Preparation method of mesoporous alumina composite adsorbent functionalized by alkali metal

A mesoporous alumina, composite adsorption technology, applied in chemical instruments and methods, through adsorption, separation methods, etc., to achieve the effects of good adsorption performance, simple process and mild conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Example 1: Preparation of Na-functionalized mesoporous γ-Al by solvent evaporation-induced self-assembly using F127 as template 2 o 3 base composite adsorbent

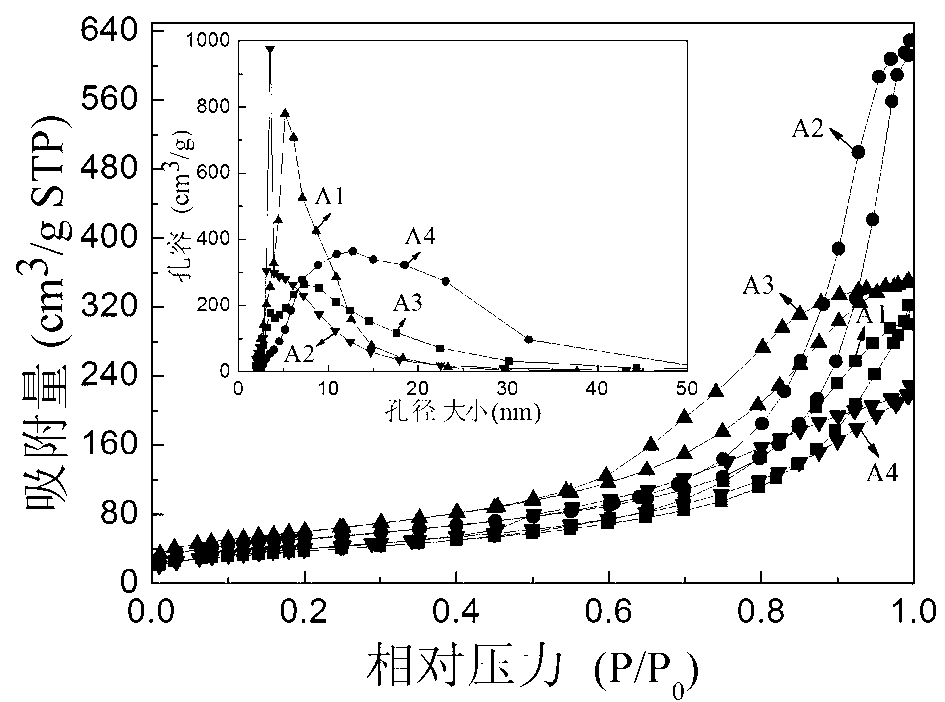

[0028] 18.75 g Al(NO 3 ) 3 9H 2 O was dissolved in 9 ml of deionized water, 3.2 g of template agent F127 was added, fully stirred at 40 °C for 36 h, and then allowed to stand for 6 h; then, under slow stirring, 32.9% Na 2 CO 3Solution 17.3 ml, the resulting product was evaporated at 100 °C to induce self-assembly for 24 h, washed with 30 ml of deionized water and 20 ml of absolute ethanol in turn, and dried at 60 °C for 12 h, under air atmosphere, 600 ℃ calcination for 2 h, heating rate 1 ℃ / min, prepared Na-functionalized mesoporous γ-Al 2 o 3 Solid base composite material with a specific surface area of 135.4 m 2 / g, the pore volume is 0.43 cm 3 / g, the average pore diameter is 12.6 nm, the sample is CO at room temperature 2 The adsorption capacity is 0.5 mmol / g (see Table 1, figure 1 and image 3...

