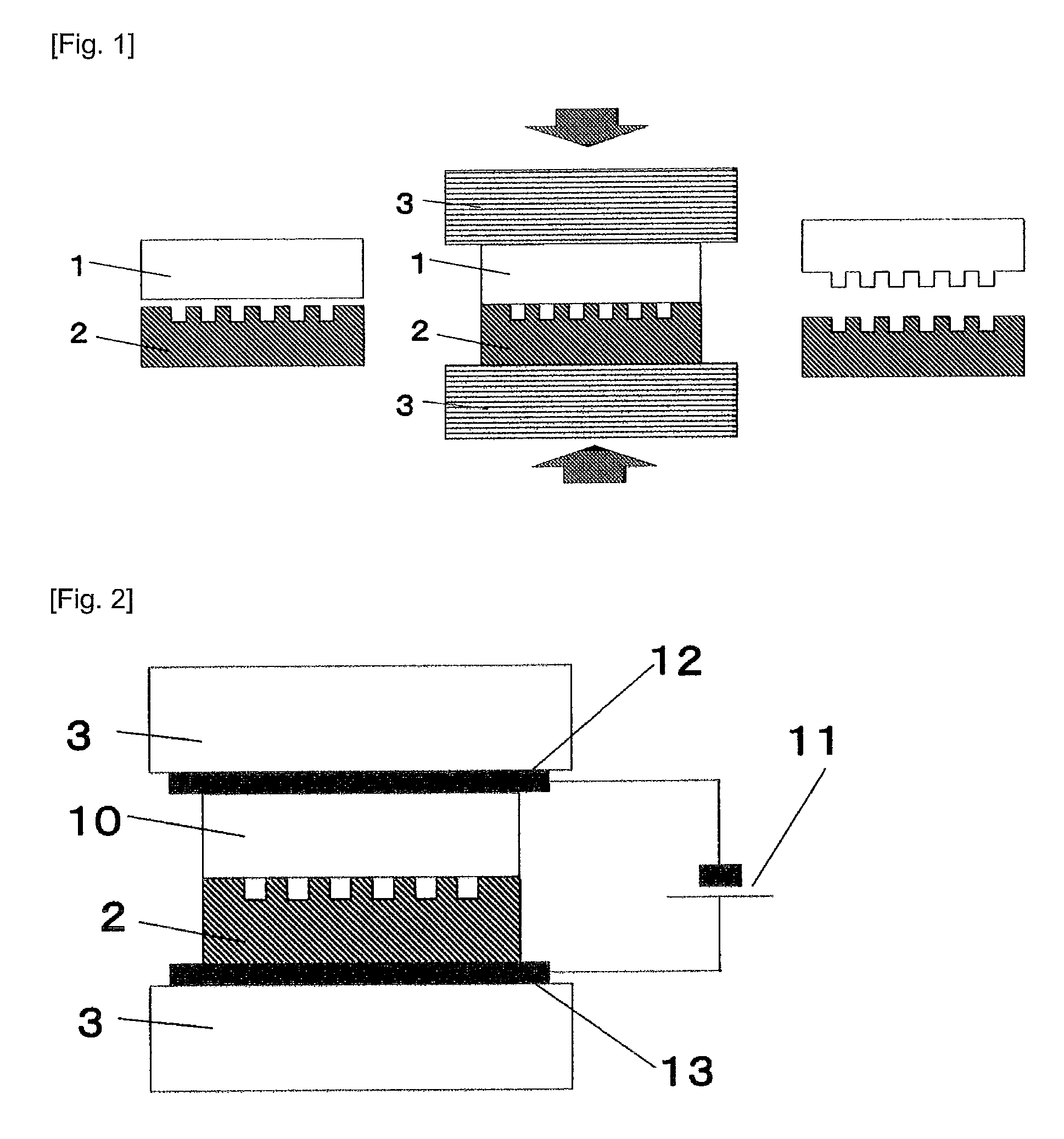

Method of molding glass parts and molding apparatus

InactiveUS8099982B2Reduced size and costSmall sizeElectric discharge heatingGlass drawing apparatusShell moldingAlkali metal

A molding apparatus of a glass material according to the present invention is characterized by containing means for holding a glass material and a molding die in contact with each other, means for heating the glass material and the molding die, and means for applying a voltage across the glass material and the molding die, in which press-molding is performed by electrostatic attraction acting between a surface of the glass material and a surface of the molding die. Further, a molded product of a glass material according to the present invention is characterized by including an alkali metal as a component, in which a concentration of the alkali metal is lowered in vicinity of a surface to be molded as compared with that of a glass base material.

Owner:NAT INST OF ADVANCED IND SCI & TECH

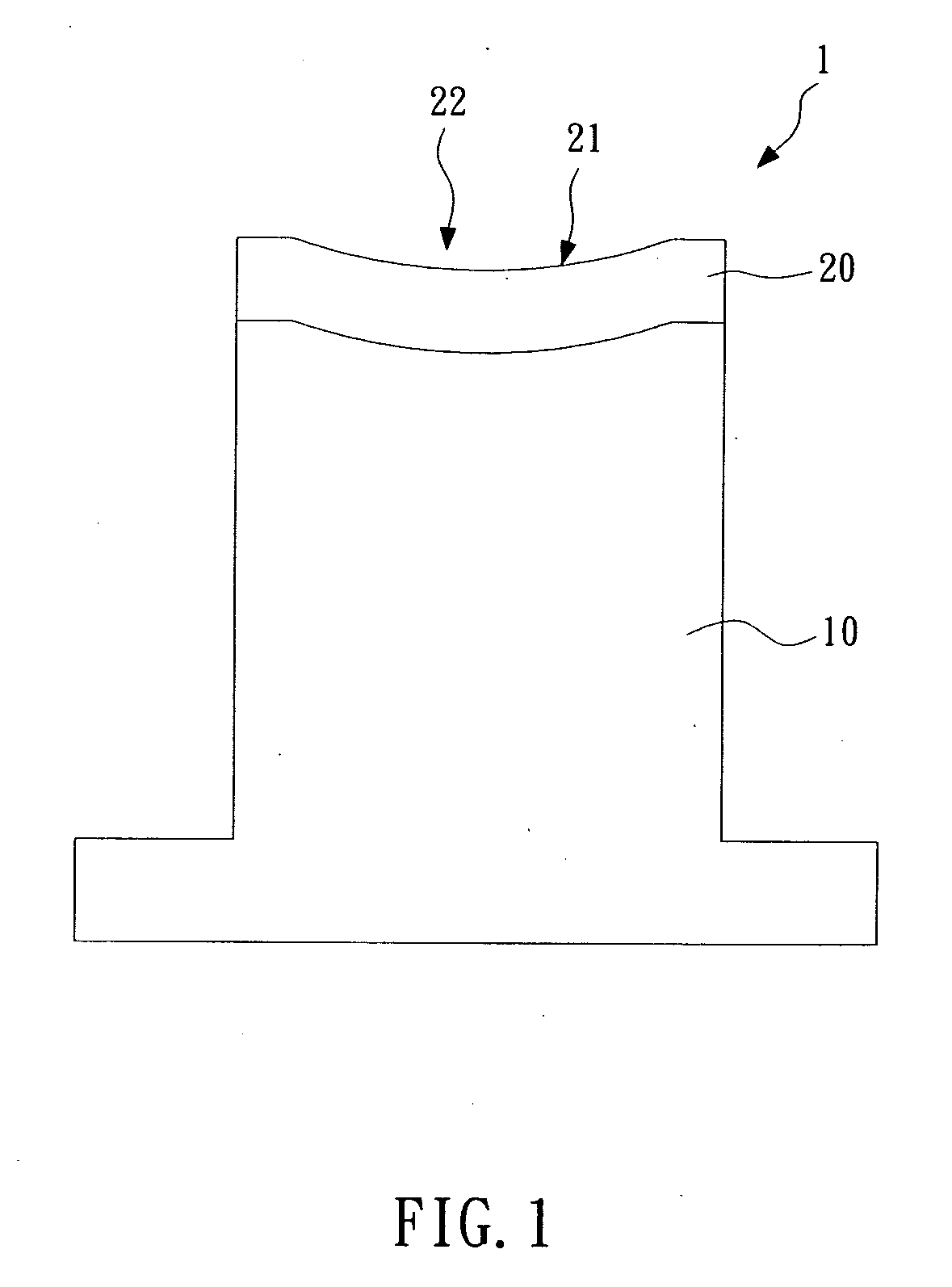

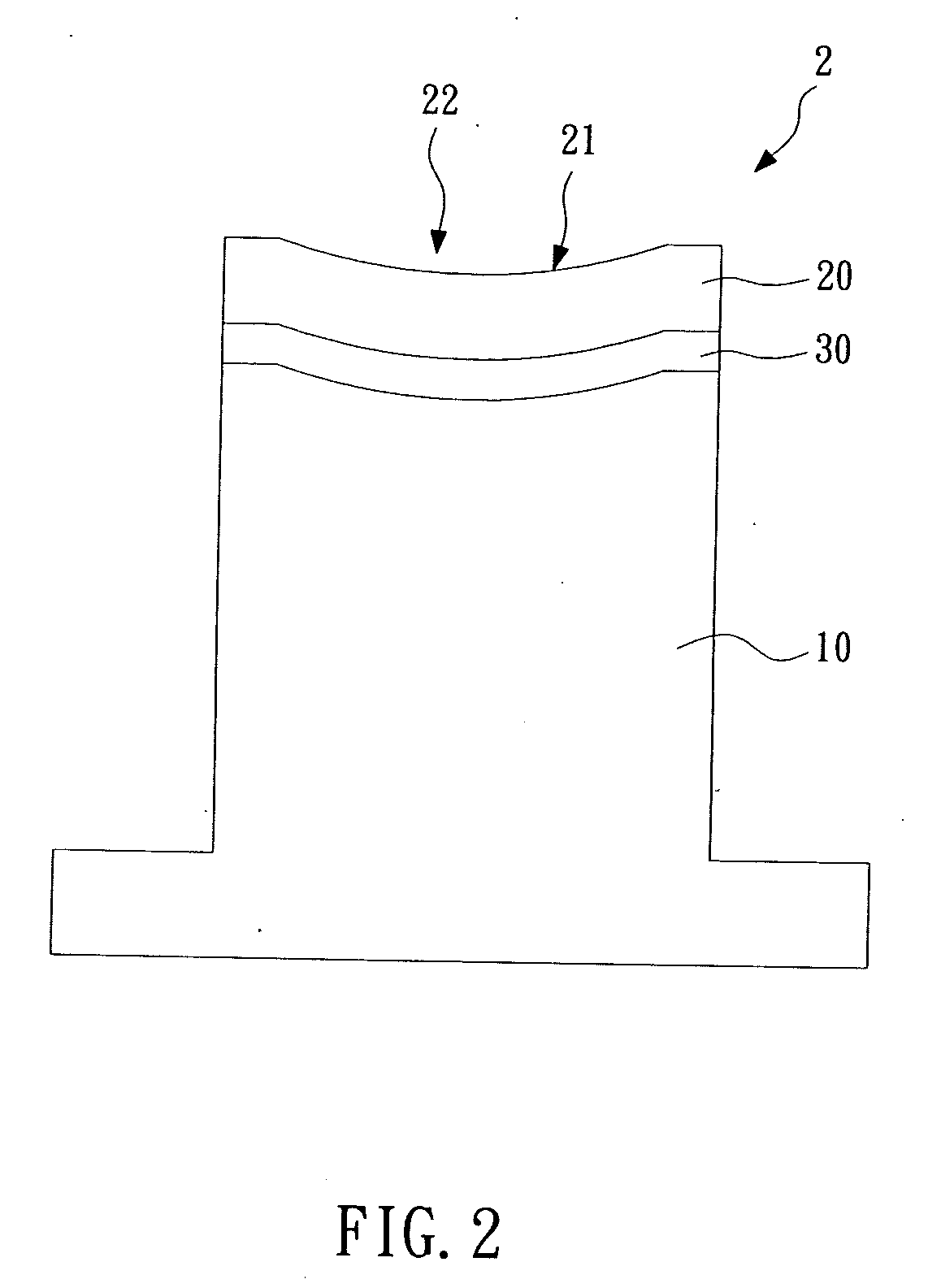

Method of molding glass parts, molding apparatus, and molded product of glass material

InactiveUS20100112341A1Good effectElectric discharge heatingGlass drawing apparatusShell moldingMetal

In order to solve problems involved in micromolding of a glass, according to the present invention, there can be provided a technology for enabling molding of a glass without applying a large load.A molding apparatus of a glass material according to the present invention is characterized by containing means for holding a glass material and a molding die in contact with each other, means for heating the glass material and the molding die, and means for applying a voltage across the glass material and the molding die, in which press-molding is performed by electrostatic attraction acting between a surface of the glass material and a surface of the molding die. Further, a molded product of a glass material according to the present invention is characterized by including an alkali metal as a component, in which a concentration of the alkali metal is lowered in vicinity of a surface to be molded as compared with that of a glass base material.

Owner:NAT INST OF ADVANCED IND SCI & TECH

Methods and apparatuses for reducing heat loss from edge directors

ActiveUS20150329401A1Reduce devitrificationGlass drawing apparatusGlass forming apparatusHeat lossesEngineering

An apparatus and methods for making a glass ribbon includes a forming wedge with a pair of inclined forming surface portions converging along a downstream direction to form a root. The apparatus further includes an edge director intersecting with at least one of the pair of downwardly inclined forming surface portions, and a replaceable heating cartridge configured to direct heat to the edge director and thermally shield the edge director from heat loss. A replaceable heating cartridge is also provided for directing heat to the edge director and thermally shielding the edge director from heat loss.

