Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

104results about "Blow heads" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

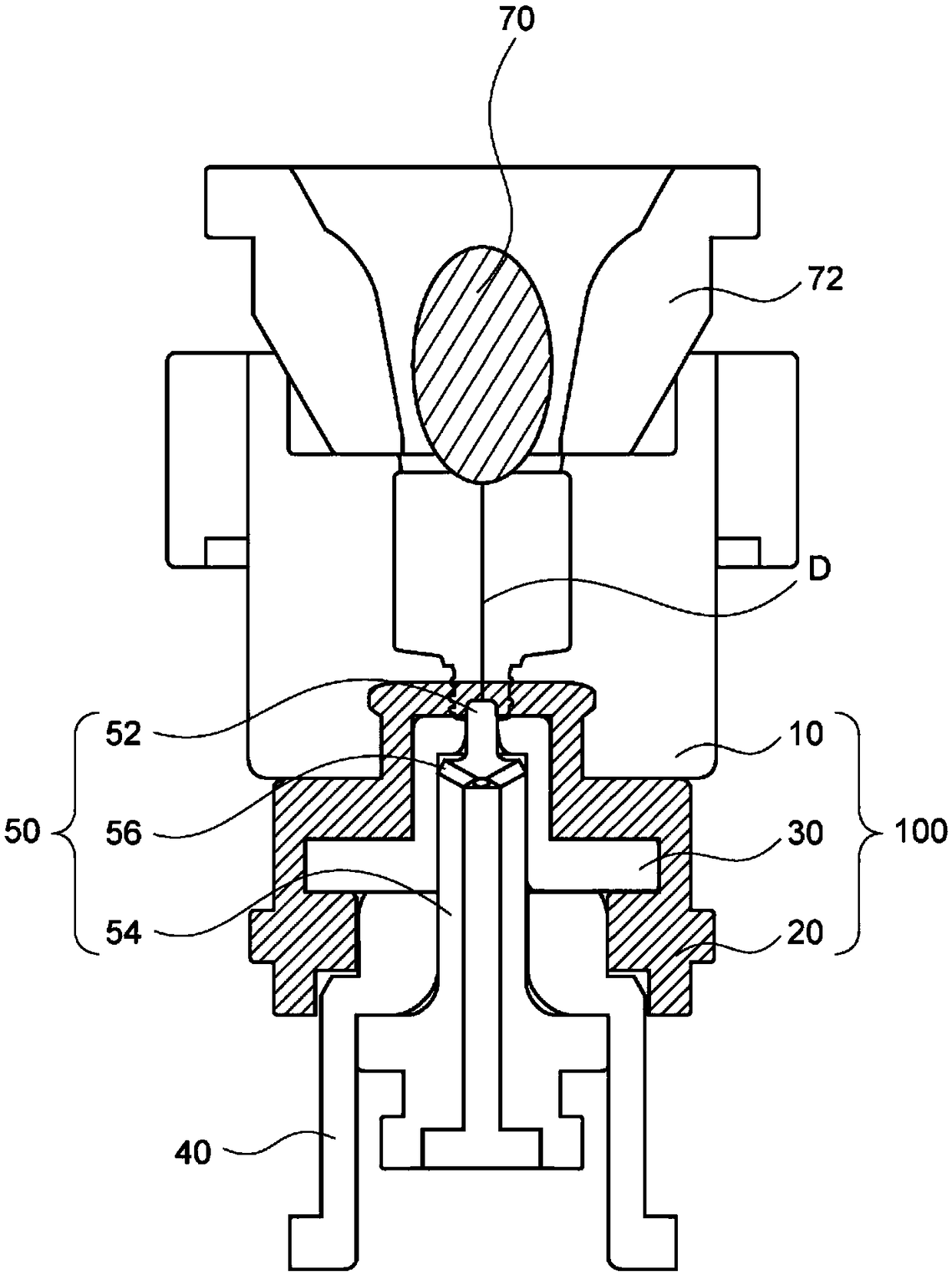

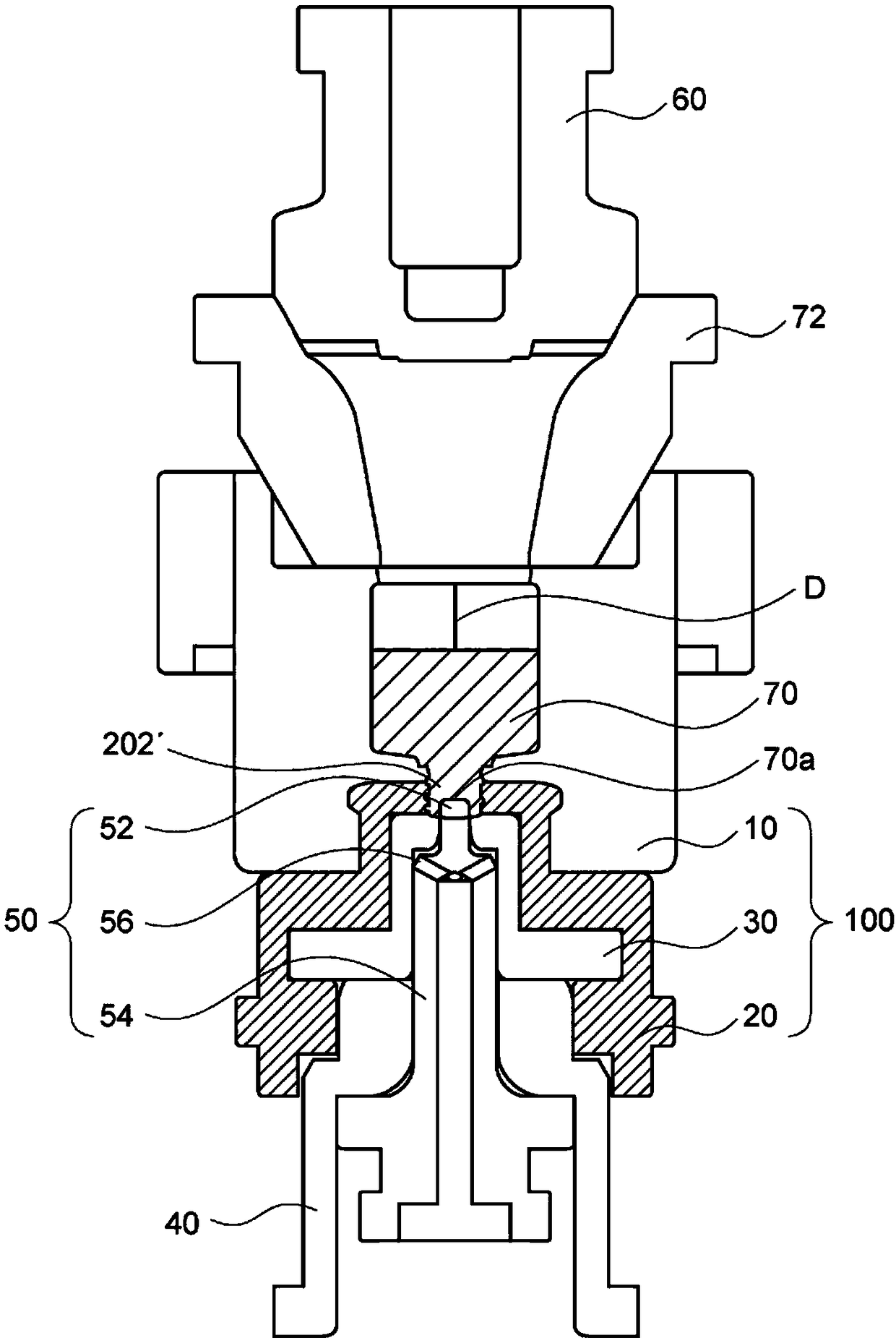

Apparatus for blowing and removing glass containers

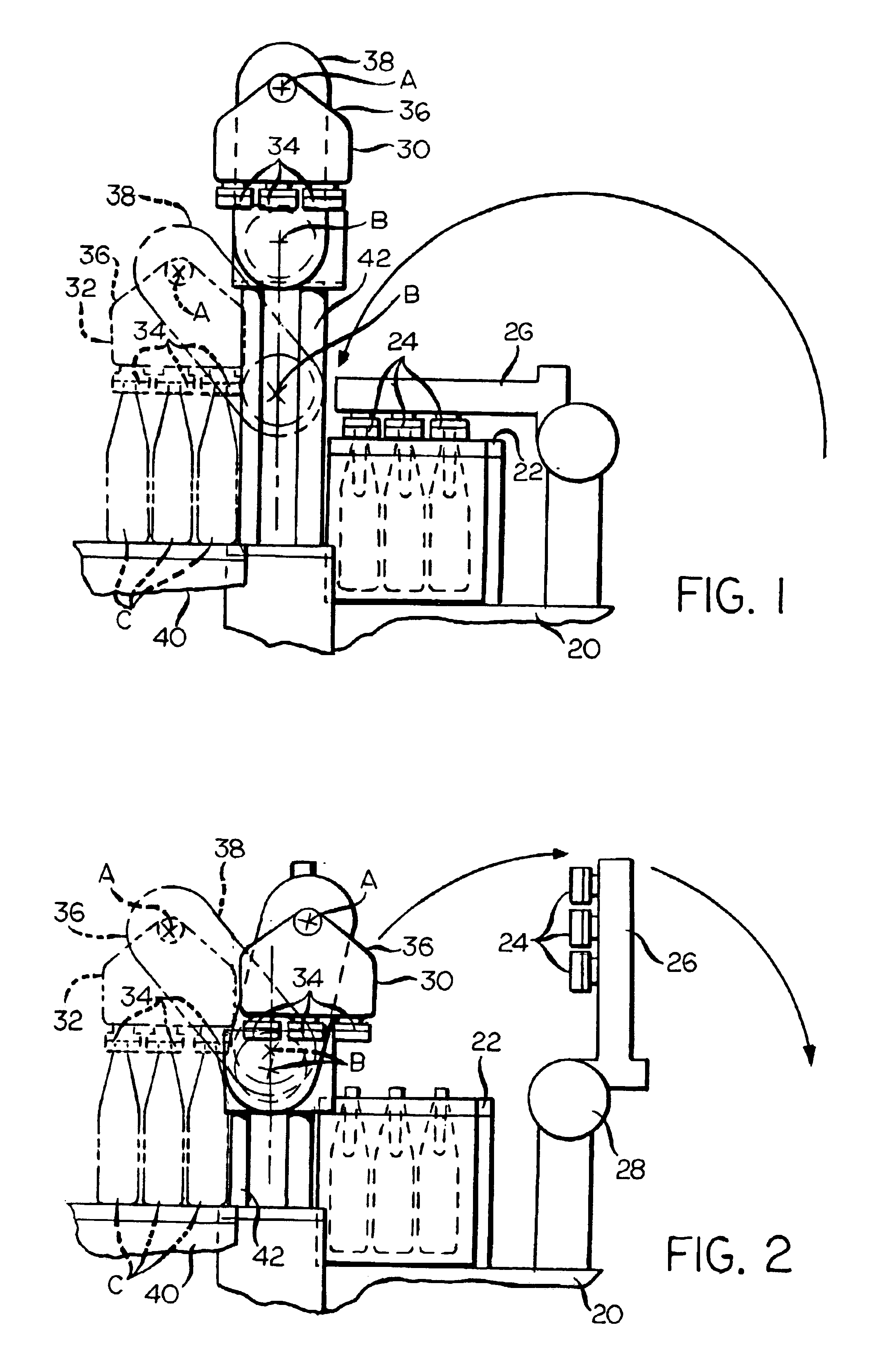

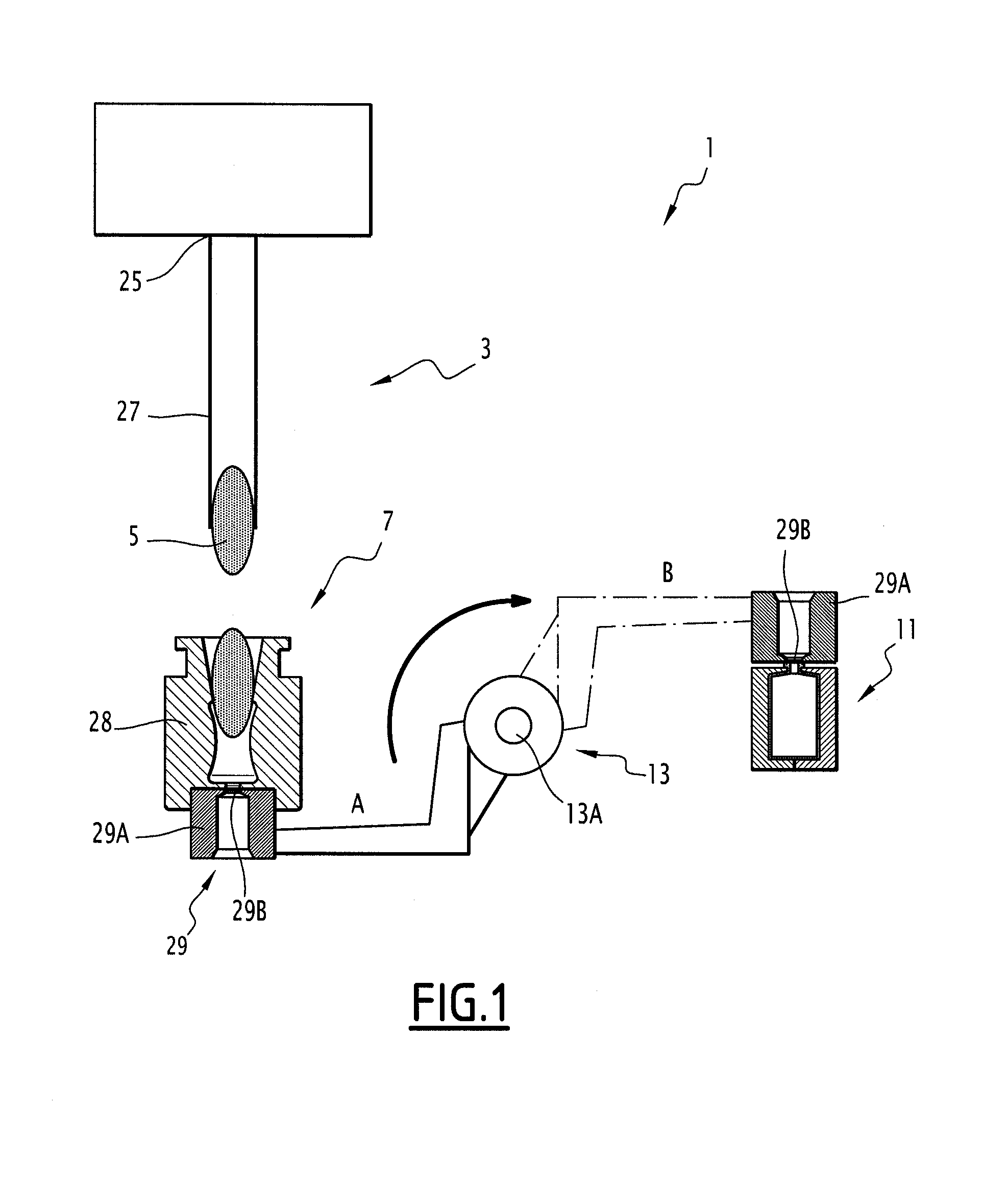

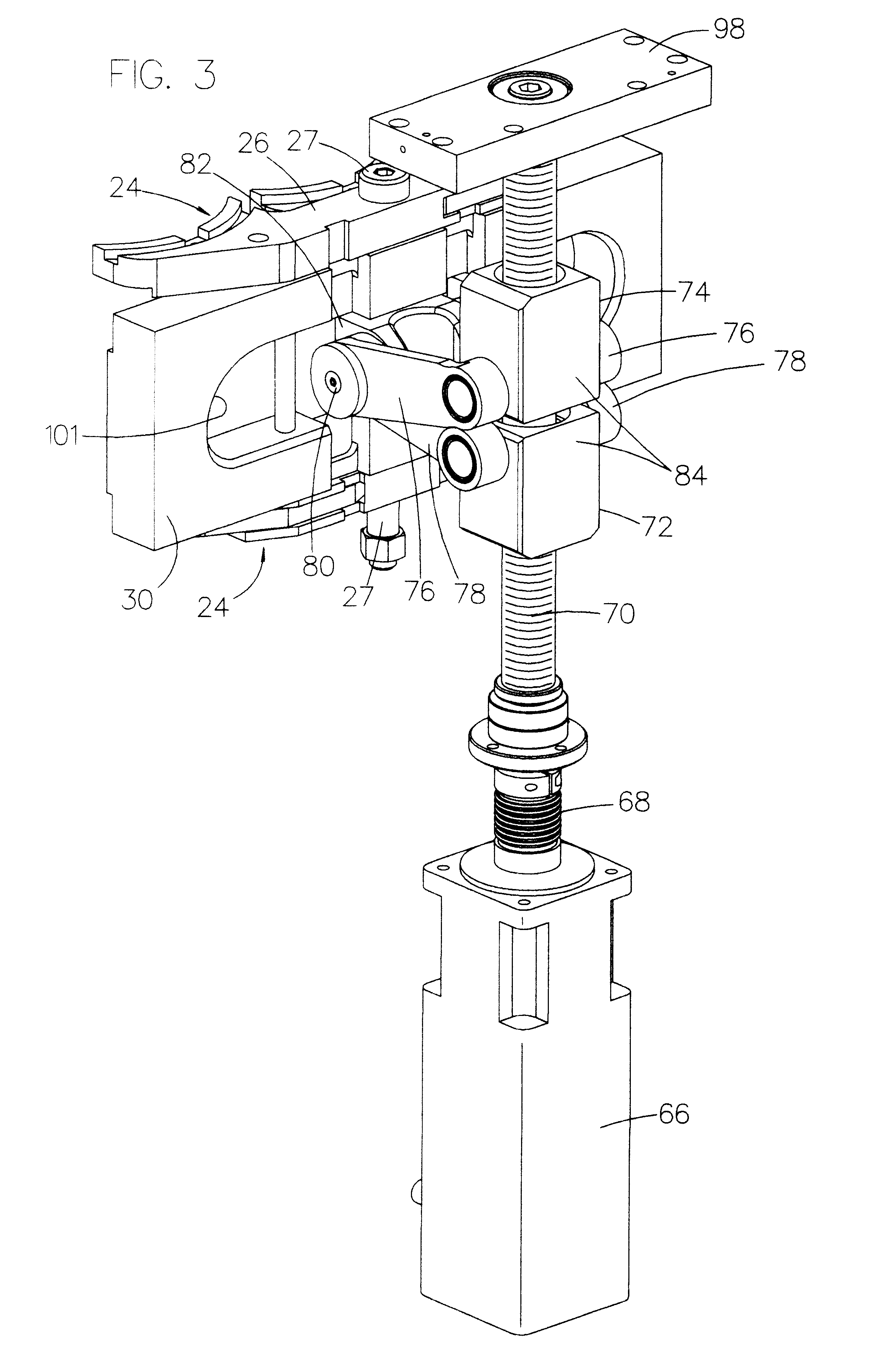

Vertically aligned first (30) and second (32) combined blowhead and takeout mechanisms are provided to sequentially blow glass parisons (P) into containers (C) in a mold set (22) and to transfer blown containers to a deadplate (40) of a glass containing forming machine (20). Each of the combined mechanisms is pivotally suspended about an axis A from a carrier arm (36) that is pivotally attached to an end of an oscillating arm (38), an opposed end of which is pivoted about an axis (B). The axis (B) of each combined blowhead and takeout mechanism is periodically raised and lowered to permit the other combined blowhead and takeout mechanism to oscillate therebeneath, to thereby permit overlapping cycles between the blowhead and takeout mechanisms. Each blowhead and takeout mechanism is provided with a chuck or tong assembly (54) to engage or release each container by its finish (F). Each tong assembly has a plurality of tong elements (74) that are simultaneously moved radially in or out by oscillation of a cam (50) that has a non-circular slot (78) in which a pin (76) carried by each tong element rides.

Owner:OWENS-BROCKWAY GLASS CONTAINER INC

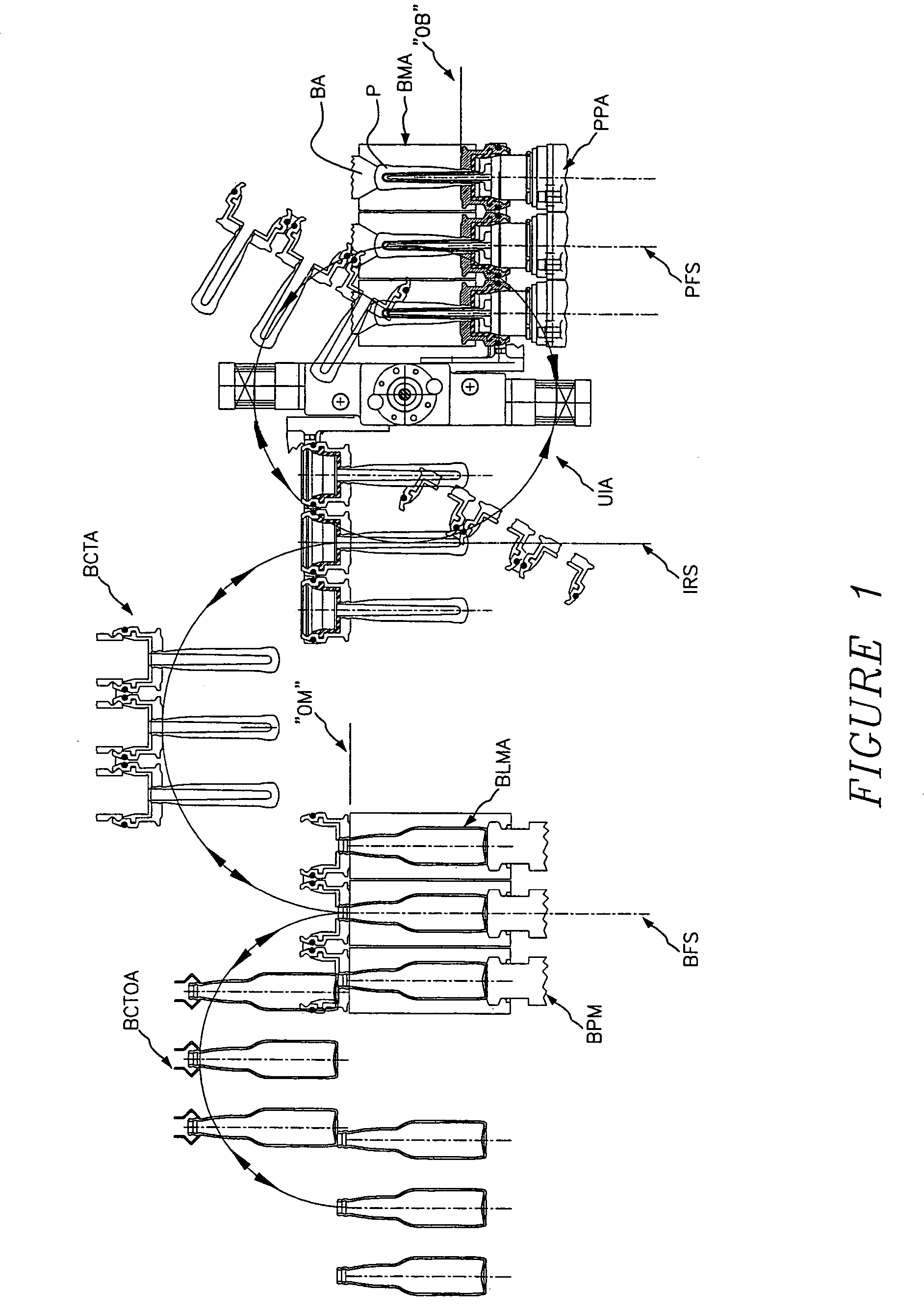

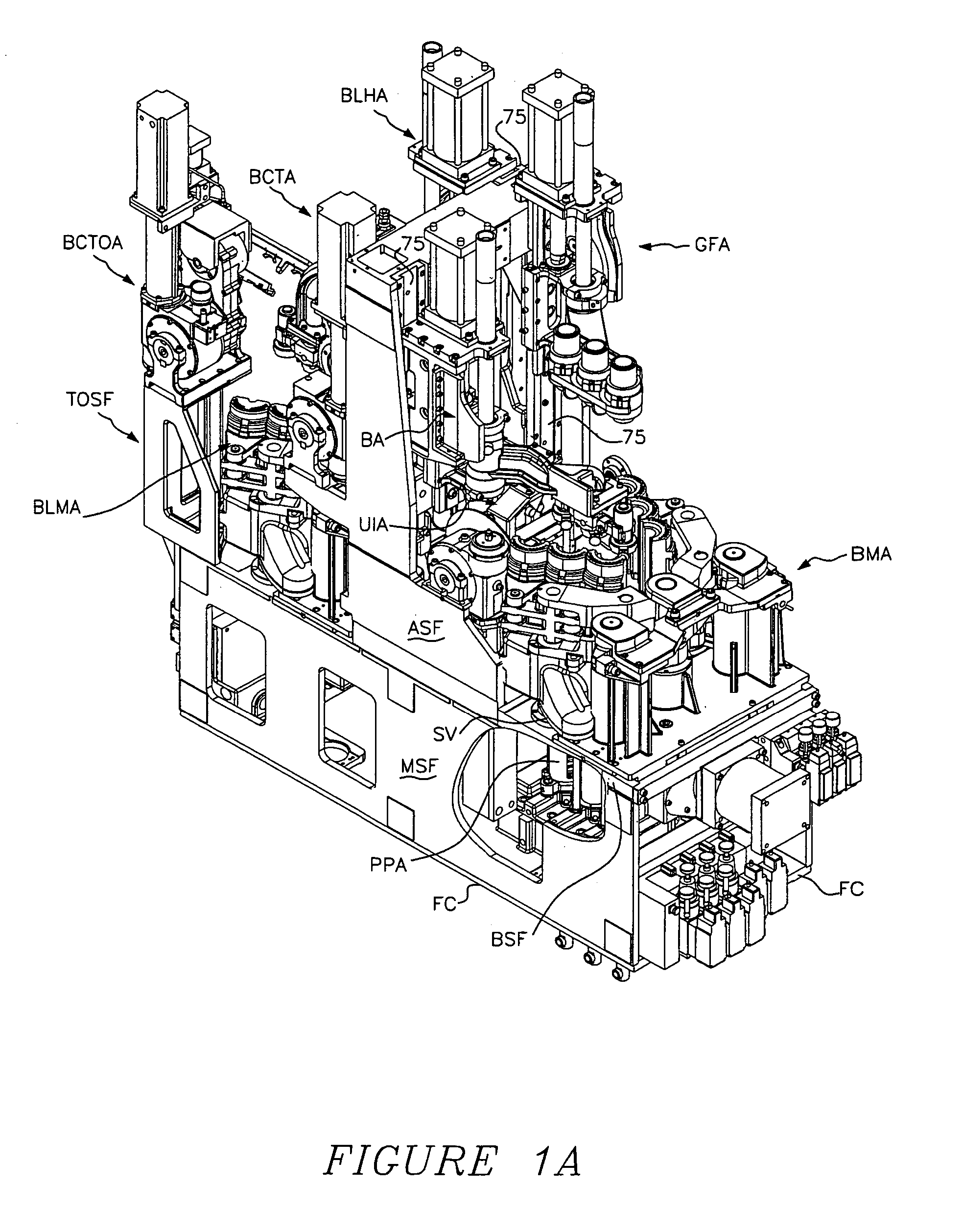

Method and a machine for the production of hollow glassware articles

InactiveUS20050235697A1Reduction in forming cycle time of machineQuality improvementGlass drawing apparatusGlass forming apparatusMolding machineGlass vessel

