Three-dimensional fiber prefabricated member reinforced aluminum oxide composite material and preparation method thereof

A fiber preform and composite material technology, applied in the field of three-dimensional fiber preform reinforced alumina composite material and its preparation, can solve the problems of high porosity, low preparation efficiency, low mechanical properties, etc., achieve high content and density, Overcome the effects of low density and excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

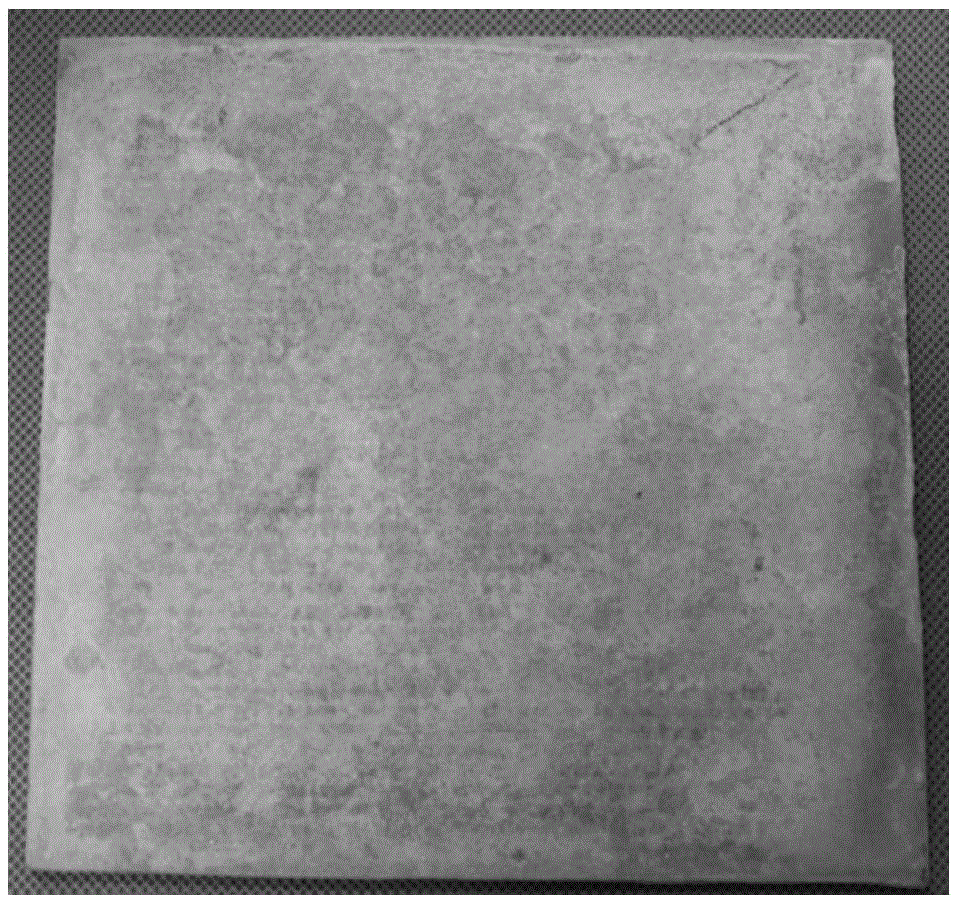

[0043] A three-dimensional fiber preform reinforced alumina composite material of the present invention, comprising a three-dimensional fiber preform and alumina, wherein the alumina is the matrix, the three-dimensional fiber preform is the reinforcing phase, and the alumina is evenly filled in the pores of the three-dimensional fiber preform In and physically combined with the three-dimensional fiber preform, the alumina is α-Al 2 o 3 Ceramics, in this implementation, the porosity of the three-dimensional fiber preform reinforced alumina composite material is 9.6%.

[0044] In this embodiment, the three-dimensional fiber preform is a three-dimensional fiber preform obtained by stacking and sewing carbon fiber cloth, and the volume fraction of fibers in the three-dimensional fiber preform is 48%.

[0045] In this example, the bending strength of the three-dimensional fiber prefabricated alumina composite material is 271MPa, and the fracture toughness is 13.0MPa·m 1 / 2 .

[0...

