High borosilicate glass bottle making machine and fast blowing method production process

A high borosilicate glass and bottle-making machine technology, which is applied in glass production, glass blowing molds, blowing-blowing glass forming machines, etc., can solve the problems of energy waste, cumbersome process flow, and low efficiency, and reduce complexity , Reduce process steps, simplify process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

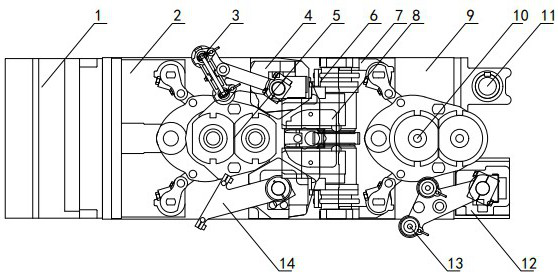

[0063] Such as figure 1 As shown, the surface of the main frame 9 is divided into a preliminary mold side and a molding side, a preliminary mold 5 is arranged in the preliminary mold side, and a molding mold 10 is provided in the molding side. In this bottle making machine, the molding side is defined As the front side of the bottle making machine, the prototype side is defined as the rear side of the bottle making machine.

[0064] The left and right ends on the rear side of the prototype 5 are respectively provided with a blank clamp mechanism 2, the blank mold 5 is a split type, and the blank clamp mechanisms 2 on both sides respectively fix half of the blank mold 5 by mechanical arms, Realize the closing and separation of the preliminary mold 5; in the same way, the forming mold clamp mechanism 7 is arranged on both sides of the forming mold 10, and the forming mold 10 is also a split type, and the forming mold clamp mechanism 7 on both sides fixes the forming mold respec...

Embodiment 2

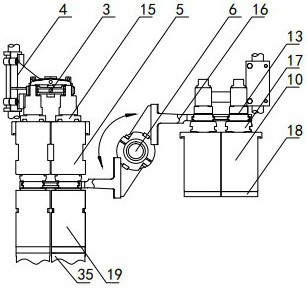

[0111] The difference between this embodiment and Embodiment 1 is: in this embodiment, the reverse blowing mechanism 19 adopts a large-mouth device, which is suitable for the production of glass bottles with a bottle mouth diameter of 38 mm to 90 mm.

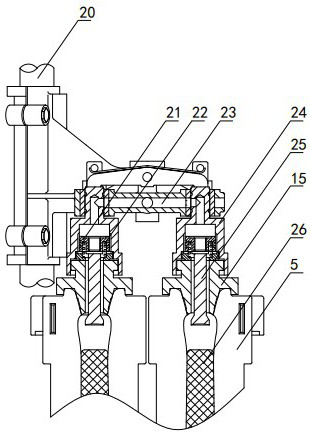

[0112] Such as Figure 12 As shown, the large mouth device includes a combination cylinder 76 that penetrates up and down. At the lower port of the combination cylinder 76, the upper end cover 78 of the pressure blow cylinder is coaxially fixed with the pressure blow cylinder 35. A gland is installed at the upper port of the combination cylinder 76. 77, a top cover is provided at the upper port of the combination cylinder 76.

[0113] A sleeve 67 is arranged inside the coupling cylinder 76 , and the sleeve 67 moves up and down along its axial direction inside the coupling cylinder 76 . The outer surface of the sleeve 67 is protrudingly provided with a boss, the upper surface of the boss and the inner surface of the upper end co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com