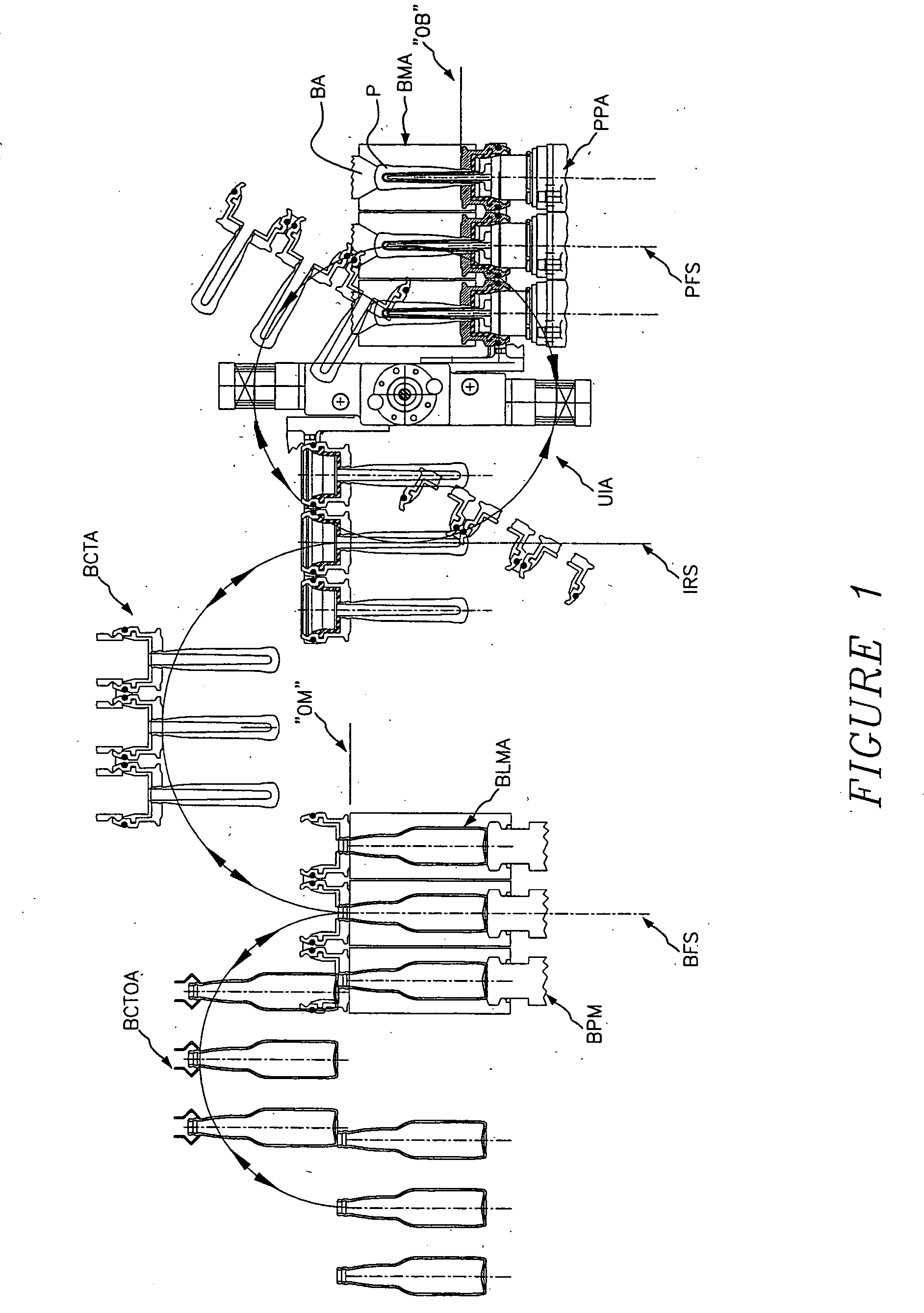

A method and a machine for the production of hollow glassware articles, by the blow-and-blow, press-and-blow, press-and-blow paste mold and direct-press processes in a glassware forming machine including single or multiple machine sections each having single or multiple-cavity, comprising: forming a parison in an inverted orientation, into a blank mold and a first transferable and open-able neck ring mold held by an inverting apparatus having a first and a second diametrically opposed arms, each arm holding a transferable and open-able neck ring mold; inverting the parison held by the first transferable and open-able neck ring mold, by rotating the first arm 180° to an upright orientation at an intermediate station, while the second arm with a second transferable and open-able neck ring mold is simultaneously placed at the parison forming station; transferring the first transferable and open-able neck ring mold holding the parison in an upright orientation, from the intermediate station, to a blow mold station, by a transference apparatus; releasing the first parison into a blow mold, and turning back the first transferable and open-able neck ring mold empty to the first arm of the inverting apparatus, at the intermediate station to be placed again at the parison forming station by rotating the first arm additional 180°, completing a 360° turn, while the second arm reaches to the intermediate station; blowing the parison into a blow mold to form a finished article; and transferring the finished article in an upright orientation, once the blow mold is opened, by a take out apparatus, to place it at a dead plate or at a carrying conveyor.