Owner:CORNING INC

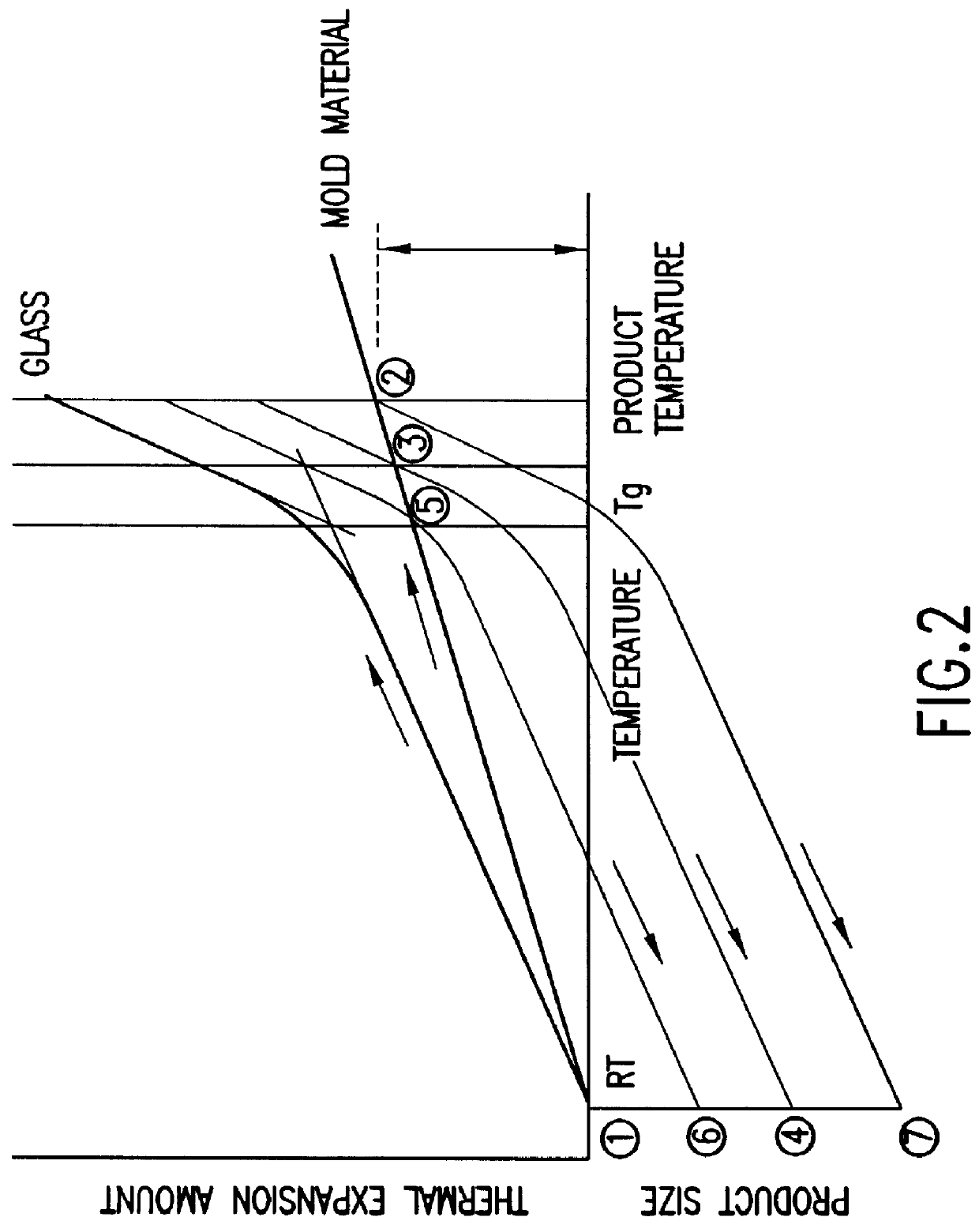

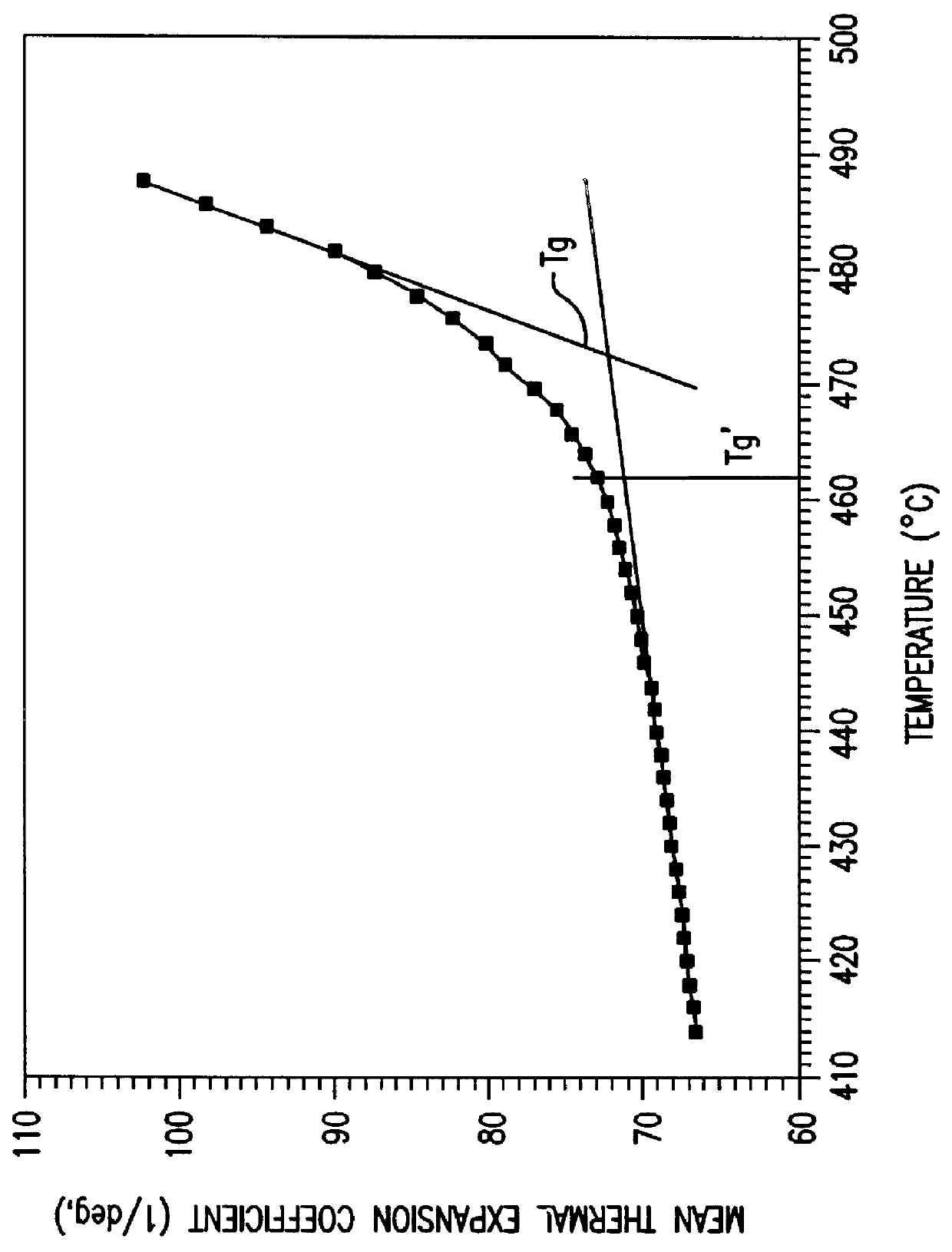

Manufacturing method for glass molded products

In a method for molding glass products having a fine structure as of an optical fiber holder with a high size precision, a mold used for the molding has the fine structure in a size such that a size difference occurring when the glass product is cooled down to a room temperature where at the end of molding with a pressure a size of the fine structure of the mold for glass product and a size of a fine structure of the glass product formed by transfer of the fine structure of the mold are the same as one another is so adjusted that a size of the fine structure of the completed glass product falls within a permissive size precision range. The mold may has a size satisfying, as a size of a fine structure at a room temperature, a formula [1+( alpha g- alpha m)x DELTA T+ alpha g'x DELTA T']xSg, wherein Sg denotes a size of a fine structure of thc glass product at the room temperature; alpha g denotes a mean thermal expansion coefficient of the glass to be molded in a temperature range from the room temperature to the glass transition temperature of the glass to be molded; alpha m denotes a mean thermal expansion coefficient of the mold in a temperature range from the room temperature to the glass transition temperature of thc glass to be molded; DELTA T denotes a difference between the room temperature and the glass transition temperature of the glass to be molded; DELTA T' denotes a difference between a temperature at which the mold's pressure exerted to the glass product is released and the glass transition temperature, in a case where the mold's pressure exerted to the glass product is released at a temperature higher than the glass transition temperature after pressing the mold with a high pressure; and alpha g' is a thermal expansion coefficient of the glass to be molded at a mean temperature of summation of the glass sag temperature and the glass transition temperature.

Owner:HOYA CORP +1

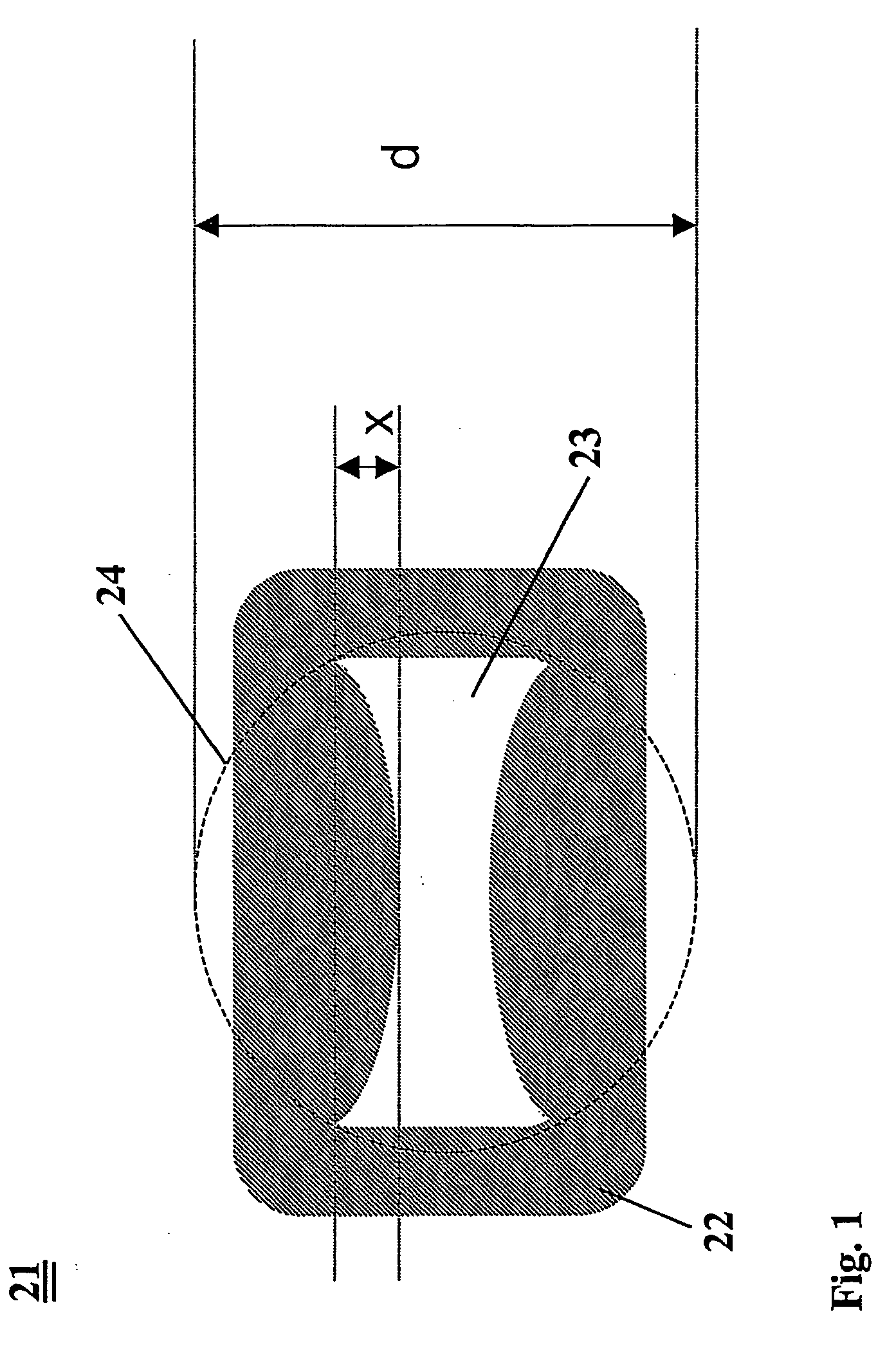

Glass tube for technical applications and process for the production thereof

InactiveUS20060141181A1Easily and more cost-effectivelyLayered productsGlass forming apparatusEngineeringReed switch

The invention relates to glass tubes for technical applications, especially for electrical or magnetic components, such as reed switches for example. According to a first embodiment, the glass tube has an inner bore (23) and at least one cross-sectional constriction (X) whereby the relationship applicable between the respective cross-sectional constriction (X) and the diameter (d) of the circumference of inner bore (23) is: x greater than or equal to 0.02*d, more preferably x greater than or equal to 0.1*d. According to a further embodiment, the glass tube has at least one inner bore with at least one inner edge, wherein the radius of curvature of the respective inner edge is less than or equal to 0.1 mm and preferably less than or equal to 0.03 mm. The glass tube is used as a preform for a subsequent redrawing process. The preform is formed by casting a molten glass into a shaft in the interior of which is located a shaping means for defining the inner bore. In this case a gas cushion prevents direct contact of the molten glass with the inner circumferential wall of the shaft and / or the outer circumferential wall of the shaping means.

Owner:SCHOTT AG

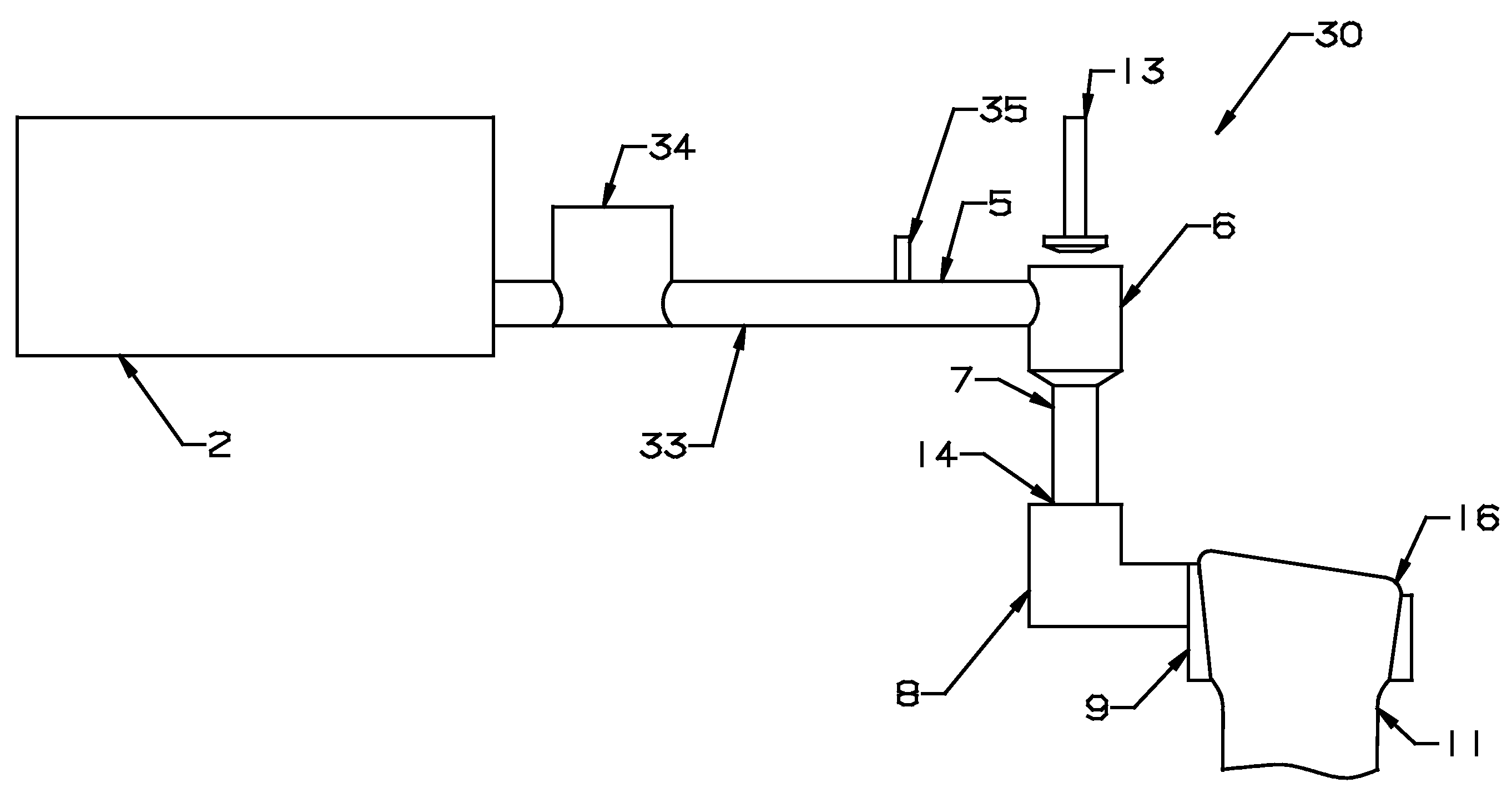

Molten glass delivery apparatus for optical quality glass

ActiveUS20090038342A1High aspect ratioImprove clarification efficiencyCharging furnaceBlowing machine gearingsEngineeringGlass sheet

A molten glass delivery system is modified to match it with the overflow downdraw process. A substantial number of defects not removed by the finer are diverted to the unusable inlet and distal edges of the sheet. In one embodiment, the stirring device is relocated from the outlet to the inlet of the finer. In another embodiment, the basic shape of the finer is preferably changed from a cylindrical shape to a Double Apex (or Gull Wing) shaped cross-section, whereby the apexes of the finer contain the glass that will form the unusable inlet end of the glass sheet. The finer vent or vents are preferably located at these apexes such that any homogeneity defects caused by the vents are diverted to the unusable inlet end of the glass sheet. The finer cross-section has a high aspect ratio for increased fining efficiency as compared to a cylindrical finer.

Owner:CORNING INC

Optical glass

The invention relates to optical glasses intended for the application fields of imaging, sensors, microscopy, medical technology, digital projection, photolithography, laser technology, wafer / chip technology, and for telecommunication, optical communication engineering and optics / lighting in the automotive sector, having a refractive index of 1.60≦nd≦1.80 and / or an Abbe number of 30≦νd≦40 with a pronounced short flint character, good chemical stability, excellent crystallization stability, good solarization stability and the following composition (in wt. % based on oxide):SiO219–45B2O3 3–7.5Nb2O525–31K2O2–8TiO20.1–2 ZrO2 6–10Ta2O50.5–8

Owner:SCHOTT AG

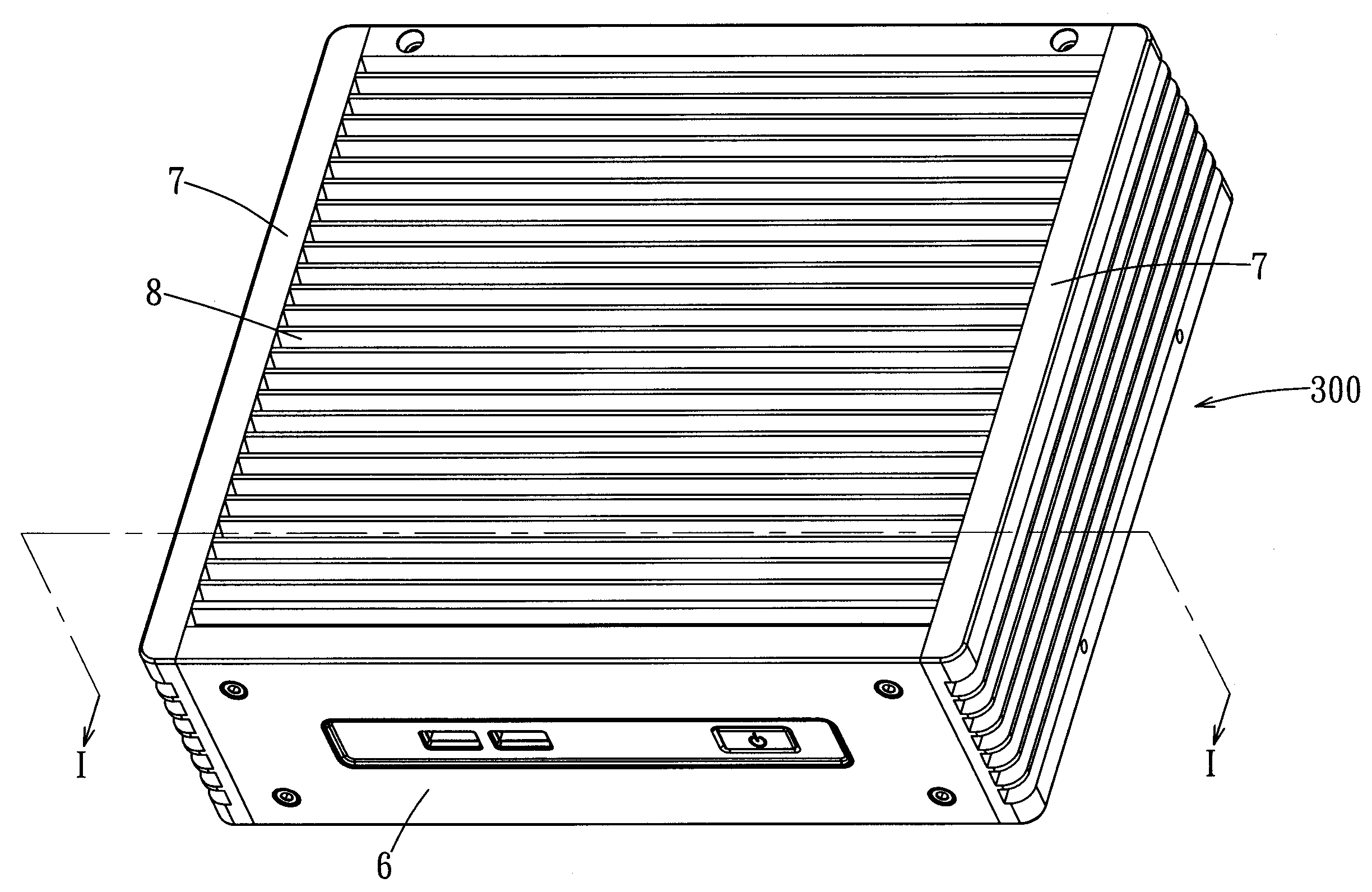

Vibration Damping Mechanism And Electronic Device Having The Damping Mechanism

InactiveUS20090195976A1Increase contact areaImprove heat transfer efficiencyPortable framesDomestic cooling apparatusEngineeringHeat transfer efficiency

A vibration damping mechanism includes a frame, cushioning members, a heat sink, and fastening members. The frame has a base plate and supporting arms disposed on the base plate. Each cushioning member is disposed on a respective one of the supporting arms, and has a through hole. The heat sink supports a hard disk thereon such that the hard disk lies flat against and is secured on the heat sink, and has a plurality of fastening holes. Each fastening member extends through the respective through hole and threadedly engages the respective fastening hole such that the heat sink is suspended on the supporting arms and abuts against the cushioning members. Thus, the area of contact between the heat sink and the hard disk is increased to enhance the heat transfer efficiency, and the cushioning members provide the heat sink and the hard disk with a cushioning effect.

