Ultrathin photovoltaic rolled glass

A photovoltaic calendering and glass technology, which is applied in the field of ultra-thin photovoltaic calendering glass, can solve the problems of not being able to meet the calendering process forming requirements, not meeting the industrial production requirements, and increasing production costs, so as to improve the clarification and decolorization effect and increase the refractive index of the glass , The effect of saving production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0010] The invention provides an ultra-thin photovoltaic rolling glass, the glass contains the following oxides by mass percentage: 73.18% SiO 2 , 8.06% CaO, 3.51% MgO, 1.35% Al 2 o 3 , 13.2% Na 2 O, 0.6% B 2 o 3 , 0.05% Sb 2 o 3 , 0.05% CeO 2 with 0.01% Fe 2 o 3 ;

[0011] Raw material batching according to the oxide content can be carried out by conventional means, such as using silica sand, limestone, dolomite, aluminum hydroxide, soda ash, boric acid, Glauber's salt, sodium nitrate, antimony powder and cullet, etc.; the above raw material batching After mixing, the oxy-fuel combustion process is used to fully melt at 1585-1650°C and clarified at 1420-1430°C; the clarified glass liquid is calendered through a calendering process at a calendering temperature of 1195°C; and then annealed at a temperature of 70-1430°C. 560° C., annealing time 10-14 minutes, and a photovoltaic rolling glass with a thickness of 2.0 mm is prepared.

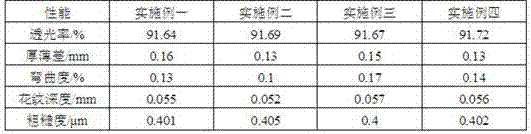

[0012] After testing, the light tra...

Embodiment 2

[0014] The invention provides an ultra-thin photovoltaic rolling glass, the glass contains the following oxides by mass percentage: 72.08% SiO 2 , 8.0% CaO, 3.92% MgO, 1.65% Al 2 o 3 , 13.35% Na 2 O, 0.85% B 2 o 3 , 0.1% Sb 2 o 3 , 0.05% CeO 2 with 0.01% Fe 2 o 3 ;

[0015] Raw material batching according to the oxide content can be carried out by conventional means, such as using silica sand, limestone, dolomite, aluminum hydroxide, soda ash, boric acid, Glauber's salt, sodium nitrate, antimony powder and cullet, etc.; the above raw material batching After mixing, the oxy-fuel combustion process is used to fully melt at 1585-1650°C and clarified at 1420-1430°C; the clarified glass liquid is calendered through a calendering process at a calendering temperature of 1195°C; and then annealed at a temperature of 70-1430°C. 560°C, annealing time of 10-14min, and a photovoltaic rolling glass with a thickness of 1.9mm was prepared.

[0016] After testing, the light transmi...

Embodiment 3

[0018] The invention provides an ultra-thin photovoltaic rolling glass, the glass contains the following oxides by mass percentage: 71.85% SiO 2 , 8.35% CaO, 3.5% MgO, 2.16% Al 2 o 3 , 13.2% Na 2 O, 0.71% B 2 o 3 , 0.15% Sb 2 o 3 , 0.08% CeO 2 with 0.012% Fe 2 o 3 ;

[0019] Raw material batching according to the oxide content can be carried out by conventional means, such as using silica sand, limestone, dolomite, aluminum hydroxide, soda ash, boric acid, Glauber's salt, sodium nitrate, antimony powder and cullet, etc.; the above raw material batching After mixing, the oxy-fuel combustion process is used to fully melt at 1585-1650°C and clarified at 1420-1430°C; the clarified glass liquid is calendered through a calendering process at a calendering temperature of 1195°C; and then annealed at a temperature of 70-1430°C. 560°C, annealing time of 10-14min, and a photovoltaic rolling glass with a thickness of 1.9mm was prepared.

[0020] After testing, the light transm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com