Owner:VITRO SAB DE CV

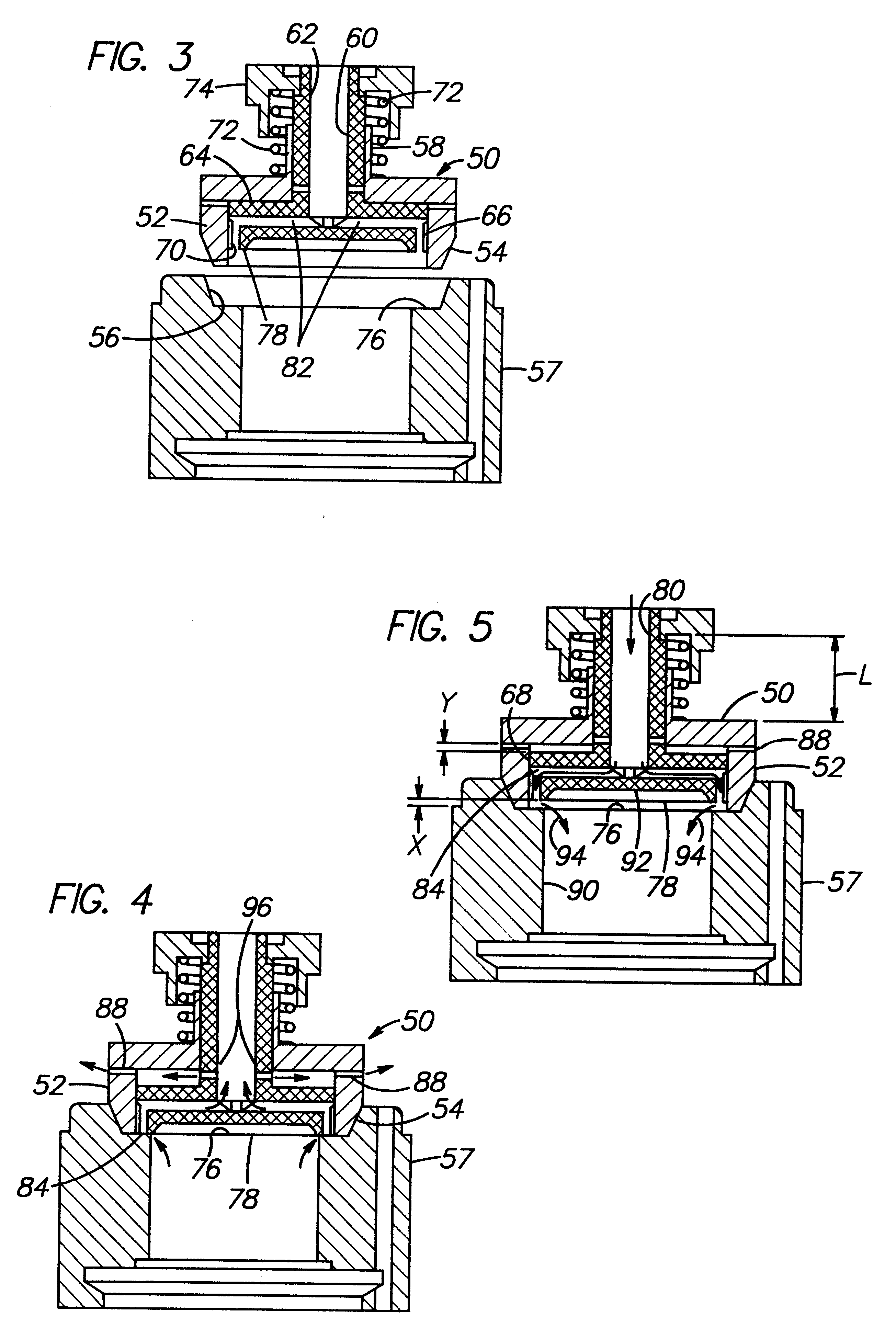

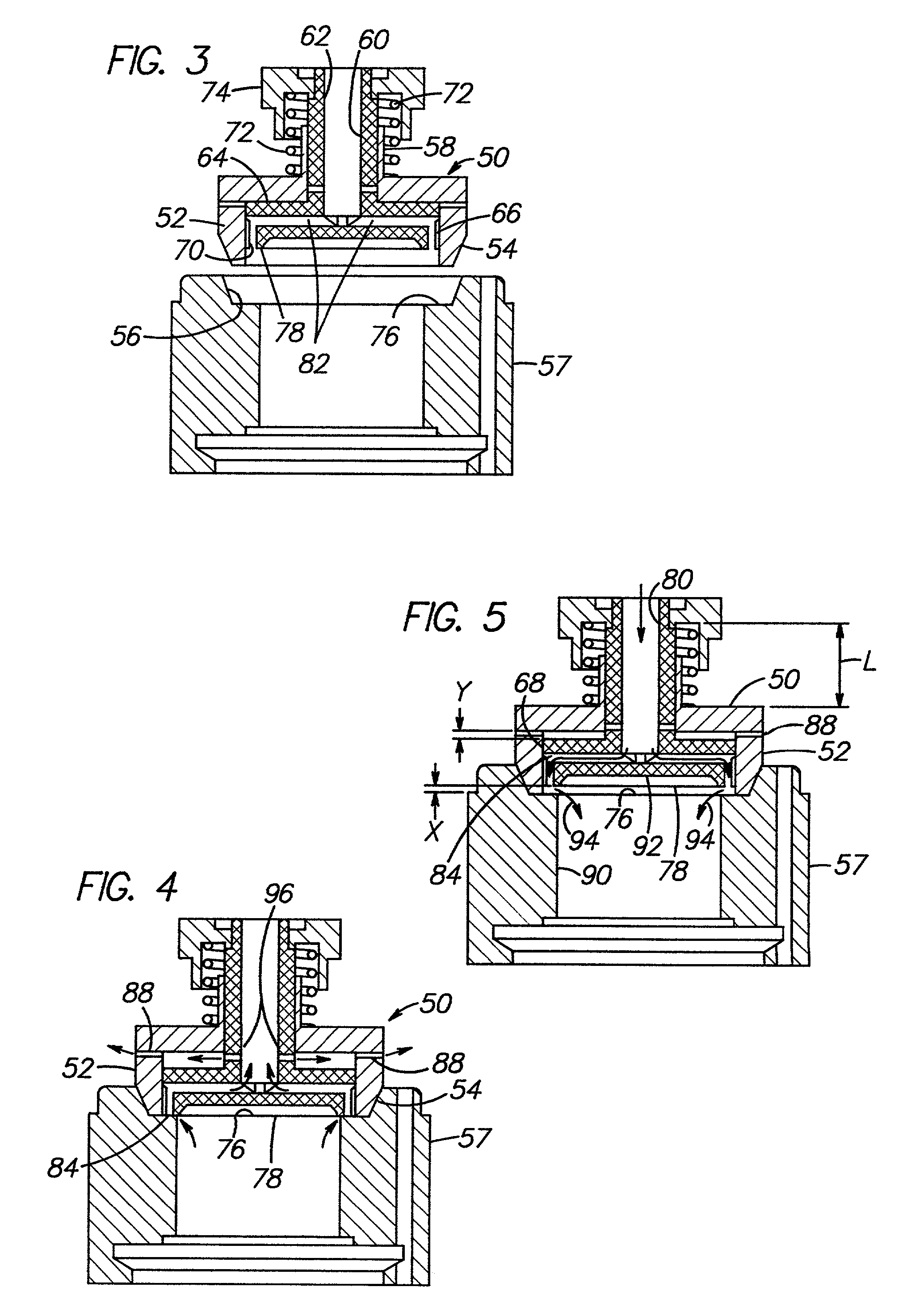

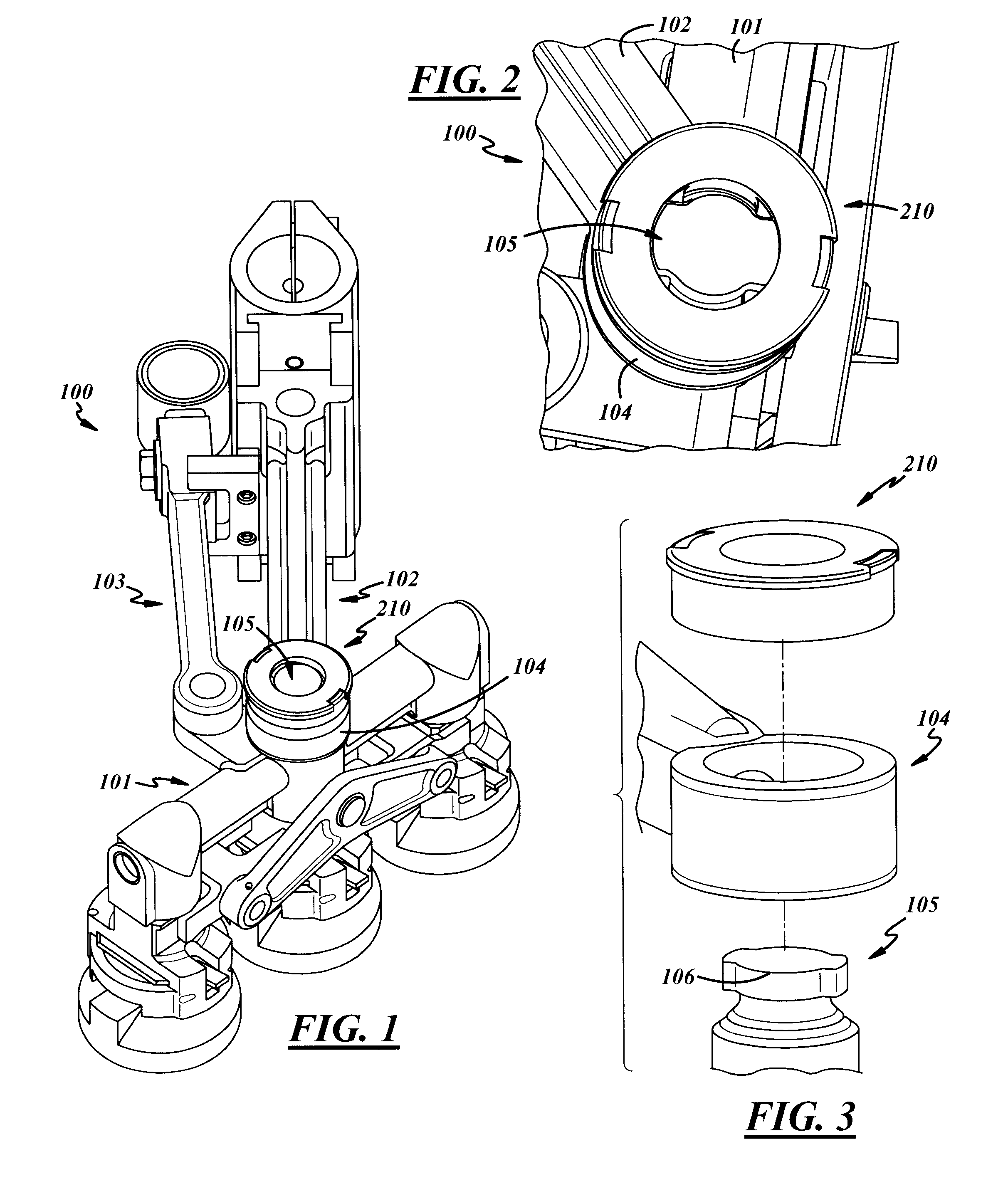

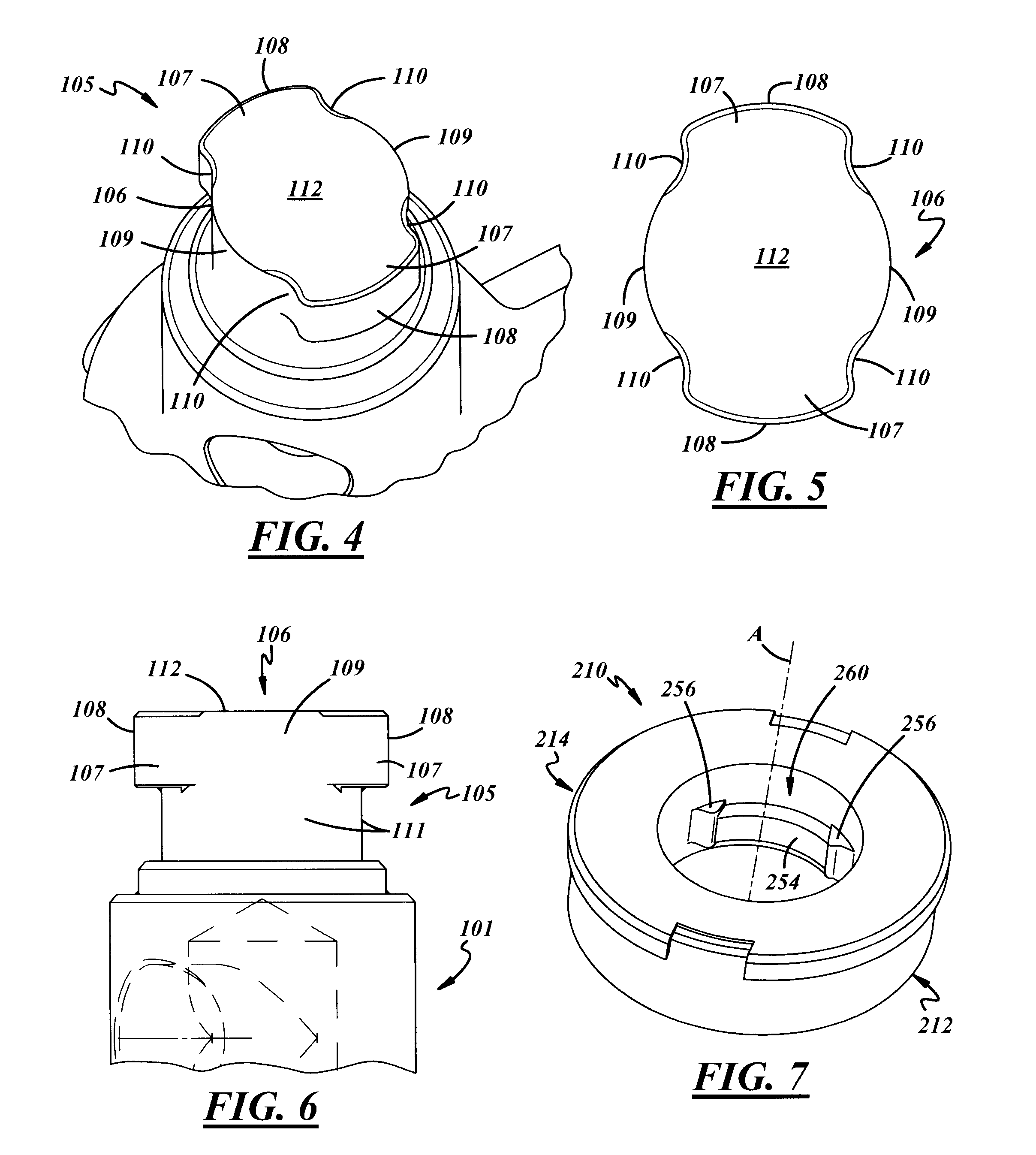

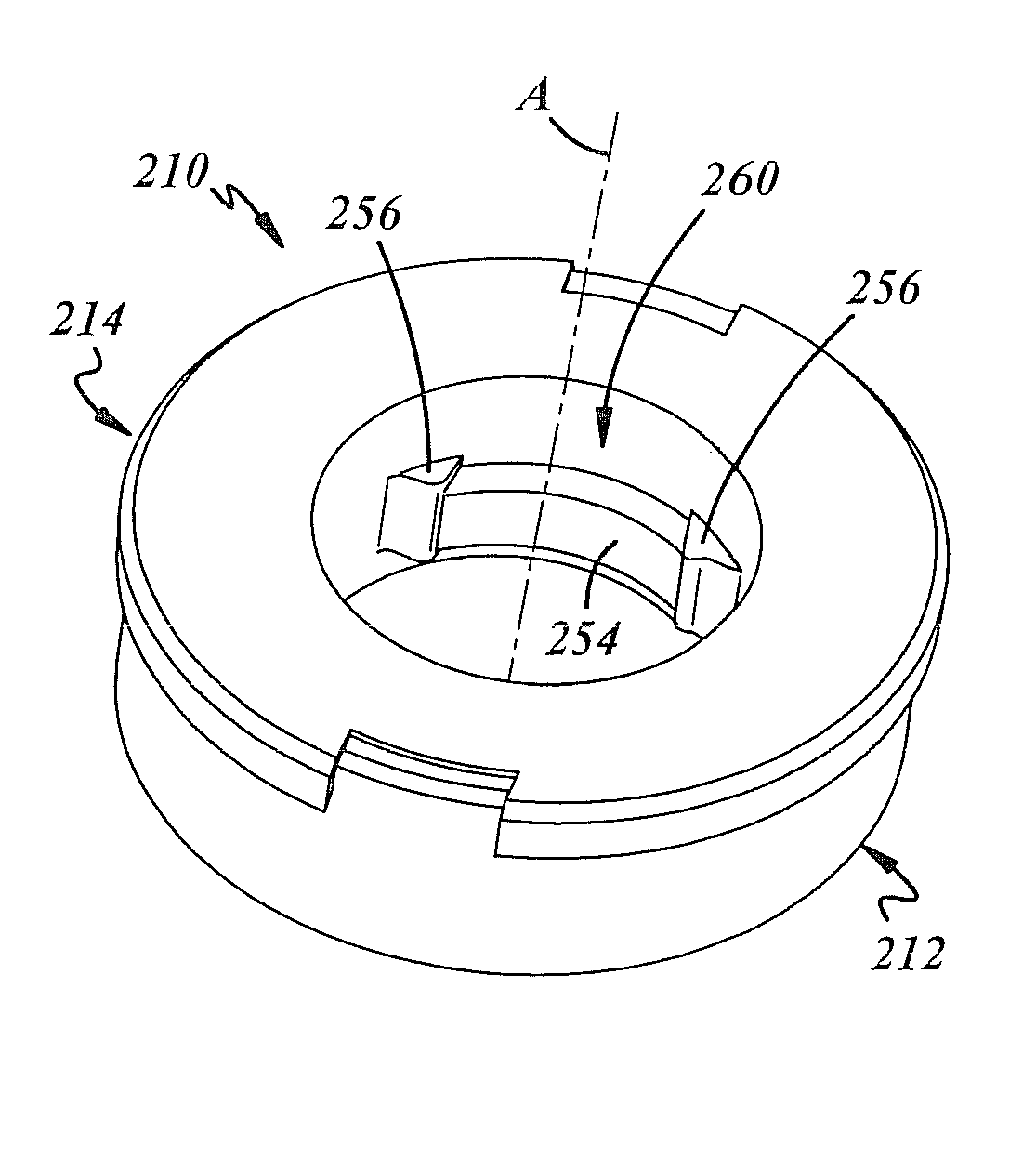

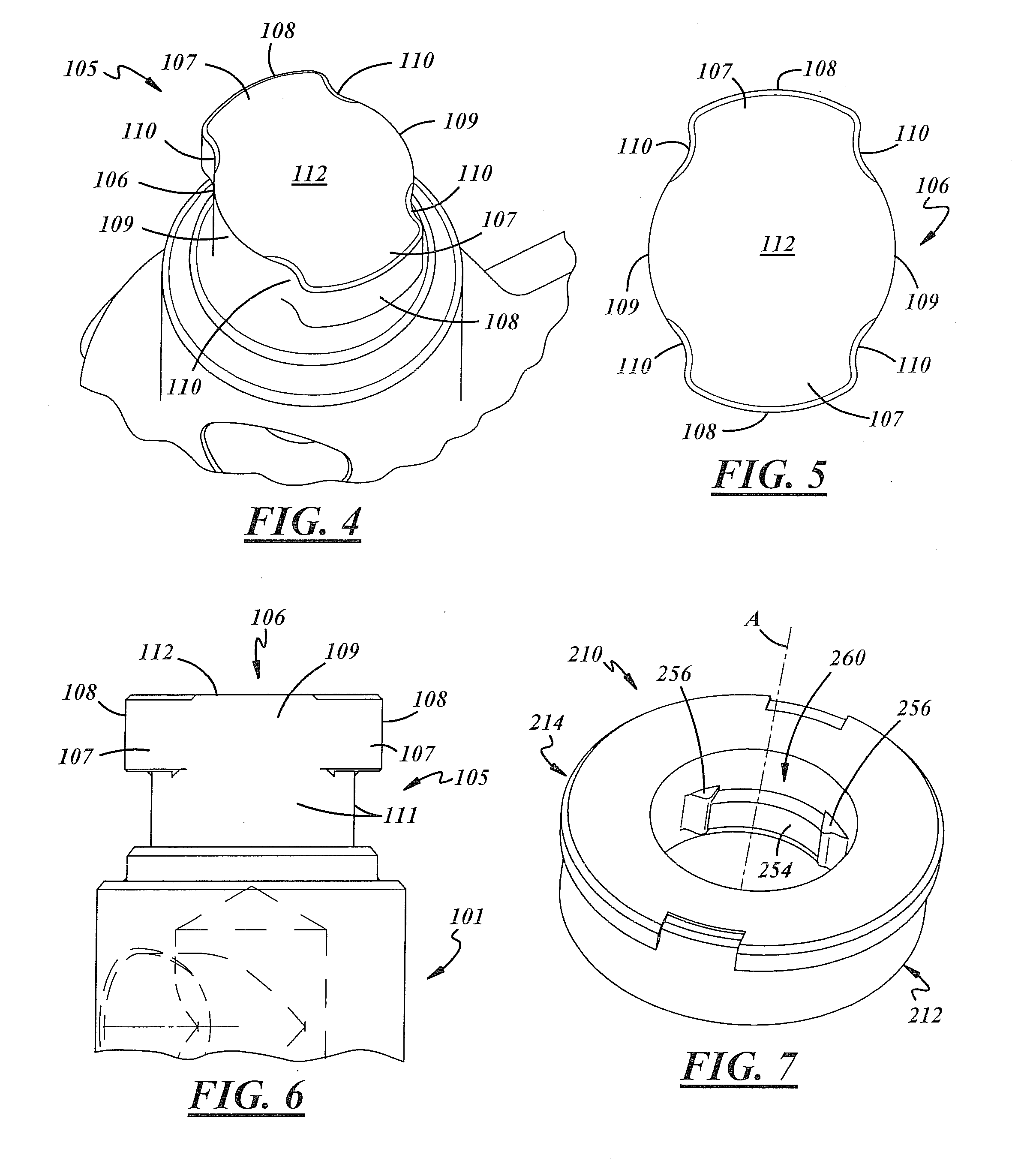

Threadless Nut

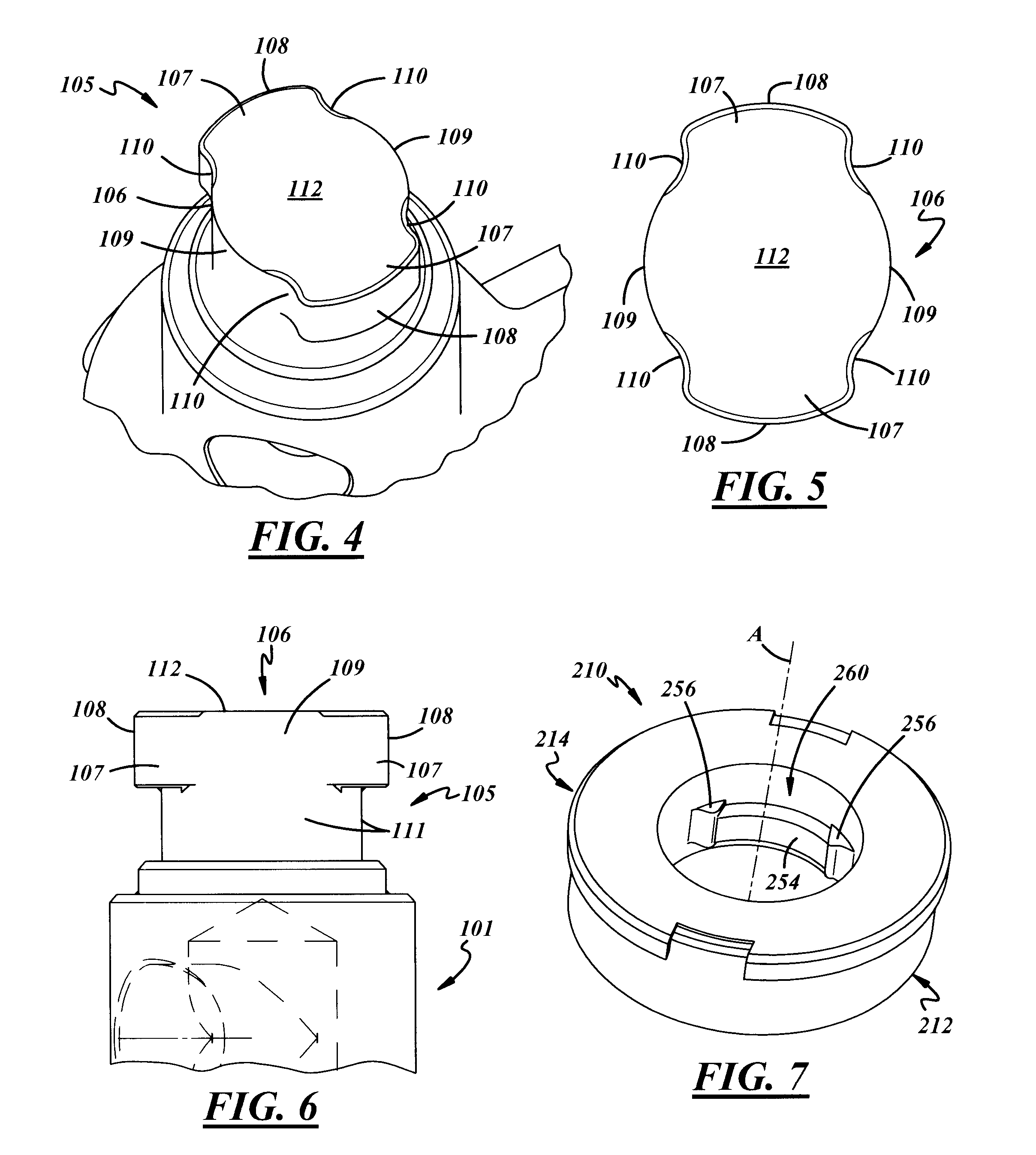

A glassware forming machine baffle arm assembly that includes a quick-connect / disconnect arrangement mounting a baffle manifold on a baffle arm. The arrangement includes a baffle arm having an aperture, and a baffle manifold having a segment extending through said aperture and permitting rotation of said baffle manifold with respect to said baffle arm. The arrangement also includes a threadless nut, and a bayonet connection between said threadless nut and said baffle manifold segment.

Owner:OWENS-BROCKWAY GLASS CONTAINER INC

Baffle mechanism for I.S. machine

An I.S. machine has a blankmold which is open at the top and includes inner and outer annular top sealing surfaces. Associated with the blankmold is a baffle including a body having a cup shaped portion closed with a vertical cylindrical bore open at the bottom, an annular bottom sealing surface for sealingly engaging the blankmold outer annular top sealing surface, and a top having a hole. A tubular sleeve communicates with the hole and extends vertically upwardly from the top of the body. A piston has a cylindrical head including a top surface, a cylindrical sealing surface and an annular bottom sealing surface having a plurality of radial notch means across the bottom thereof. A tubular rod extends vertically upwardly from the top surface for slidable displacement in the tubular sleeve, and a collar is secured to the top of the rod. A spring located between the collar and the cup shaped portion urges the cylindrical head vertically upwardly to a position whereat the cylindrical head top surface engages the top of the cup shaped portion. The collar is pneumatically displaced vertically downwardly at a high pressure to bring the cup shaped portion annular surface into sealing engagement with the blankmold outer annular sealing surface. The pressure is then reduced so that a predetermined distance separates the cylindrical head annular bottom sealing surface and the blankmold inner annular sealing surface so that settle air can be introduced into the mold, and then the pressure is again raised to the high pressure for parison formation.

Owner:EMHART GLASS SA

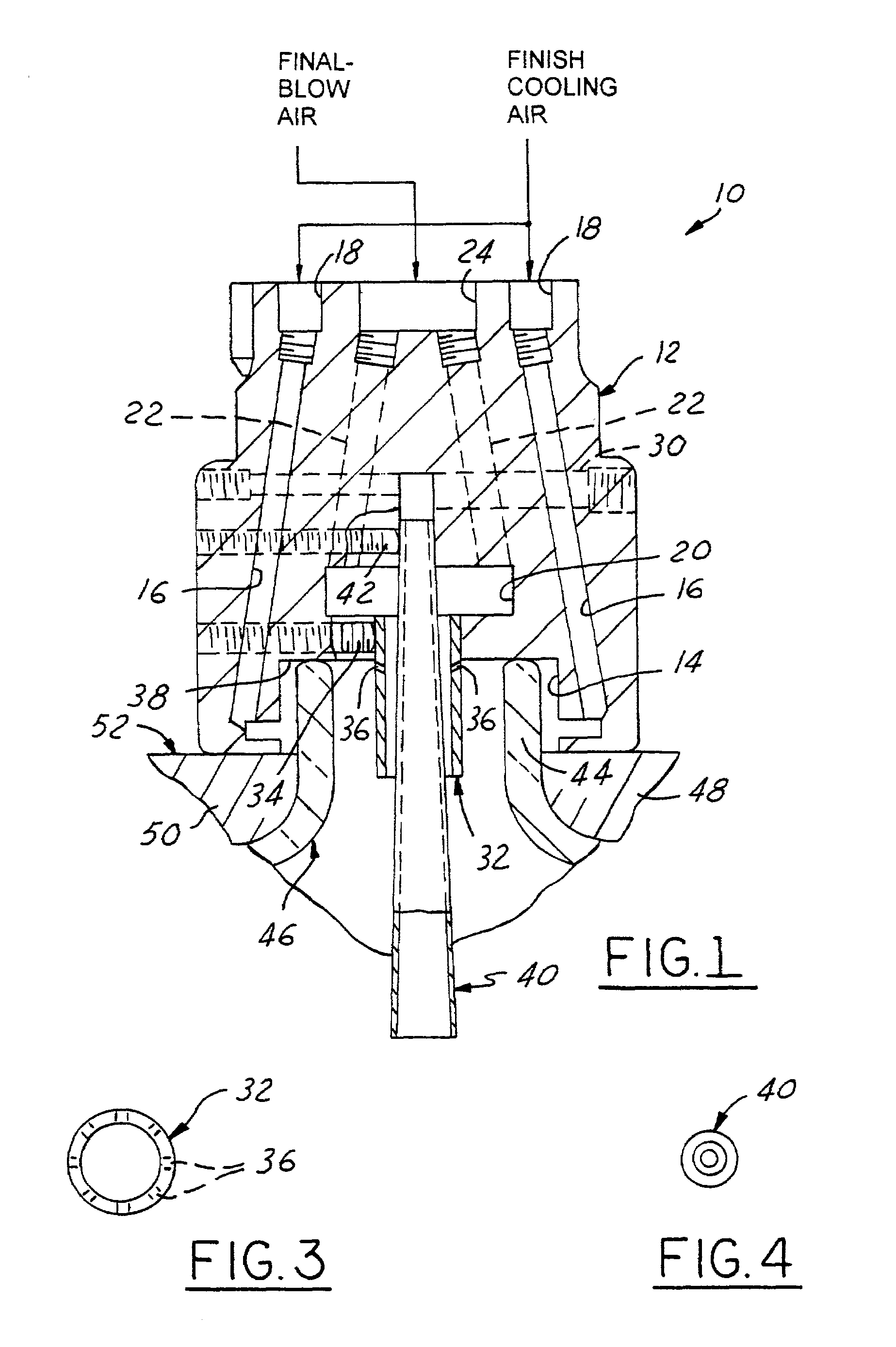

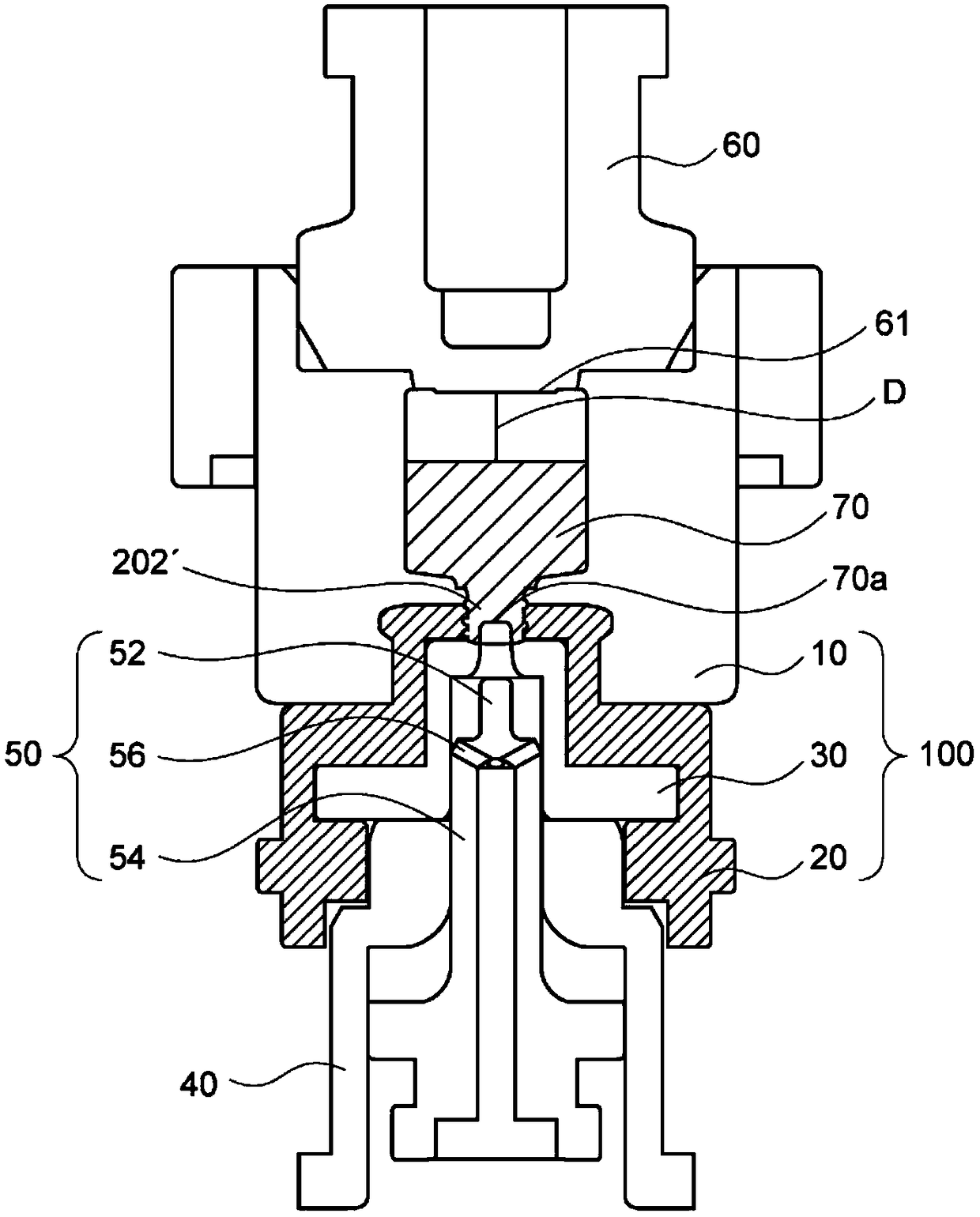

Dual-stage blowhead assembly

A blowhead assembly for receipt over a parison finish to blow the parison within a blow mold and simultaneously cool the parison finish includes a blowhead body having a first chamber at one end for receipt over the finish of a parison in a blow mold, and at least one passage in the blowhead extending to the chamber from a first inlet for directing cooling air onto the external surface of a parison finish in the chamber. A second chamber in the blowhead body is spaced from the first chamber, and at least one second passage in the blowhead body extends to the second chamber from a second inlet for directing blow air into the second chamber. A first tube extends from the second chamber through the first chamber for receipt within a parison finish in the first chamber to feed blow air from the second chamber into the parison. A second tube extends from an exhaust passage in the blowhead body through the second chamber and through the first tube for receiving exhaust air from the parison. The second tube is coaxial with the first tube and extends beyond the free end of the first tube. The second tube has at least a free end that flares radially outwardly for deflecting blow air from the first tube radially outwardly within the parison.

Owner:OWENS-BROCKWAY GLASS CONTAINER INC

Method and a machine for the production of hollow glassware articles

InactiveUS7024887B2Reduction in forming cycle time of machineQuality improvementGlass drawing apparatusGlass forming apparatusEngineeringNeck rings

A method and a machine for the production of hollow glassware articles, by the blow-and-blow, press-and-blow, press-and-blow paste mold and direct-press processes in a glassware forming machine including single or multiple machine sections each having single or multiple-cavity, comprising: forming a parison in an inverted orientation, into a blank mold and a first transferable and open-able neck ring mold held by an inverting apparatus having a first and a second diametrically opposed arms, each arm holding a transferable and open-able neck ring mold; inverting the parison held by the first transferable and open-able neck ring mold, by rotating the first arm 180° to an upright orientation at an intermediate station, while the second arm with a second transferable and open-able neck ring mold is simultaneously placed at the parison forming station; transferring the first transferable and open-able neck ring mold holding the parison in an upright orientation, from the intermediate station, to a blow mold station, by a transference apparatus; releasing the first parison into a blow mold, and turning back the first transferable and open-able neck ring mold empty to the first arm of the inverting apparatus, at the intermediate station to be placed again at the parison forming station by rotating the first arm additional 180°, completing a 360° turn, while the second arm reaches to the intermediate station; blowing the parison into a blow mold to form a finished article; and transferring the finished article in an upright orientation, once the blow mold is opened, by a take out apparatus, to place it at a dead plate or at a carrying conveyor.