Owner:AOPEN

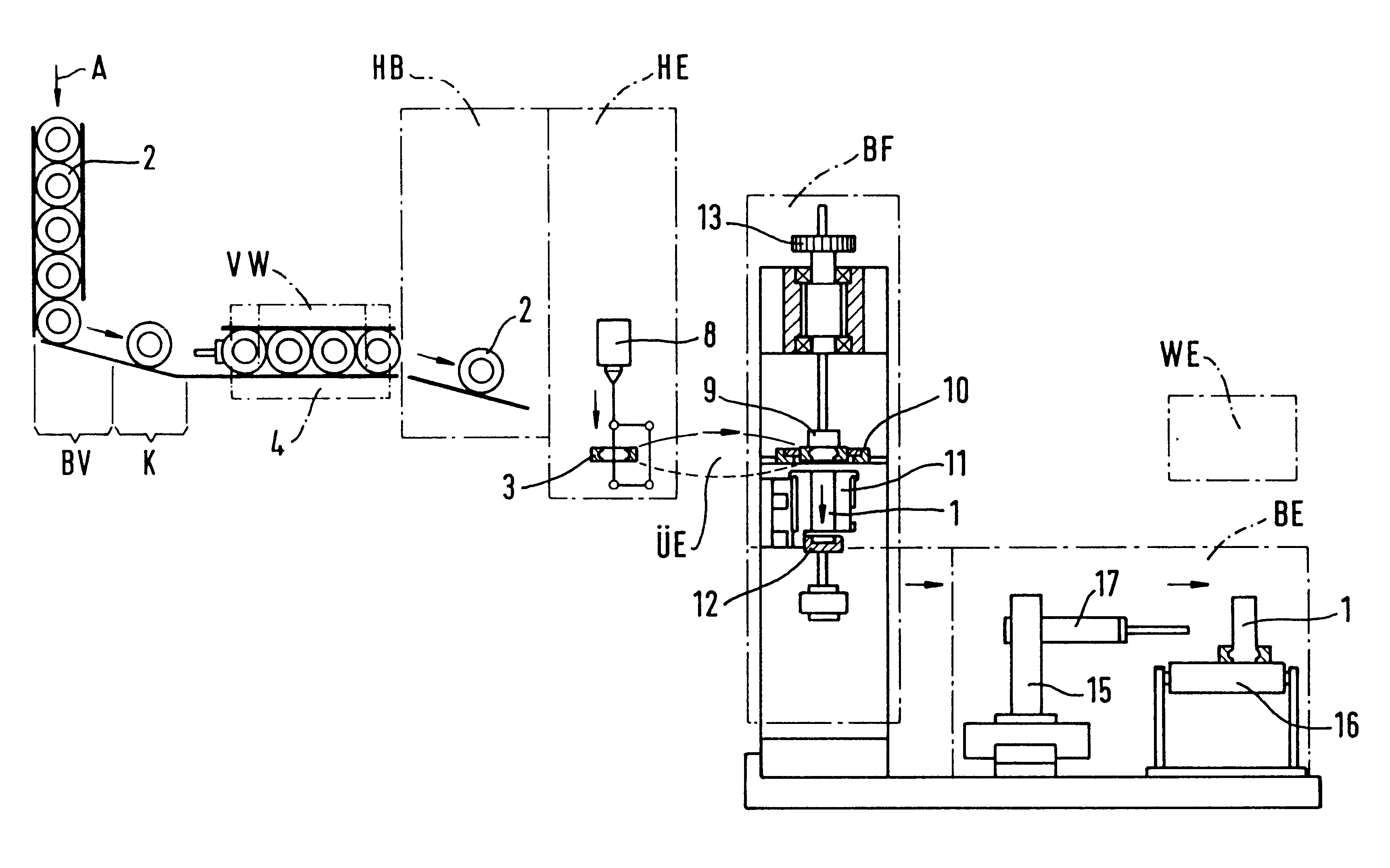

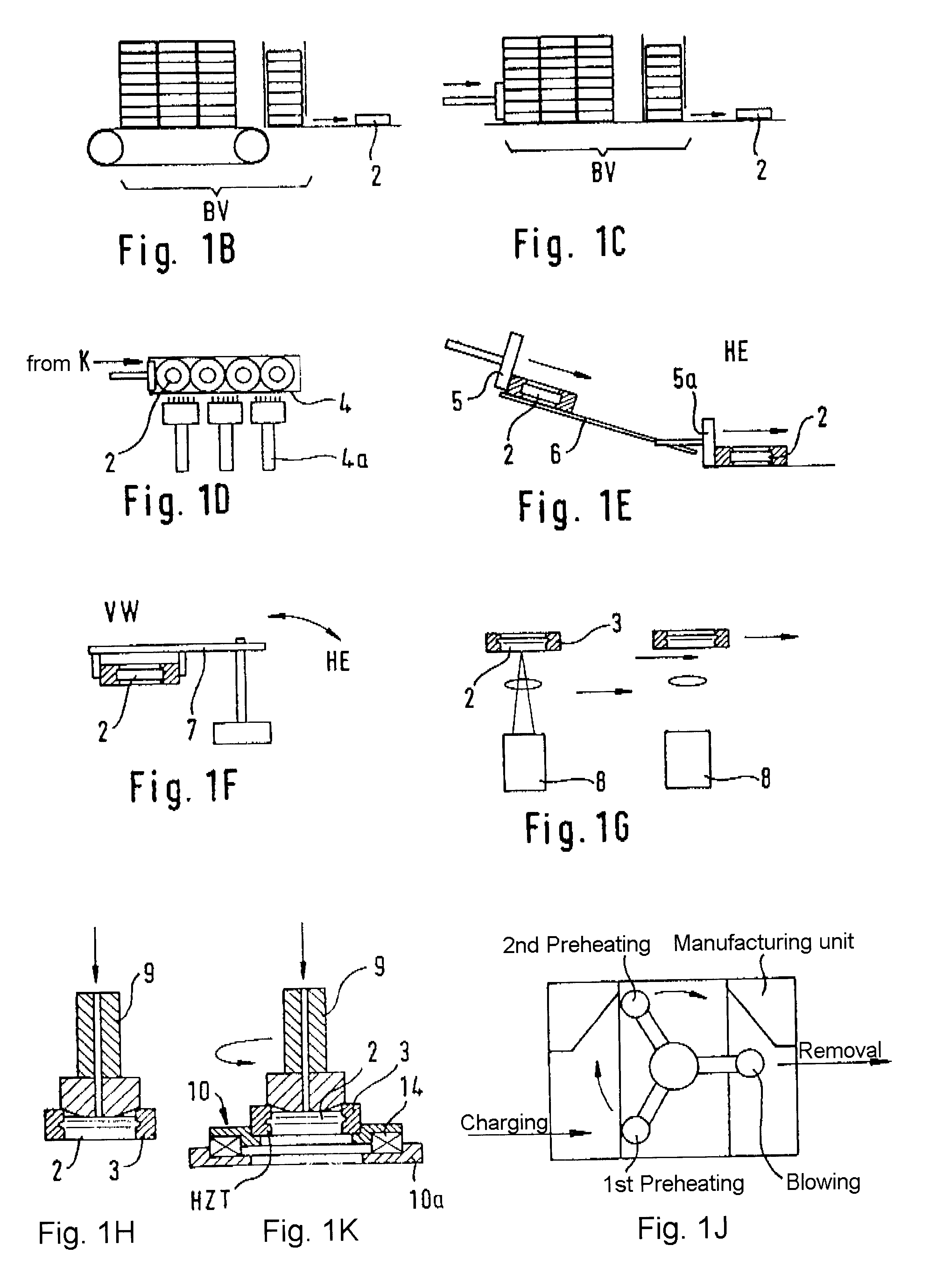

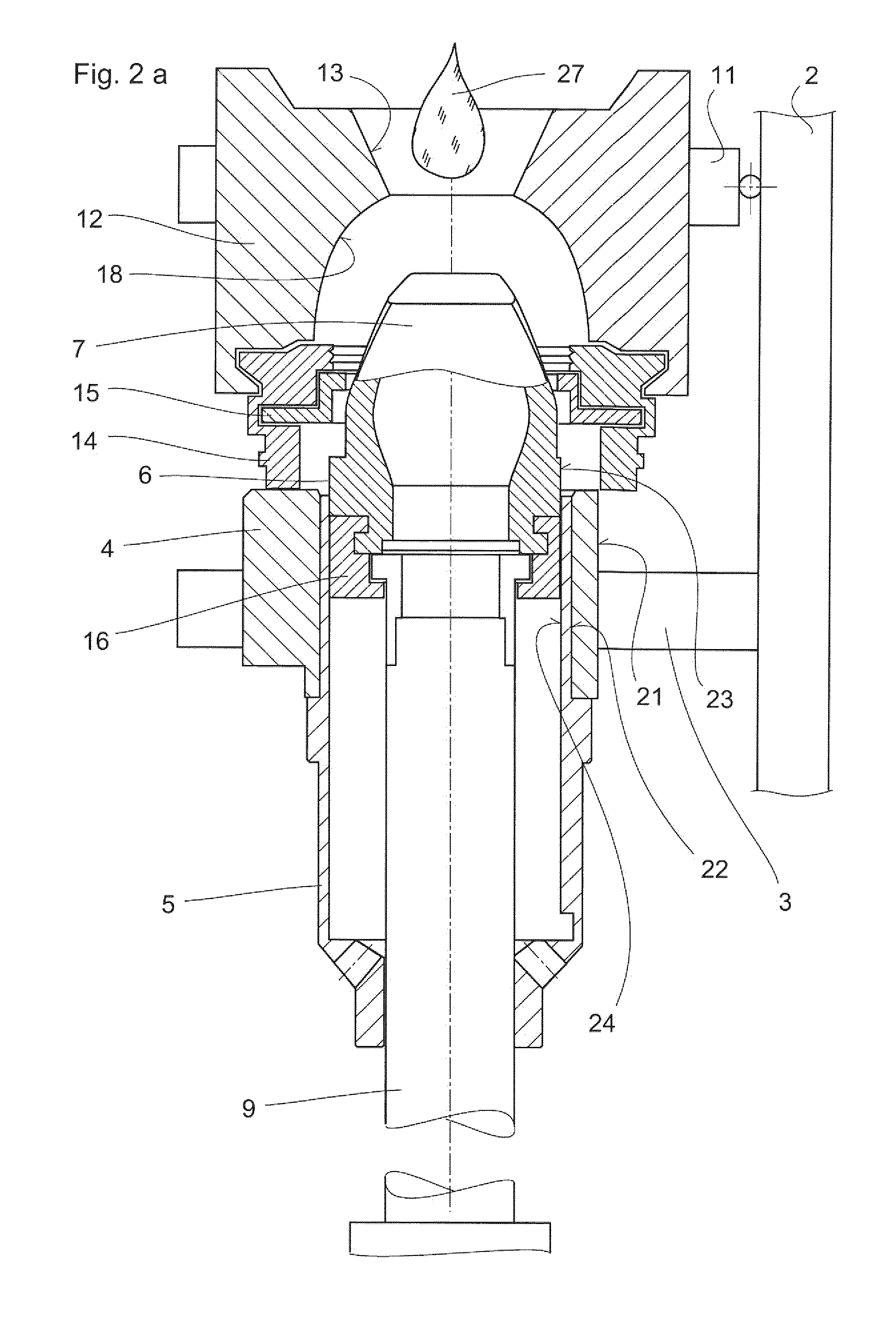

Method for producing glass goblets, tumblers and similar hollow glasses, and corresponding device for carrying out said method

InactiveUS6497119B1Cheap productionInexpensive productionBlowing machine gearingsGlass drawing apparatusBlow moldingEngineering

A device and process for forming hollow glassware comprising producing solid glass blanks in a manufacturing line, storing the blanks, feeding the blanks to a manufacturing line for forming hollow glassware, preheating the blanks during the feeding step, supplying the preheated blanks to a heating stage, heating to form solid plastically deformable glass globs, transferring the glass gobs to a blow molding stage and blow molding the glass gobs supported by a bottom lifter in a blow mold.

