Fibre reinforced coal ash based geopolymer foam material and preparation method thereof

A fiber-reinforced and foamed material technology, applied in the field of porous ceramics, can solve the problems of reduced strength, increased water absorption, low density and thermal conductivity, and achieve the effects of reducing air pollution, simple process, and reducing solid waste pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

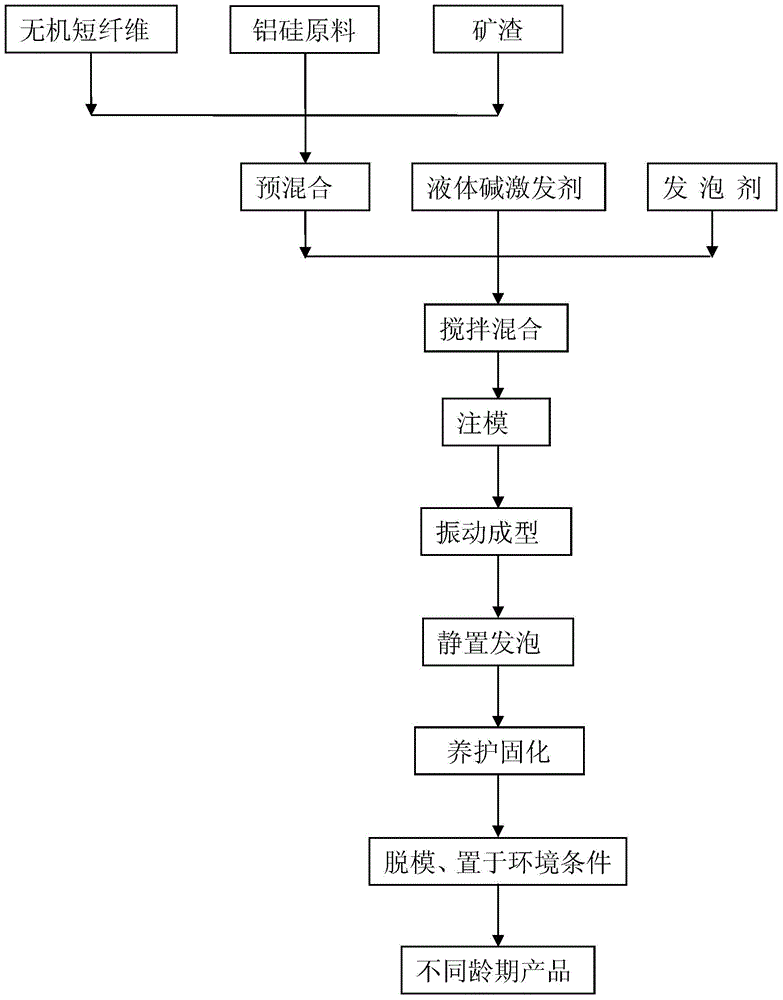

Method used

Image

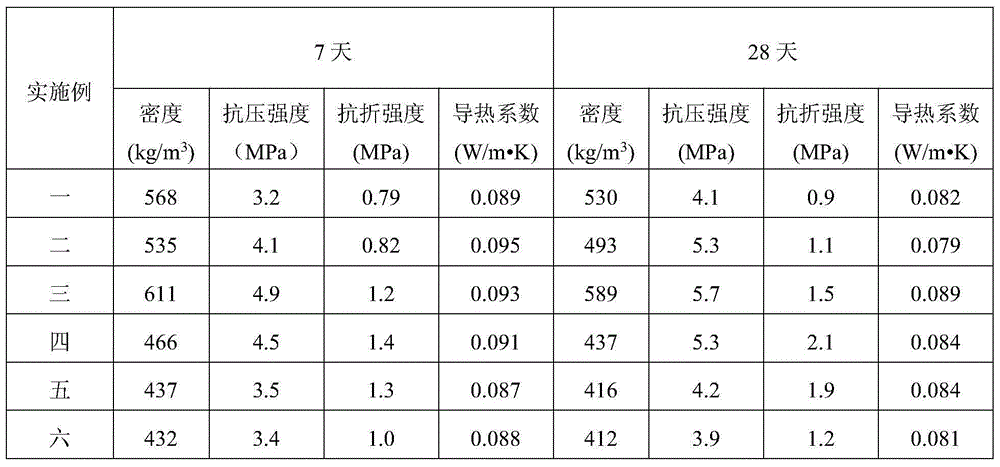

Examples

Embodiment 1

[0021] The Suzhou soil (the main crystal phase is kaolin) was calcined at 700°C for 2 hours to obtain metakaolin. Weigh 100g of the material, 50g of slag, 500g of fly ash, the particle size of various raw materials is 0.045mm and the sieve residue is less than 30%, weigh 40g of glass fiber with a length of 0.5mm to 1mm and 2.5g of aluminum powder, and add them to the solid raw material. Mix well.

[0022] Measure 120ml water glass, modulus 2.8, density 1.35g / m1; Measure 120ml concentration and be 30wt% sodium hydroxide solution; Water glass solution and sodium hydroxide solution are mixed, leave standstill 2 hours to obtain alkaline activator solution, Measure 25ml compound foam stabilizer (density close to 1g / cm 3 ), oleic acid in the compound foam stabilizer: triethanolamine: water = 1:3:36 (volume ratio) and alkali activator solution, mix and stir evenly, then add to the above solid materials, and stir while adding the solution until the mixture is uniform. Pour the mixed...

Embodiment 2

[0028] The Suzhou soil (the main crystal phase is kaolin) was calcined at 700°C for 2 hours to obtain metakaolin. Weigh 40g of the material, 70g of slag, 30g of silica fume, 500g of fly ash, the particle size of various raw materials is 0.045mm and the sieve residue is less than 30%, weigh 40g of aluminum-silicon fiber with a length of 0.5mm to 1mm and 4g of aluminum powder foaming agent, Add to the solid ingredients and stir to combine.

[0029] Measure 110ml water glass, modulus 2.8, density 1.35g / m1; Measure 130ml concentration and be 30wt% sodium hydroxide solution; Water glass solution and sodium hydroxide solution are mixed, leave standstill 2 hours to obtain alkaline activator solution, Measure 30ml of compound foam stabilizer (density close to 1g / cm 3 ), oleic acid in the compound foam stabilizer: triethanolamine: water = 1:3:36 (volume ratio) and alkali activator solution, mix and stir evenly, then add to the above solid materials, and stir while adding the solution ...

Embodiment 3

[0034] The Suzhou soil (the main crystal phase is kaolin) was calcined at 700°C for 2 hours to obtain metakaolin. Weigh 40g of the material, 70g of slag, 30g of silica fume, 500g of fly ash, and the particle size of various raw materials is 0.045mm, and the sieve residue is less than 30%. Sodium alkyl sulfonate compound foaming agent is added to the solid raw material, stirred and mixed evenly.

[0035] Measure 110ml water glass, modulus 2.8, density 1.35g / m1; Measure 130ml concentration and be 30wt% sodium hydroxide solution; Water glass solution and sodium hydroxide solution are mixed, leave standstill 2 hours to obtain alkaline activator solution, Measure 30ml of compound foam stabilizer (density close to 1g / cm 3 ), oleic acid in the compound foam stabilizer: triethanolamine: water = 1:3:36 (volume ratio) and alkali activator solution, mix and stir evenly, then add to the above solid materials, and stir while adding the solution until the mixture is uniform.

[0036] Pour...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com