Owner:VITRO

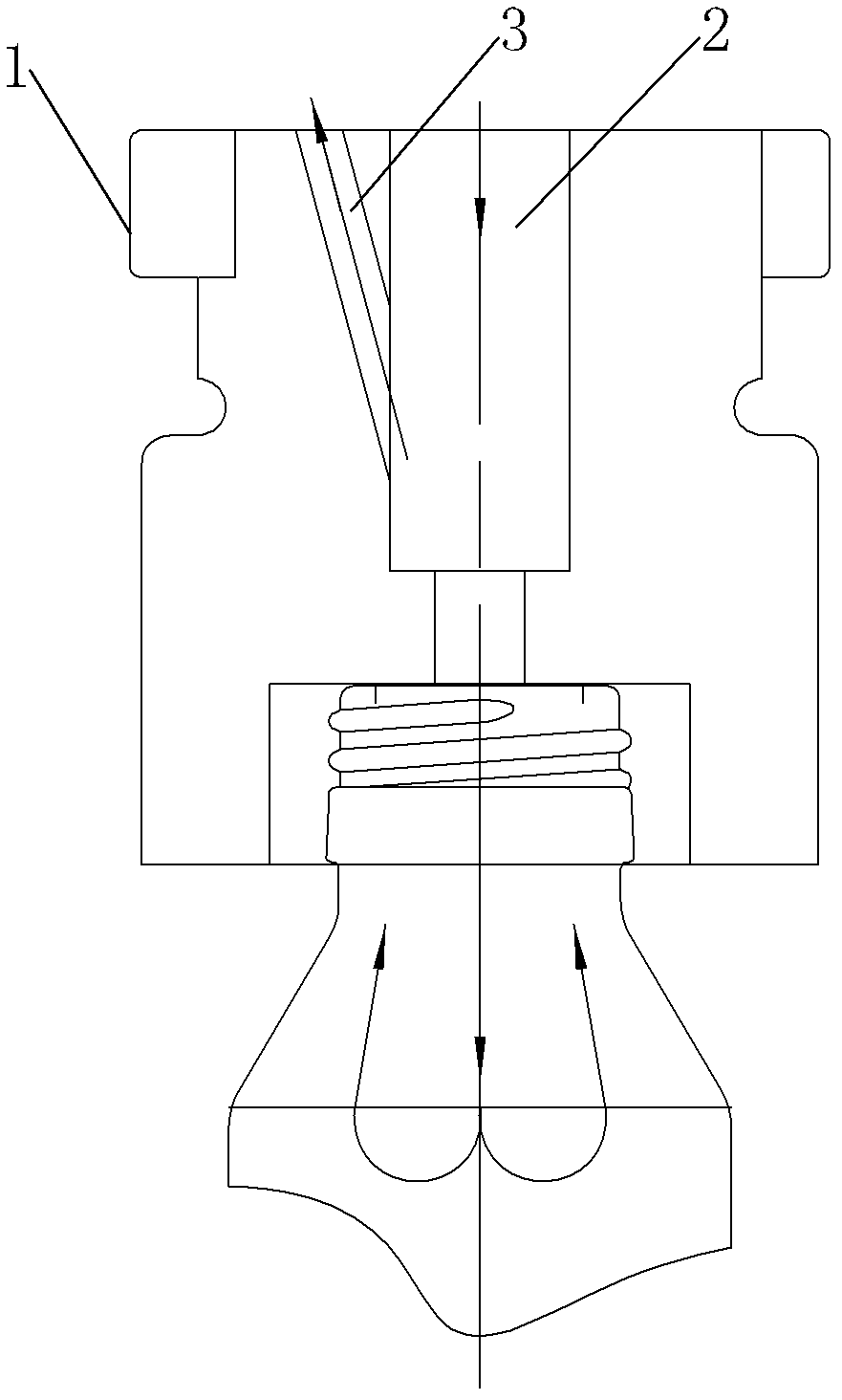

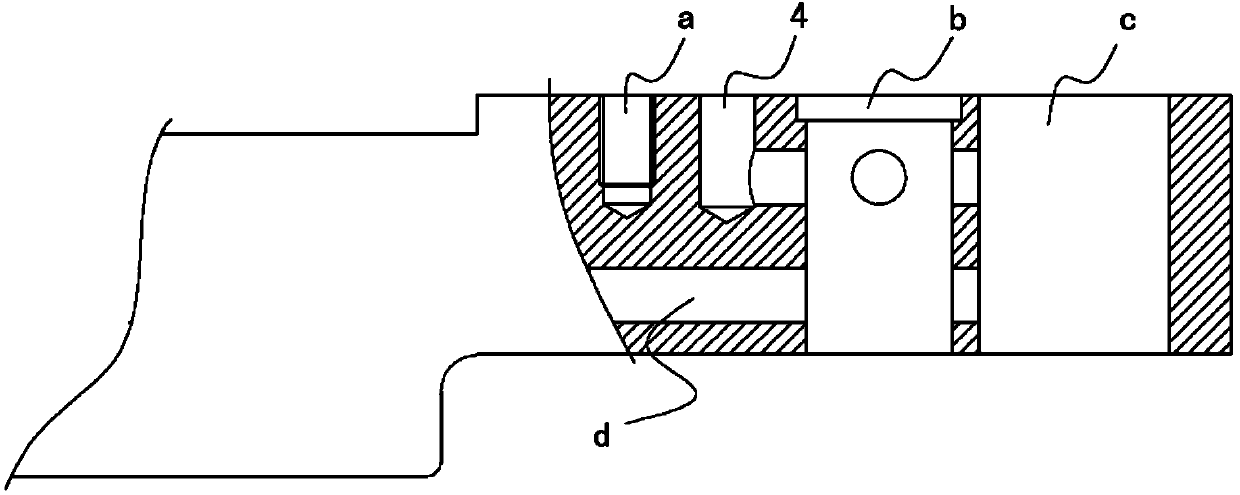

Blow head of bottle-making machine

InactiveCN102583960AShorten programming timeEliminate defects such as bulge, mouth bulge, and insufficient bottle body moldingBlow headsEngineeringBottle

The invention discloses a blow head of a bottle-making machine. The blow head comprises a blow head body; an air intake pipeline is vertically arranged at the center of the blow head body and is internally provided with an air blowpipe; the root of the air blowpipe is tightly matched with the inlet of the air intake pipeline, and a clearance exists between the inner wall of the air inlet pipeline and the part of the air blowpipe, except for the root; an inclined exhaust pipeline is arranged in the blow head body; and one end of the exhaust pipeline is communicated with the middle part of the air intake pipeline, and the other end of the exhaust pipeline is communicated to the exterior of the blow head body. According to the invention, the air blowpipe is added in the air intake pipeline, the exhaust pipeline is inclined by an angle of 45 degrees, and equipment suction is changed to natural exhaust. According to practice, the defects such as trunk expansion, mouth expansion and bottle body forming deficiency of produced glass bottles are eliminated, time for computer programming is reduced, equipment maintenance is reduced, and efficiency is enhanced.

Owner:DEQING CAIFU GLASS

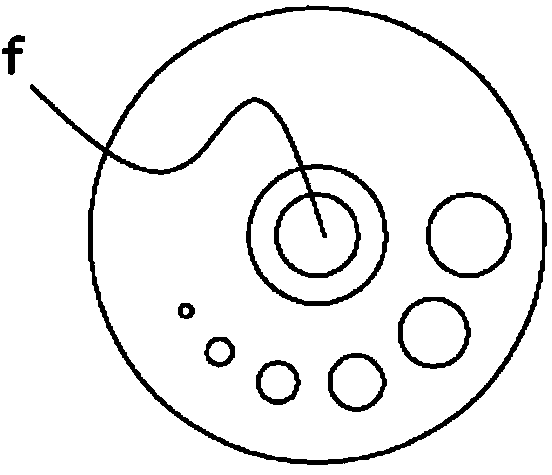

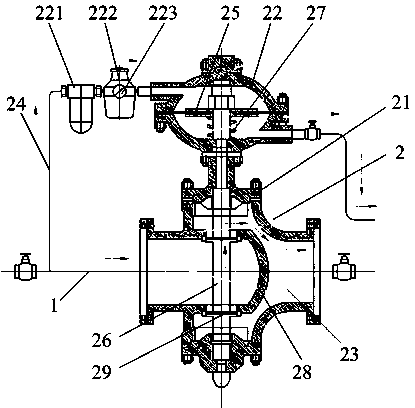

Glass tube diameter adjusting device applied in DANNER horizontal pulling tube production

ActiveCN106495450AGuaranteed stabilityBlow headsFlow control using electric meansControl signalEngineering

The invention provides a glass tube diameter adjusting device applied in DANNER horizontal pulling tube production. The device comprises a filtering and pressure reducing device, an electric valve, a laser diameter measuring device and a controller; the filtering and pressure reducing device conducts filtering treatment and pressure reducing and stabilizing on high-pressure compressed air and outputs low-pressure gas to the electric valve; the electric valve adjusts the valve opening degree of the electric valve according to valve position and opening degree information carried in a control signal and outputs corresponding flow of low-pressure clean gas to a pulling tube driver blowing interface; the laser diameter measuring device measures the glass tube diameter, converts the glass tube diameter into a corresponding electric signal and transmits the electric signal to the controller; the controller converts the electric signal into the valve position and opening degree information of the electric valve in the PID control process and transmits the control signal carrying the valve position and opening degree information to the electric valve. According to the device, compressed air obtained after filtering and pressure reducing is used to provide the clean gas with the stable pressure, the flow of gas in a glass tube is automatically changed according to glass tube diameter changes, and therefore the glass tube diameter stability is guaranteed.

Owner:TRIUMPH JUNHENG CO LTD

Baffle mechanism for I.S. machine

An I.S. machine has a blankmold which is open at the top and includes inner and outer annular top sealing surfaces. Associated with the blankmold is a baffle including a body having a cup shaped portion closed with a vertical cylindrical bore open at the bottom, an annular bottom sealing surface for sealingly engaging the blankmold outer annular top sealing surface, and a top having a hole. A tubular sleeve communicates with the hole and extends vertically upwardly from the top of the body. A piston has a cylindrical head including a top surface, a cylindrical sealing surface and an annular bottom sealing surface having a plurality of radial notch means across the bottom thereof. A tubular rod extends vertically upwardly from the top surface for slidable displacement in the tubular sleeve, and a collar is secured to the top of the rod. A spring located between the collar and the cup shaped portion urges the cylindrical head vertically upwardly to a position whereat the cylindrical head top surface engages the top of the cup shaped portion. The collar is pneumatically displaced vertically downwardly at a high pressure to bring the cup shaped portion annular surface into sealing engagement with the blankmold outer annular sealing surface. The pressure is then reduced so that a predetermined distance separates the cylindrical head annular bottom sealing surface and the blankmold inner annular sealing surface so that settle air can be introduced into the mold, and then the pressure is again raised to the high pressure for parison formation.

Owner:EMHART GLASS SA

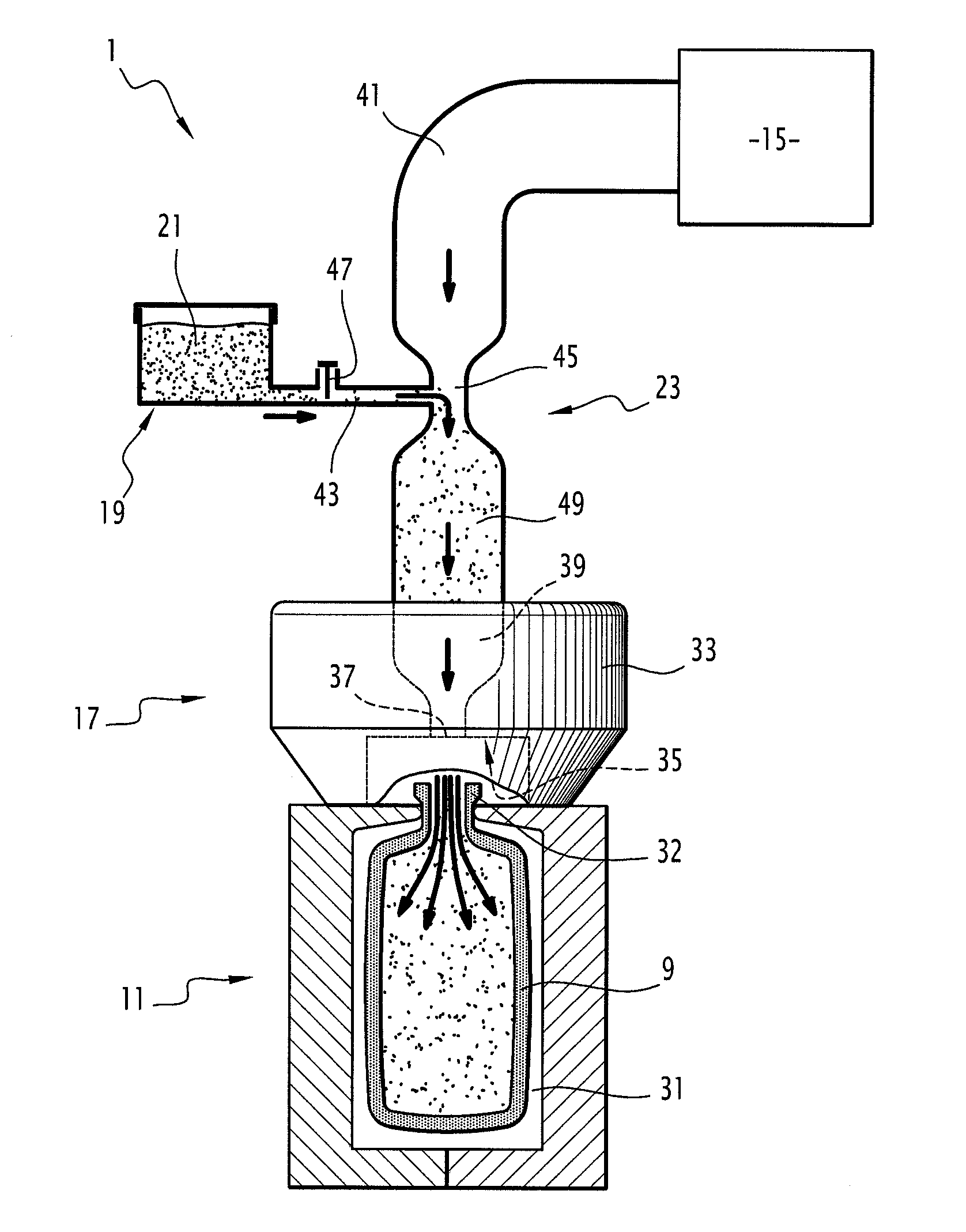

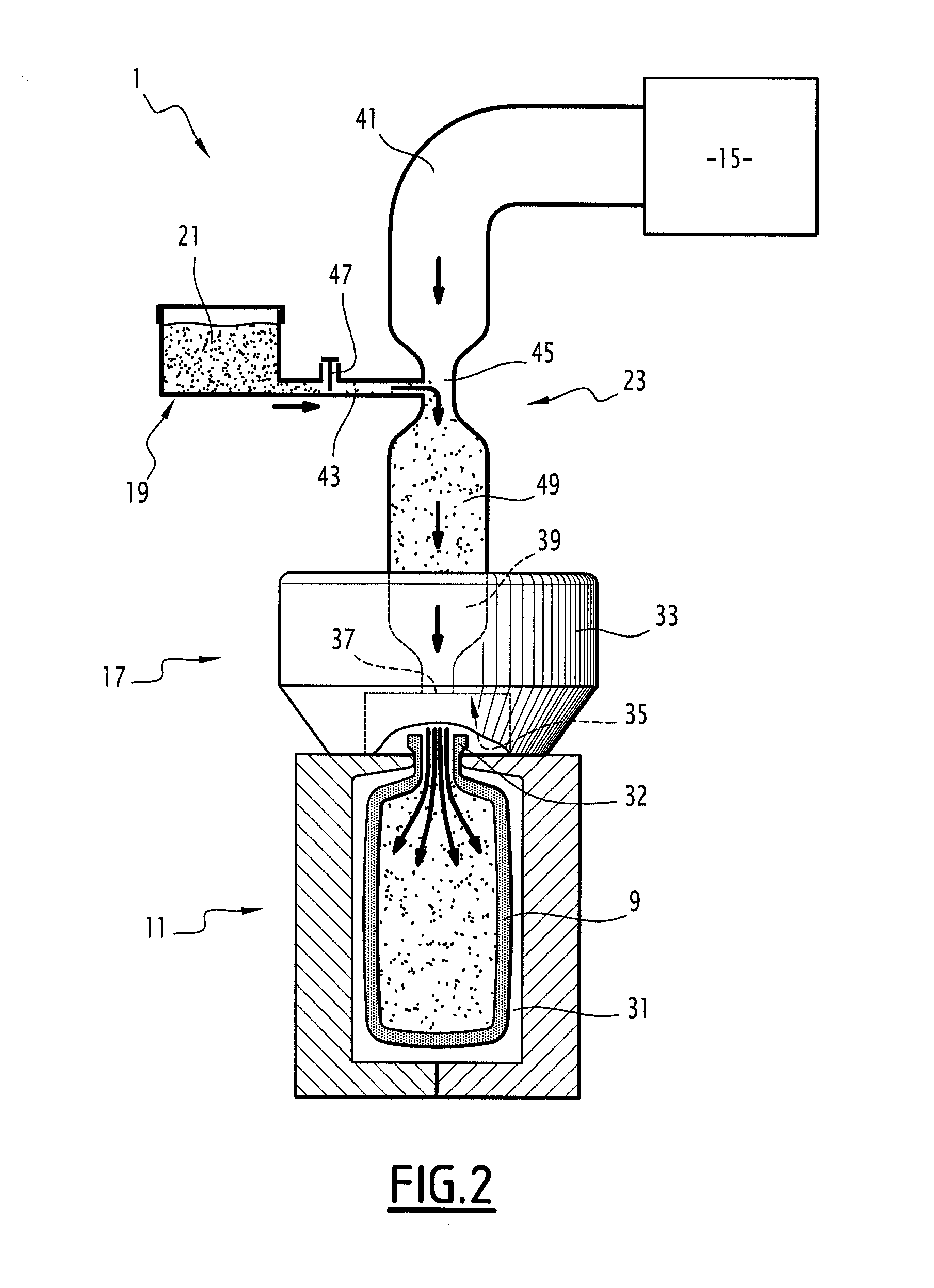

Facility and method for manufacturing a hollow glass article

A facility for manufacturing a hollow glass article, including: a finishing mold intended to receive a blank of the hollow glass article and defining a cavity for forming the hollow glass article, at least one gas source, and a blowing head connected to the gas source and adapted for achieving at least one injection of the gas into the inside of the blank contained in the cavity. The facility further includes: at least one reservoir of coloring powder, and a system for injecting the coloring powder into the inside of the blank while the blank is located in the finishing mold and into the inside of the hollow glass article while the hollow glass article is located in the finishing mold, so that the injection of the coloring powder takes place before, during, after, before and during, during and after, or before, during and after the gas injection.

Owner:POCHET DU COURVAL

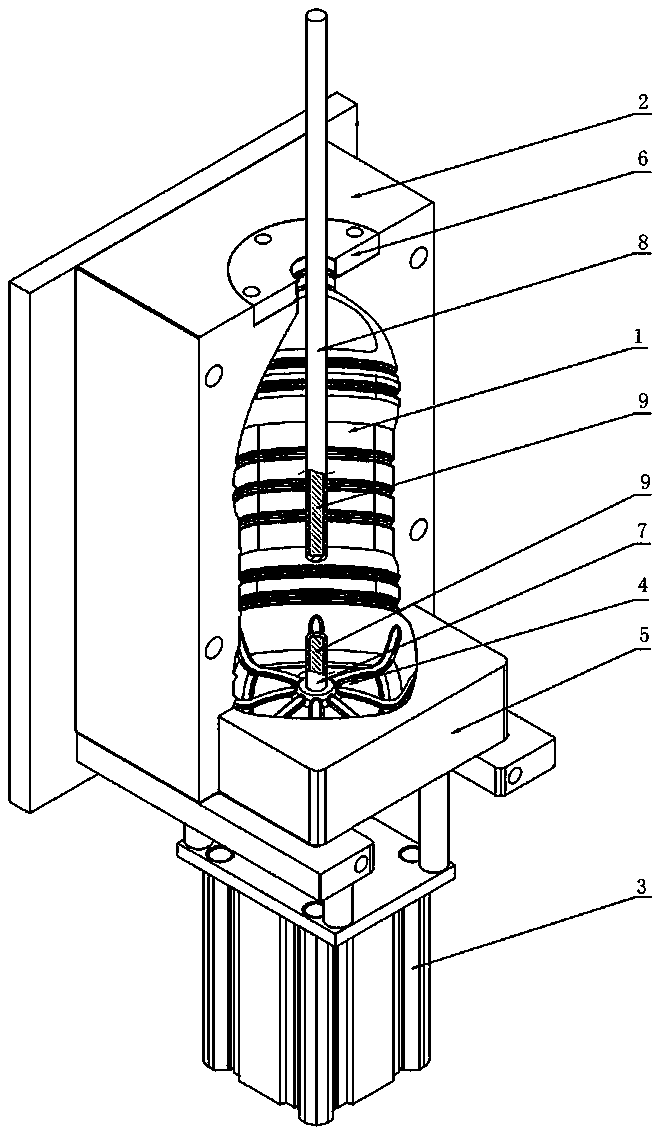

Blow molding mold and method equipped with heating stretching system

PendingCN110303664AFully stretchedUniform wall thicknessBlowing machine gearingsBlow headsBlow moldingBottle

The invention discloses a blow molding mold equipped with a heating stretching system. The blow molding mold equipped with the heating stretching system comprises a front mold and a rear mold which form a mold cavity in an encircling mode, a bottom mold located at the bottom of the mold cavity, a bottom mold plate used for installing the bottom mold and a stretching rod stretched from the top of the mold cavity into the mold cavity, wherein a bearing mechanism is arranged in the mold cavity, the bearing mechanism comprises a bearing rod and a drive mechanism which drives the bearing rod to stretch into the middle of the mold cavity, and heating elements are arranged in the stretching rod and / or the bearing rod. According to the blow molding mold equipped with the heating stretching system,the heating elements are arranged in the stretching rod and / or the bearing rod, and when a bottle is blown, temperature of the stretching rod and the bearing rod is approximate to temperature of a bottle blank, situations of early cooling and the like cannot occur, and materials at the bottom of the bottle blank are fully stretched, uniformly distributed at the bottom of the bottle, and cooled and shaped well. Due to the fact that the materials are fully stretched, not only is inner stress at the bottom of the bottle reduced, but also a bursting probability is reduced.

Owner:GUANG DONG XING LIAN PRECISE MACHINERY

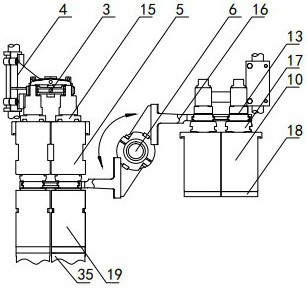

High borosilicate glass bottle making machine and fast blowing method production process

ActiveCN114105448AIncrease productivityAvoid Yield DefectsBlow headsBlow machinesProcess engineeringBottle

The invention discloses a high borosilicate glass bottle making machine and a fast blowing method production process, and belongs to the technical field of glass instruments. Which comprises a prototype side and a forming side, a prototype mold (5) and a forming mold (10) are arranged on the prototype side and the forming side respectively, an air flapping mechanism (4) and a reverse blowing mechanism are arranged on the prototype side, and a forward blowing mechanism (12) is arranged on the forming side, and is characterized in that an air flapping head (15) directly butted with the prototype mold (10) is arranged in the air flapping mechanism (4); a flapping opening in the bottom of the flapping head (15) is opened or closed along with flapping airflow; and a core mechanism is arranged at the top of the reverse blowing mechanism and comprises a plurality of layers of cores which are sleeved inside and outside. According to the high borosilicate glass bottle making machine and the fast blowing method production process, air is directly flapped after the air flapping head is in butt joint with the prototype mold, the process steps are reduced, meanwhile, the core mechanism with multiple layers of cores is arranged, reverse blowing failure is avoided, and the high borosilicate glass bottle making machine and the fast blowing method production process are particularly suitable for production of high borosilicate glass bottles and have the advantages of being high in efficiency and high in yield.

Owner:SHANDONG JIAFENG GLASS MACHINERY

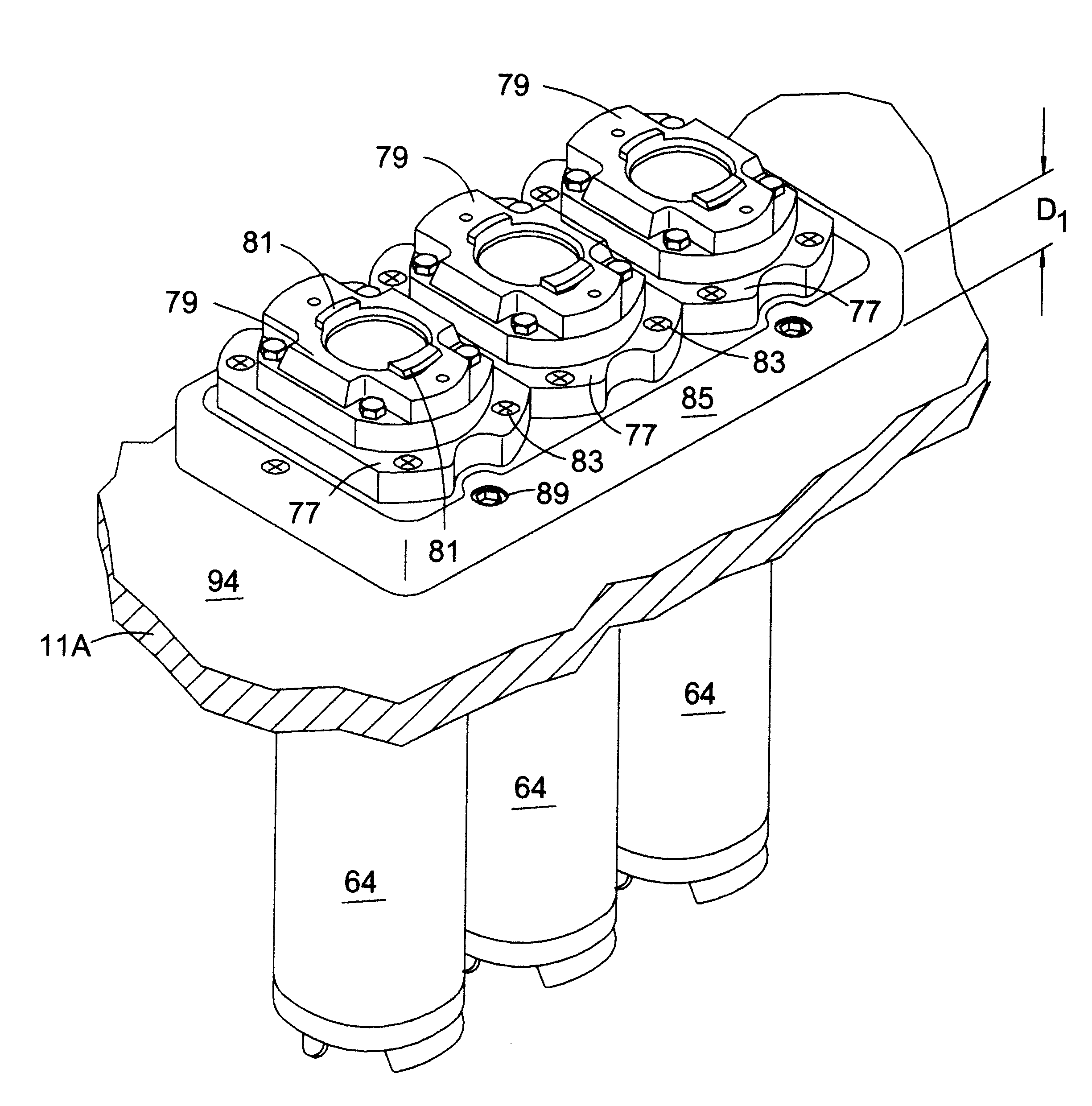

I. S. machine

An I.S. Machine for making glass bottles, having a plurality of sections, each having a blank station for forming a parison. Each section has a section frame having a top surface, and a plunger mechanism including at least one plunger canister having a lower cylinder and an upper flange. A horizontal mounting plate having a top surface and vertical openings for receiving the lower cylinder of each of the plunger canisters is fixedly secured on the top surface of the section frame. The section frame top surface has vertical openings for receiving the lower cylinders of each of the plunger canisters and the flange of the plunger mechanism is secured to the top surface of the mounting plate.

