Phenyl vinyl siloxane resin, high-refractive-index light-emitting diode (LED) packaging silicon resin composition and preparation method of silicon resin composition

A technology of phenylvinylsiloxane and tetramethyldivinyldisiloxane, which is applied in the field of electronic packaging, can solve the problems of easy yellowing of materials and affect the brittleness of polysiloxane, and achieves easy post-processing, Improved curing effect, high refractive index effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

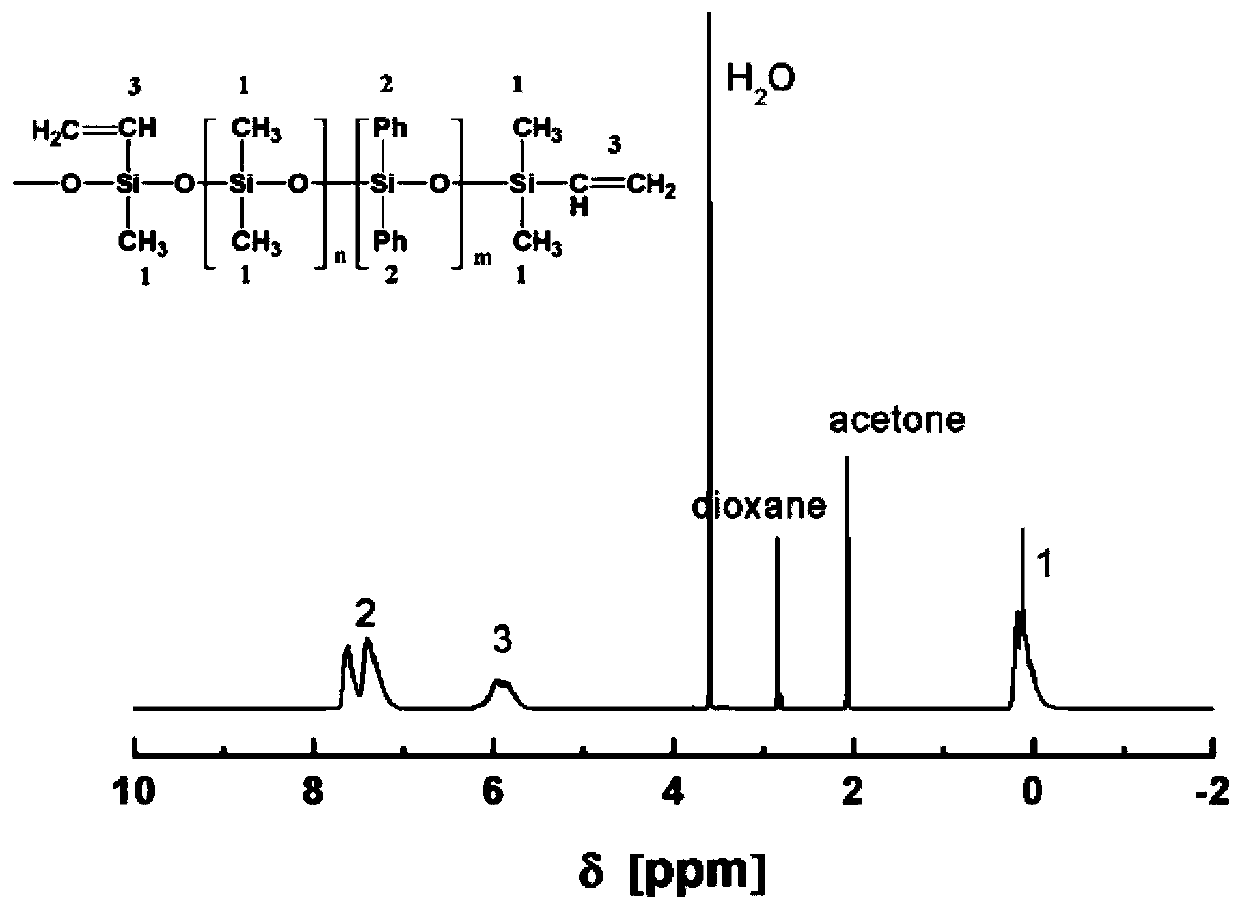

Image

Examples

Embodiment 1

[0092] This embodiment provides a phenyl vinyl siloxane resin, the preparation method of which is as follows.

[0093] Mix 50g of diphenyldimethoxysilane, 15g of methylvinyldimethoxysilane, 20g of octamethylcyclotetrasiloxane, and 5g of tetramethyldivinyldisiloxane and place in a round bottom flask Toluene is added to prepare a mixed solution with a monomer mass ratio of 50%, and 0.1 g of trifluoromethanesulfonic acid is added dropwise to make the solution acidic. At 40°C, pure water with the same molar ratio as the reactive functional group was slowly added dropwise within 3 hours to carry out the hydrolysis reaction, and hydrolysis was carried out for 1 hour after the addition was completed. Transfer the solution to a separatory funnel and wash with water until the solution is neutral. Use a rotary evaporator to remove the solvent and water under reduced pressure at 55°C, add 0.1% potassium hydroxide to adjust the pH, carry out the condensation reaction at 150°C for 2h, transf...

Embodiment 2

[0097] This embodiment provides a phenyl vinyl siloxane resin, the preparation method of which is as follows.

[0098] Mix 50g of diphenyldimethoxysilane, 15g of methylvinyldimethoxysilane, 20g of octamethylcyclotetrasiloxane, and 5g of tetramethyldivinyldisiloxane and place in a round bottom flask Toluene is added to prepare a mixed solution with a monomer mass ratio of 50%, and 0.1 g of trifluoromethanesulfonic acid is added dropwise to make the solution acidic. At 40°C, pure water with the same molar ratio as the reactive functional group was slowly added dropwise within 3 hours to carry out the hydrolysis reaction, and hydrolysis was carried out for 1 hour after the addition was completed. Transfer the solution to a separatory funnel and wash with water until the solution is neutral. Use a rotary evaporator to remove the solvent and water under reduced pressure at 55°C, add 0.1% potassium hydroxide to adjust the pH, carry out condensation reaction at 150°C for 0.5h, transfer...

Embodiment 3

[0100] This embodiment provides a phenyl vinyl siloxane resin, the preparation method of which is as follows.

[0101] Mix 50g of diphenyldimethoxysilane, 15g of methylvinyldimethoxysilane, 20g of octamethylcyclotetrasiloxane, and 5g of tetramethyldivinyldisiloxane and place in a round bottom flask Toluene is added to prepare a mixed solution with a monomer mass ratio of 50%, and 0.1 g of trifluoromethanesulfonic acid is added dropwise to make the solution acidic. At 40°C, pure water with the same molar ratio as the reactive functional group was slowly added dropwise within 3 hours to carry out the hydrolysis reaction, and hydrolysis was carried out for 1 hour after the addition was completed. Transfer the solution to a separatory funnel and wash with water until the solution is neutral. Use a rotary evaporator to remove the solvent and water under reduced pressure at 55°C, add 0.1% potassium hydroxide to adjust the pH, carry out the condensation reaction at 150°C for 5h, transf...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

| Shore hardness | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com