Silica-alumina composite carrier and method for preparing same

A technology of alumina carrier and composite carrier, which is applied in catalyst activation/preparation, catalyst carrier, chemical instruments and methods, etc., to achieve the effect of prolonging the operation period, increasing the deposition amount, and good pore penetration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

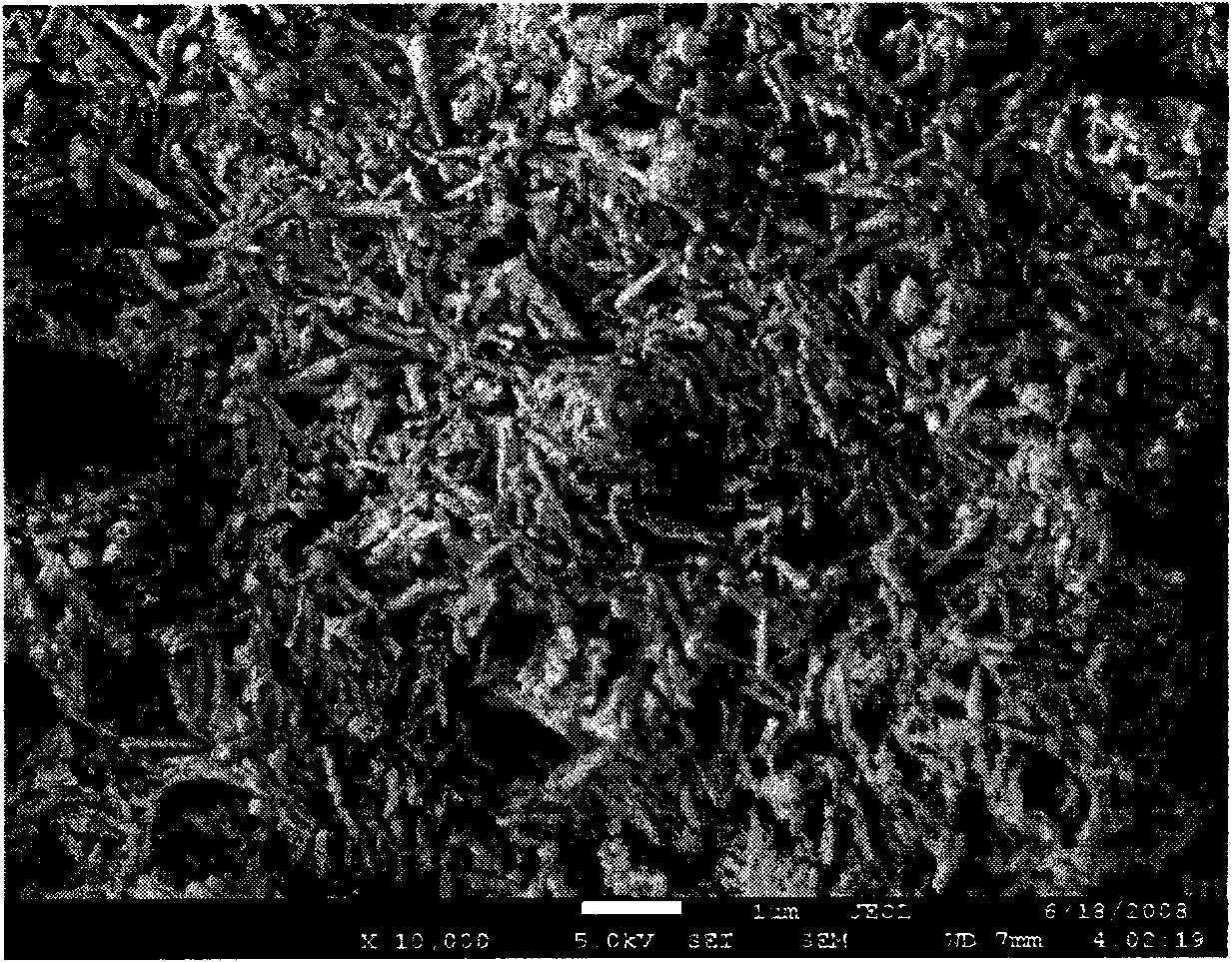

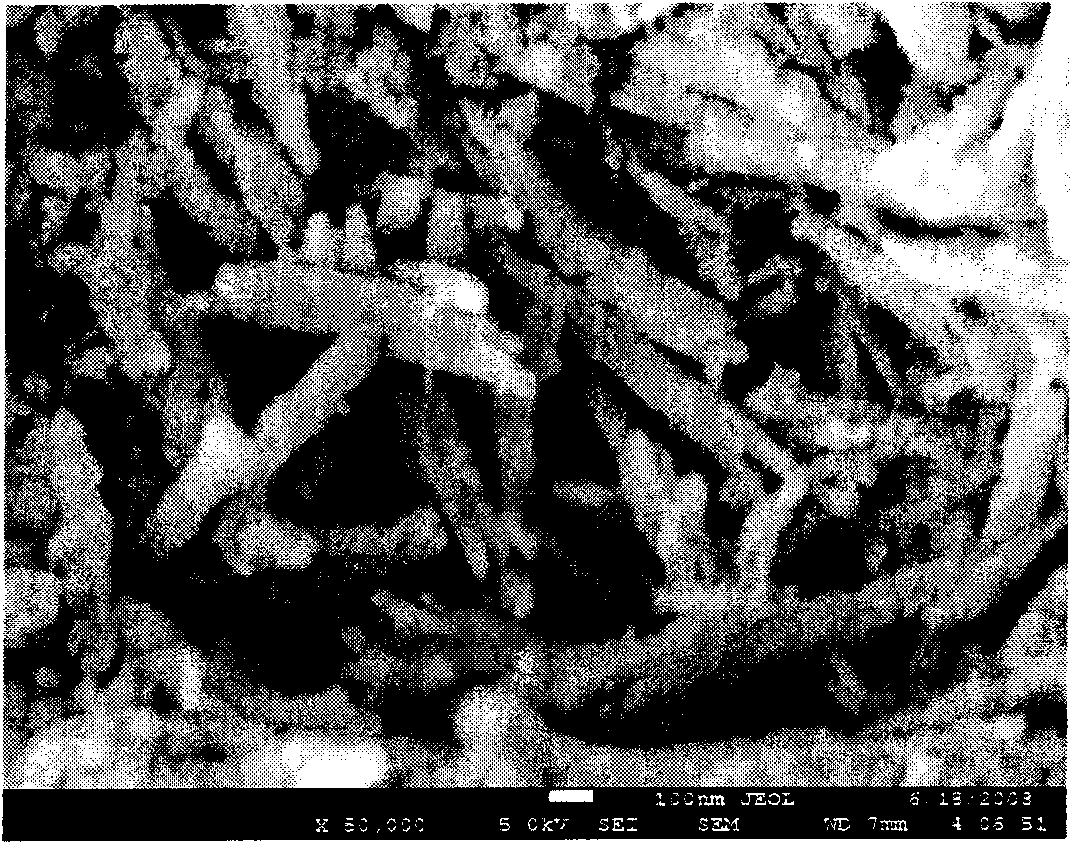

Embodiment 1

[0051] Under stirring conditions, 750g of aluminum nitrate nonahydrate and 130g of urea were mixed and heated to 100°C, and added to the mixture of 80g of polyisobutylene maleate triethanolamine maleate and 148g of 150HVI neutral oil at the same temperature to form supersolubilizing micelles , and then dropwise added 34.8g of silica sol (the weight content of silicon dioxide is 30%), mixed uniformly, and reacted at 130° C. for 10 hours to obtain nanometer silicon hydroxide-aluminum hydroxide gel. Wash three times with 200ml of distilled water, and dry at 120°C for 8 hours. Mix 104 g of nano silicon hydroxide-aluminum hydroxide gel dry powder and 30 g of pseudo-boehmite evenly. Mix 6g dilute nitric acid (mass concentration 17%), 60g water and 10g ethanol uniformly, then add in the mixture of nano silicon hydroxide-aluminum hydroxide gel dry powder and binder, stir well, mix on the mixer Uniform, and then shaped in the extruder, the pressure is controlled at 10MPa. The formed ...

Embodiment 2

