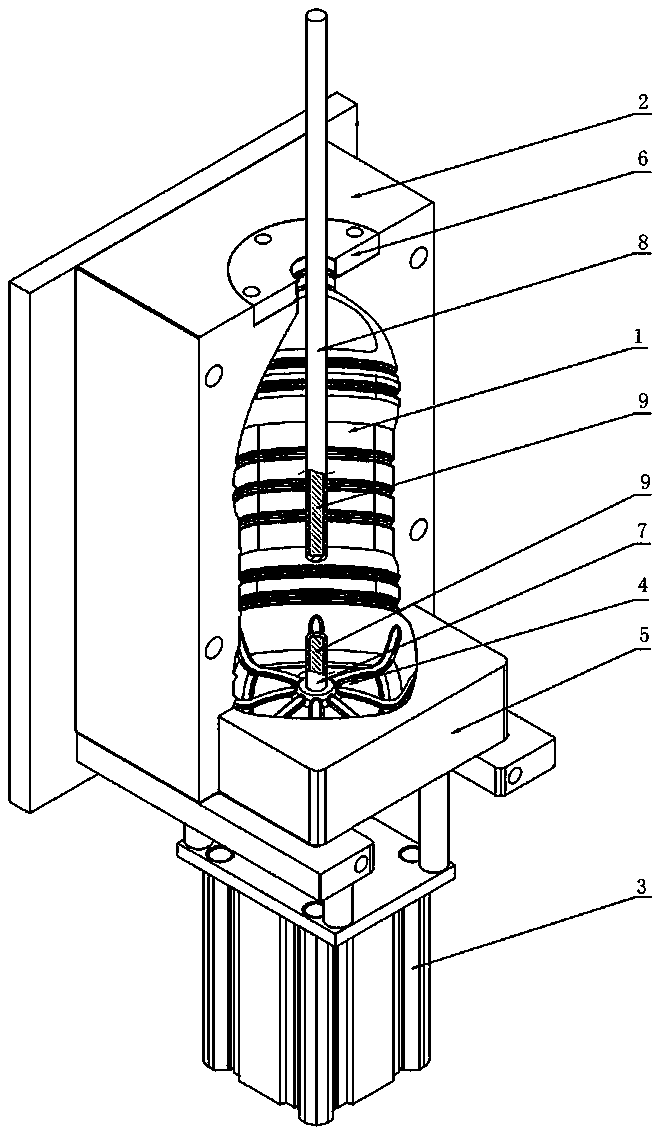

Blow molding mold and method equipped with heating stretching system

A technology of blow molding and stretching system, which is applied in glass forming, glass reshaping, glass blowing molds, etc. It can solve the problems of uneven distribution of plastics, easy cracking feet, and difficult pulling of materials, etc., to achieve Effects of reducing weight, enhancing overall strength, and reducing internal stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0031] The method adopted in this embodiment is basically the same as that of Embodiment 1, and the only difference lies in the difference in step 3, which is as follows: when blowing the bottle, first retract the support rod 7 to the lowest position, and pull the stretch rod 8 When stretching the preform to half of the height of 10mm~60mm from the bottom surface of the mold, inject low-pressure air, and pre-blow molding while stretching. After the supporting rod 7 and the stretching rod 8 are in contact, the supporting rod 7 and the stretching rod 8 hold the bottom of the billet and run down to the bottom together, and at the same time, the main blowing high-pressure air makes the preform expand and cling to the inner wall of the mold cavity, Then cool to form a blow-molded container, the above-mentioned height from the bottom surface of the mold is preferably 20 mm to 50 mm, most preferably 40 mm.

Embodiment 3

[0033]The method adopted in this embodiment is basically the same as that of Embodiment 1, except that the difference lies in step 3, which is as follows: when blowing the bottle, first extend the supporting rod 7 by 20 mm to 40 mm, preferably 30 mm, Keeping still, the stretching rod 8 stretches the preform until the pre-blowing air enters, and when it touches the supporting rod 7, it pauses for 0.01s~0.1s, and the preferred pause time is 0.01s~0.3s, so that the preform is in the After being fully stretched under the action of pre-blowing, the supporting rod 7 and the stretching rod 8 together clamp the bottom of the billet and run down to the bottom, and at the same time, the main blowing of high-pressure air makes the preform expand and cling to the inner wall of the mold cavity, It is then cooled to form a blow molded container.

[0034] In the above three embodiments, the pressure of the pre-blowing air is 0.5MPa~1MPa, and the pressure of the main blowing high-pressure air...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com