Owner:EMHART GLASS SA

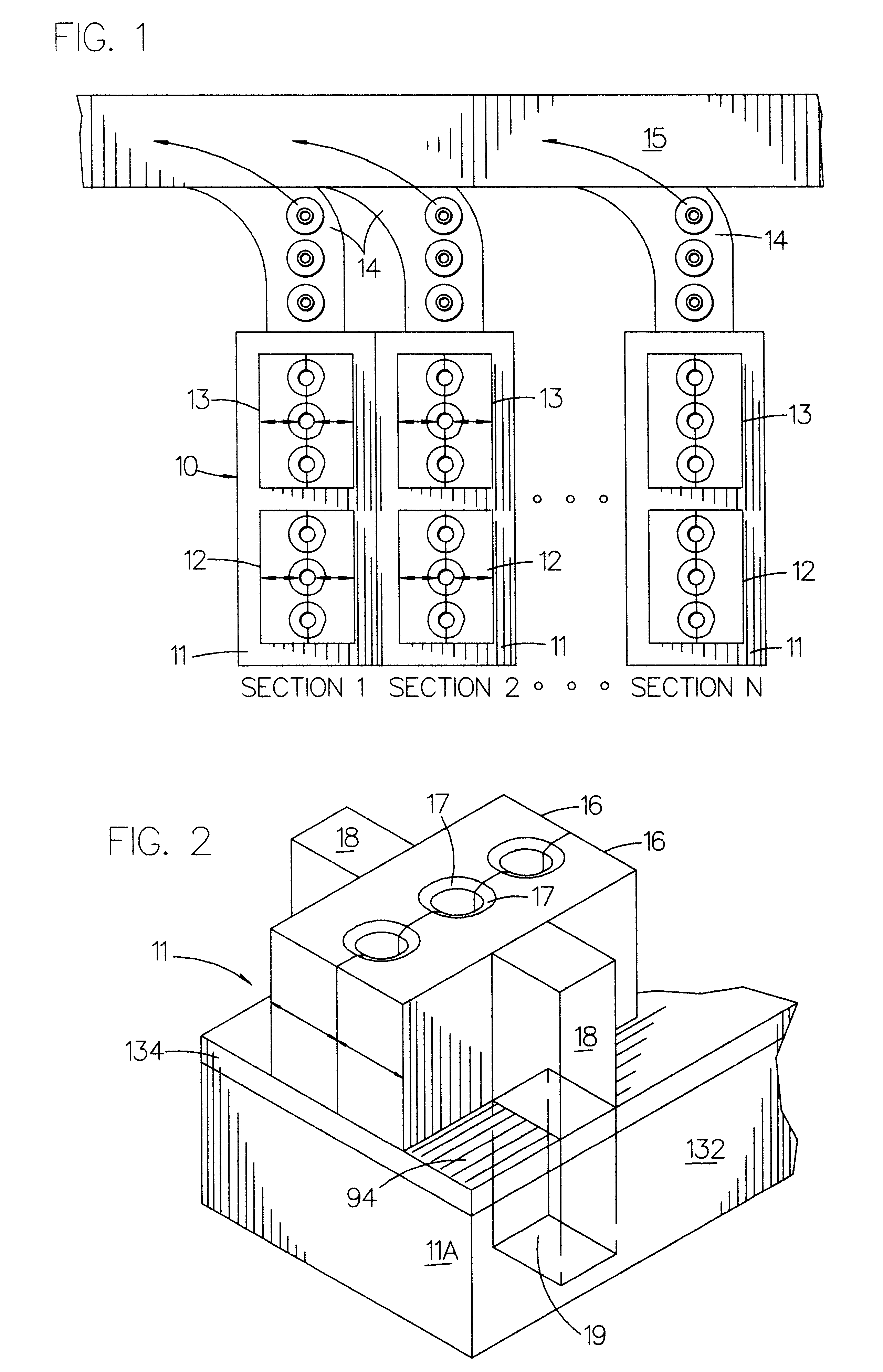

Vacuum system for an I.S. machine

A vacuum system is disclosed for opposed engaged pairs of blow mold halves on a section of an I.S. machine. The system includes a bottom housing which is open at the top and closed by a top plate assembly including a top plate having a vertical opening for each of the opposed pairs of blow mold halves and an annular manifold support portion below the top plate. A vacuum manifold which has a cylindrical inlet conduit and a vertical outlet conduit beneath each of the top plate vertical openings is supported by the annular mold support portion. A vacuum tube slides into the cylindrical inlet conduit and is mounted on the annular manifold portion. The vacuum tube has a hole for communicating with each of the vacuum manifold vertical outlets.

Owner:EMHART GLASS SA

Threadless nut

A glassware forming machine baffle arm assembly that includes a quick-connect / disconnect arrangement mounting a baffle manifold on a baffle arm. The arrangement includes a baffle arm having an aperture, and a baffle manifold having a segment extending through said aperture and permitting rotation of said baffle manifold with respect to said baffle arm. The arrangement also includes a threadless nut, and a bayonet connection between said threadless nut and said baffle manifold segment.

Owner:OWENS-BROCKWAY GLASS CONTAINER INC

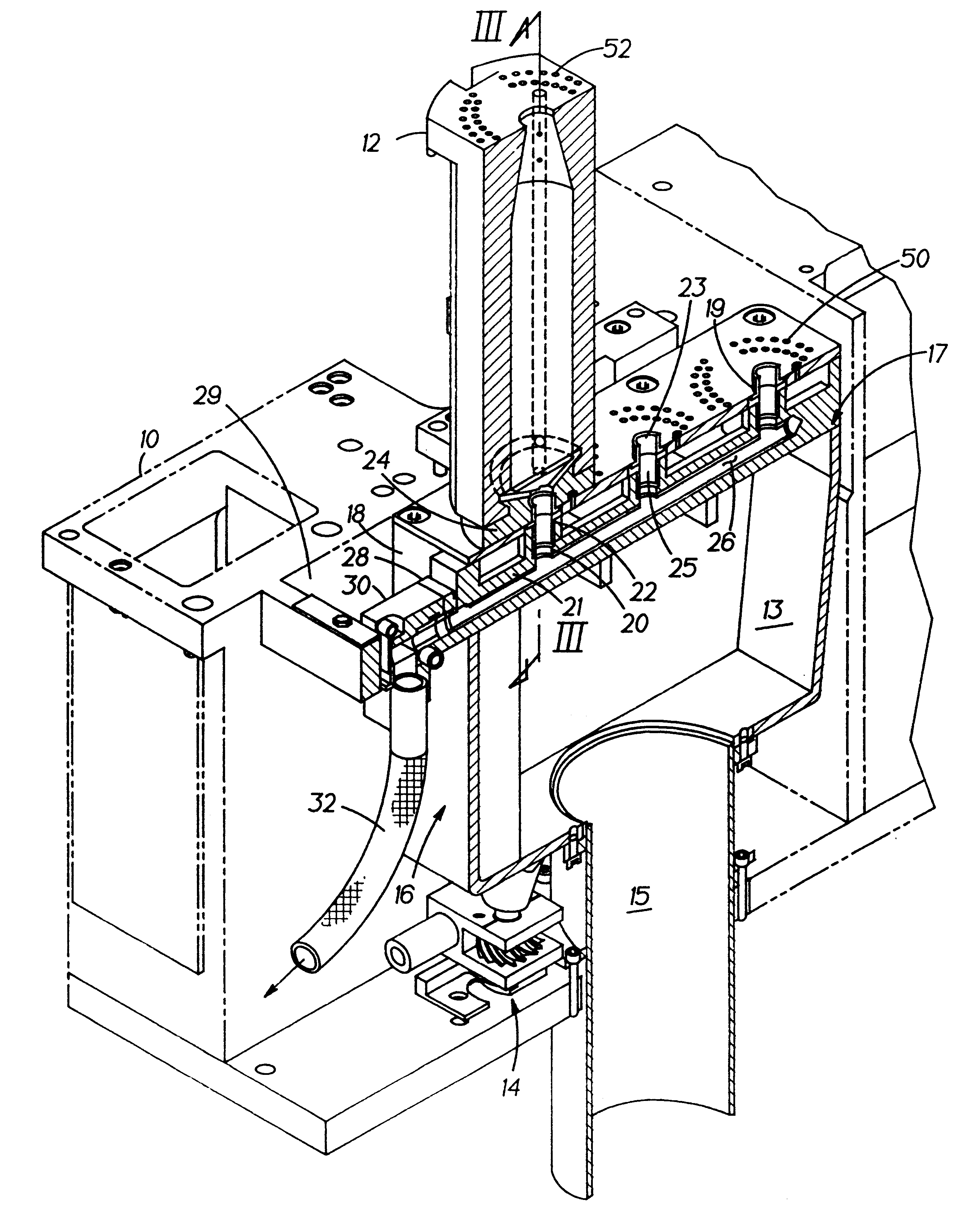

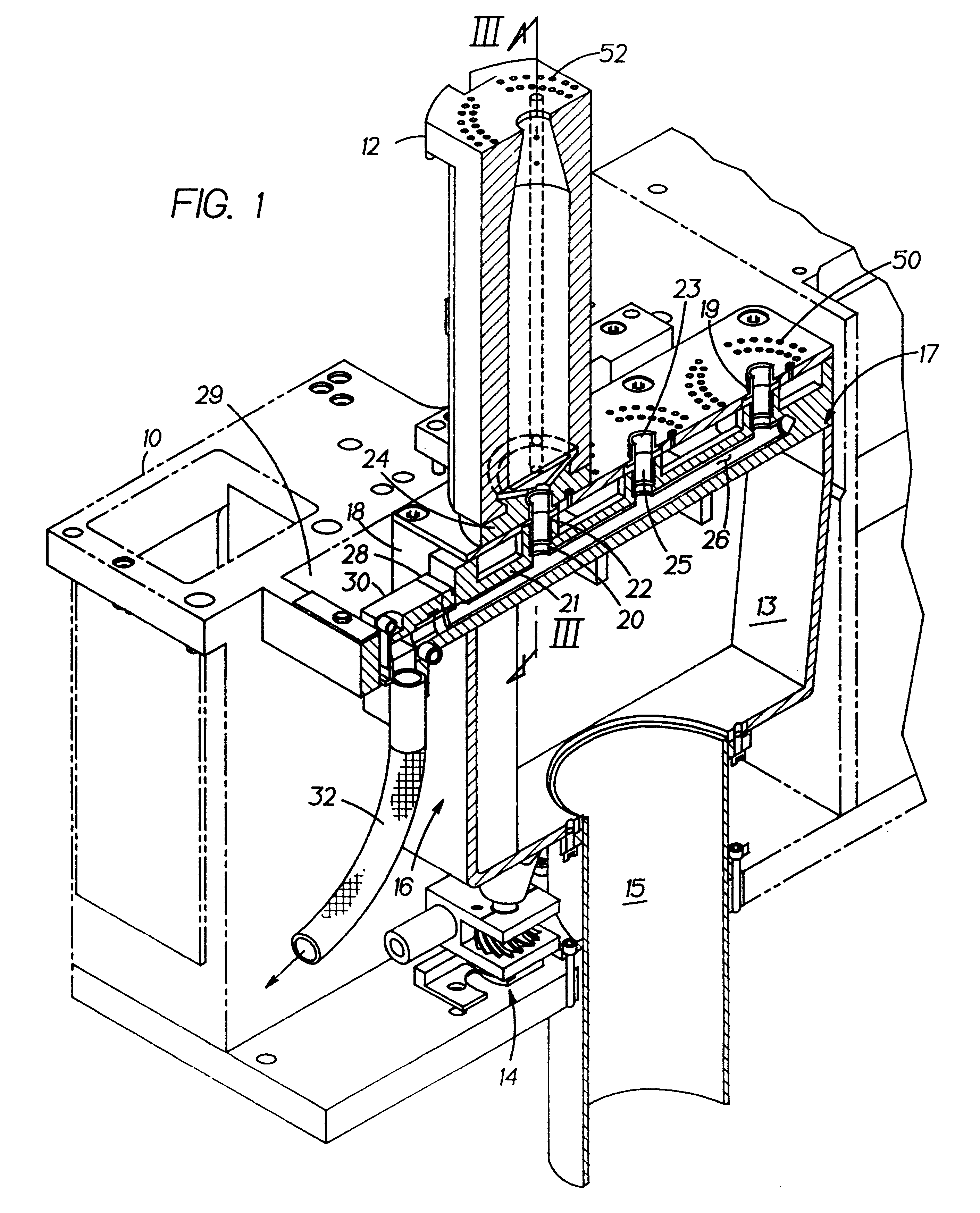

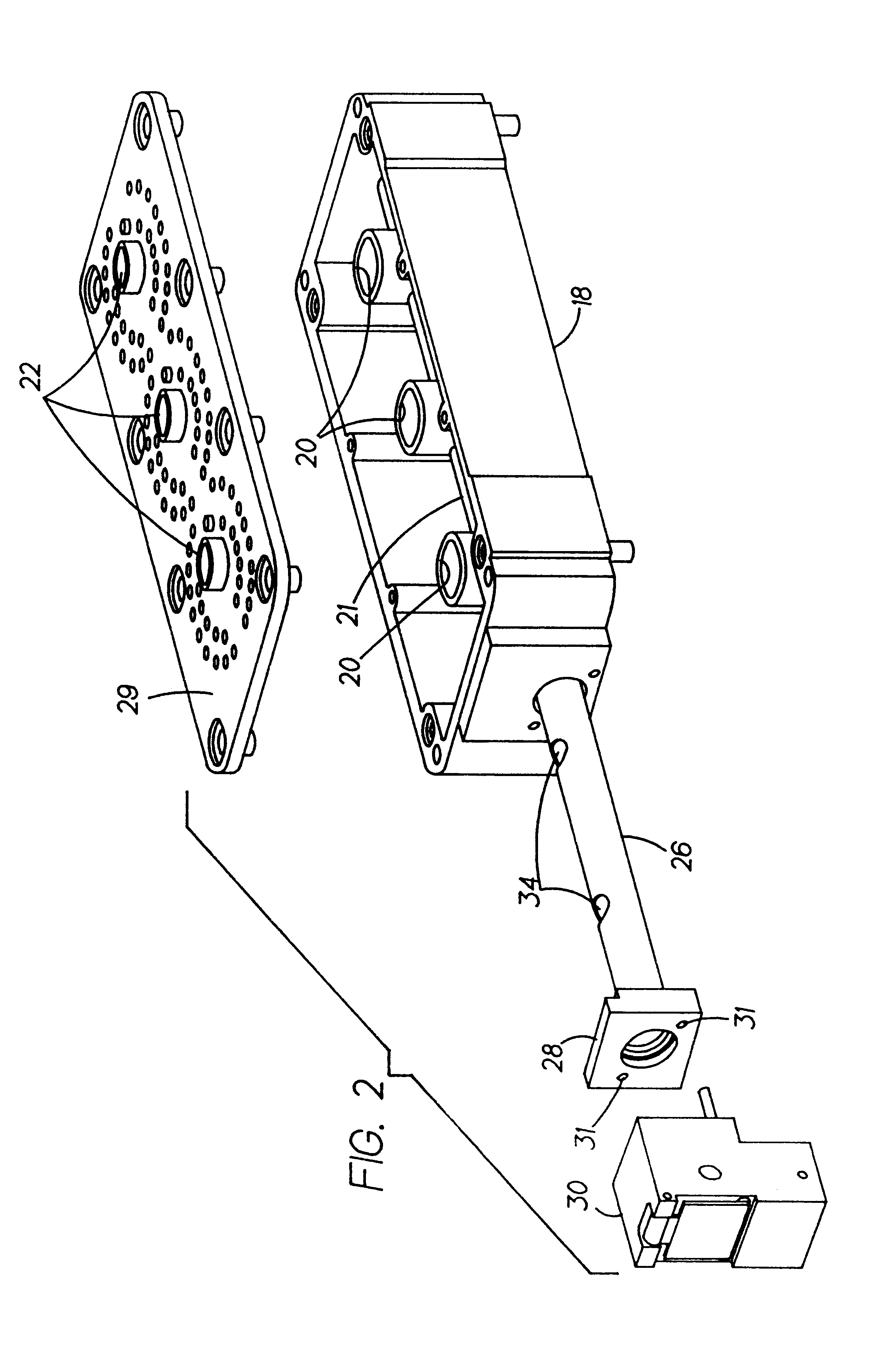

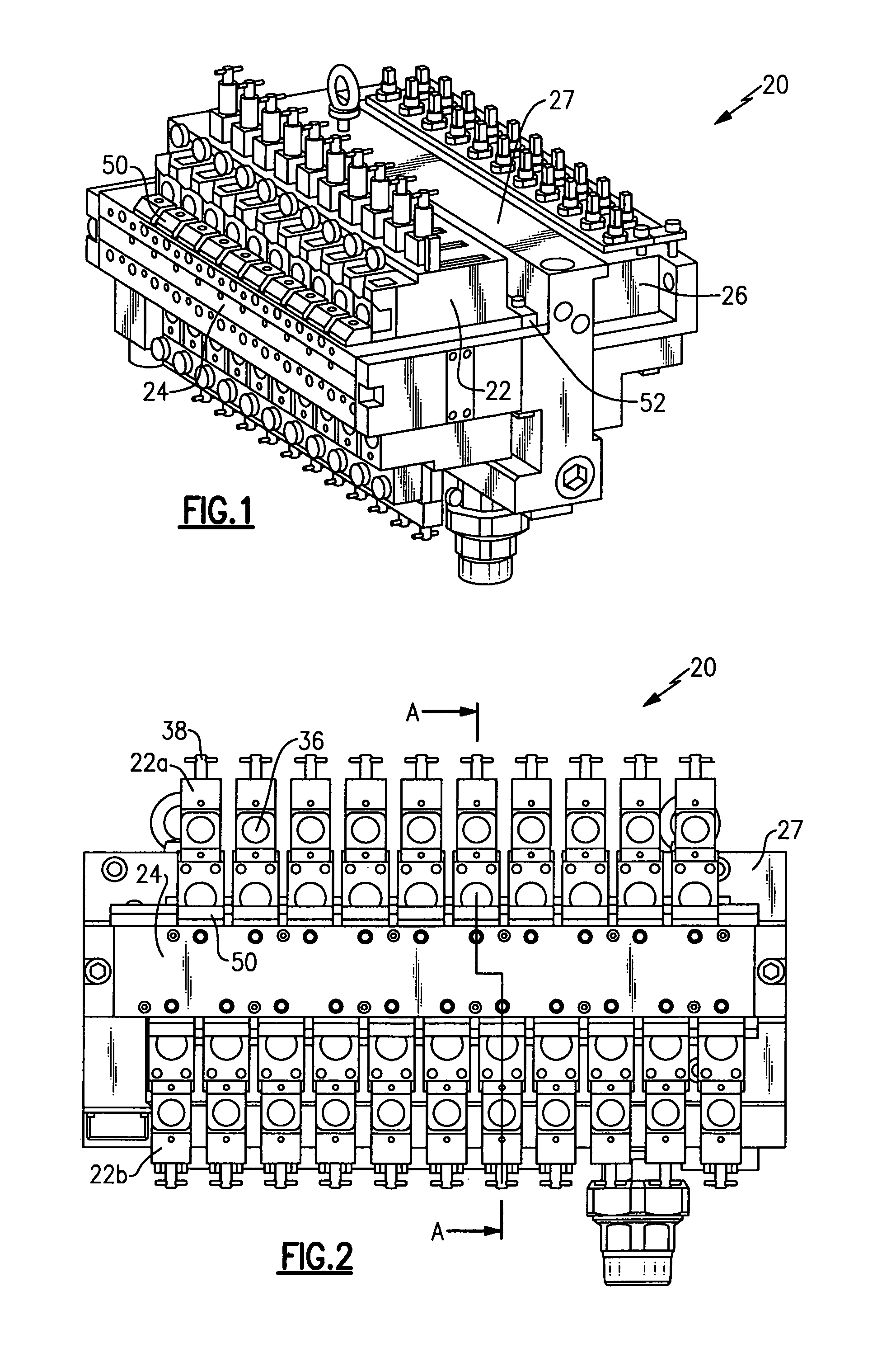

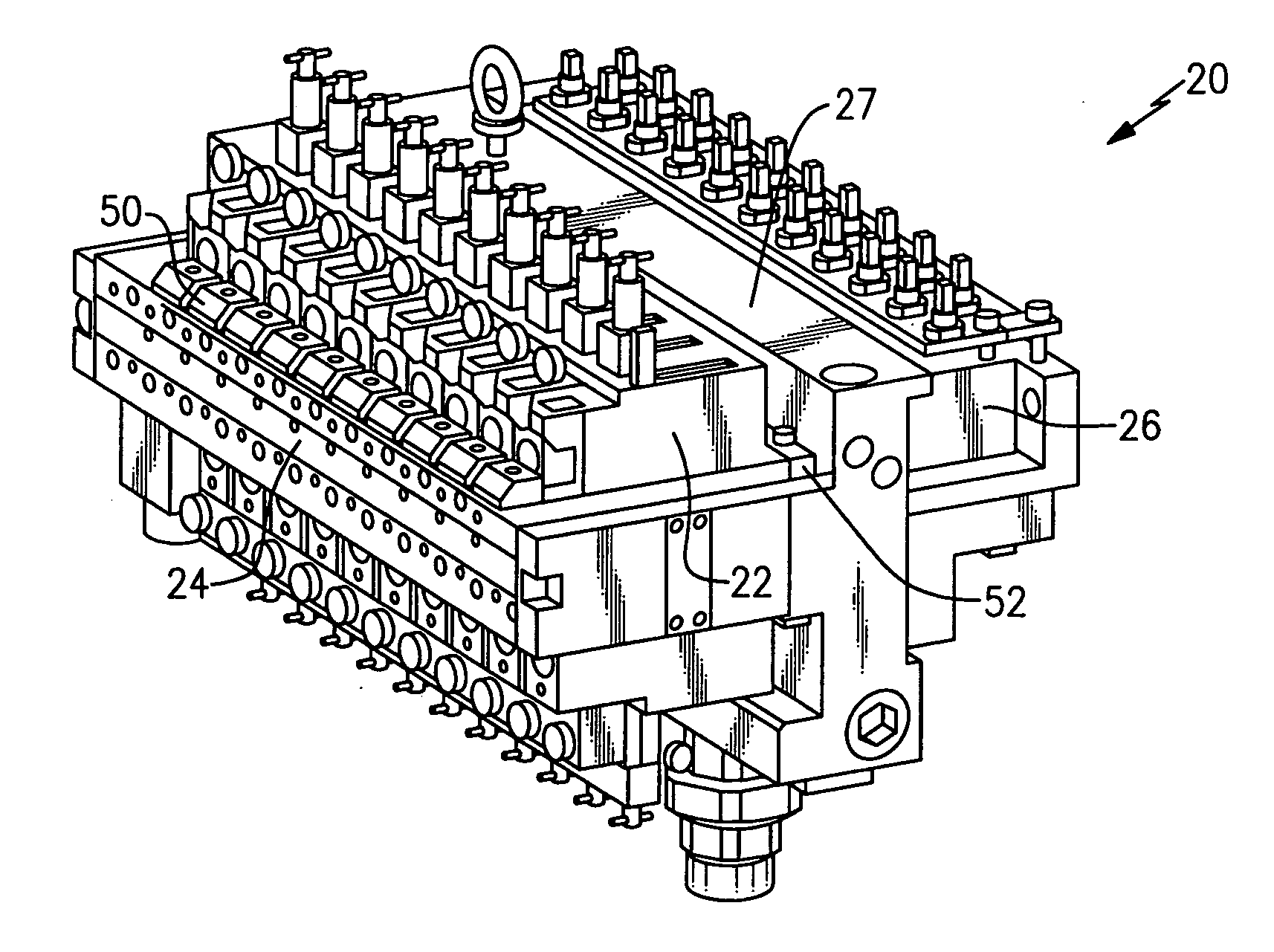

Interchangeable valve for a valve block used with a glass machine

An air valve manifold (20) to be used with a glass making machine includes a base (24) and a valve (22) including a valve body attached to the base (24). The valve body includes a first projection (42) on a front of the valve body and an opposing second projection (44) on an opposing rear of the valve body. A first attachment feature (50) is secured to the front of the base to retain at least a portion of the first projection (42) of the valve body. A second attachment feature (52) is secured to the base to retain at least a portion of the opposing second projection (44) of the valve body.