Owner:SCHOTT ZWIESEL

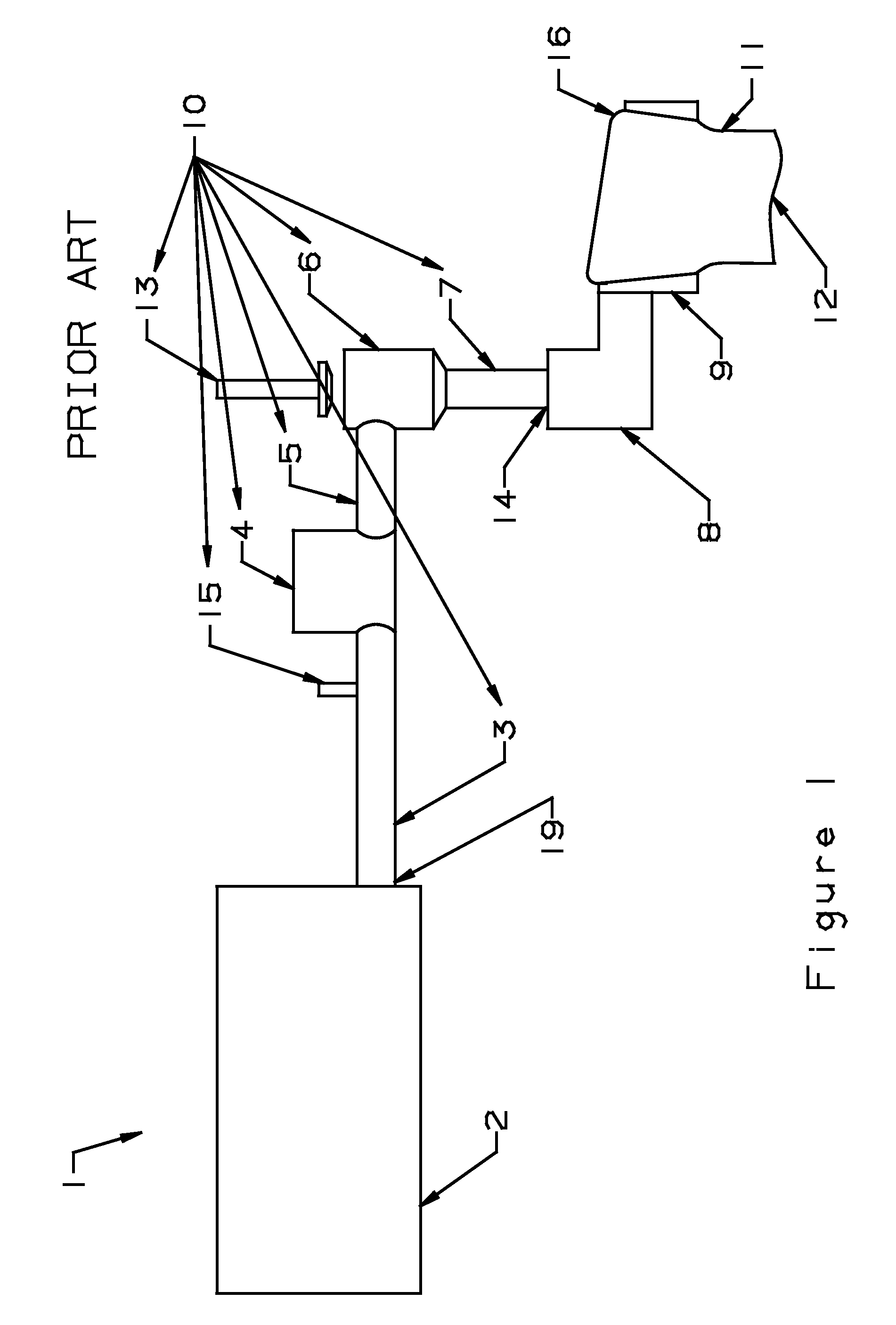

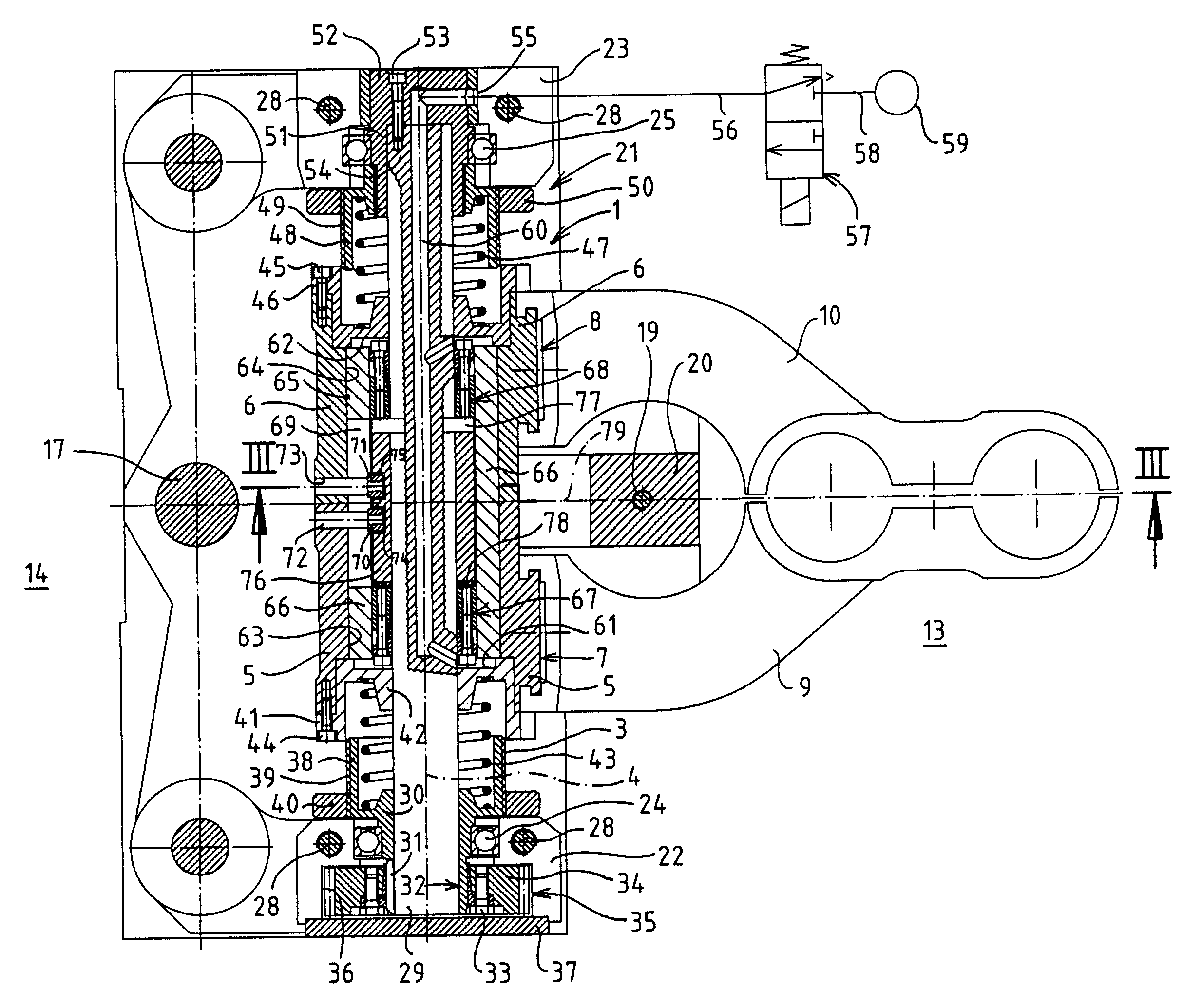

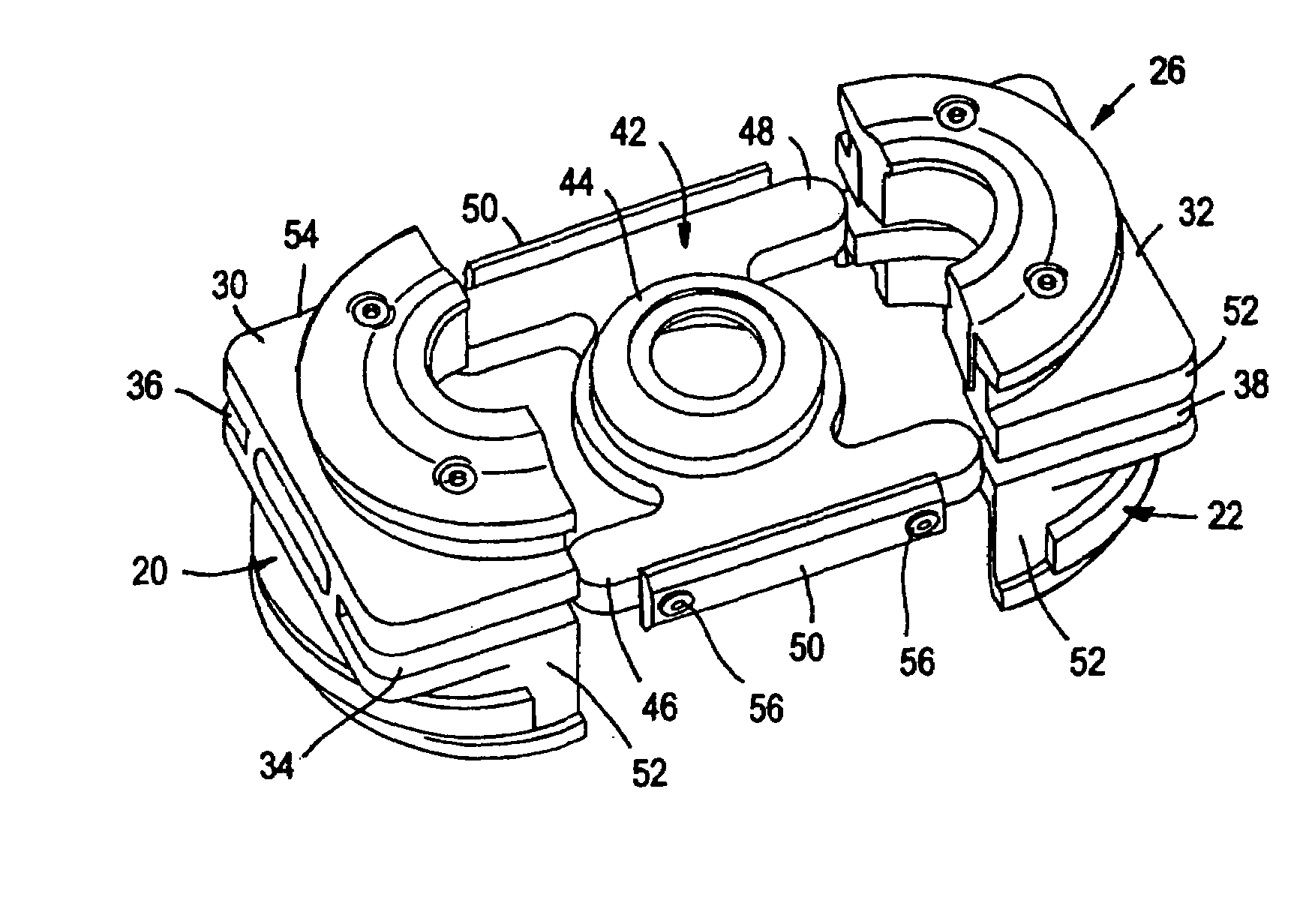

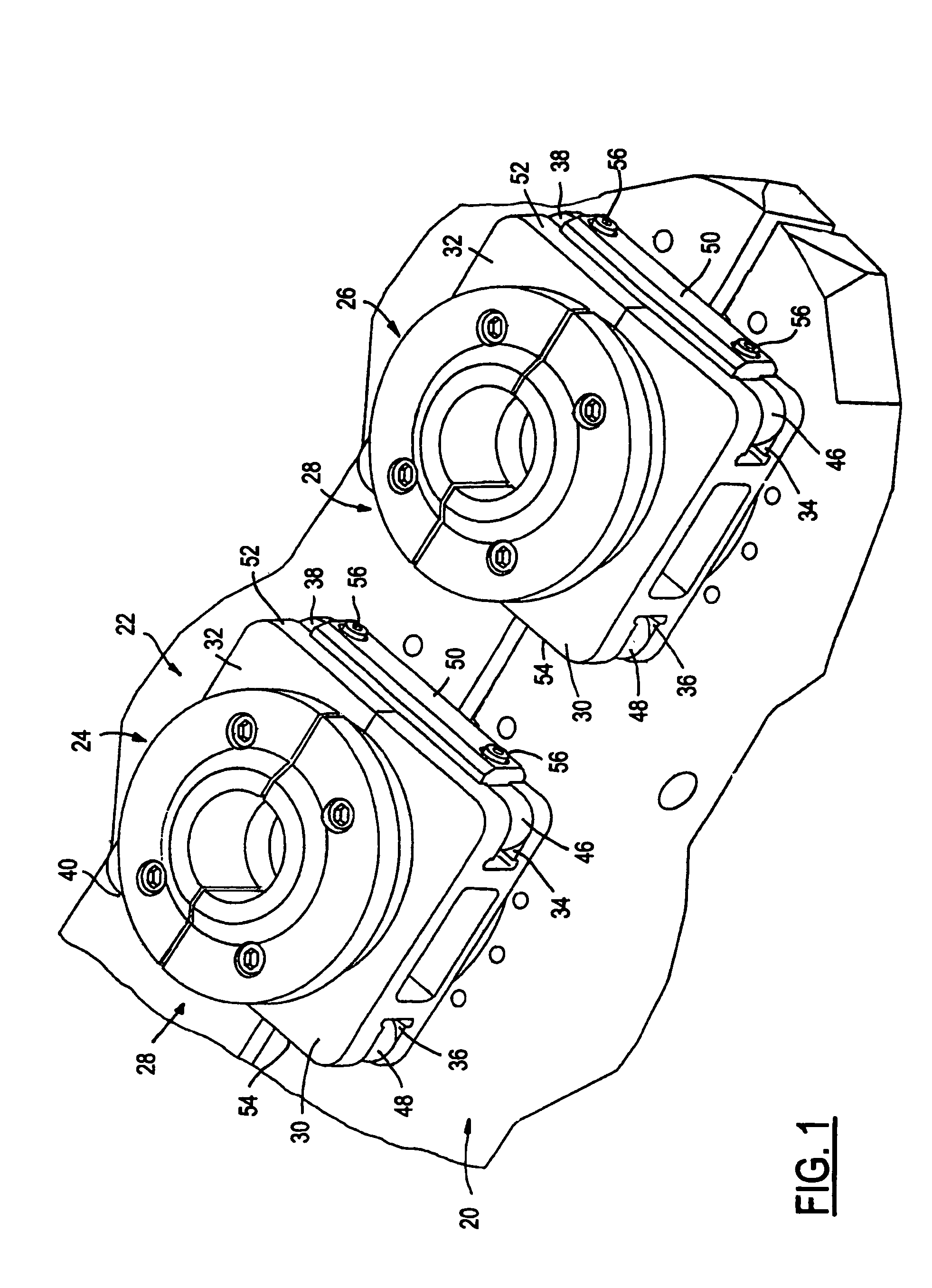

Inverter mechanism for a glass forming machine

InactiveUS7047766B2Improve rotational driveEasy to disassembleGlass drawing apparatusGlass forming apparatusDrive shaftEngineering

An invert mechanism for moving parisons between a pre-forming station and a finishing forming station of a glass forming machine is disclosed. The mechanism is disposed above a cover plate of a frame of the glass forming machine. An electric motor is disposed with its horizontal longitudinal axis above the cover plate. A driven shaft of the electric motor is connected to a horizontal invert shaft by means of a transmission. Between the driven shaft of the electric motor and the transmission a planetary gear is connected.