Embodiment 2

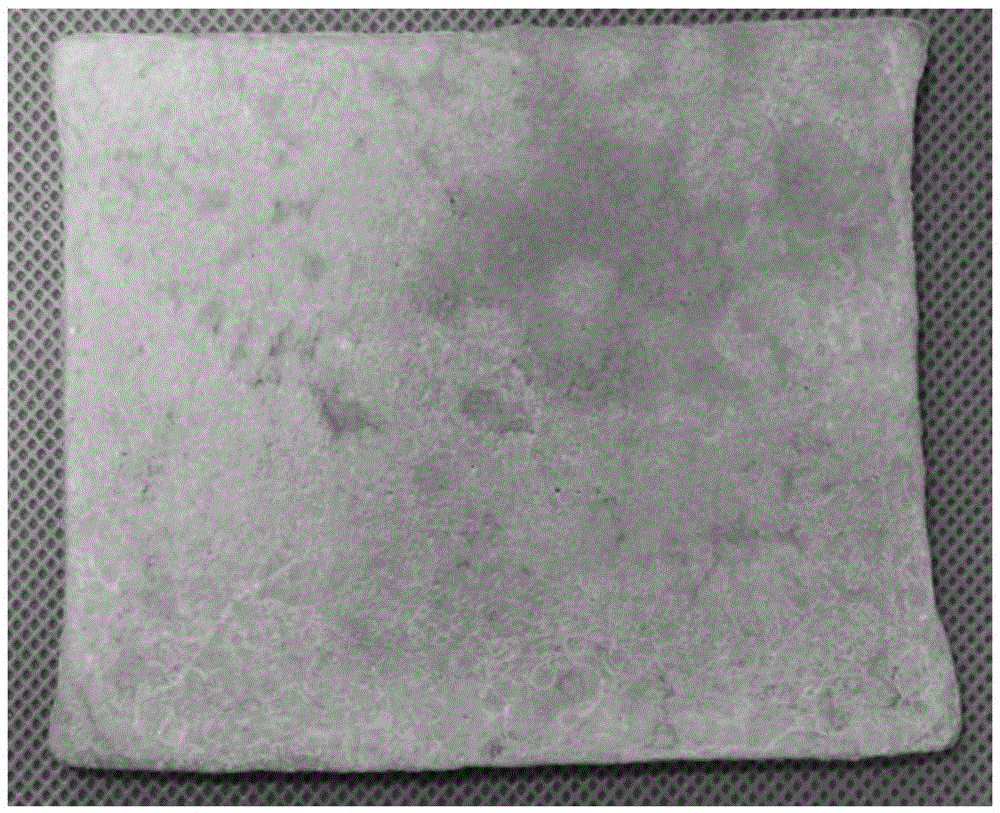

[0056] A three-dimensional fiber prefabricated alumina composite material of the present invention comprises a three-dimensional fiber preform and alumina, wherein alumina is used as a matrix, the three-dimensional fiber preform is used as a reinforcing phase, and alumina is uniformly filled in the three-dimensional fiber preform In the pores and physically bonded to the three-dimensional fiber preform, the alumina is α-Al 2 o 3Ceramics, in this implementation, the porosity of the three-dimensional fiber preform reinforced alumina composite material is 11.2%.

[0057] In this embodiment, the three-dimensional fiber preform is a three-dimensional carbon fiber preform with a three-dimensional five-directional weaving structure, and the volume fraction of fibers in the three-dimensional fiber preform is 52%.

[0058] In this example, the bending strength of the three-dimensional fiber prefabricated alumina composite material is 378MPa, and the fracture toughness is 16.7MPa·m 1 / ...

Embodiment 3

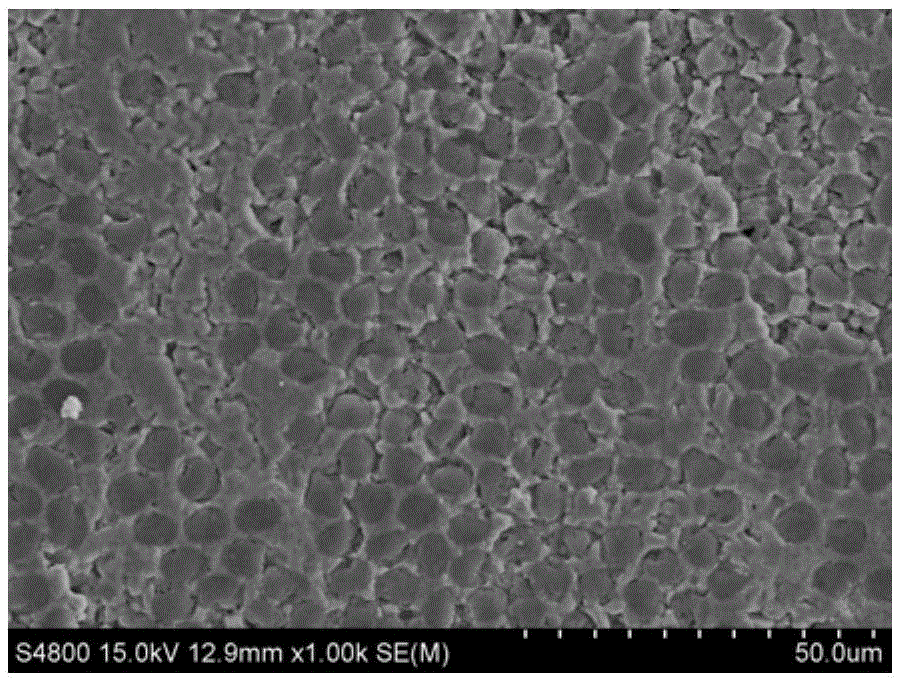

[0069] A three-dimensional fiber prefabricated alumina composite material of the present invention comprises a three-dimensional fiber preform and alumina, wherein alumina is used as a matrix, the three-dimensional fiber preform is used as a reinforcing phase, and alumina is uniformly filled in the three-dimensional fiber preform In the pores and physically bonded to the three-dimensional fiber preform, the alumina is α-Al 2 o 3 Ceramics, in this implementation, the porosity of the three-dimensional fiber preform reinforced alumina composite material is 15.4%.

[0070] In this embodiment, the three-dimensional fiber preform is a three-dimensional carbon fiber preform with a two-dimensional semi-woven structure, and the volume fraction of fibers in the three-dimensional fiber preform is 43%.

[0071] In this example, the bending strength of the three-dimensional fiber prefabricated alumina composite material is 309MPa, and the fracture toughness is 14.8MPa·m 1 / 2 .

[0072] A...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bending strength | aaaaa | aaaaa |

| Fracture toughness | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com