Owner:ROSS EUROPA

Interchangeable valve for a valve block used with a glass machine

An air valve manifold (20) to be used with a glass making machine includes a base (24) and a valve (22) including a valve body attached to the base (24). The valve body includes a first projection (42) on a front of the valve body and an opposing second projection (44) on an opposing rear of the valve body. A first attachment feature (50) is secured to the front of the base to retain at least a portion of the first projection (42) of the valve body. A second attachment feature (52) is secured to the base to retain at least a portion of the opposing second projection (44) of the valve body.

Owner:ROSS EUROPA

Threadless Nut

A glassware forming machine baffle arm assembly that includes a quick-connect / disconnect arrangement mounting a baffle manifold on a baffle arm. The arrangement includes a baffle arm having an aperture, and a baffle manifold having a segment extending through said aperture and permitting rotation of said baffle manifold with respect to said baffle arm. The arrangement also includes a threadless nut, and a bayonet connection between said threadless nut and said baffle manifold segment.

Owner:OWENS-BROCKWAY GLASS CONTAINER INC

Positive blowing mechanism of bottle making row machine

The invention discloses a positive blowing mechanism of a bottle making row machine. The blowing mechanism is characterized in that a hollow channel is formed in the middle of a blowing head body of a blowing head; a blowing tube is provided; the top of the blowing tube is fixed at the bottom of an air distribution valve in a threaded connection manner; the lower part of the blowing tube penetrates through the hollow channel of the blowing head and reaches the opening of a glass bottle; an annular air exhaust side way is formed between the outer side wall of the blowing tube and the inner wall of the hollow channel; positive blown air enters the positive blowing channel, passes through an inlet channel of a valve core, passes through the air distribution valve and enters the blowing tube to form a blowing channel; the annular air exhaust side way is communicated with exhaust holes through an outlet channel of the valve core so as to form an exhaust channel. The blowing mechanism can sufficiently utilize positive blown air to accomplish blowing of the glass bottle, can avoid energy waste and is beneficial for cooling and heat radiation of the glass bottle.

Owner:ANHUI LONGRUI GLASS PROD CO LTD

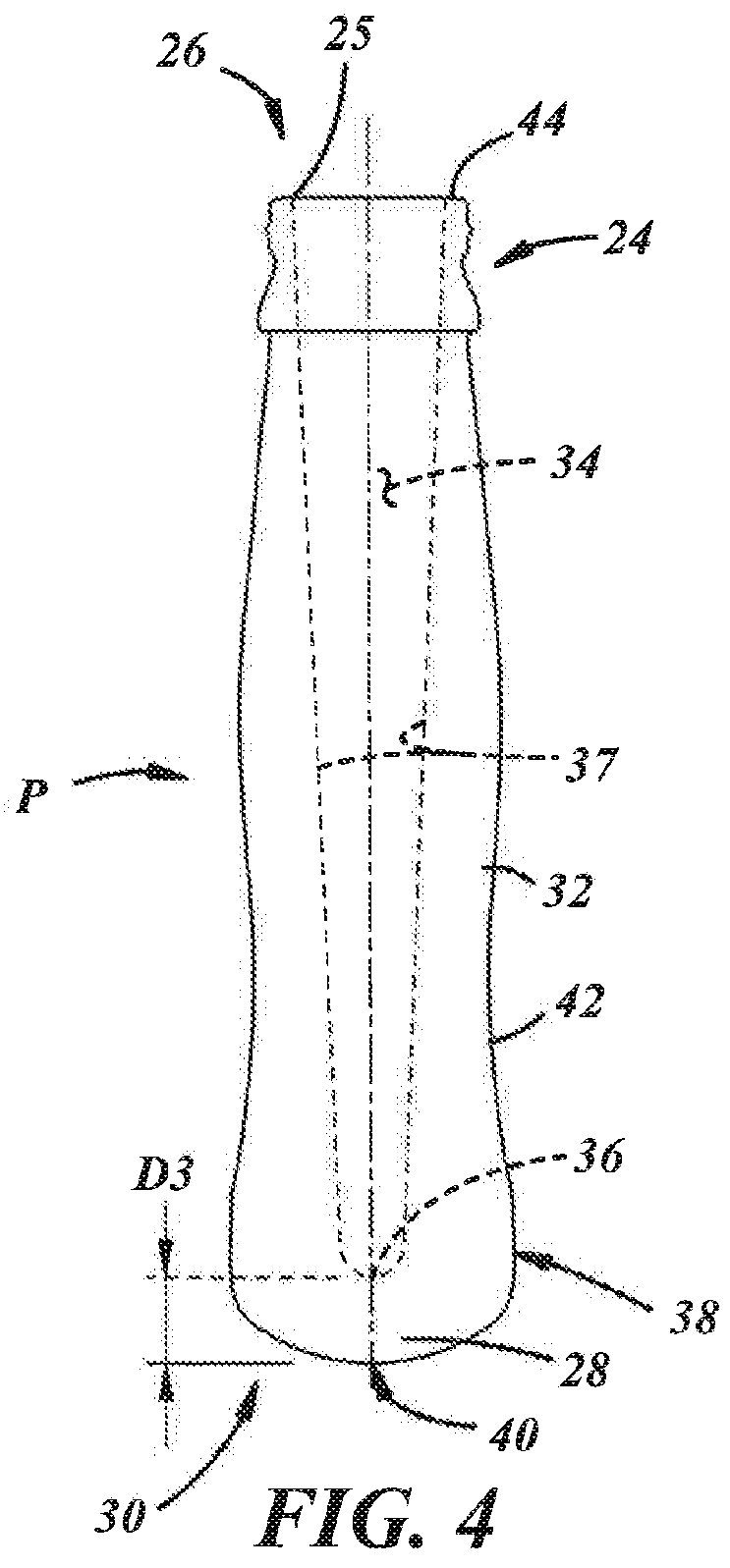

Forming Glass Containers Responsive to Suspended Parison Elongation

A method of and system for forming a glass container, and an apparatus for sensing elongation of a parison in a blow mold of a glassware thrilling machine. A suspended parison is allowed to elongate in a mold along a central longitudinal axis. At least one position of a closed end of the parison is sensed within the mold before the closed end of the parison contacts a transversely extending surface in the mold. A process parameter is adjusted responsive to the sensing step.

Owner:OWENS-BROCKWAY GLASS CONTAINER INC

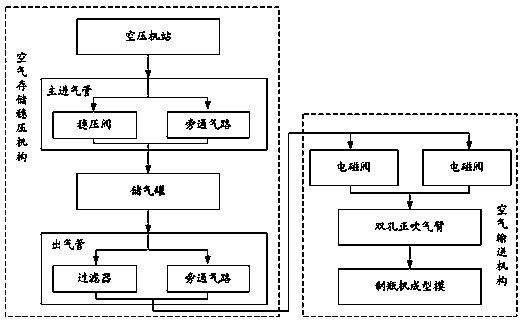

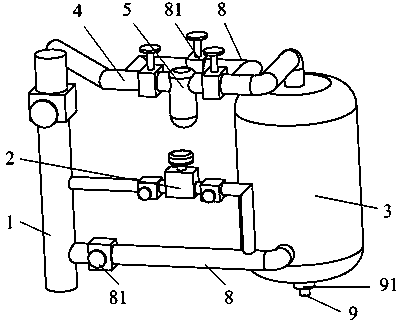

Front air blowing and supplying system of bottle-making machine

The invention discloses a front air blowing and supplying system of a bottle-making machine which comprises an air storing pressure-stabilizing mechanism and an air conveying mechanism, wherein the air storing pressure-stabilizing mechanism comprises a main air inlet pipe, a pressure stabilizing valve and an air storage tank; the main air inlet pipe is communicated with the air storage tank through the pressure stabilizing valve; the air conveying mechanism comprises an air outlet pipe communicated with the air storage tank; a filter is arranged on the air outlet pipe; the other end of the air outlet pipe is communicated with electromagnetic valves; the electromagnetic valves are communicated with a double-hole front air blowing arm arranged on a forming die through rubber tubes. According to the invention, the independent air storage tank is used for supplying air for a front air blowing line of the bottle-making machine, so that the air pressure is not affected by air used by other mechanisms, and the air pressure is stable; the main air inlet pipe is communicated with the air storage tank through the pressure stabilizing valve, so that the situation that the air source of the air storage tank is stable and not affected by the fluctuation of the air pressure of the main air inlet pipe.

Owner:DAYE HUAXING GLASS

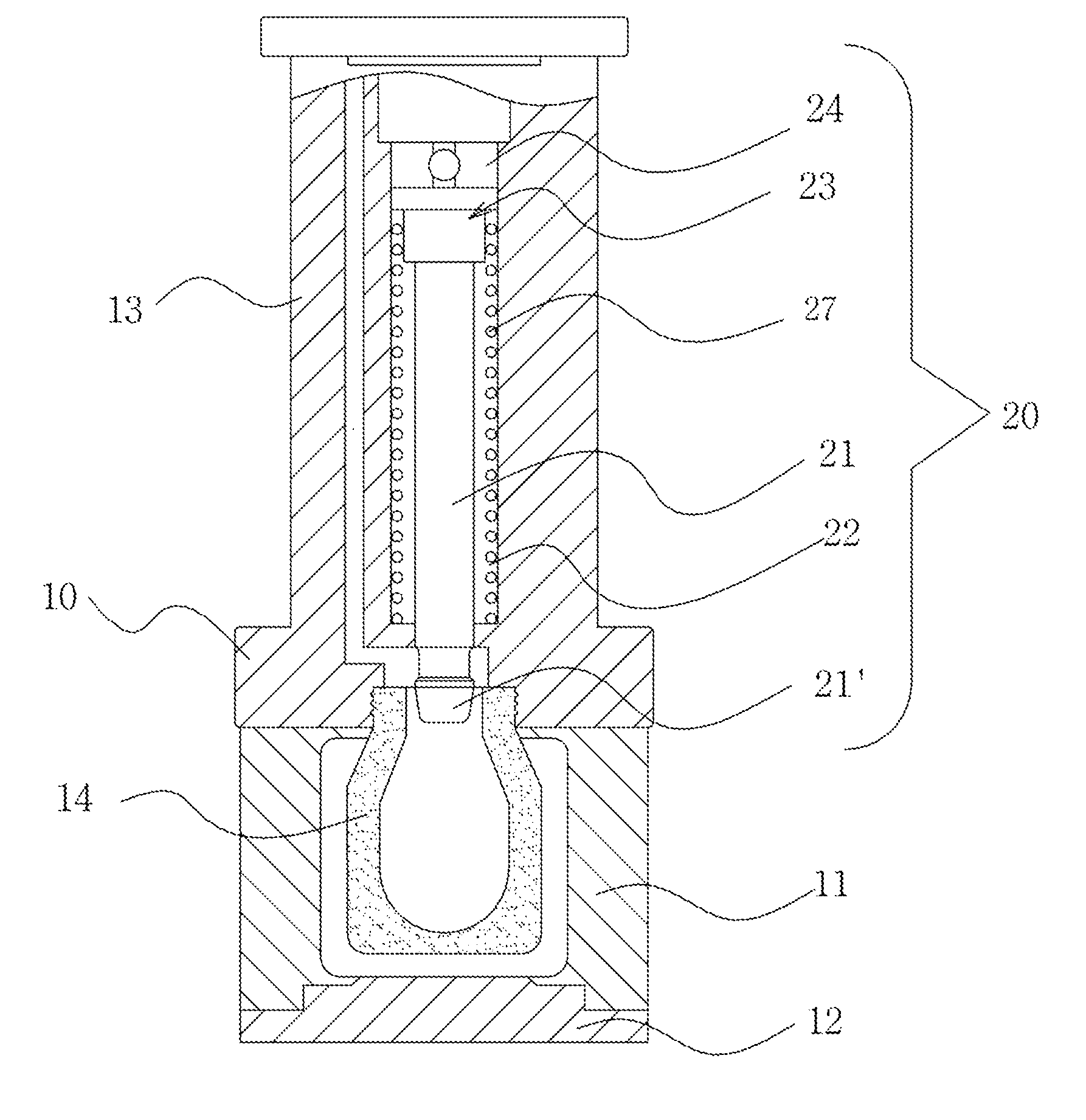

Apparatus for blow molding glass bottle, and molding method therefor

The present invention relates to an apparatus for blow-molding a glass bottle, and more particularly, to an apparatus for blow-molding a glass bottle in which molding air is injected into a pair of mold bodies such that molten glass accommodated in the mold bodies is formed into a glass bottle and a groove is formed at the center of the inner side of the bottom surface of the glass bottle. The apparatus for blow-molding a glass bottle of the present invention uses a blow mold (10) configured to include: a pair of mold bodies (11) forming a tubular body; a base mold (12) which molds the bottom surface of the glass bottle; and a blowing head (13) which are arranged in the upper portions of the mold bodies (11) and into which molding air is injected such that the glass bottle is expanded after primary molding and closely contacts the inner walls of the mold bodies (11) and the base mold (12). A groove molder (20) is provided on the inner circumferential edge portion of the blowing head (13) such that a groove portion (15) can be molded on the inner side of the bottom surface of the glass bottle (14).

Owner:PACIFIC GLAS

Method for manufacturing glass container

InactiveCN108698875AStable interior spaceBeautiful appearanceBlow headsBottlesInterior spaceEngineering

Provided is a method for manufacturing a glass container with which a glass container having a distinctively shaped inner space and excellent aesthetic appearance can be manufactured in good yield. The method for manufacturing a glass container includes steps (A) to (E): (A) a step of introducing a gob into a mold through a funnel; (B) a step of blowing air into the mold through the funnel, bringing a plunger disposed on a side opposite the side to which the funnel is fitted in contact with the gob, separating the plunger from the gob, and forming a recess on the surface of the gob; (C) a stepof removing the funnel from the mold and fitting a baffle to the mold; (D) a step of blowing air from the plunger, and forming an inner space inside the gob with the recess as a starting point whilesimultaneously forming an outer shape by pressing the outer side of the gob to a molding surface of the mold to obtain a glass container of the final shape; (E) a step of transferring the glass container of the final shape to a cooling mold and cooling the same.

Owner:KOA GLASS CO LTD

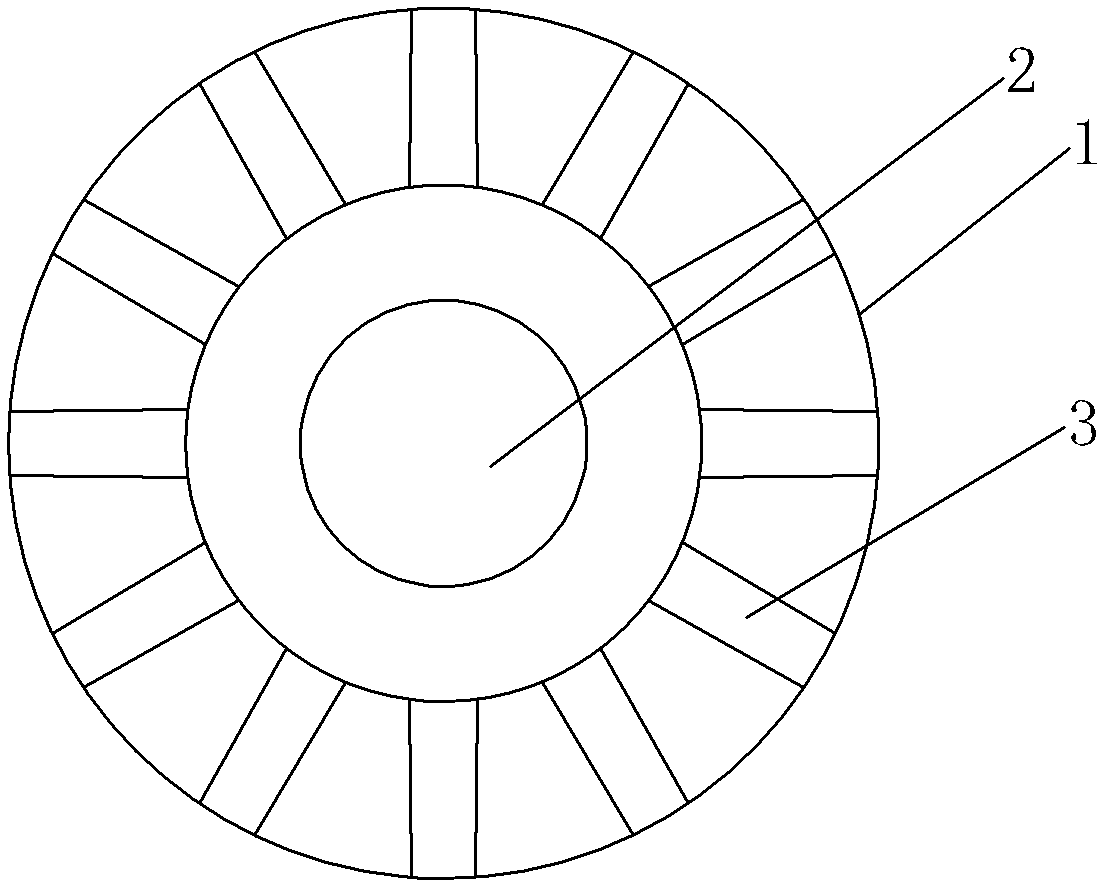

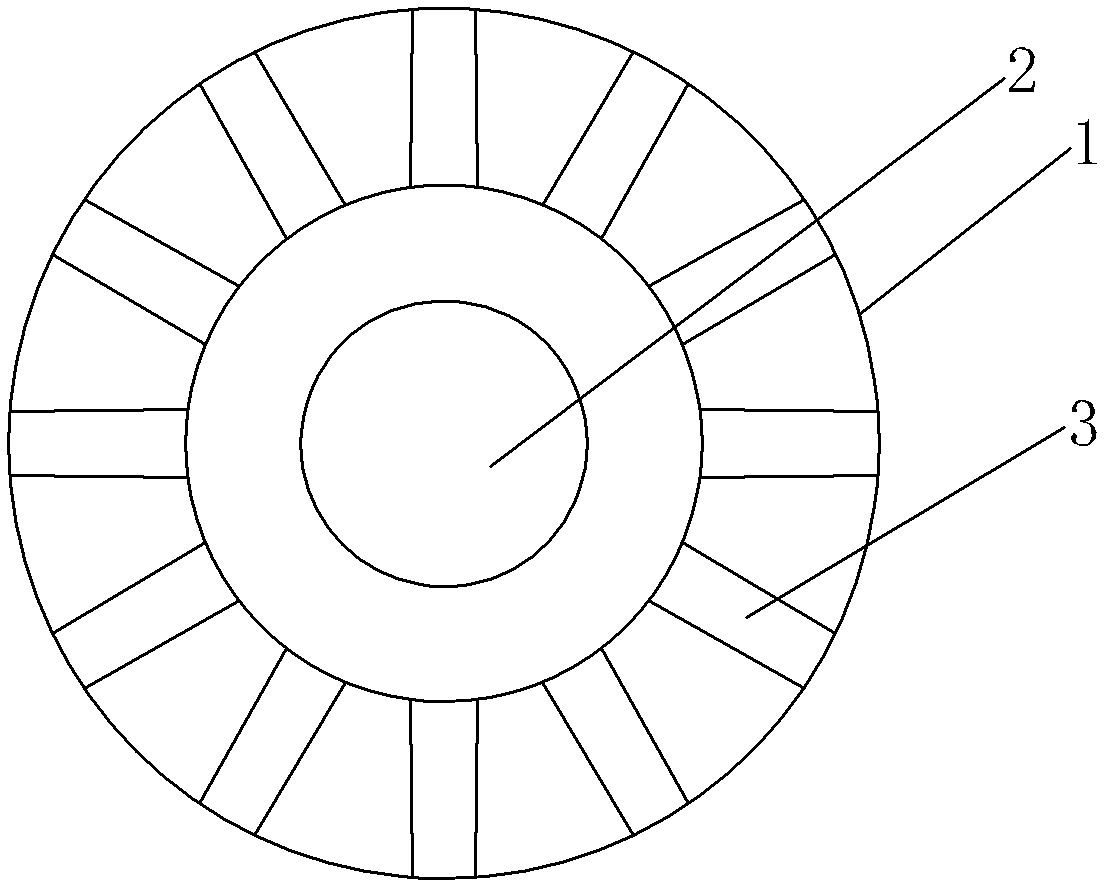

Blowing head for forming glass products

ActiveCN106746504AQuality improvementAvoid defectsBlow headsGlass productionInlet channelEngineering

The invention relates to a blowing head for forming glass products, the blowing head for forming glass products comprises a nozzle body and a blowing tube, the nozzle body is internally provided with an air inlet channel, the blowing tube is installed in an air inlet channel, the head end of the blowing tube is provided with a blowing head, the blowing closes a space between the blowing tube and the air inlet channel, the nozzle body is uniformly provided with a plurality of vertical balanced airways outside the air inlet channel, the lower part of the nozzle body is provided with a cavity, the cavity is internally provided with a ventilation groove, the ventilation groove and the vertical balanced airways are communicated, a current sharing ring is arranged inside the cavity, a plurality of balanced air holes are evenly arranged on the ring body of the current sharing ring, the balanced air holes and the cavity are communicated, the nozzle body is provided with a transverse air exhausting hole, an inlet of the transverse air exhausting hole is communicated with the air inlet channel, an outlet of the transverse air exhausting hole is provided with an air exhausting device, and the air exhausting device controls the air exhausting amount of the air exhausting hole; and in a glass product forming process, through controlling of the air exhausting amount of the air exhausting hole, internal and external air pressures of a bottle mouth can be controlled, the pressure at the bottle mouth can effectively be balanced, bottle mouth cracks and other problems can be prevented, and the quality of the glass products can be improved.

Owner:常熟市兄弟玻璃模具有限公司

Process and machine for manufacturing a hollow article made of thin glass

The invention relates to a process for manufacturing a hollow glass article comprising at least one thin side wall (42), in which process:at least one parison of molten glass is introduced into a blank mold,a blank of the article is formed in the blank mold from said parison,the blank of the article is transferred into a finishing mold, andthe article is formed in the finishing mold.During forming of the article, excess glass is directed towards the exterior of the side wall of the article to form a convex bulge (43) and the bulge is removed to give the side wall of the article a substantially constant thickness.The invention also relates to a corresponding machine and product.