Owner:HEYE HLDG

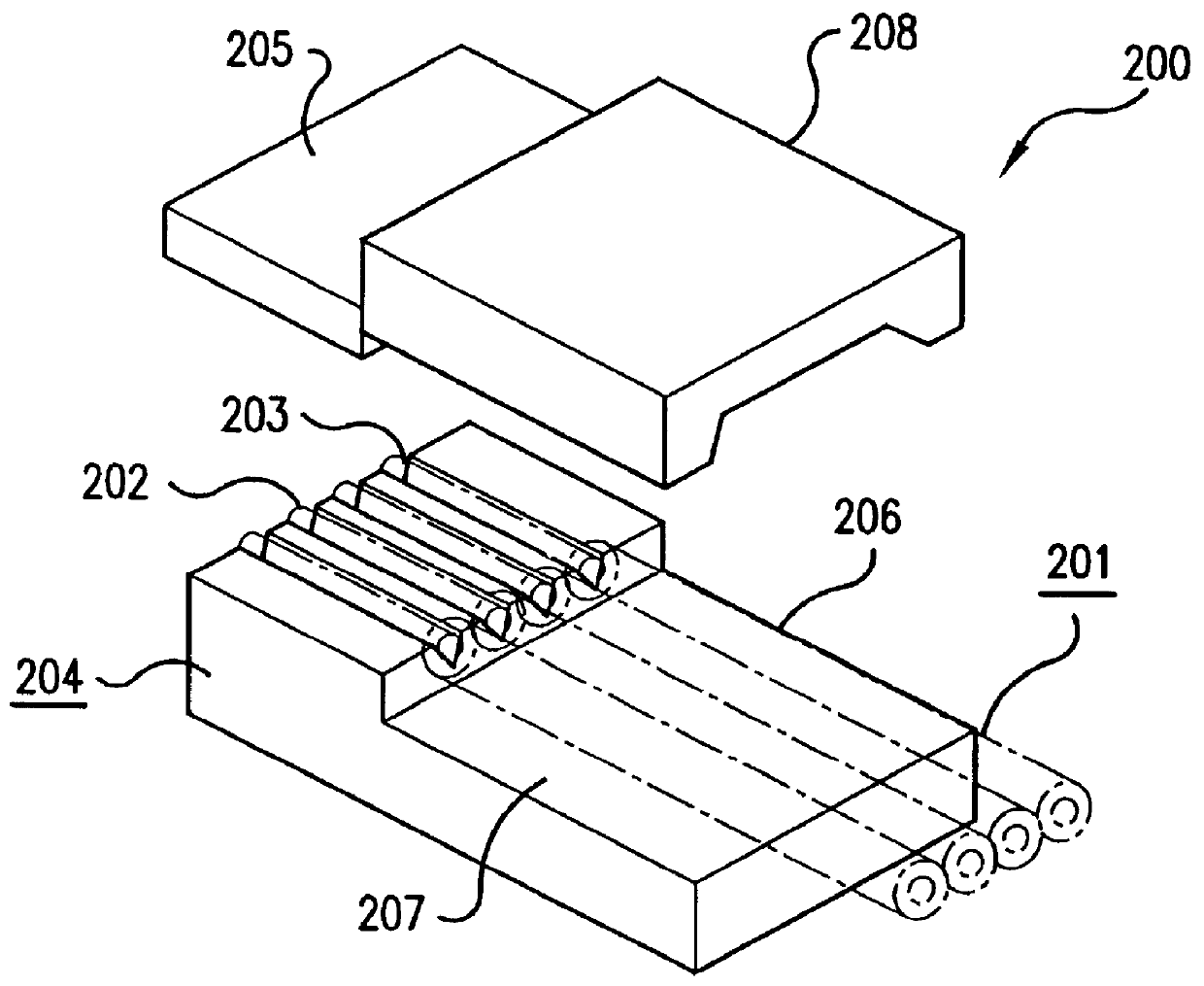

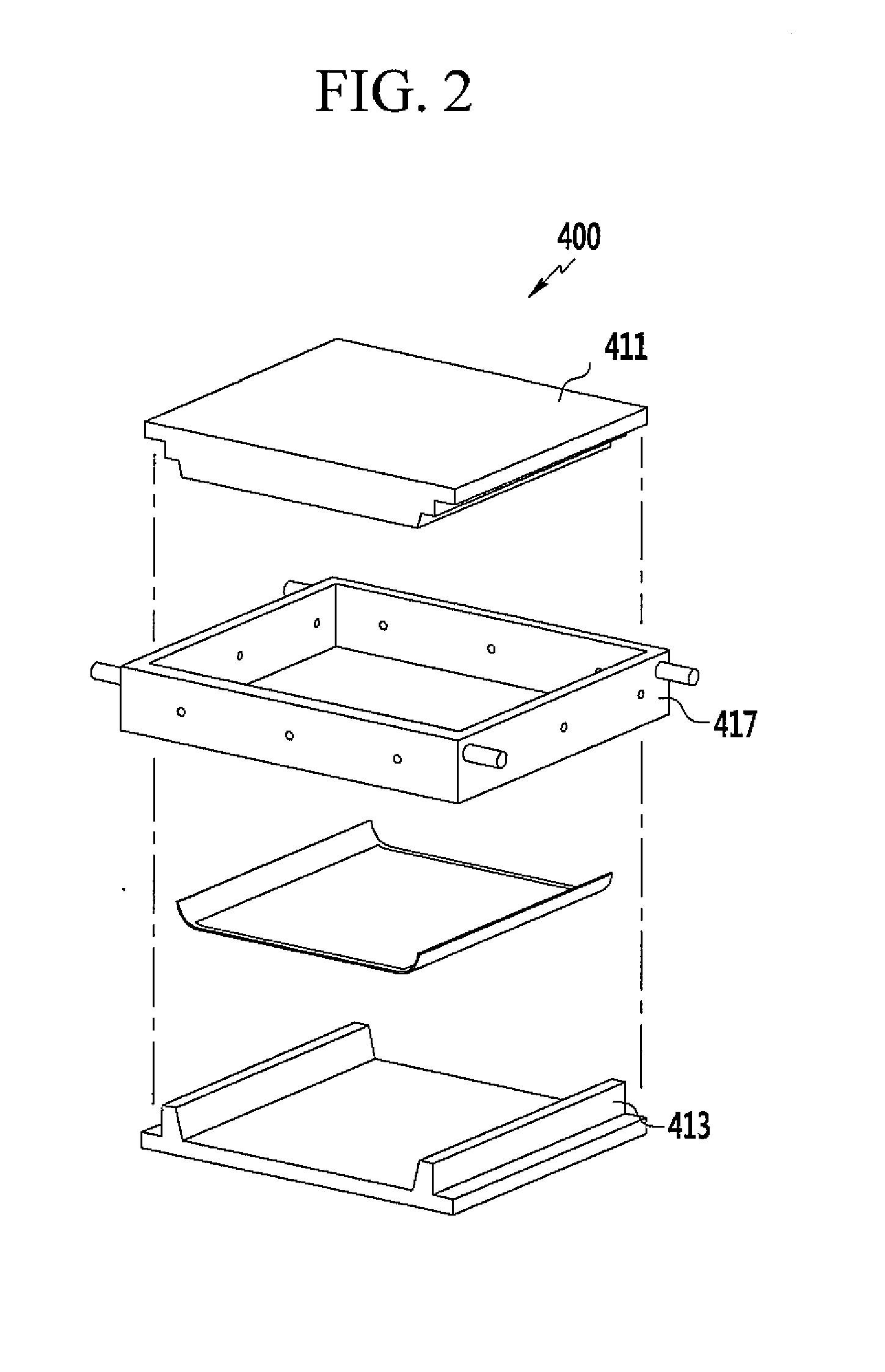

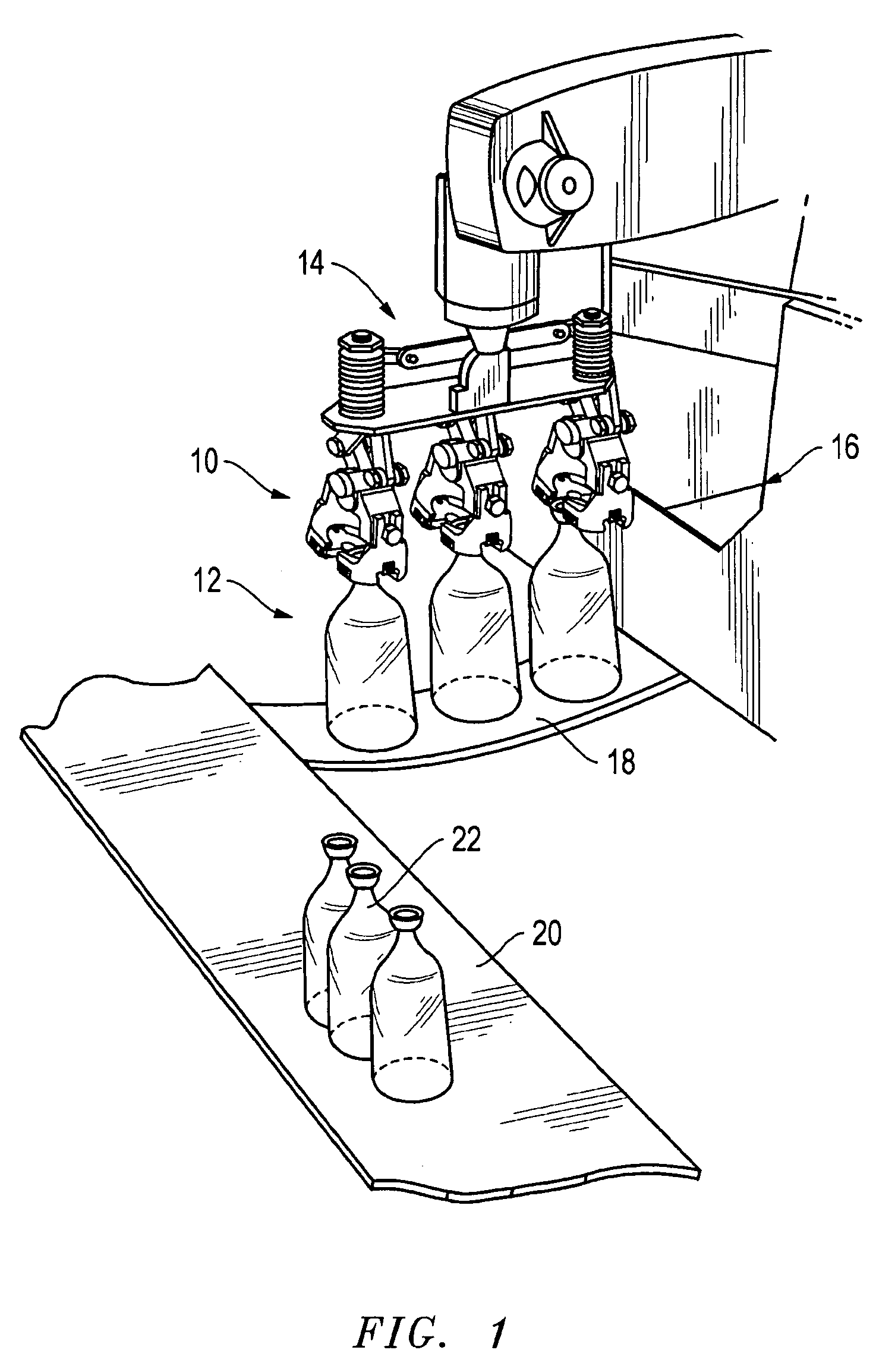

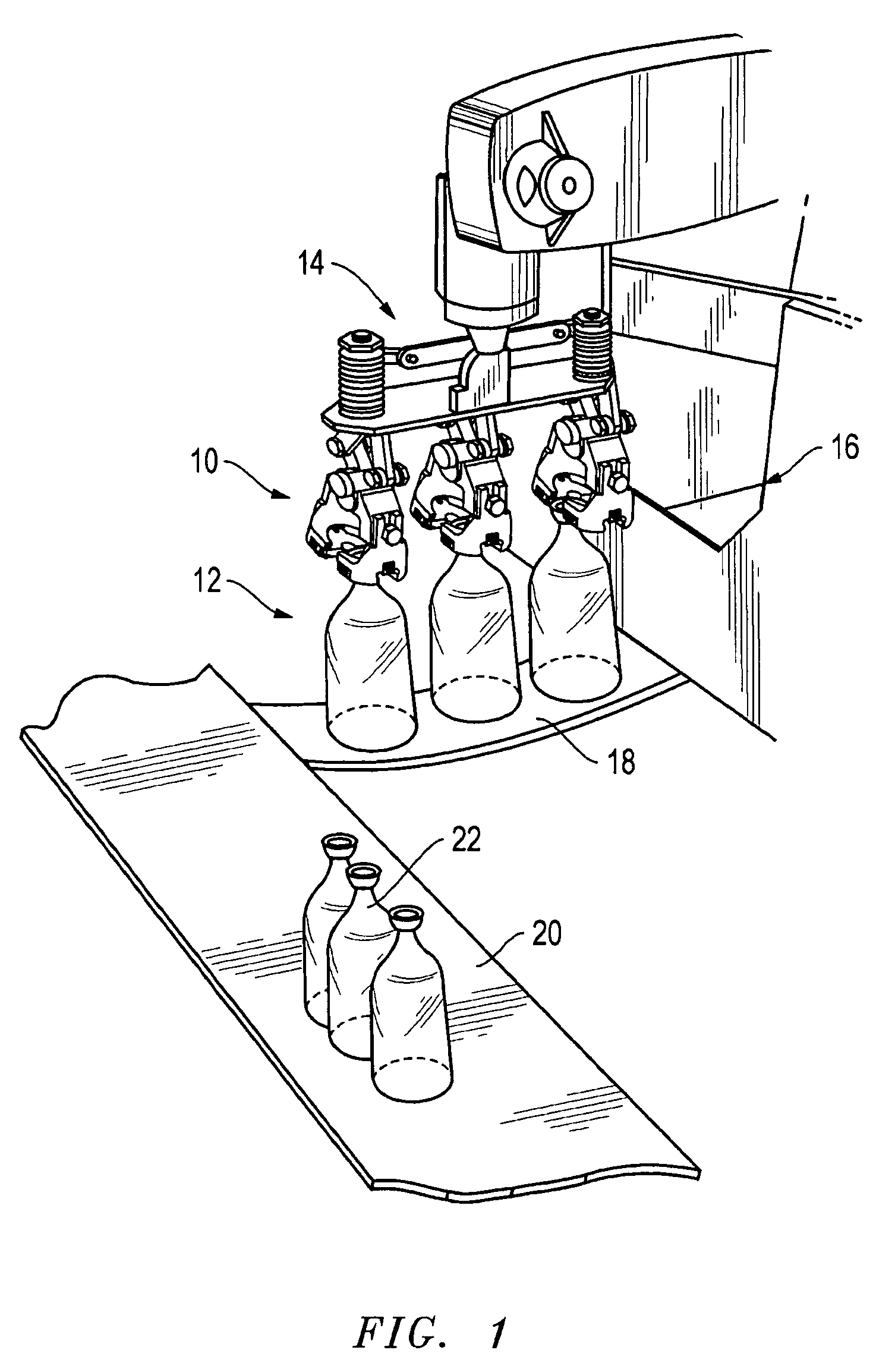

Apparatus and method for manufacturing 3D glass

InactiveUS20140373573A1Easy to manufactureShorten production timeGlass transportation apparatusGlass reforming apparatusMetallurgyShell molding

