Centrifugal casting production method of high-boron high-speed steel composite roller

A composite roll and centrifugal casting technology, which is applied in the direction of rolls, metal rolling, and manufacturing tools, can solve the problems of low density, low hardness of the roll surface, and poor wear resistance, and achieve reduced production costs, uniform hardness, and wear resistance and good effect on thermal fatigue resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] 1) Melting high-boron high-speed steel liquid:

[0040] ①Heating and melting ordinary steel scrap, pig iron, ferrochrome, ferrotungsten, nickel plate and ferromolybdenum, adding ferrosilicon for pre-deoxidation and alloying after molten steel is melted;

[0041] ② After adjusting the ingredients before the furnace, raise the temperature to 1520°C, add ferrovanadium, aluminum, ferrotitanium and ferroboron in sequence and raise the temperature. When the temperature of molten steel reaches 1580°C, it is out of the furnace;

[0042] ③Crush the rare earth ferrosilicon into small pieces with a particle size of 8-12mm, dry it at 200°C, place it at the bottom of the ladle, and use the method of pouring into the ladle to treat the molten steel with rare earth modification;

[0043] 2) Pretreatment of high boron high speed steel liquid before pouring:

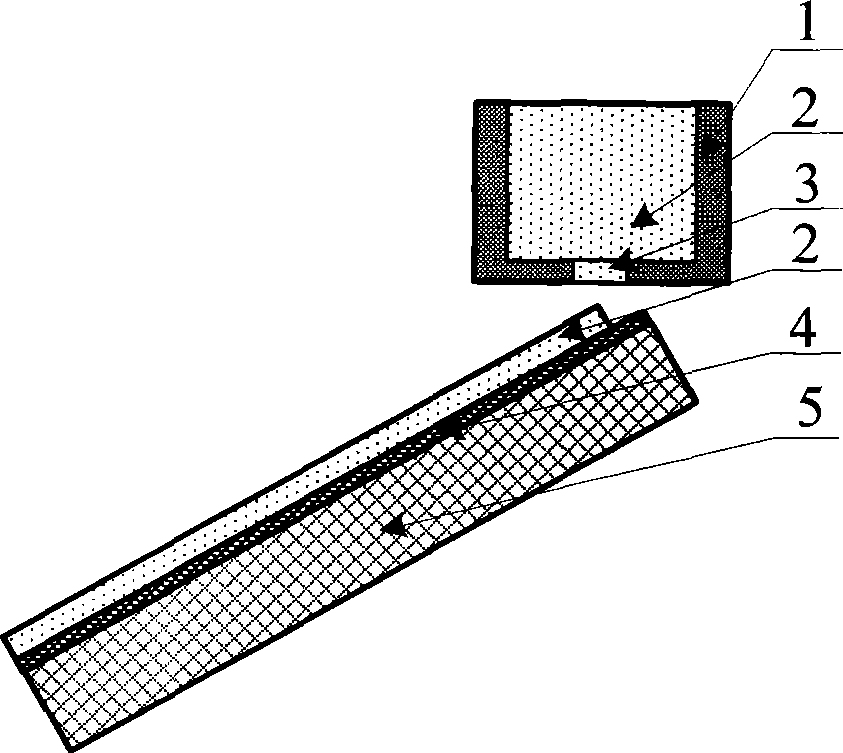

[0044] like figure 1 As shown, when the temperature of the high-boron high-speed steel liquid reaches 70°C above the liquidus ...

Embodiment 2

[0057] 1) Melting high boron high speed steel liquid

[0058] ①Heating and melting ordinary steel scrap, recarburizer, ferrochrome, ferrotungsten, nickel plate and ferromolybdenum, adding ferrosilicon for pre-deoxidation and alloying after molten steel is melted;

[0059] ② After adjusting the composition before the furnace, the temperature is raised to 1540°C, and ferrovanadium, aluminum, ferrotitanium and ferroboron are added in sequence and the temperature is raised, and the molten steel is released when the temperature reaches 1560°C;

[0060] ③Crush the rare earth ferrosilicon into small pieces with a particle size of 8-12mm, dry it at 180°C, place it at the bottom of the ladle, and use the method of flushing into the ladle to perform rare earth modification on the molten steel;

[0061] 2) Pretreatment of high boron high speed steel liquid before pouring

[0062] like figure 1 As shown, when the temperature of the high-boron high-speed steel liquid reaches 60°C above t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com