Positive blowing mechanism of bottle making row machine

A technology of air blowing mechanism and row machine, which is applied in the direction of blowing head and glass production, which can solve the problems of not taking away, waste of compressed gas, etc., and achieve the effects of saving electric energy, improving production efficiency, and overcoming energy waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

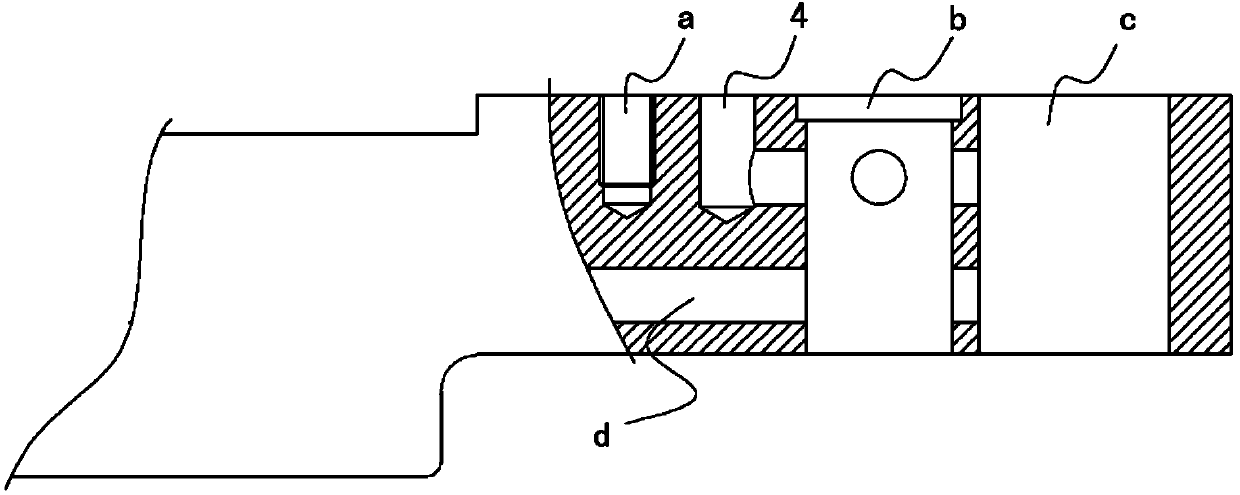

[0032] In this embodiment, a blowing mechanism of a bottle-making row machine, its composition includes: figure 2 As shown, on the blowing bracket A with the positive blowing channel d, screw holes a, exhaust holes 4, valve core holes b and lock ring holes c are sequentially arranged along the normal blowing direction;

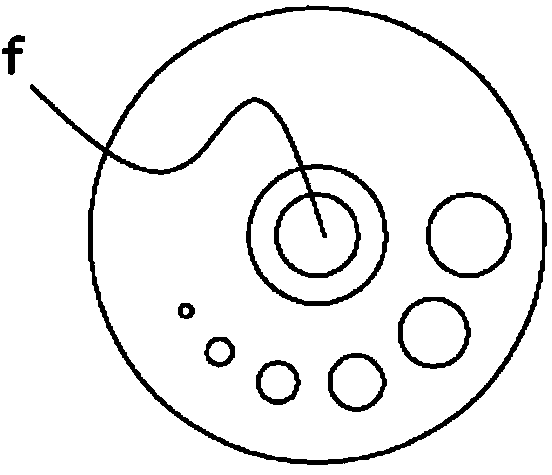

[0033] like figure 1 As shown, the orifice plate 1 with the through hole is fixedly arranged on the air blowing support A through the fixing screw 12 and the screw hole a, as Figure 1b As shown, there is a screw hole f in the middle of the orifice plate 1, which is aligned with the screw hole a on the blowing bracket A and then fixed by the fixing screw 12. On the orifice plate 1, there are sequentially arranged screw holes f along the outer circumference of the screw hole f. For different through holes, the orifice plate 1 forms a connected structure with the through hole and the exhaust hole 4, or forms a blocking structure for the exhaust hole 4 with the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com