Flexible capacitance type touch sensor production method

A technology of tactile sensors and flexible capacitors, applied in chemical instruments and methods, piezoelectric/electrostrictive/magnetostrictive devices, instruments, etc., can solve the problems of difficult mass production, large sensor size, manufacturing process and MEMS processing technology Incompatibility and other issues, to achieve the effect of high yield and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] A kind of implementation example is specifically introduced below, and the present invention is described in further detail, but the present invention is also suitable for the manufacture of the array structure that is made up of many this flexible capacitive touch sensor units, and this manufacture method provides for the research of other flexible MEMS technology equally Useful experience.

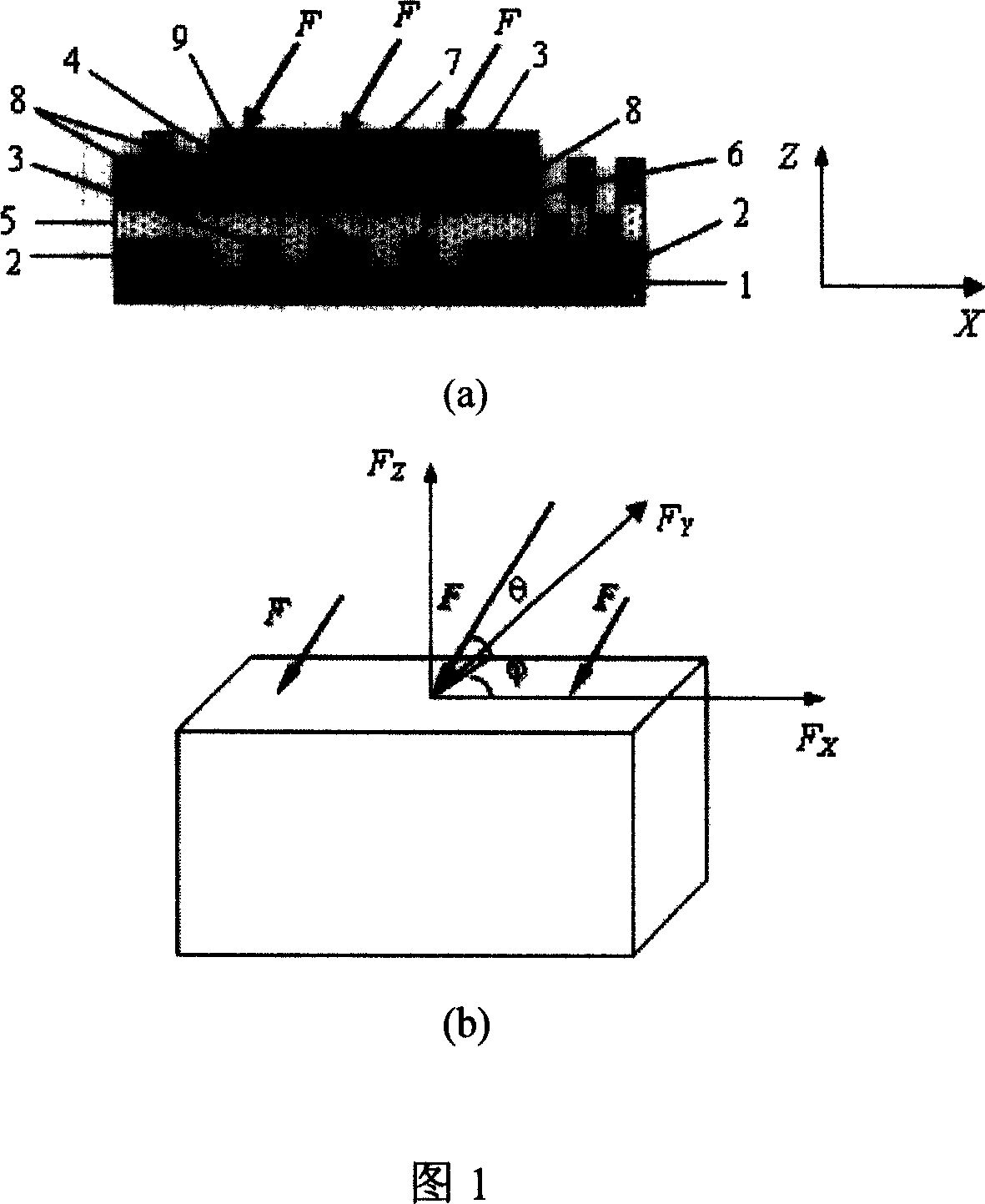

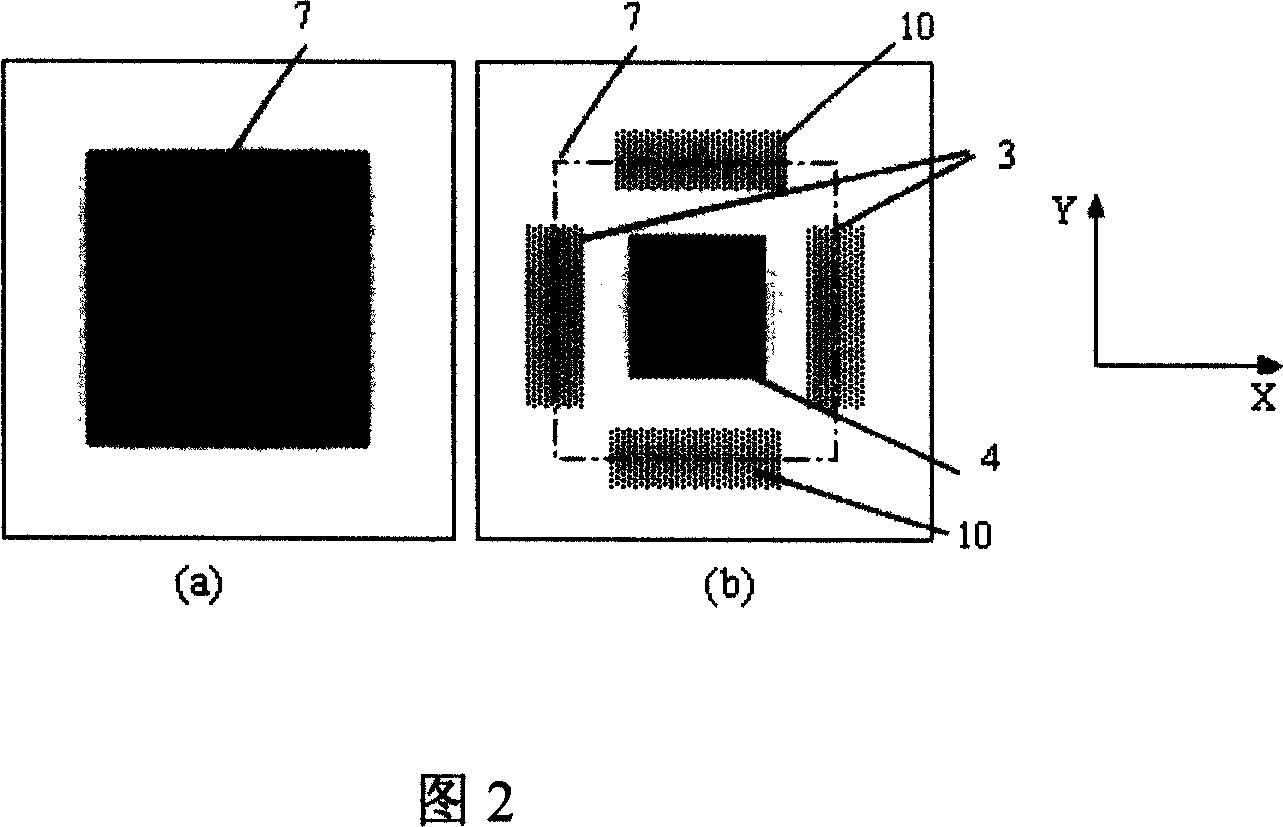

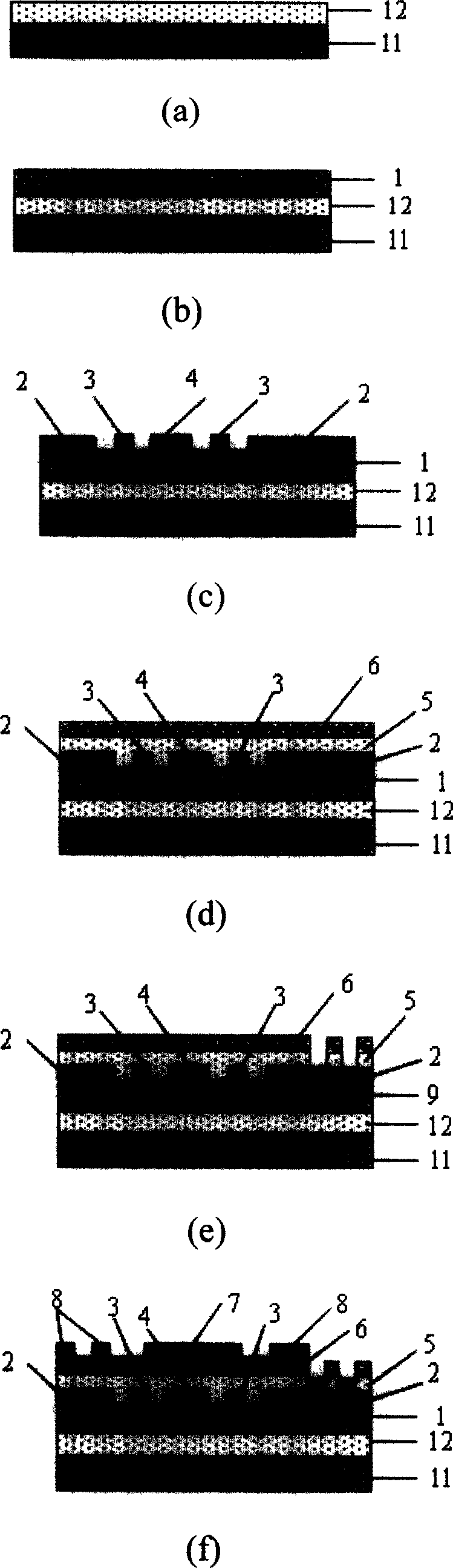

[0045] Referring to Fig. 1 (a), (b) is a XZ cross-sectional view of a flexible capacitive touch sensor and a schematic diagram when it is subjected to an external force F from the environment, and Fig. 2 is a top view of the capacitive tactile sensing sensitive electrode and driving electrode. The size design of the flexible capacitive tactile sensor is carried out from the edge effect of the flexible capacitive sensor: the size of the driving electrode 7 is 3500 μm×3500 μm, the size of the sensitive central electrode 4 is 1000 μm×1000 μm, and the sensitive electrode 3 parallel to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com