Owner:SAMSUNG DISPLAY CO LTD

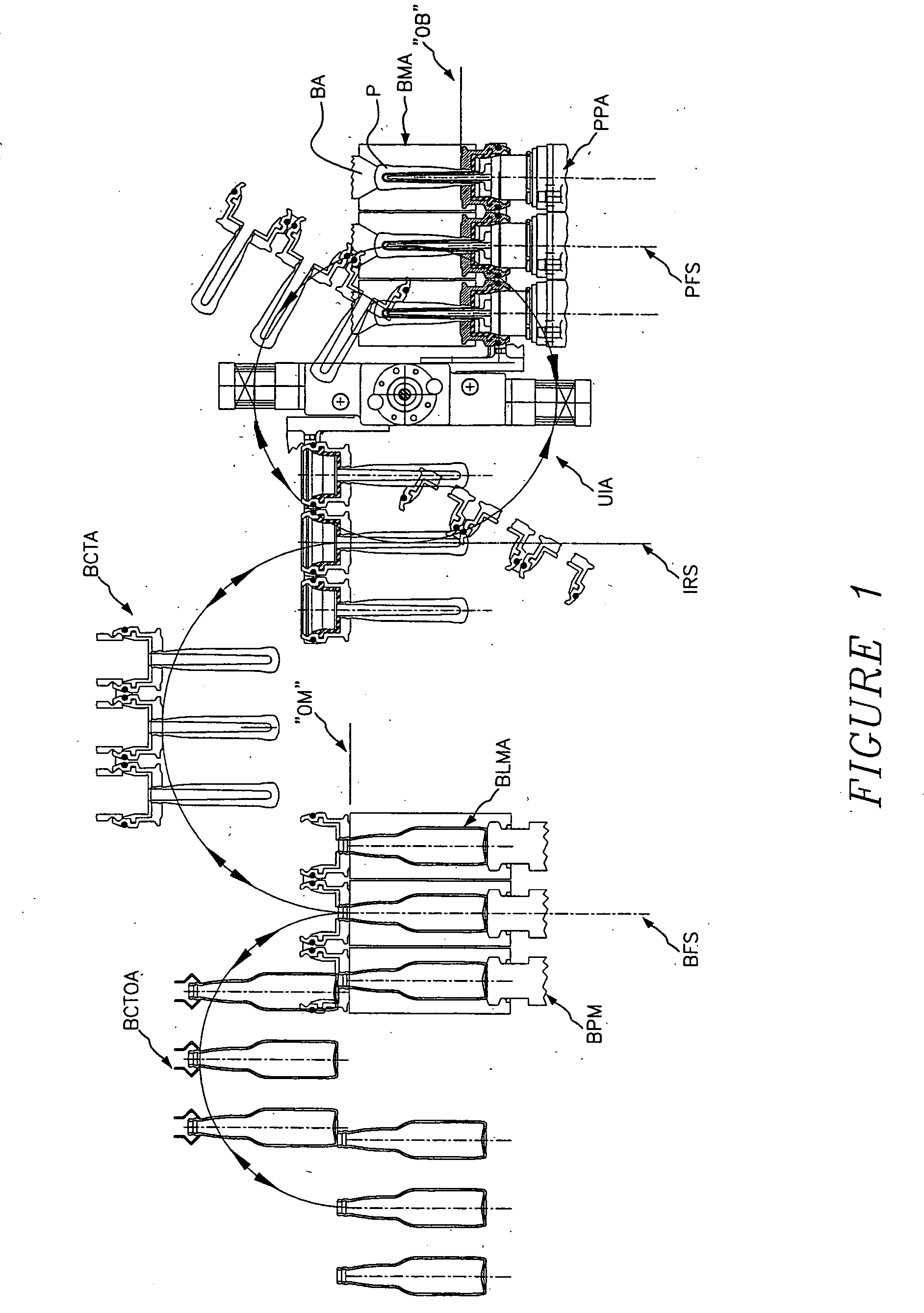

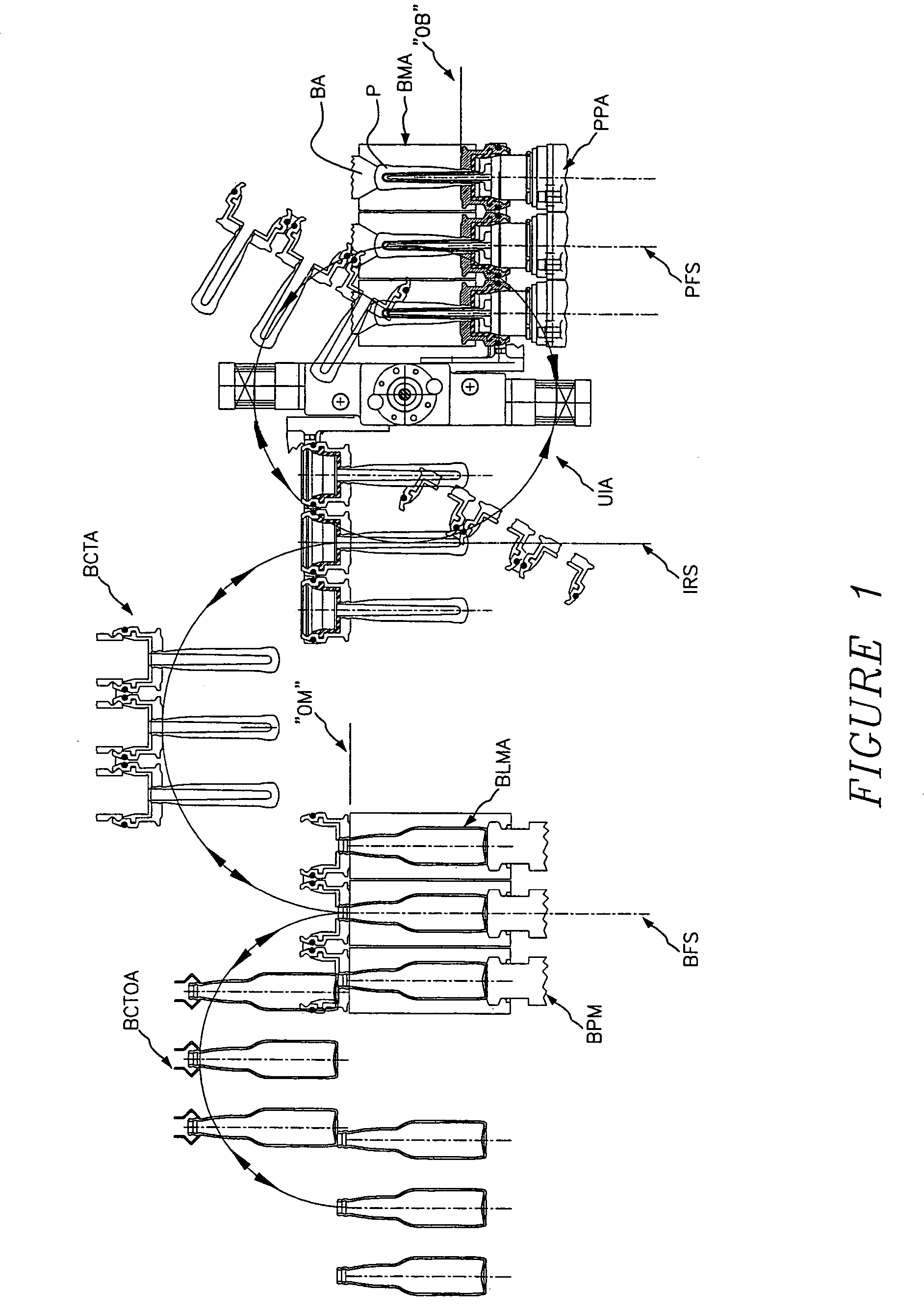

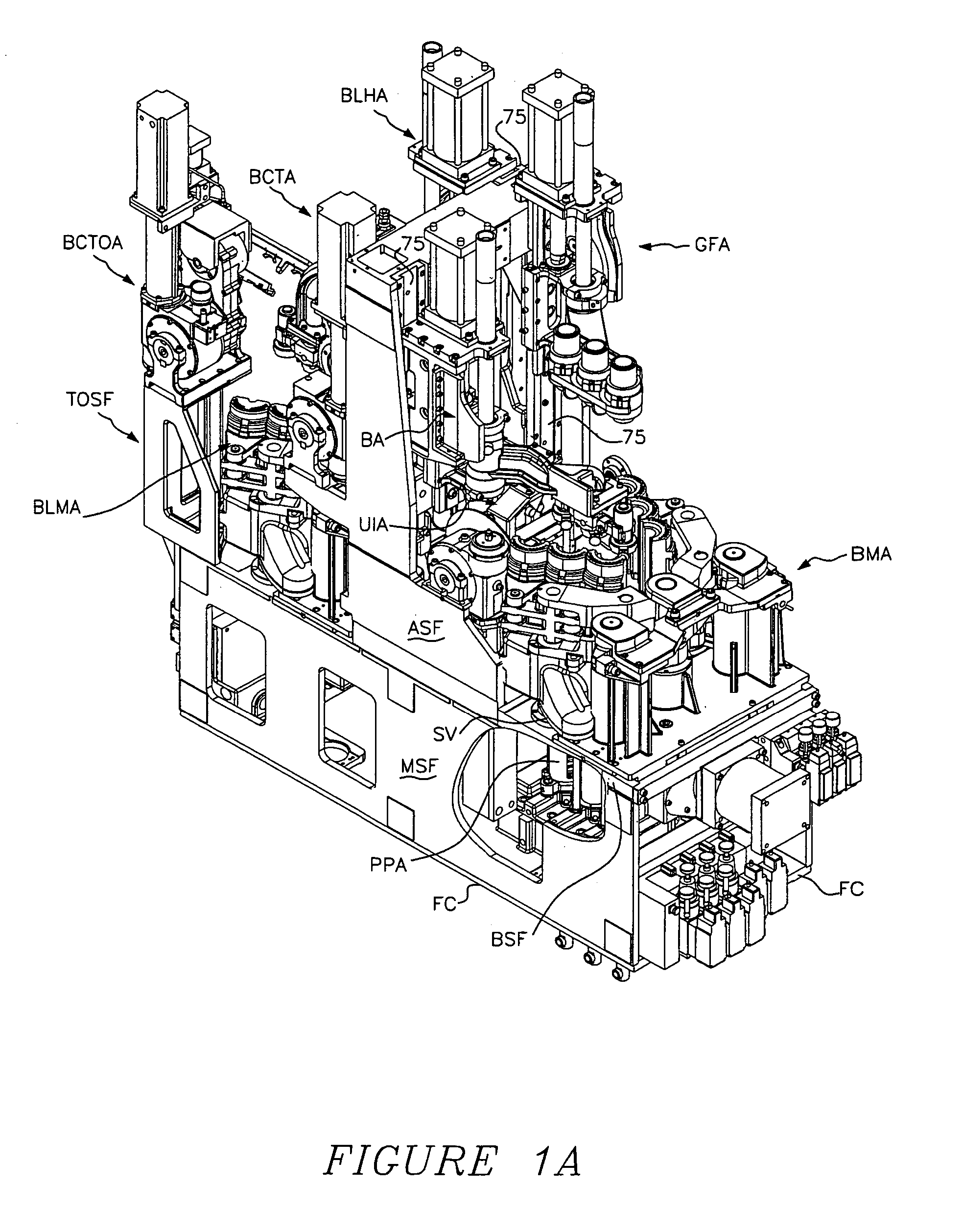

Method and a machine for the production of hollow glassware articles

InactiveUS20050235697A1Reduction in forming cycle time of machineQuality improvementGlass drawing apparatusGlass forming apparatusMolding machineGlass vessel

A method and a machine for the production of hollow glassware articles, by the blow-and-blow, press-and-blow, press-and-blow paste mold and direct-press processes in a glassware forming machine including single or multiple machine sections each having single or multiple-cavity, comprising: forming a parison in an inverted orientation, into a blank mold and a first transferable and open-able neck ring mold held by an inverting apparatus having a first and a second diametrically opposed arms, each arm holding a transferable and open-able neck ring mold; inverting the parison held by the first transferable and open-able neck ring mold, by rotating the first arm 180° to an upright orientation at an intermediate station, while the second arm with a second transferable and open-able neck ring mold is simultaneously placed at the parison forming station; transferring the first transferable and open-able neck ring mold holding the parison in an upright orientation, from the intermediate station, to a blow mold station, by a transference apparatus; releasing the first parison into a blow mold, and turning back the first transferable and open-able neck ring mold empty to the first arm of the inverting apparatus, at the intermediate station to be placed again at the parison forming station by rotating the first arm additional 180°, completing a 360° turn, while the second arm reaches to the intermediate station; blowing the parison into a blow mold to form a finished article; and transferring the finished article in an upright orientation, once the blow mold is opened, by a take out apparatus, to place it at a dead plate or at a carrying conveyor.

Owner:VITRO SAB DE CV

Three-dimensional printing on glass containers

This disclosure describes substrate(s) formed with a three-dimensional (3D) feature thereon, and method(s) of printing the same. One method includes identifying a plurality of locations on a substrate surface where the three-dimensional feature will be formed, determining a height value of the three-dimensional feature at each location, assigning a grayscale value to each location based on the height value, and applying ink to the substrate surface at each location according to the assigned grayscale value.

Owner:OWENS-BROCKWAY GLASS CONTAINER INC

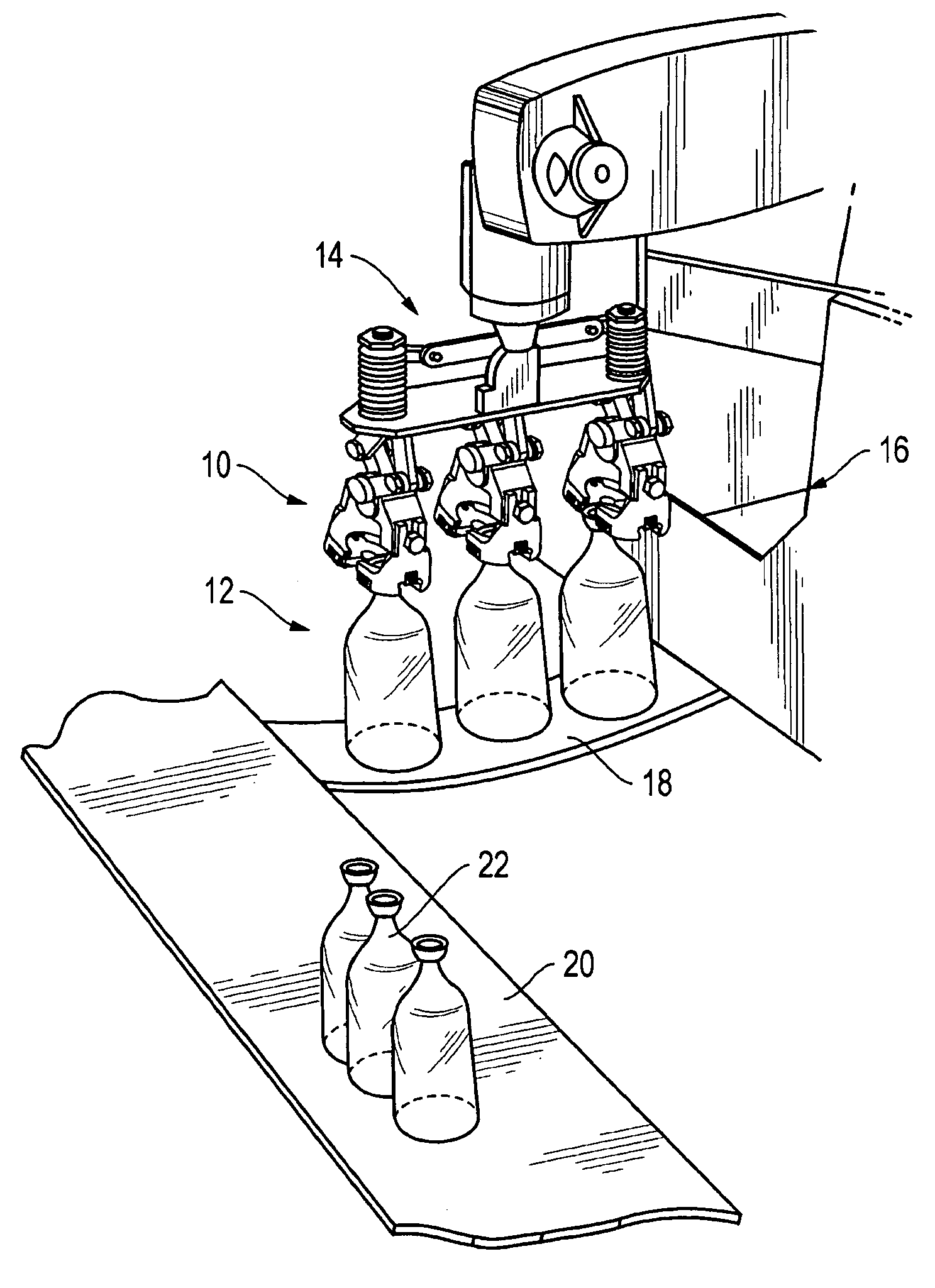

System, method, and apparatus for interchangeably accommodating both fixed and floating takeout inserts

InactiveUS20060230789A1Light weightMinimize damageLayered productsFilm/foil adhesivesEngineeringBottle

A takeout jaw for handling glass bottles includes a holder for both fixed and floating inserts. This design allows an insert to be in a fixed position when the insert is provided with a nominal thickness. When a floating insert of a lesser thickness is installed, the spring clip does not engage the floating insert, which allows the floating insert to move vertically or float. The takeout holder contains either type of insert within the pocket with retaining clips that engage chamfers formed on the inserts.

Owner:POCO GRAPHITE

Optical glass

The invention relates to optical glasses intended for the application fields of imaging, sensors, microscopy, medical technology, digital projection, photolithography, laser technology, wafer / chip technology, and for telecommunication, optical communication engineering and optics / lighting in the automotive sector, having a refractive index of 1.60≦nd≦1.80 and / or an Abbe number of 30≦νd≦40 with a pronounced short flint character, good chemical stability, excellent crystallization stability, good solarization stability and the following composition (in wt. % based on oxide):SiO219-45B2O3 3-7.5Nb2O525-31K2O2-8TiO20.1-2 ZrO2 6-10Ta2O50.5-8.

Owner:SCHOTT AG

Mold for press-molding glass elements

A mold for press-molding glass elements is disclosed, which comprises a substrate and a protective film; wherein the protective film, being arranged on the substrate, is made of molybdenum-ruthenium (Mo—Ru) alloy instead of those precious metal alloys such as platinum-iridium (Pt—Ir) alloy, iridium-rhenium (Ir—Re) alloy and iridium- ruthenium (Ir—Ru) alloy, etc., being used as the protective film of prior-art molds. According, the mold of the invention can be manufactured at a comparatively lower cost while is capable of being used for press-molding glass elements of high precision and high softening point.

Owner:ETHER PRECISION +2

Neck ring guide for glassware making machine

A neck ring guide for aligning neck ring sections in a glassware forming machine has a center body and a pair of spaced parallel runners coupled to the center body for receipt in guide slots in the neck ring sections. Keepers on the outboard sides of the runners retain the runners in the guide slots. Instead of keepers, the runners may be retained in the guide slots by roll pins on the neck ring sections engaged in retainer slots in the runners.

Owner:OWENS-BROCKWAY GLASS CONTAINER INC

Threadless Nut

A glassware forming machine baffle arm assembly that includes a quick-connect / disconnect arrangement mounting a baffle manifold on a baffle arm. The arrangement includes a baffle arm having an aperture, and a baffle manifold having a segment extending through said aperture and permitting rotation of said baffle manifold with respect to said baffle arm. The arrangement also includes a threadless nut, and a bayonet connection between said threadless nut and said baffle manifold segment.

Owner:OWENS-BROCKWAY GLASS CONTAINER INC

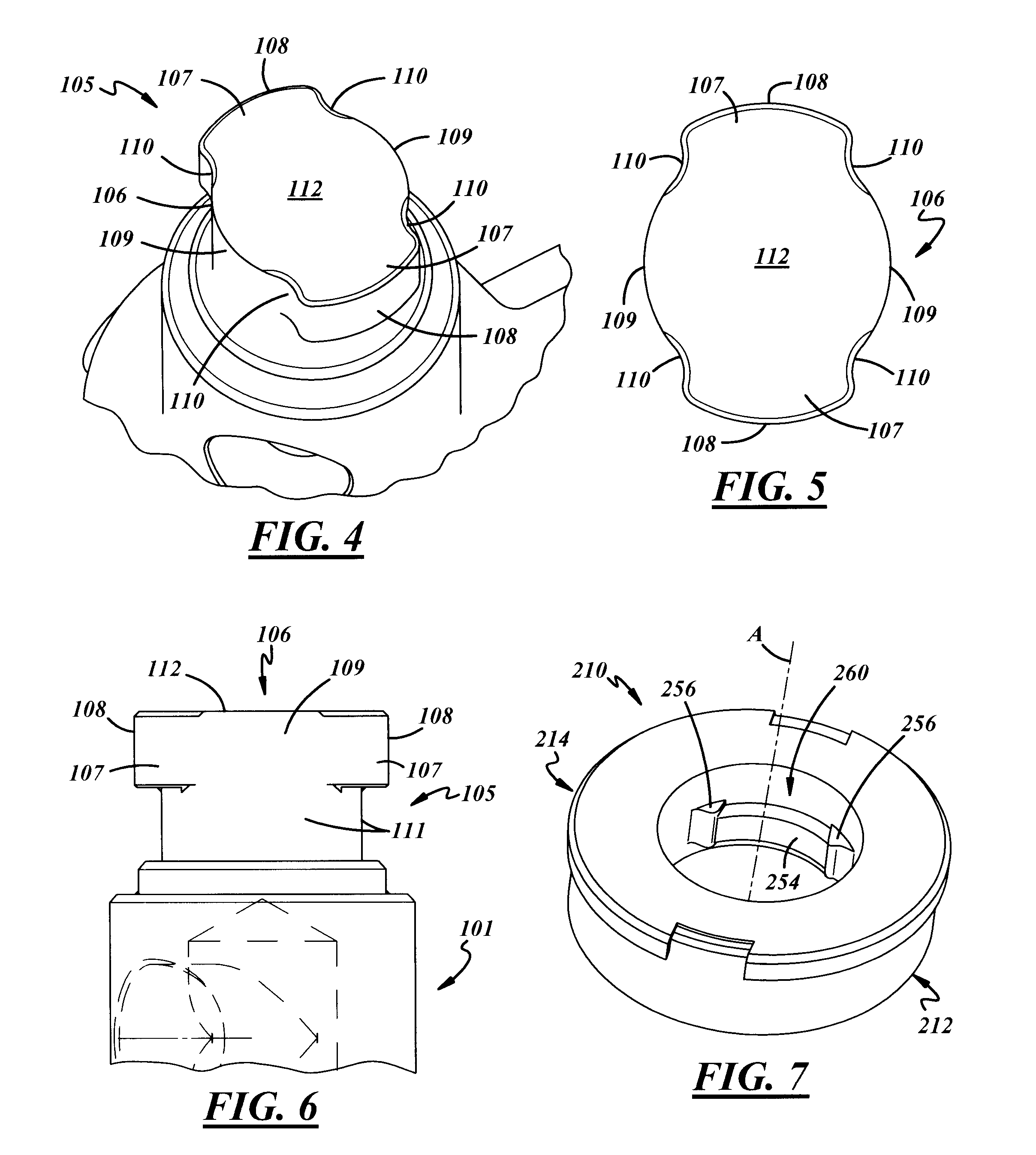

Process and device for manufacturing a hollow glass body

InactiveUS20150135773A1Not to damageBlowing machine gearingsGlass drawing apparatusGuide tubeHollow core

A process for manufacturing a hollow glass body by means of an individual section (IS) machine in a press and blow, narrow-neck press and blow, or blow and blow process, with a driving means that moves a plunger axially, to produce selected geometrical contours in a glass gob. The process steps include:aligning and attaching a positioning ring directly, or via intermediate elements, on the IS machine, on which positioning ring a positioning device is provided,aligning a guide tube, on an outer jacket surface on which a guide device is disposed and interacts with the positioning device of the positioning ring in the assembled condition,aligning a plunger with a non-rotationally symmetrical plunger head with a guide device disposed thereon , which interacts with a positioning device provided in the assembled condition on, or in, the inner jacket surface of the guide tube such that the non-rotationally symmetrical outer contour of the plunger head passes through an aperture tool allocated to the IS machine during the press or blow procedure, and the contours of the plunger head and of the aperture tool generate the profile of the inner, or outer, wall of the hollow glass body.