Embodiment 2

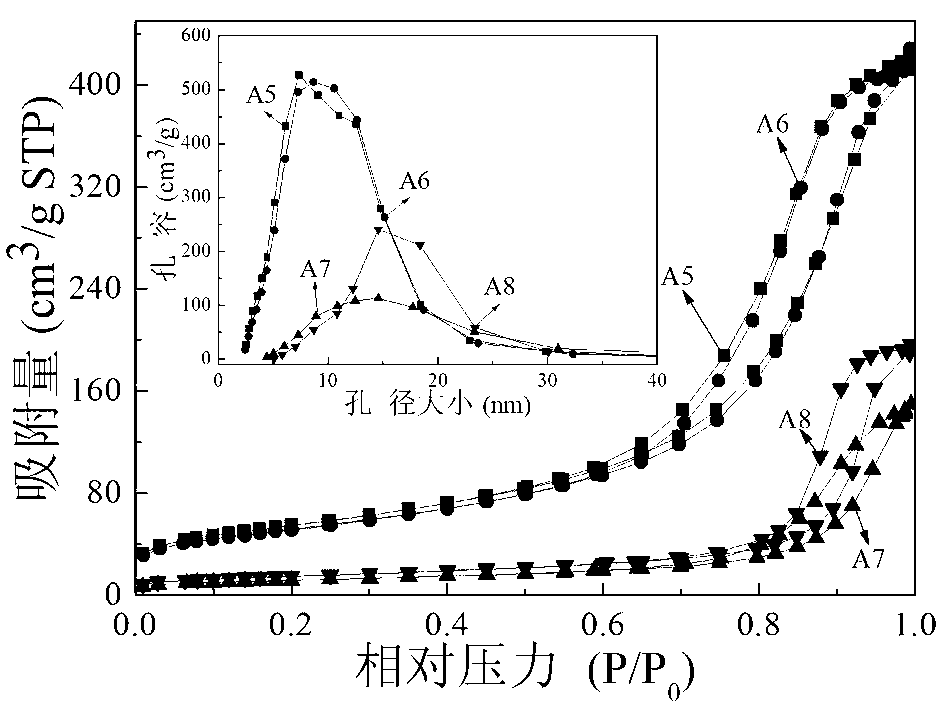

[0030] Example 2: Preparation of Na-functionalized mesoporous γ-Al by hydrothermal method using F127 as template 2 o 3 base composite adsorbent

[0031] 18.75 g Al(NO 3 ) 3 9H 2 O was dissolved in 9 ml of deionized water, 3.2 g of template agent F127 was added, fully stirred at 40 °C for 36 h and then allowed to stand for 6 h; then Na was added dropwise with a mass fraction of 32.9 % at 40 °C under slow stirring 2 CO 3 solution of 17.3 ml, the resulting product was transferred to a hydrothermal kettle, heated at 90 °C for 36 h, washed with 30 ml of deionized water and 20 ml of absolute ethanol in turn, dried, and roasted at 600 °C for 2 h in an air atmosphere. Heating rate 1℃ / min, Na-functionalized mesoporous γ-Al was prepared 2 o 3 Solid base composite material with a specific surface area of 185.6 m 2 / g, the pore volume is 0.86 cm 3 / g, the average pore diameter is 18.6 nm, the sample is CO at room temperature 2 The adsorption capacity is 0.7 mmol / g (see Table 1...

Embodiment 3

[0033] Example 3: Preparation of Na-functionalized mesoporous γ-Al by solvent evaporation-induced self-assembly using F127 as template 2 o 3 base composite adsorbent

[0034] 12.07 g AlCl 3 ·6H 2 O was dissolved in 12 ml of deionized water, 3.2 g of template agent F127 was added, fully stirred at 40 °C for 36 h and then allowed to stand for 6 h; then 30% Na at 40 °C was added dropwise under slow stirring. 2 CO 3 The solution was 19 ml, and the product obtained was self-assembled by solvent evaporation at 100 °C for 24 h, washed with 30 ml of deionized water and 20 ml of absolute ethanol in turn, dried, and calcined at 600 °C for 2 h in an air atmosphere with a heating rate of 1 ℃ / min to prepare Na-functionalized mesoporous γ-Al 2 o 3 Solid base composite material with a specific surface area of 217.4 m 2 / g, the pore volume is 0.53 cm 3 / g, the average pore diameter is 9.7 nm, the sample is CO at room temperature 2 The adsorption capacity is 1.4 mmol / g (see Table 1,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com