Owner:POCHET DU COURVAL

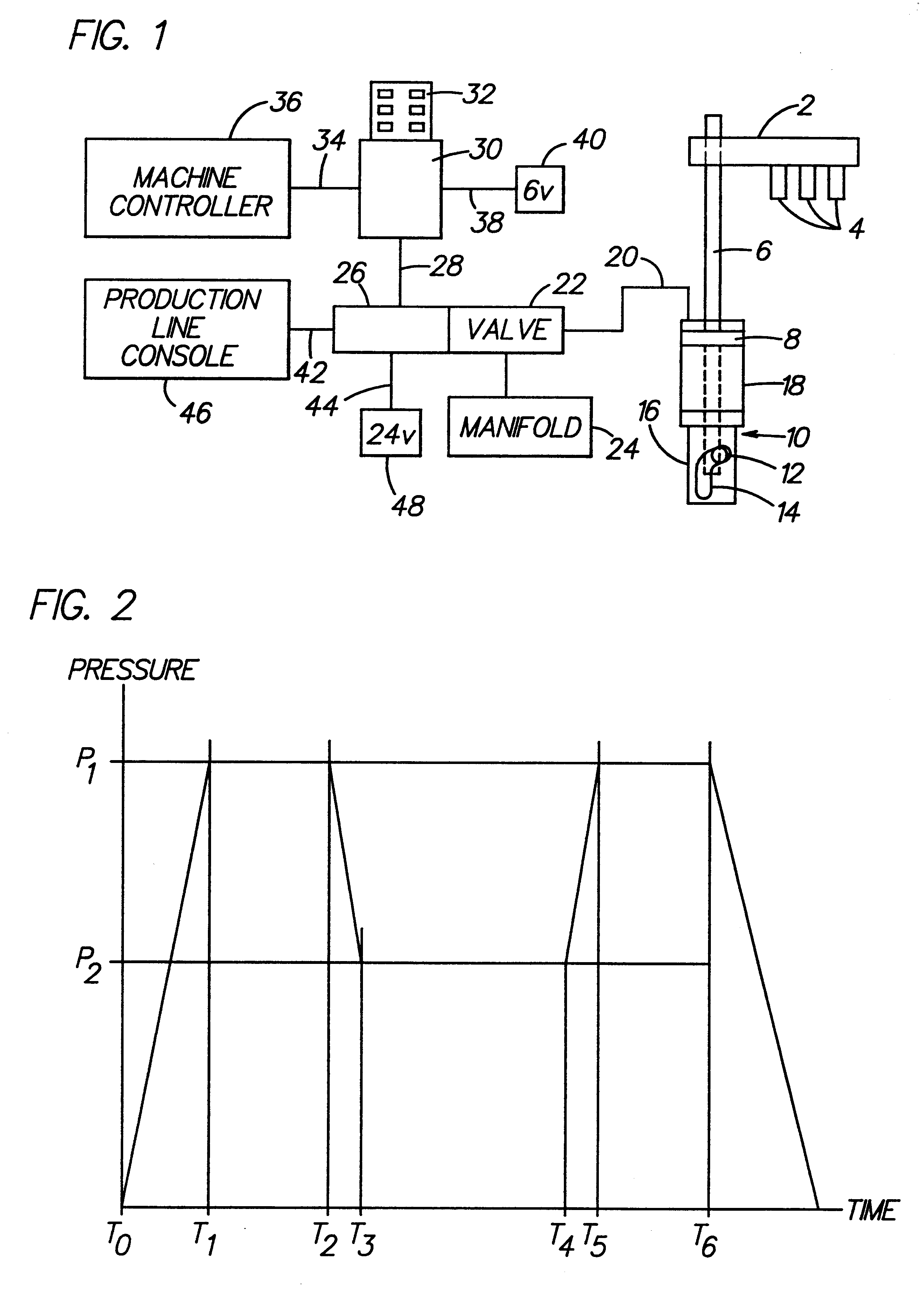

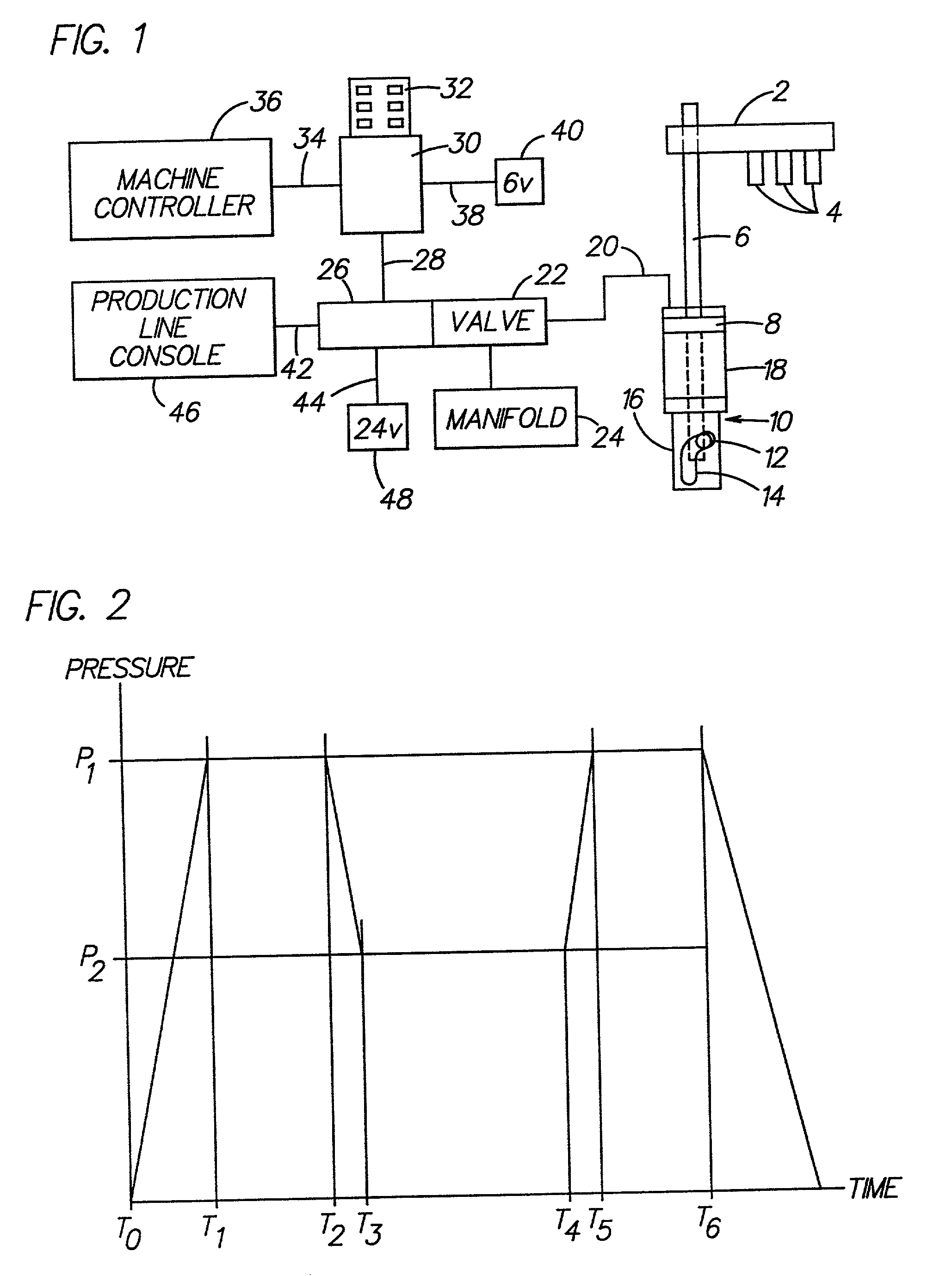

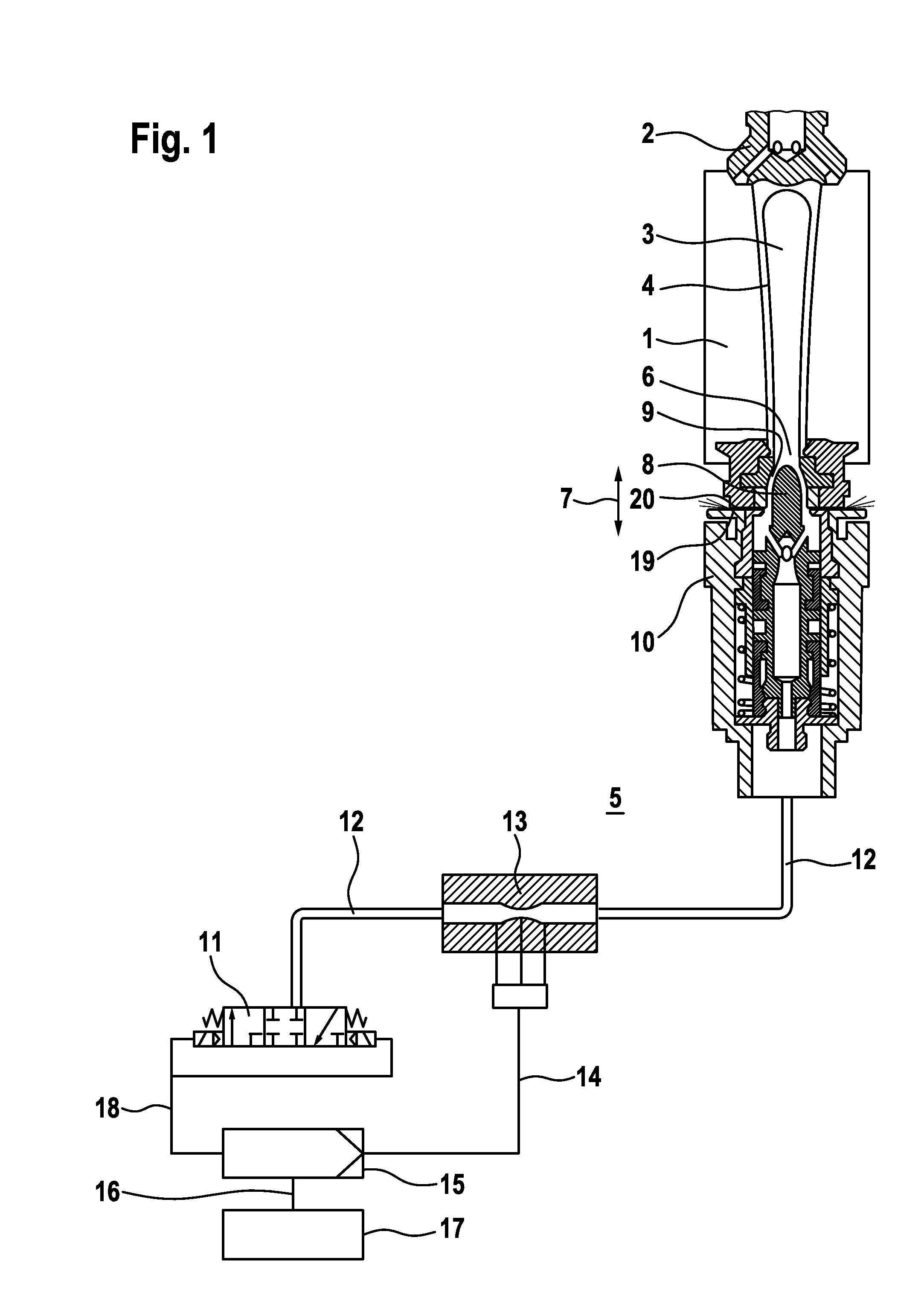

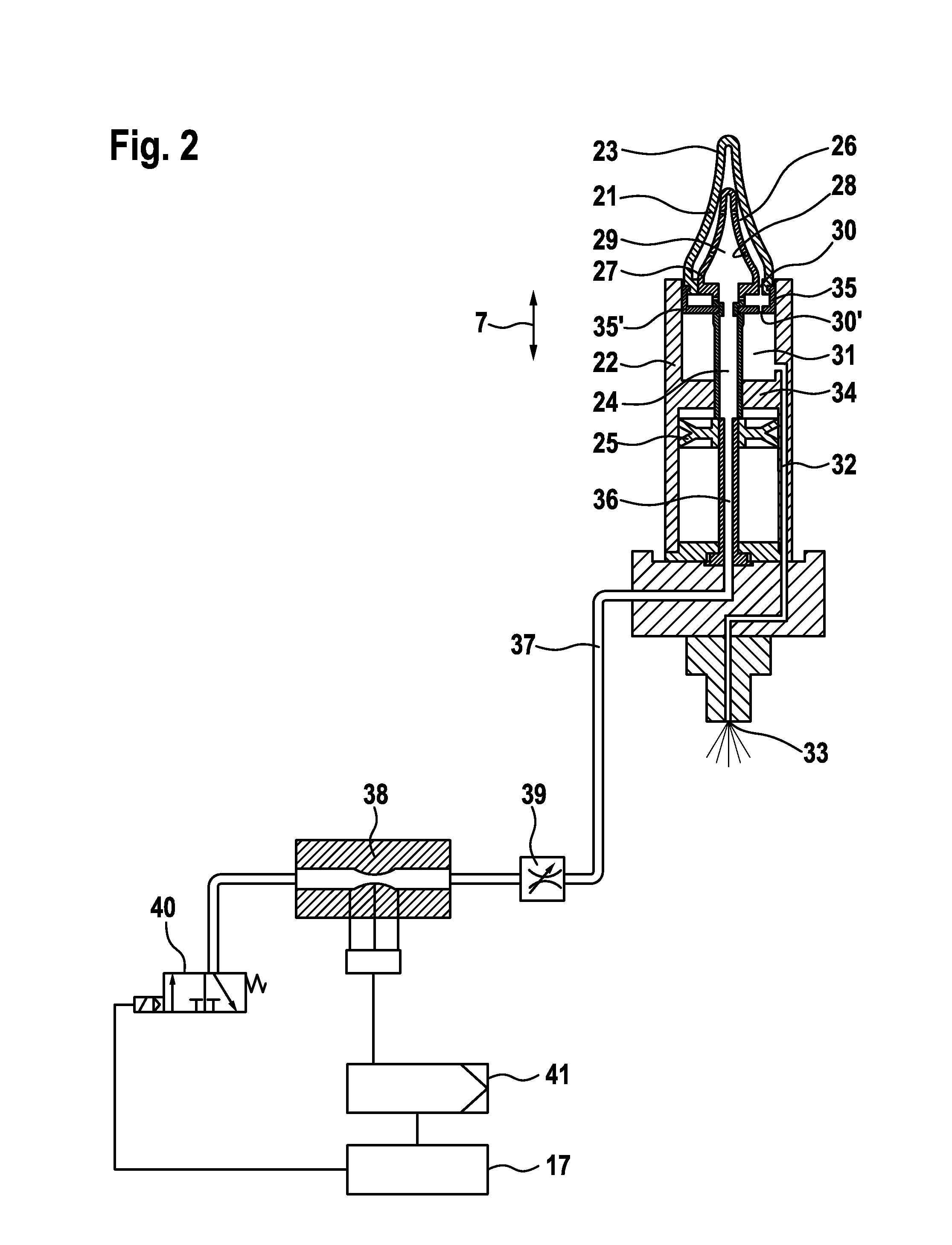

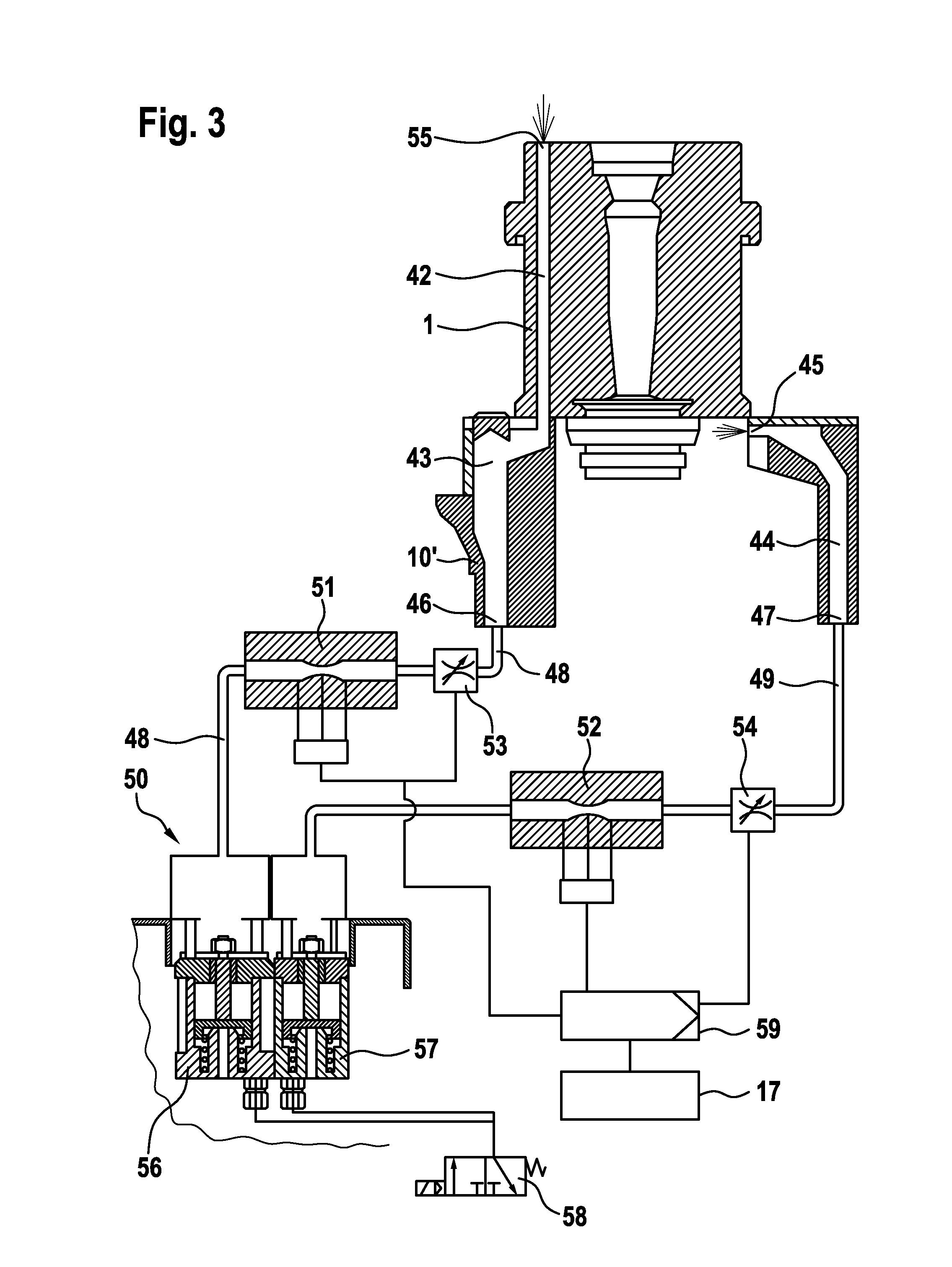

Method and apparatus for controlling the blowing air and cooling air of an I.S. glassware forming machine

ActiveUS9458042B2Minimize manual interventionBlowing machine gearingsBlow headsThermodynamicsMolding machine

In order to achieve reproducible operating parameters of the shaping process of an I.S. glassware forming machine, a central control of all blowing and cooling air flows is proposed, in which in accordance with sections a volume flow of the cooling air including the inlet-side and outlet-side temperatures thereof are measured by means of a measuring device (51, 52) and a heat loss which is associated with the section is ascertained. The heat thus removed in sections is compared with standard values, wherein in the event that tolerance zones are exceeded a variation of the volume flow is initiated by the actuation of restrictors (53, 54). All of the sections of the glassware forming machine which are intended for passage of cooling air are monitored in this way, namely on the basis of a determinable heat loss, so that uniform cooling conditions, which are adapted to a mathematical model, and in this respect a reproducible product quality are achieved.