Owner:SAINT-GOBAIN OBERLAND

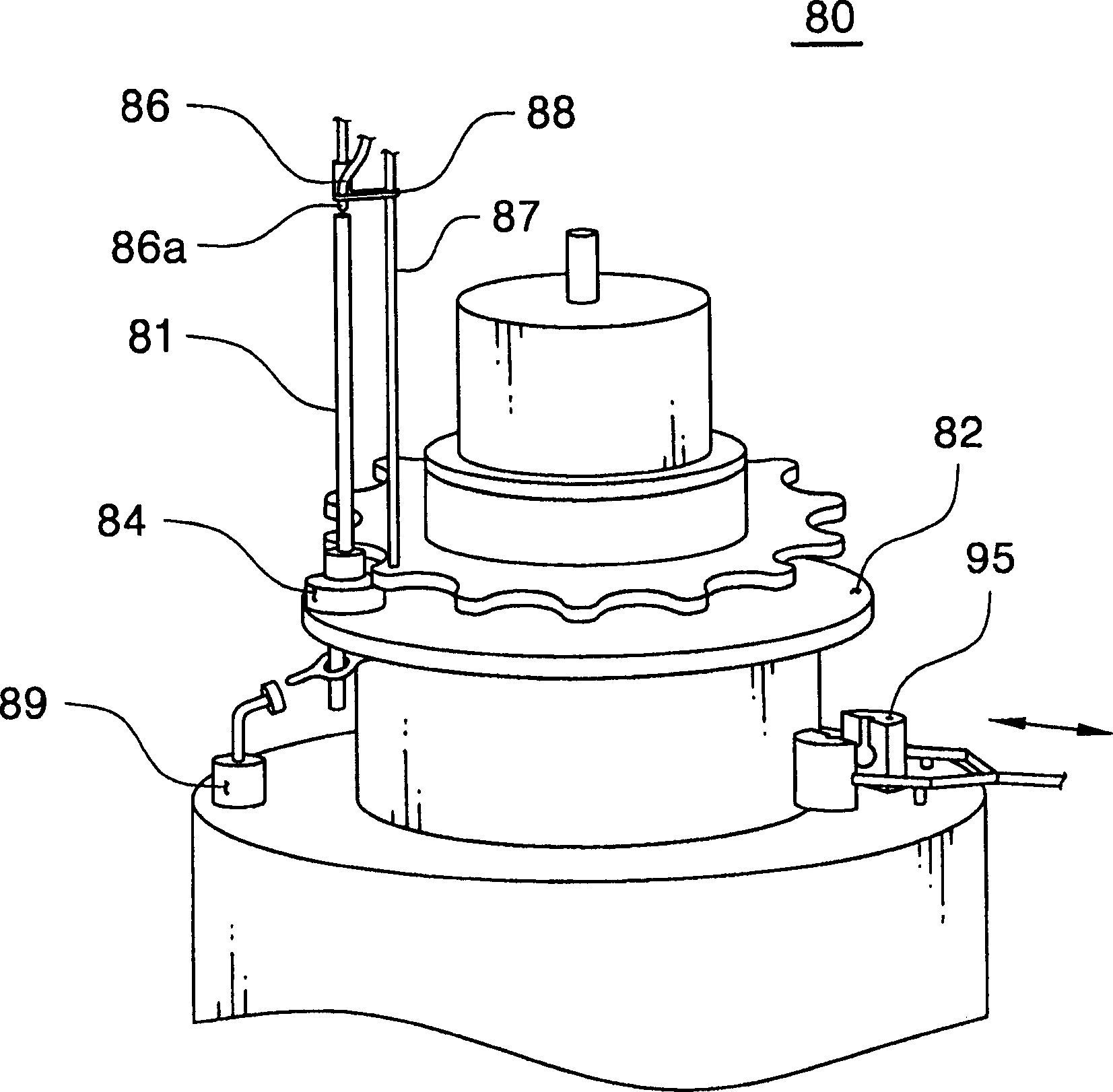

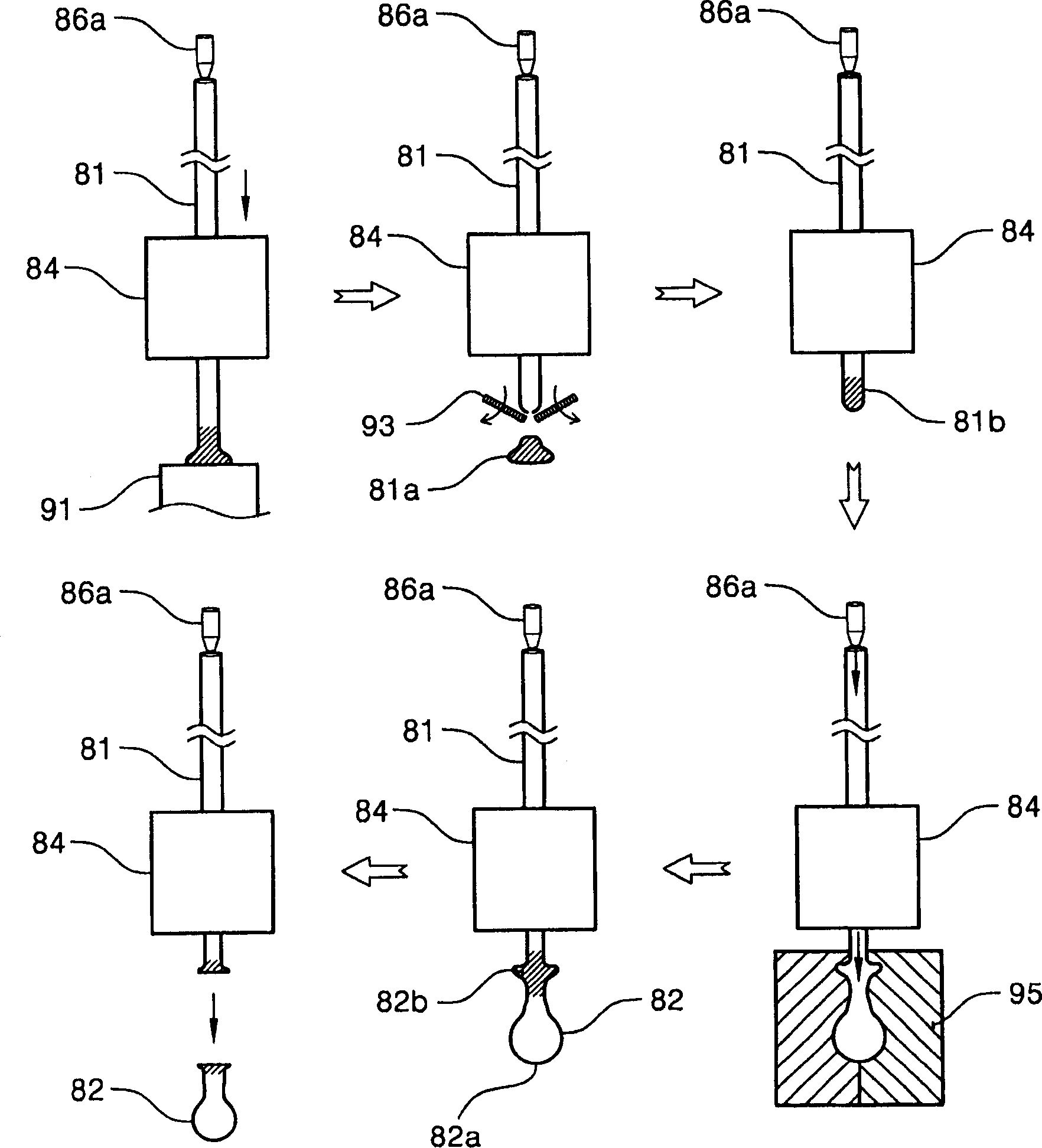

Method and system for manufacturing bulb

The present invention relates to a method and system for manufacturing a bulb. More particularly, the present invention relates to a method and system for manufacturing a bulb in which a flare and a dome are formed on both ends of a glass tube to thereby manufacture a bulb material tube, and a lower portion of the bulb material tube is heated and a blowing process is performed in a mold such that waste of the glass tube is prevented. A method for manufacturing a bulb, comprising: heating both ends of a glass tube of a predetermined length, then applying a pressure to both ends of the glass tube to form flares of an enlarged diameter on both ends; heating a center portion of the glass tube with flares formed at both end thereof while being rotated at a predetermined speed, and, at the same time, applying a force in the direction of both ends such that the separated center portion is closed off to form two closed off bulb material tubes; heating a lower portion of the bulb material tube while rotating the same; and performing blow forming by rotating the heated bulb material tube in a state where its lower portion is positioned in a mold, and injecting a gas in the bulb material tube through its flare to thereby form a bulb. The system for manufacturing a bulb includes a flare forming device, a bulb material tube separating device, and a blow forming device.

Owner:崔益秀

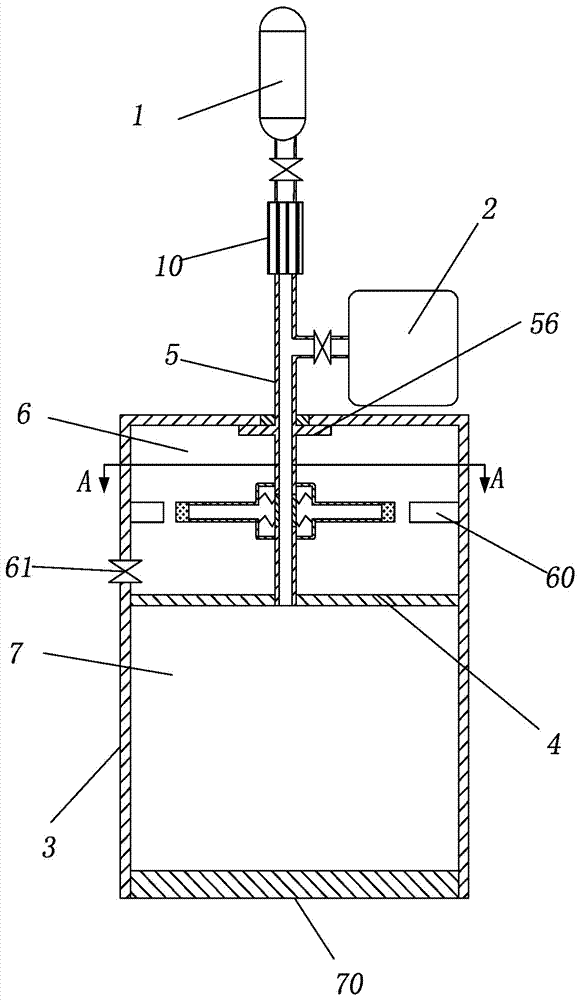

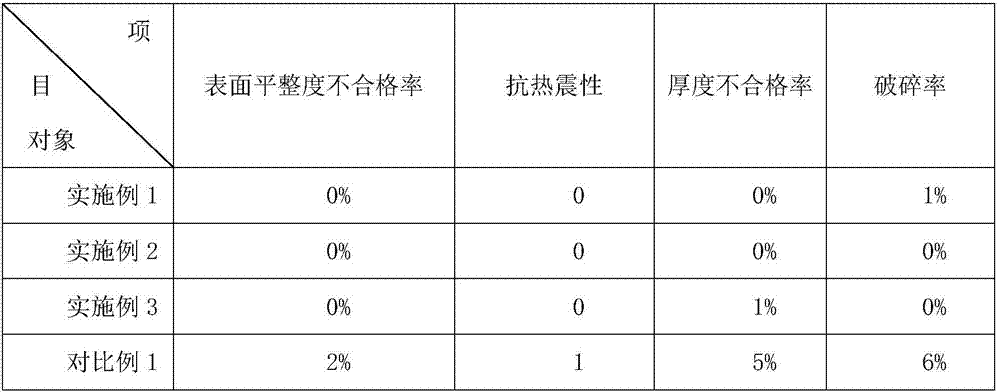

Preparation method of high-performance glass bottle

PendingCN110316964AGood chemical stabilityHigh strengthPress and blow machinesBlow machinesHeating timeDrying time

The invention relates to the technical field of glass bottles, in particular to a preparation method of a high-performance glass bottle. The method can effectively remove internal stress of the glassbottle, so that the glass bottle has good strength and impact resistance and is not easy to break. The method includes the steps of S1, raw material preparation; S2, raw material crushing; S3, drying,wherein crushed raw materials are dried, the moisture content is reduced, the drying temperature is 100-120 DEG C, the drying time is 2-3 hours, and the raw materials need to be continuously stirredin the drying process; S4, raw material mixing and stirring, wherein all the raw materials are added into a mixing device for stirring and mixing, so that the raw materials are uniformly mixed and stirred, the stirring rotation speed is 250-260 r / min; S5, melting, wherein the mixed raw materials are conveyed into a smelting furnace for heating, the heating temperature is 1550-1600 DEG C, and heating time is 9-11 hours; S6, molding of the glass bottle; S7, cooling; S8, annealing, wherein the annealing temperature is 380-600 DEG C, and the annealing time is 180-220 minutes; S9, cooling; S10, inspecting and packaging.

Owner:CANGZHOU XINGCHEN GLASS PROD

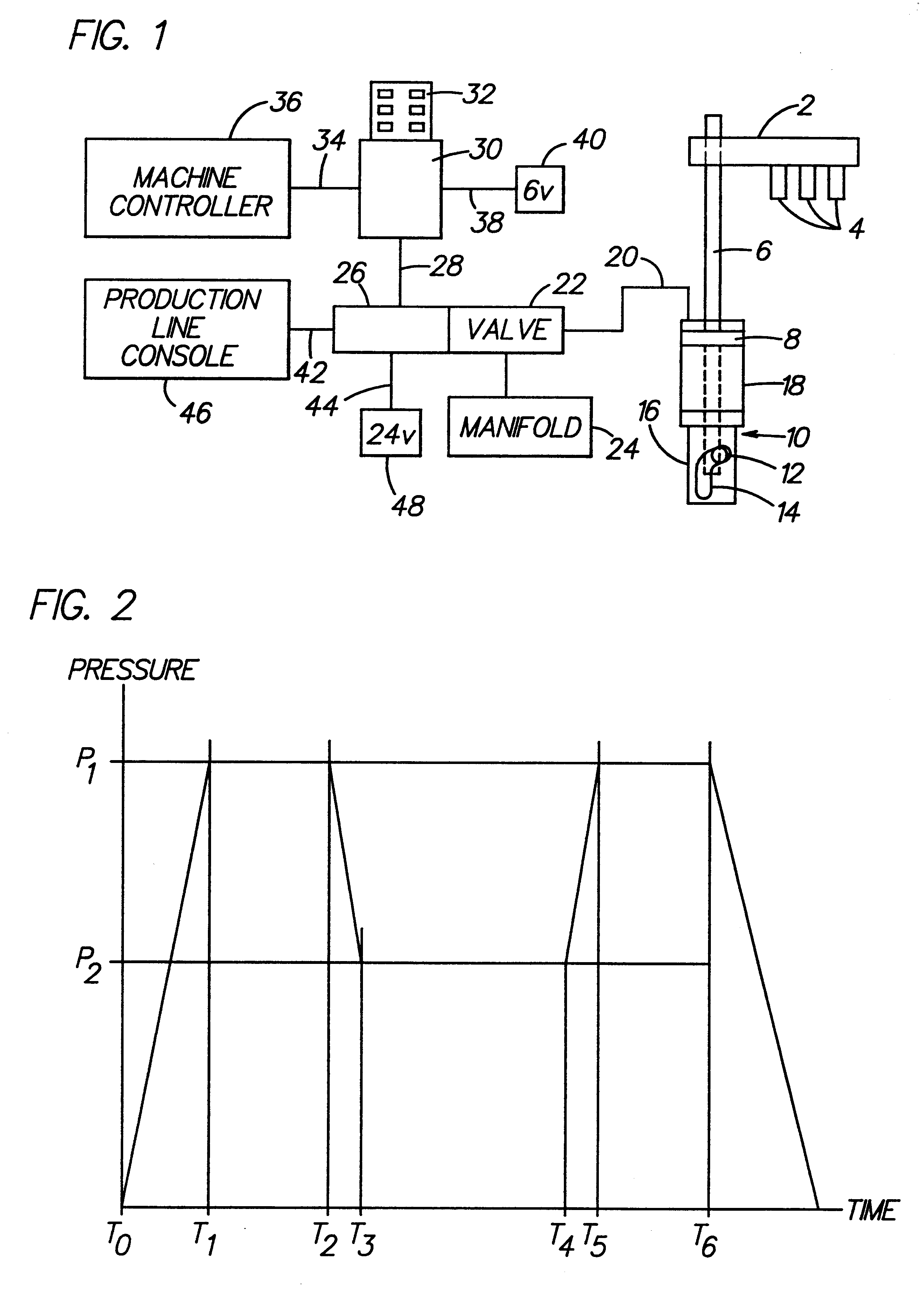

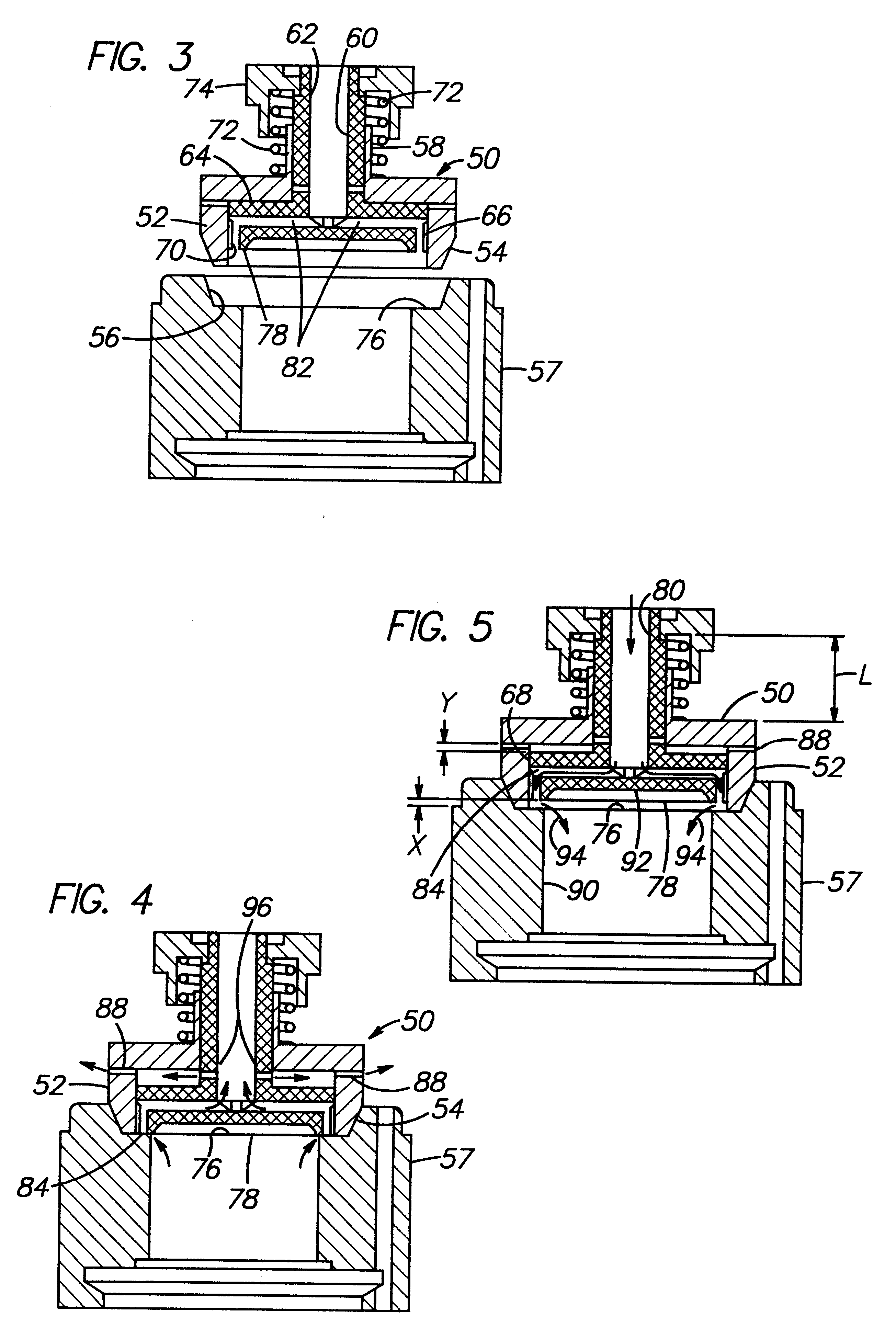

Baffle mechanism for I.S. machine

An I.S. machine has a blankmold which is open at the top and includes inner and outer annular top sealing surfaces. Associated with the blankmold is a baffle including a body having a cup shaped portion closed with a vertical cylindrical bore open at the bottom, an annular bottom sealing surface for sealingly engaging the blankmold outer annular top sealing surface, and a top having a hole. A tubular sleeve communicates with the hole and extends vertically upwardly from the top of the body. A piston has a cylindrical head including a top surface, a cylindrical sealing surface and an annular bottom sealing surface having a plurality of radial notch means across the bottom thereof. A tubular rod extends vertically upwardly from the top surface for slidable displacement in the tubular sleeve, and a collar is secured to the top of the rod. A spring located between the collar and the cup shaped portion urges the cylindrical head vertically upwardly to a position whereat the cylindrical head top surface engages the top of the cup shaped portion. The collar is pneumatically displaced vertically downwardly at a high pressure to bring the cup shaped portion annular surface into sealing engagement with the blankmold outer annular sealing surface. The pressure is then reduced so that a predetermined distance separates the cylindrical head annular bottom sealing surface and the blankmold inner annular sealing surface so that settle air can be introduced into the mold, and then the pressure is again raised to the high pressure for parison formation.

