Method and system for manufacturing bulb

A technology of light bulbs and glass tubes, applied in manufacturing tools, glass manufacturing equipment, glass molding, etc., can solve problems such as complex structures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

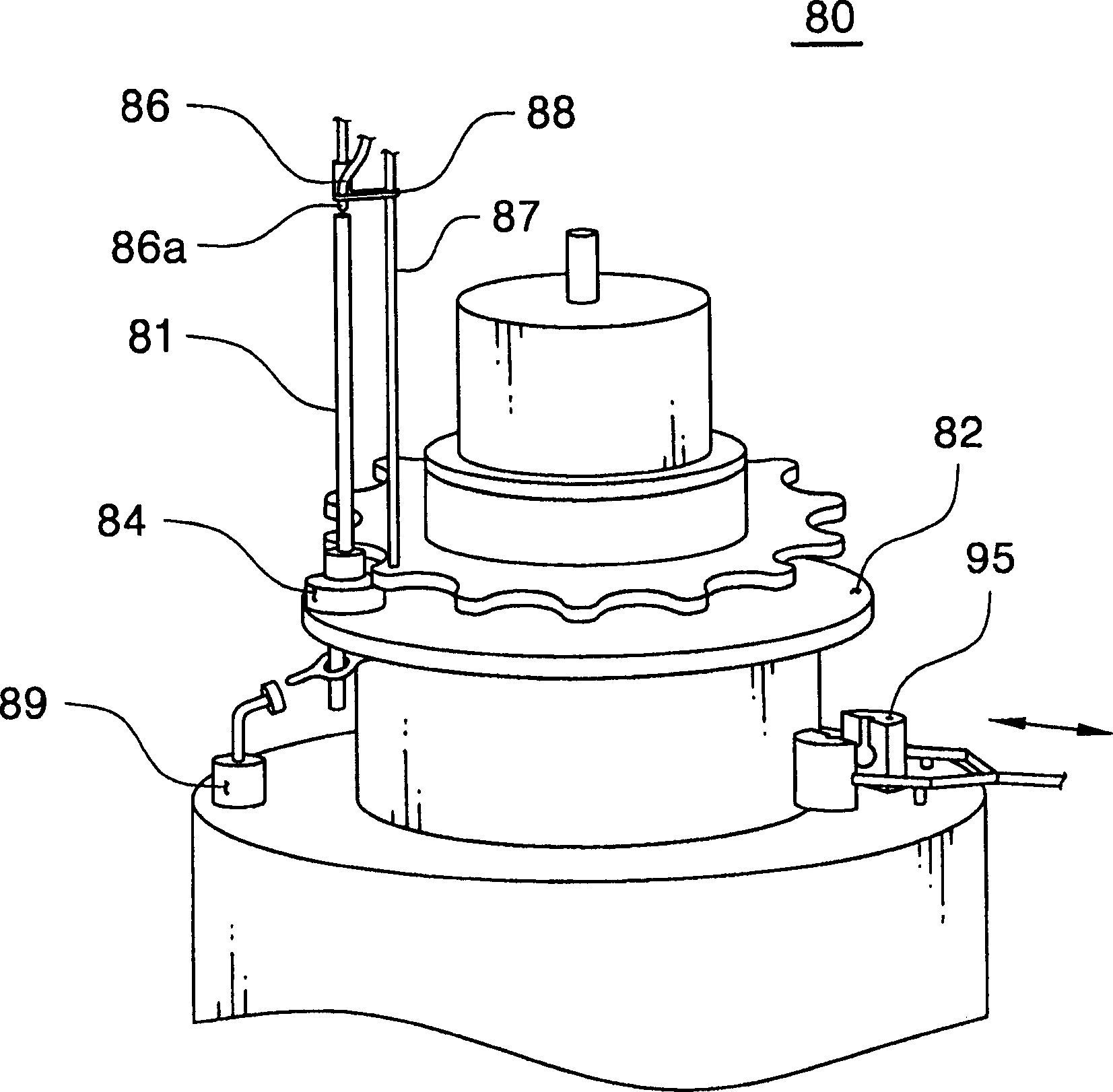

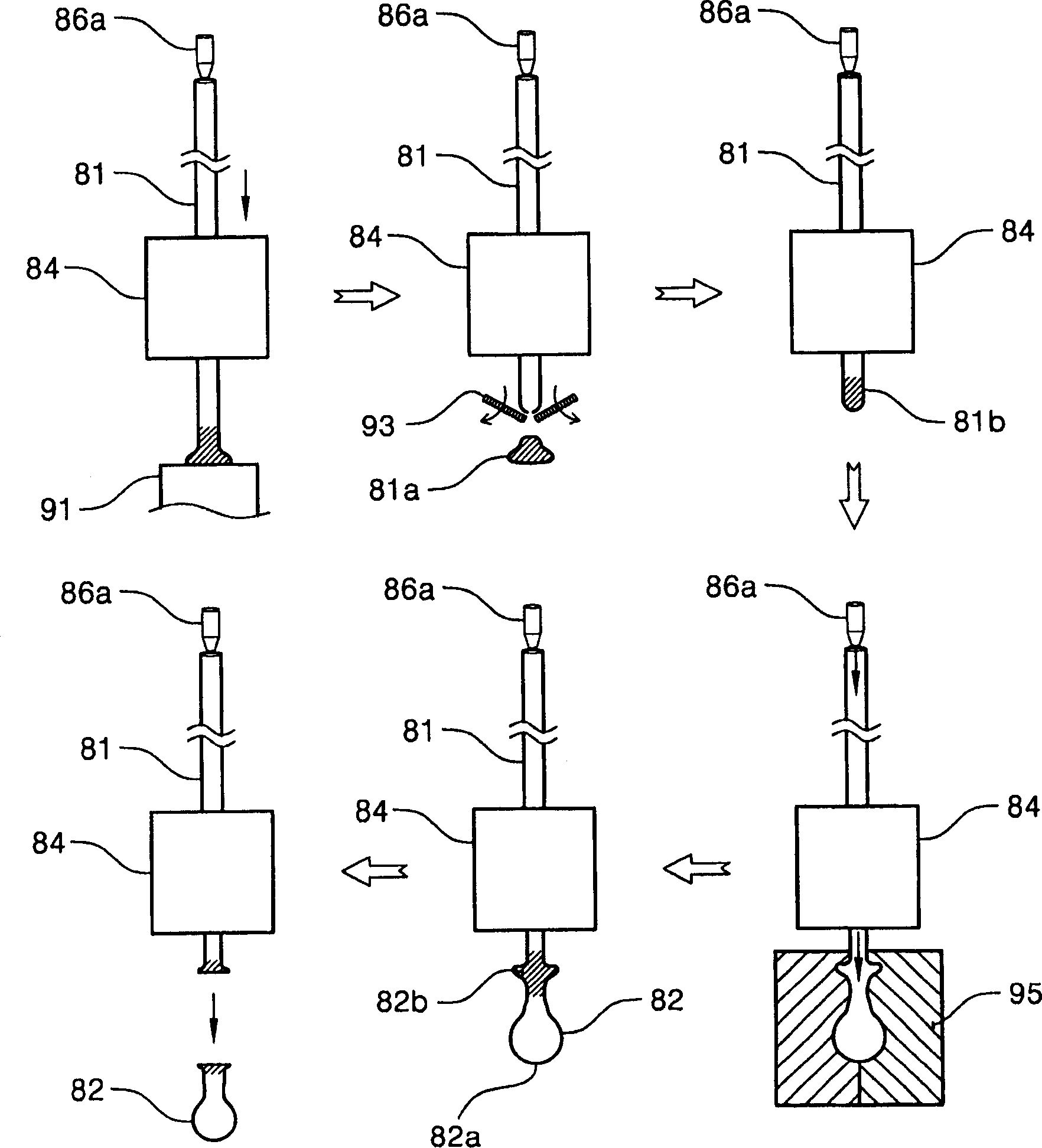

[0051] A system and method for manufacturing a light bulb according to one embodiment of the present invention will now be described with reference to the accompanying drawings.

[0052] image 3 is a flowchart of a method of manufacturing a light bulb according to one embodiment of the present invention.

[0053] A method of manufacturing a light bulb according to an embodiment of the present invention includes forming a flare in step S10, performing separation of the bulb material tube in step S20, forming a dome in step S30, supplying the bulb material tube in step S40, and Lower heating is performed in step S50, and blow molding is performed in step S60.

[0054] In the flare forming step S10, both ends of the glass tube 21 having a predetermined length are heated and then pressure is applied to both ends of the glass tube 21 to form flares with enlarged diameters on both ends. In other words, in the flaring step S10, both ends of the glass tube 21 having a predetermined...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com