Owner:HEYE INT

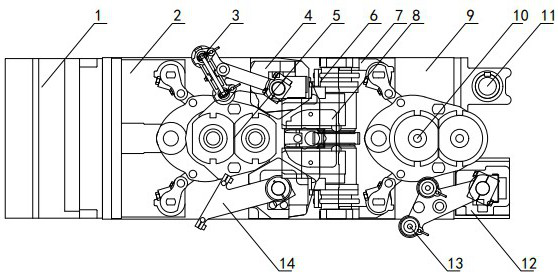

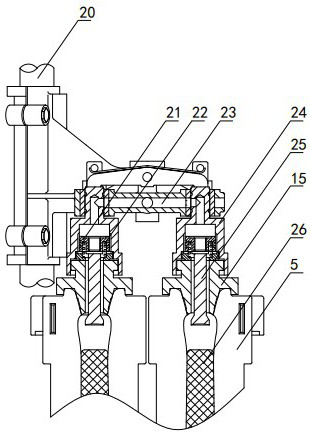

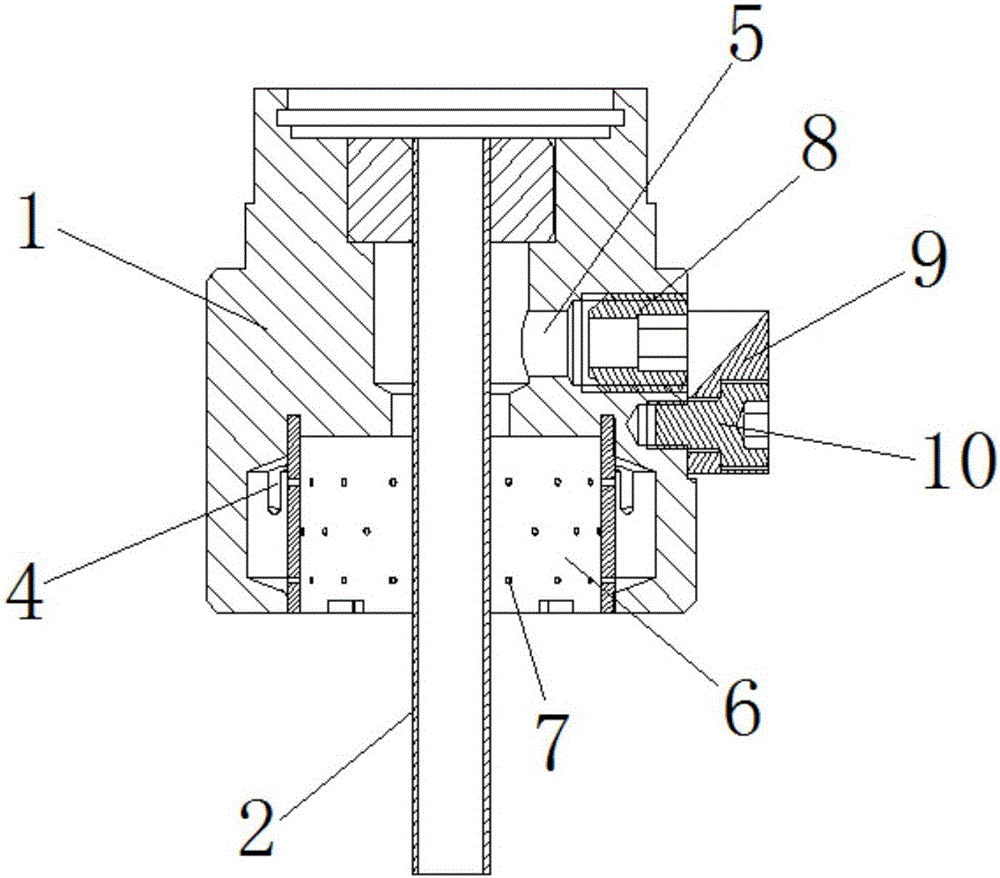

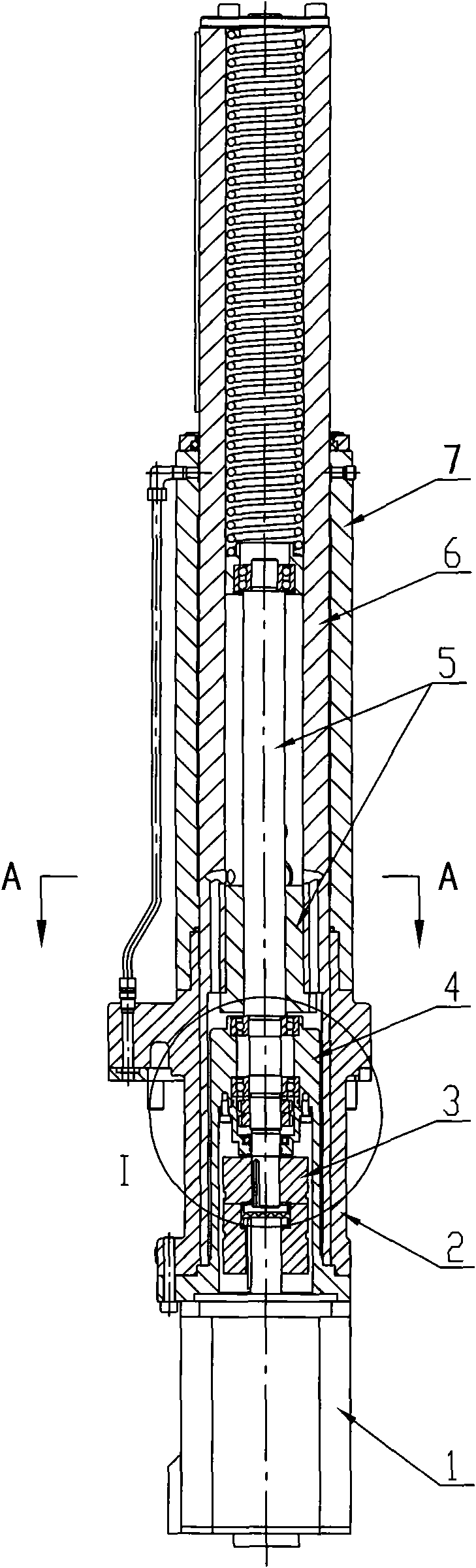

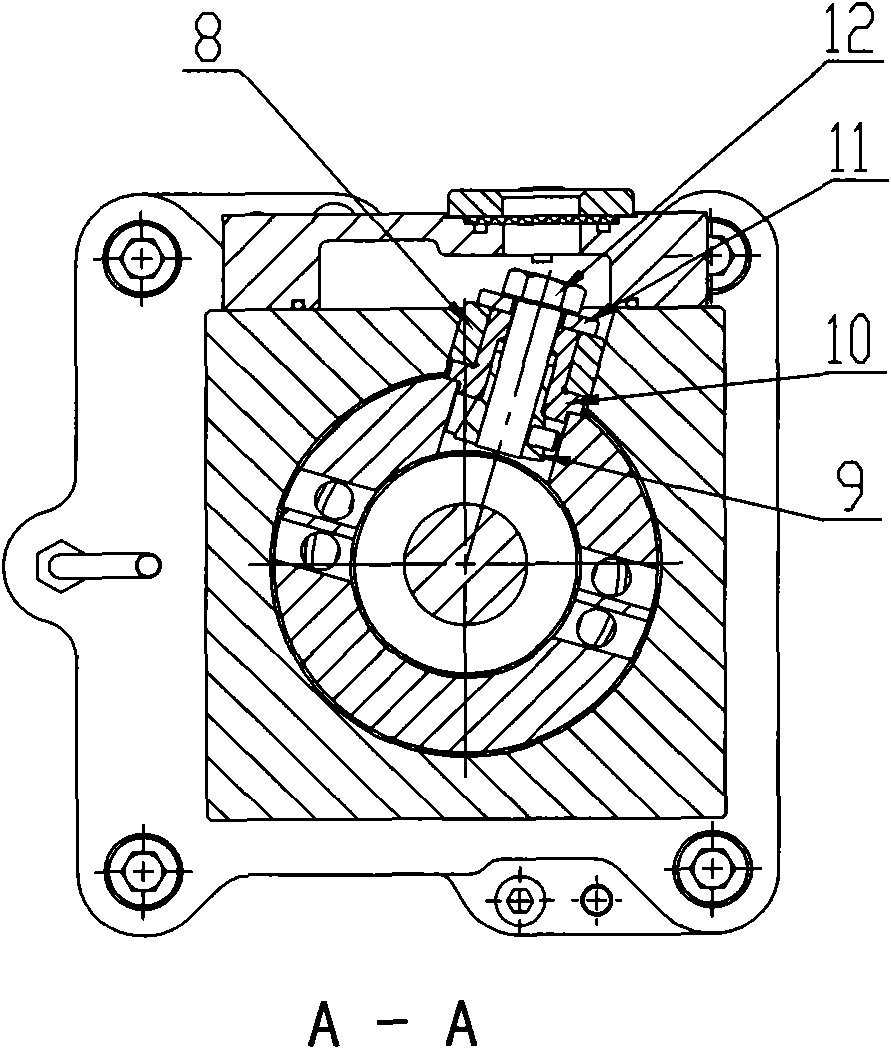

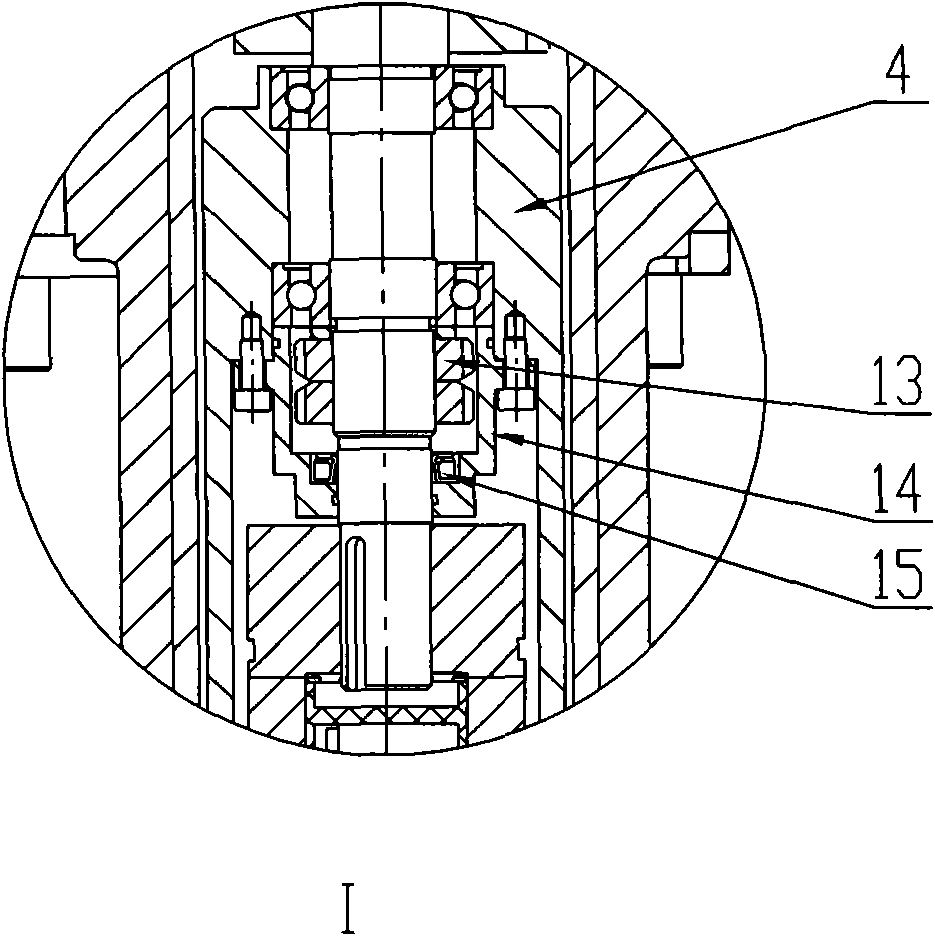

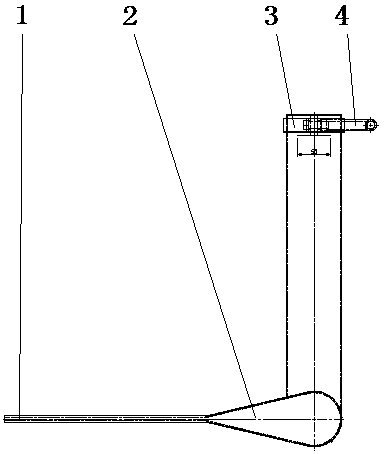

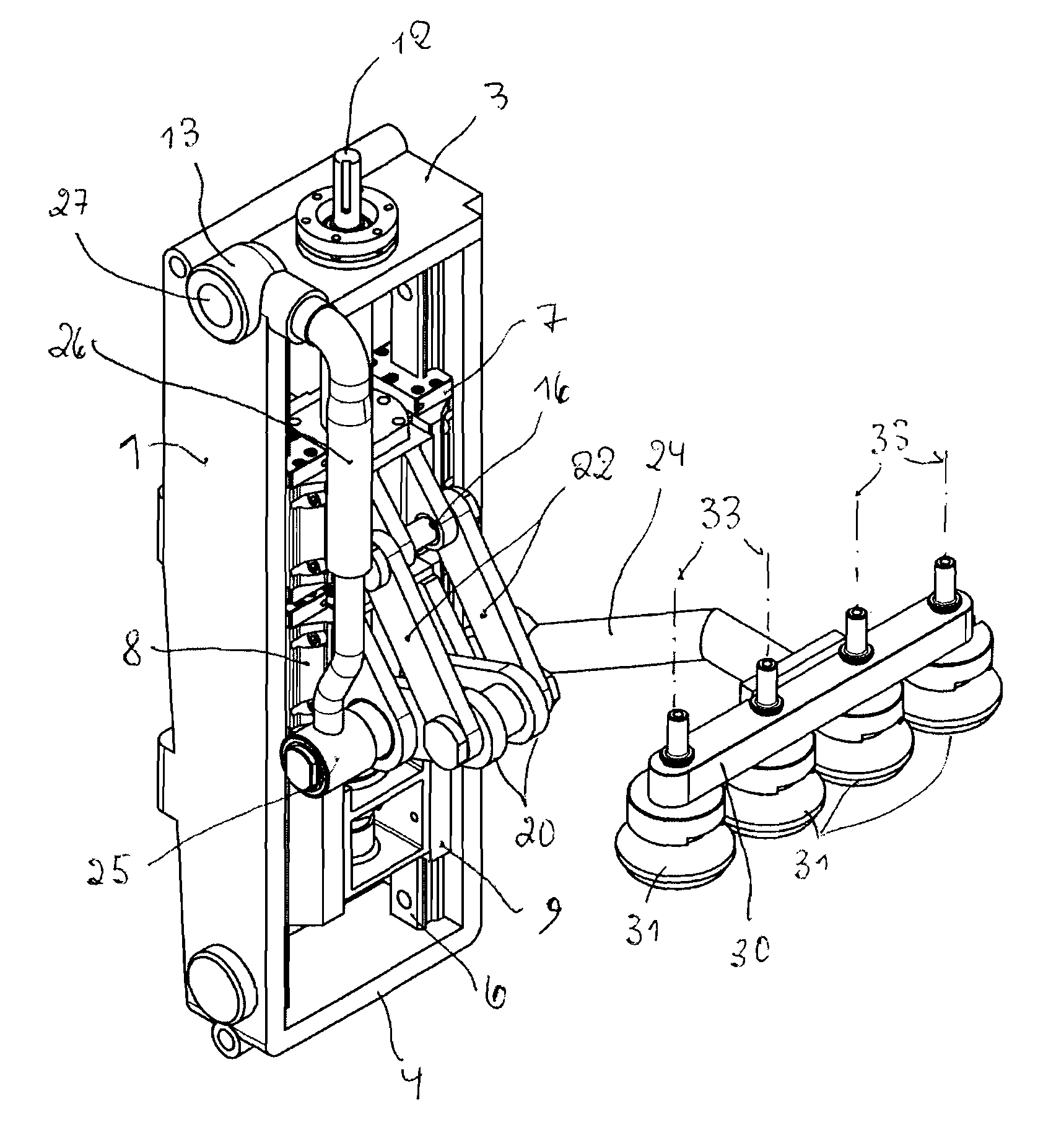

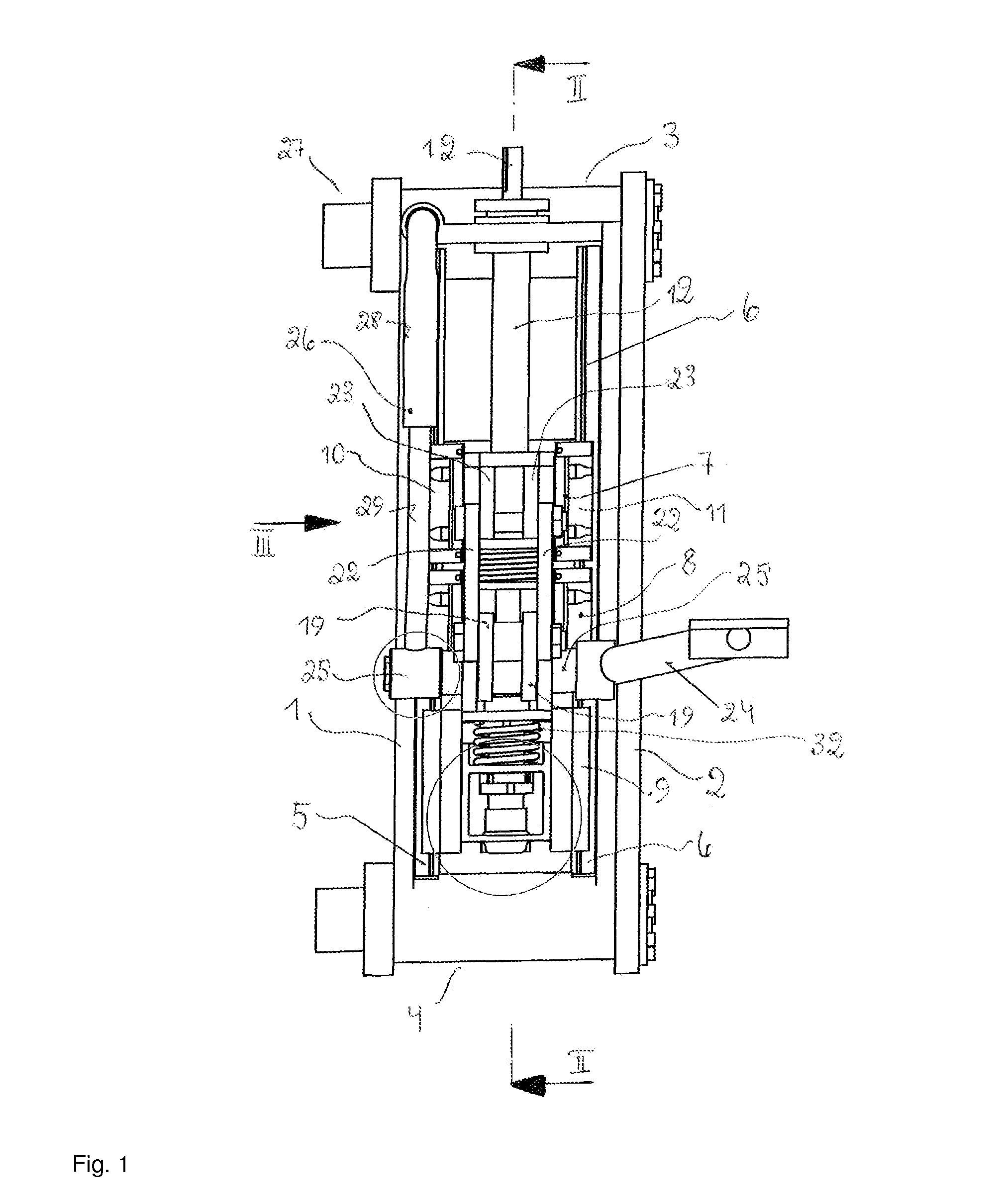

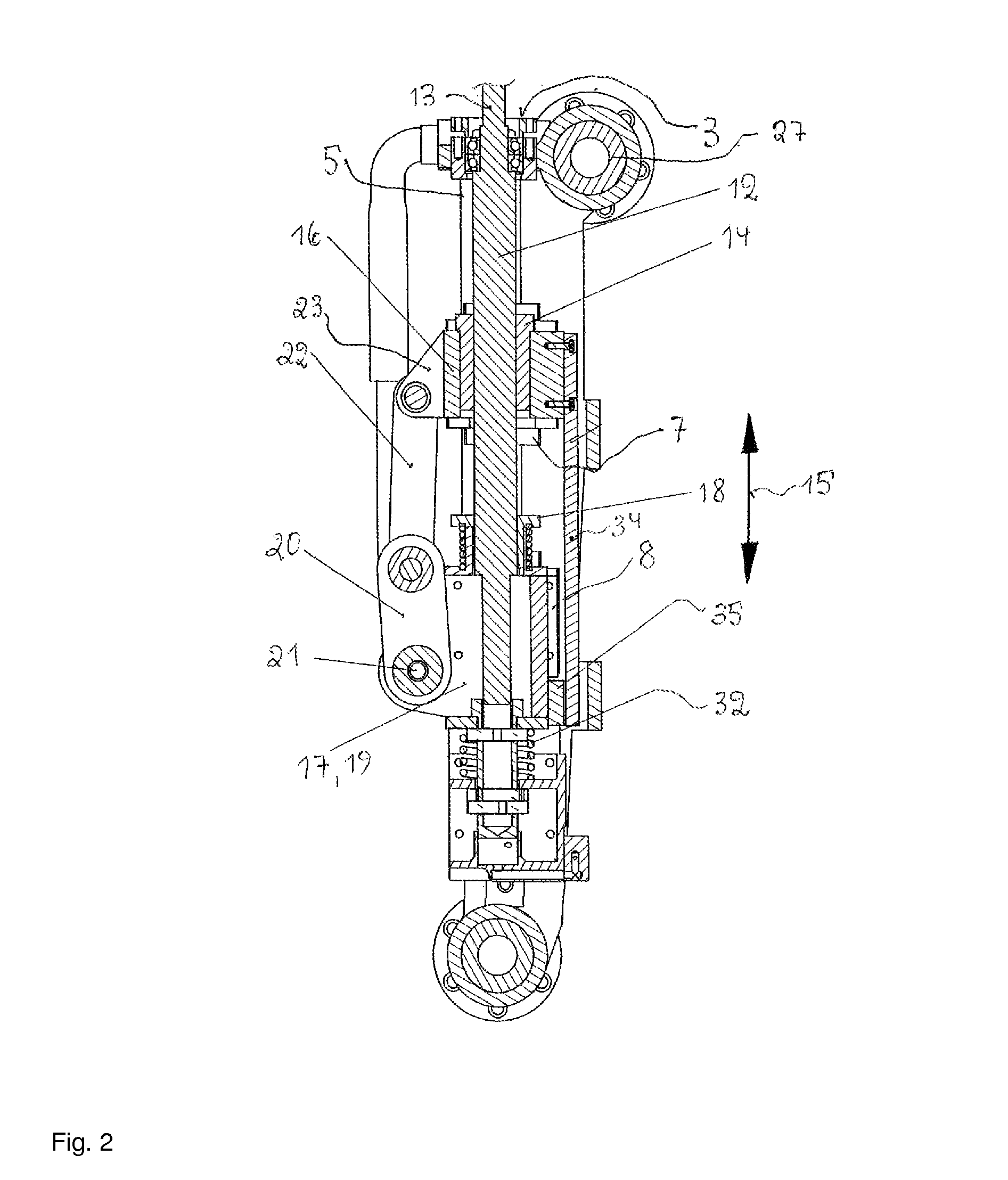

Servo puffing and direct-blowing mechanism

The invention relates to a servo puffing and direct-blowing mechanism, belonging to the field of glass machinery. The mechanism comprises a servo motor (1), a base (2), a coupler (3), a bearing block (4), a ball screw pair (5), a main shaft (6), a cam (7) and a cam roller assembly, wherein the upper part of the base (2) is connected with the lower part of the cam (7), the bearing block (4) and the coupler (3) are installed in the hollow base (2), the main shaft (6) is hollow, the ball screw pair (5) is installed in the central cavity of the main shaft (6), the cam (7) is a rectangular hollow body, the main shaft (6) is installed in a central round hole, the front surface of the cam (7) is provided with a cam slot, and the cam roller of the cam roller assembly is installed in the cam slot. The mechanism is operated by being driven by the rotation of the servo motor instead of compress air to drive the piston, thereby lowering energy consumption, reducing noise, improving the operability and safety of the mechanism and decreasing maintenance complexity.

Owner:SHANDONG SANJIN GLASS MASCH CO LTD

Tuyere

The invention discloses a tuyere. An air inlet end is perpendicular to an air outlet end, the diameter of the air inlet end is smaller than that of the air outlet end, the air inlet end half penetrates the air outlet end, a hot molten end at the air outlet end is directly connected with one end of an air inlet pipe at the air inlet end and is in a water drop shape, the tip of the hot molten end isconnected with an extrusion nozzle which is of a long strip structure, the hot molten end is of a hollow structure, the extrusion nozzle is seamlessly connected with the hot molten end in a communicated manner, and a flow rate adjusting valve is arranged at the top end of the air inlet pipe. The tuyere is reasonable in structure, better heat exchange can be realized in an integrated machine, rawmaterials can be further pyrolyzed, stability of the raw materials is enhanced effectively, the tuyere has higher applicability and applicable to the industry of production and processing of glassware, air volume can be adjusted as required, so that superheat degree of the raw materials is controlled, and product quality is controlled.

Owner:江苏三科海洋装备有限公司

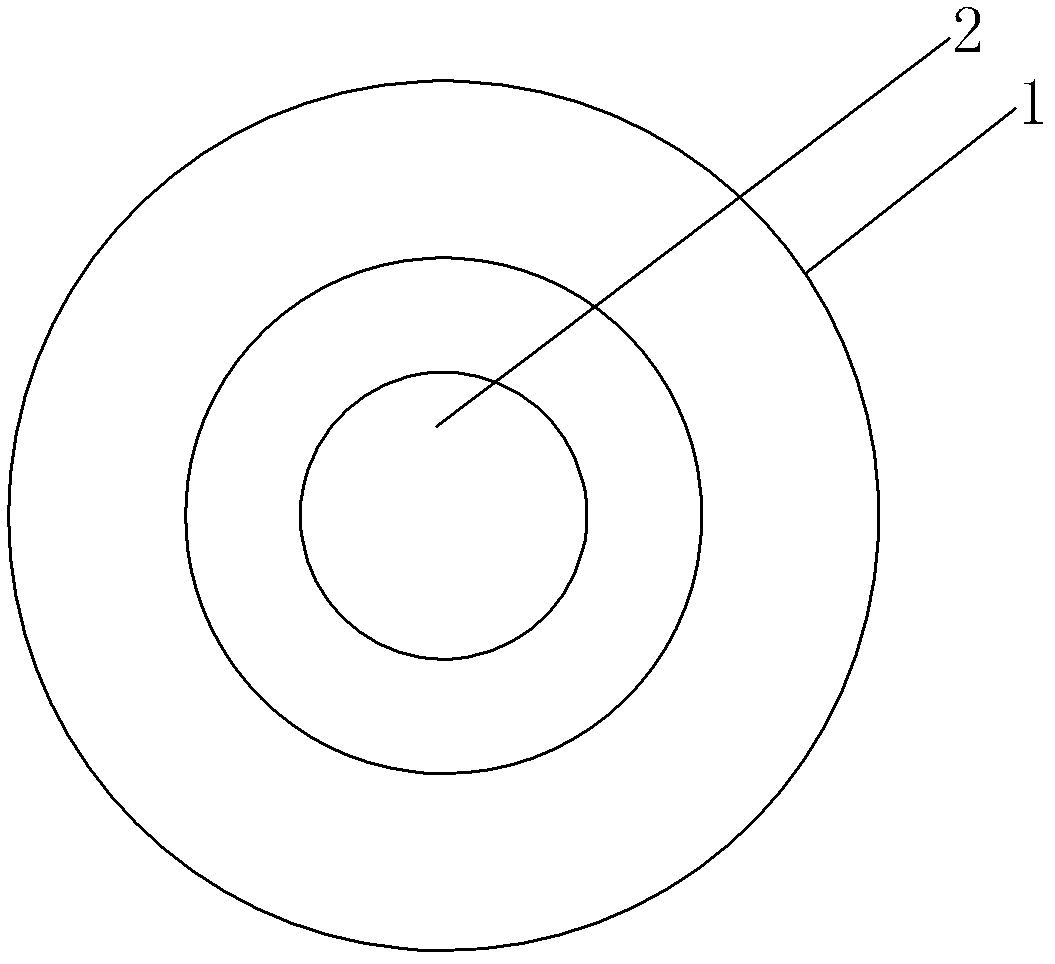

Air blowing head convenient for radiating

The invention discloses an air blowing heat convenient for radiating, which comprises an air blowing head body. An air inlet is arranged at the center of the air blowing head body, and a plurality of radiating grooves are evenly radiated toward the periphery with the air inlet hole as the center. The plurality of radiating grooves are arranged on the air blowing head body, so that a plurality of radiating runners are formed, air flow can take away the heat on the air blowing head through the radiating grooves for cooling the air blowing head, and accordingly bad influence on glass bottle processing is reduced.

Owner:DEQING CAIFU GLASS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com