Owner:EMHART GLASS SA

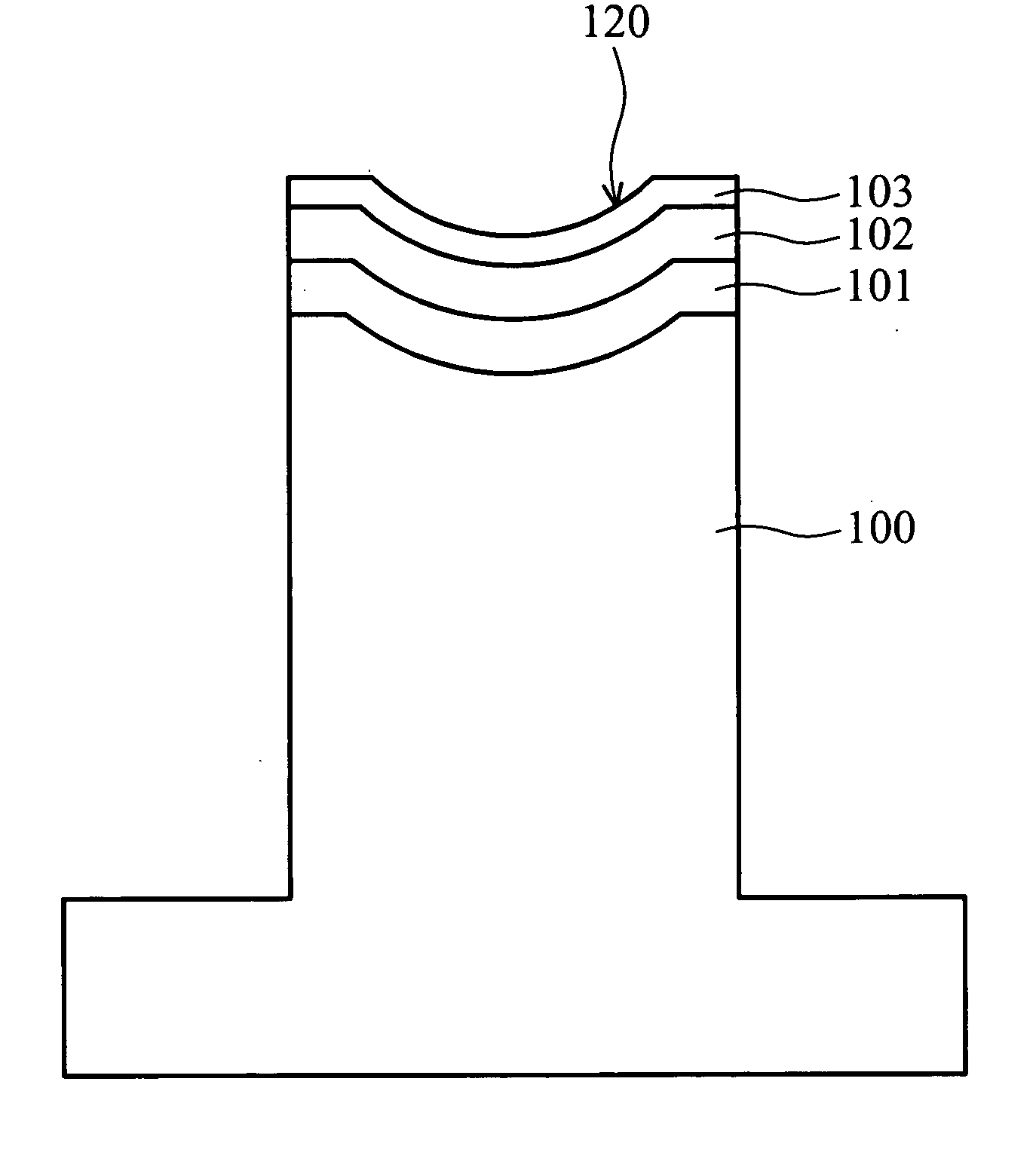

Glass molding die, renewal method thereof, and glass fabricated by the molding die

InactiveUS20050223742A1Good renewabilityShorten update timeCharging furnaceGlass transportation apparatusAlloyMetallic Nickel

A molding die for molding glass and renewal method thereof. The molding die includes a substrate, a nickel-phosphorous alloy layer, with phosphorous content 30 wt % or less, overlying the substrate, an intermediate layer overlying the nickel-phosphorous alloy layer, and a passivation film overlying the intermediate layer.

Owner:ASIA OPTICAL INT LTD

Method and apparatus for frit sealing with a variable laser beam

InactiveUS8247730B2Increase speedImprove sealingDiffusing elementsElectroluminescent light sourcesFritLight beam

Owner:CORNING INC

System, method, and apparatus for interchangeably accommodating both fixed and floating takeout inserts

InactiveUS7418834B2Light weightMinimize damageGlass furnace apparatusFilm/foil adhesivesEngineeringBottle

A takeout jaw for handling glass bottles includes a holder for both fixed and floating inserts. This design allows an insert to be in a fixed position when the insert is provided with a nominal thickness. When a floating insert of a lesser thickness is installed, the spring clip does not engage the floating insert, which allows the floating insert to move vertically or float. The takeout holder contains either type of insert within the pocket with retaining clips that engage chamfers formed on the inserts.

Owner:POCO GRAPHITE

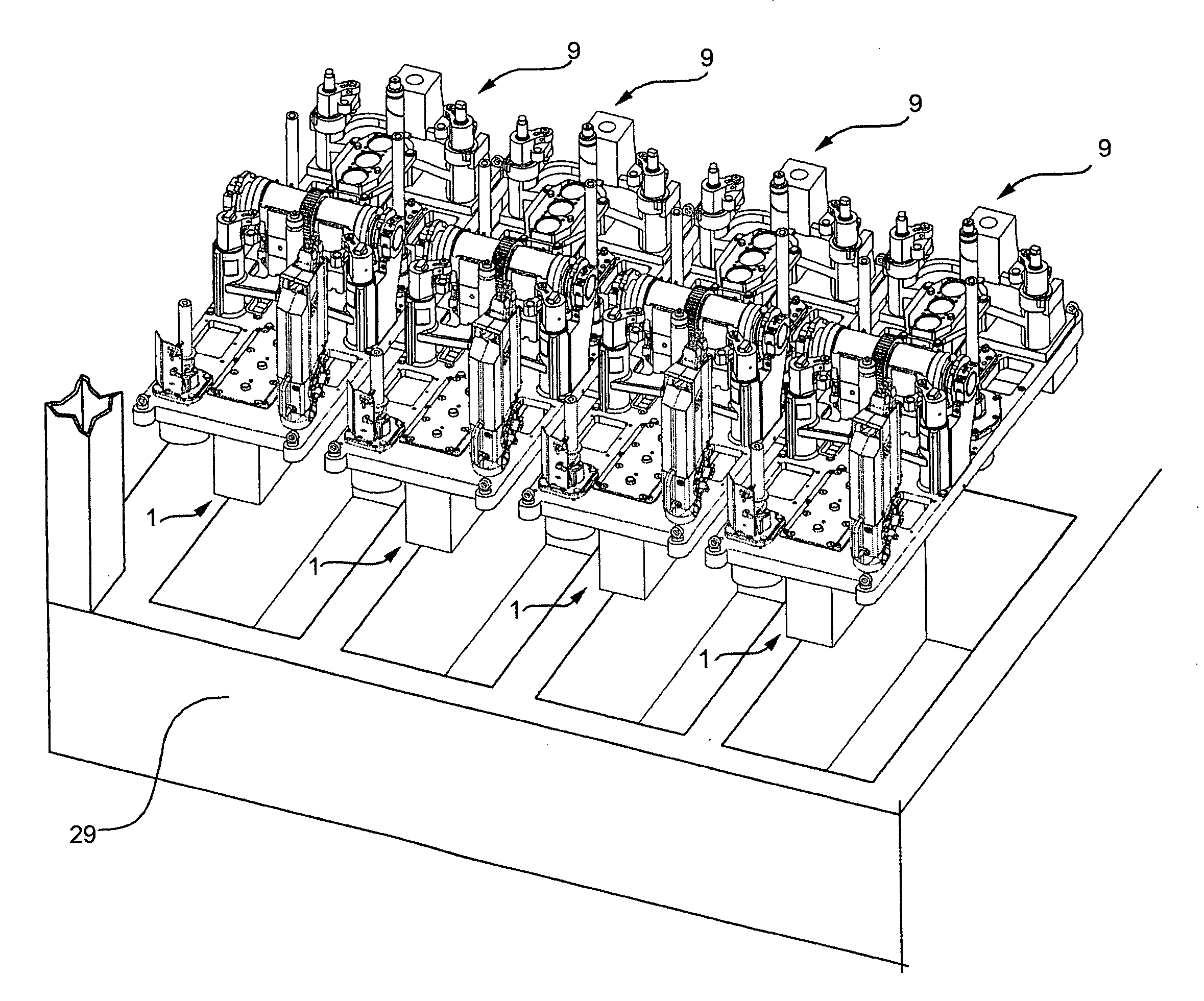

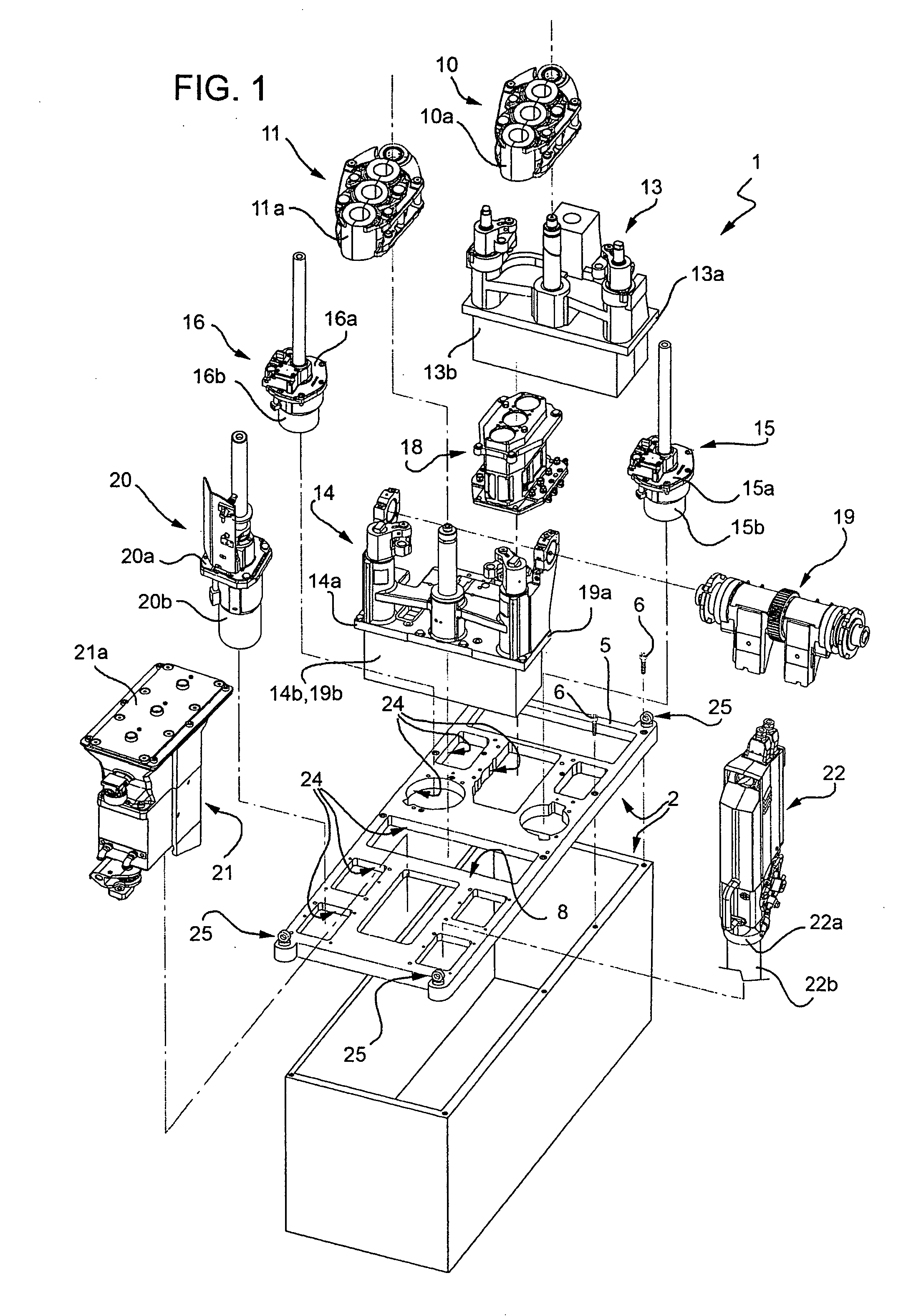

Forming section of a hollow glass items production machine and relevant support structure

InactiveUS20100018255A1Straightforward and low-costGlass pressing apparatusPress and blow machinesPunchingEngineering

In a machine for forming glass items, a forming section has a forming assembly, and a bottom support structure for supporting the forming assembly. The forming section has a rough mold; a finish mold; a transfer assembly for transferring at least one glass mass being formed from the rough mold to the finish mold; an extractor for extracting at least one glass item from the finish mold; a glass mass guide device, a mold closing device, and a punching device associated with the rough mold. The forming section also has and a pneumatic blower device and a cooling device associated with at least the finish mold The bottom support structure has a bottom hollow frame, and at least one top plate separate from the bottom frame and on which the whole forming assembly rests and is connected.

Owner:BOTTERO SPA

Manufacturing method for bottle

The invention relates to the technical field of glass processing and particularly relates to a manufacturing method for a bottle. The method comprises the following steps: (1) preparing materials; (2) melting; (3) forming, namely heating the compressed air and then introducing into an initial forming mold, introducing the molten glass into the initial forming mold, blowing the heated compressed air into the initial forming mold, thereby acquiring an initially formed bottle, and then transferring the initially formed bottle into a forming mold and blowing into the compressed air, thereby acquiring a formed bottle; (4) post-processing, namely annealing, spraying and packaging, thereby acquiring an end product of a glass bottle. According to the technical scheme, the waist breaking can be effectively prevented and the production quality of the glass bottle can be improved.

Owner:CHONGQING HAOSHENG GLASS

Method and a machine for the production of hollow glassware articles

InactiveUS7024887B2Reduction in forming cycle time of machineQuality improvementGlass drawing apparatusGlass forming apparatusEngineeringNeck rings

A method and a machine for the production of hollow glassware articles, by the blow-and-blow, press-and-blow, press-and-blow paste mold and direct-press processes in a glassware forming machine including single or multiple machine sections each having single or multiple-cavity, comprising: forming a parison in an inverted orientation, into a blank mold and a first transferable and open-able neck ring mold held by an inverting apparatus having a first and a second diametrically opposed arms, each arm holding a transferable and open-able neck ring mold; inverting the parison held by the first transferable and open-able neck ring mold, by rotating the first arm 180° to an upright orientation at an intermediate station, while the second arm with a second transferable and open-able neck ring mold is simultaneously placed at the parison forming station; transferring the first transferable and open-able neck ring mold holding the parison in an upright orientation, from the intermediate station, to a blow mold station, by a transference apparatus; releasing the first parison into a blow mold, and turning back the first transferable and open-able neck ring mold empty to the first arm of the inverting apparatus, at the intermediate station to be placed again at the parison forming station by rotating the first arm additional 180°, completing a 360° turn, while the second arm reaches to the intermediate station; blowing the parison into a blow mold to form a finished article; and transferring the finished article in an upright orientation, once the blow mold is opened, by a take out apparatus, to place it at a dead plate or at a carrying conveyor.

Owner:VITRO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com