Damaged blade repairing method and device for blisk based on double laser beams

A technology of integral blisk and repair method, which is applied in the field of laser repair, can solve the problems affecting the internal quality of the repaired part, the safety of mechanical performance components in service, the existence of pores, and lack of fusion, so as to improve the internal quality and comprehensive mechanical properties, The effect of reducing pores and removing internal stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The technical solutions in the examples of the present invention will be clearly and completely described below in conjunction with the accompanying drawings in the examples of the present invention. Obviously, the described examples are only some examples of the present invention, not all examples.

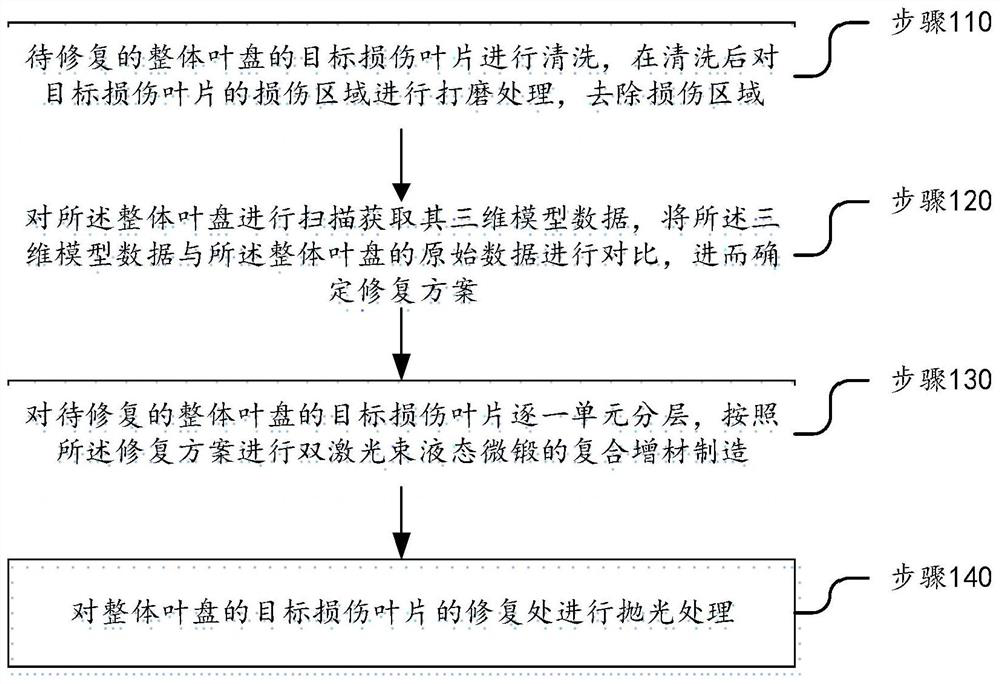

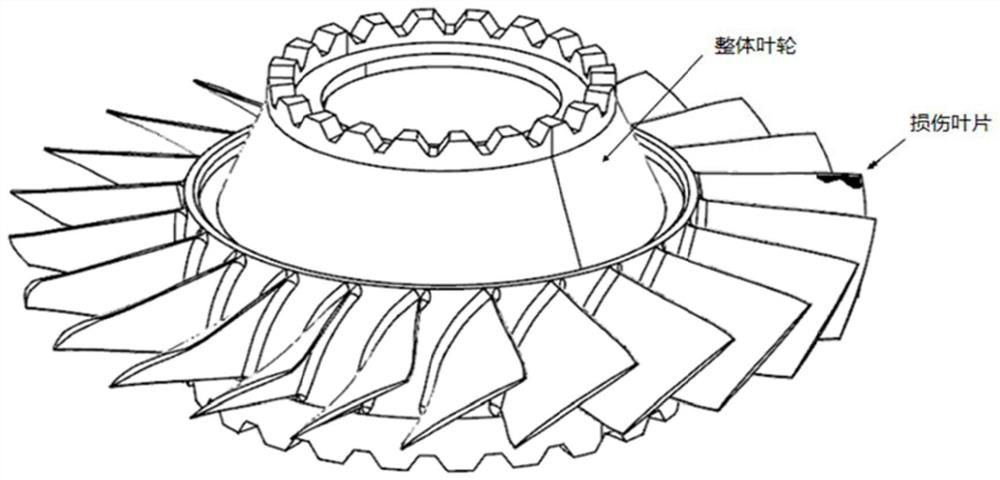

[0039] to combine figure 1 , figure 2 as well as Figure 5 , embodiment 1, is the damaged blade repair method based on the integral blisk of double laser beam that the present invention proposes, and described method comprises the following:

[0040] Step 110: cleaning the target damaged blade of the blisk to be repaired, and after cleaning, the damaged area of the target damaged blade is polished to remove the damaged area;

[0041] Step 120: Scanning the blisk to obtain its three-dimensional model data, comparing the three-dimensional model data with the original data of the blisk, and then determining a repair plan;

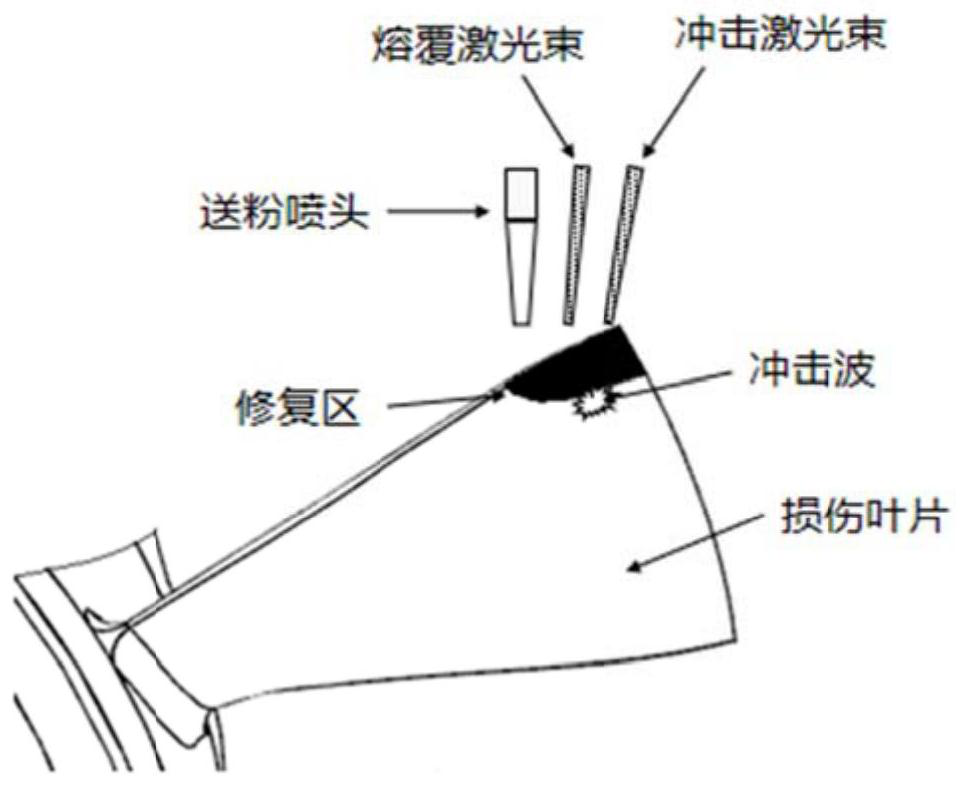

[0042] Step 130: The target damaged blades of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com