[0053] The silica-alumina composite carrier SA1 obtained in Example 1 is impregnated with active metals, and the obtained residual oil hydrogenation catalyst HDN-1 contains 14% (mass fraction) Mo, 4% (mass fraction) Ni, and the appearance is shown in image 3 , pore distribution see Figure 4 .

[0054] The residual oil hydrogenation catalyst HDN-1 was used in the hydrodemetallization experiment of the residual oil raw material (properties are shown in Table 1), and the test conditions were as follows: temperature 390°C, hydrogen-to-oil volume ratio 1000, liquid hourly volume space velocity 1.0h -1 , hydrogen partial pressure 15.7MPa, continuous operation for 1500 hours. Investigate the demetallization properties in the residual oil, the weight content of metal impurities in the oil produced at different reaction times, see Figure 5 .

Embodiment 3

[0062]Mix 56g minus three-line dewaxed oil and 16g SP-80, heat to dissolve at 80°C, and mix well; heat 750g of aluminum nitrate nonahydrate to 80°C to melt, slowly add to the above mixture, and mix for 20 minutes to form a uniform supersolubilizing colloid. Then 148g of silica sol (the weight content of silicon dioxide is 30%) was added dropwise, and mixed evenly. 220 g of saturated ammonia water at 20° C. was added dropwise and aged for 3 hours to obtain a nano silicon hydroxide-aluminum hydroxide gel. Wash three times with 200ml of distilled water, and dry at 120°C for 10 hours. Mix 138.8g of nano-silica hydroxide-aluminum hydroxide gel dry powder with 92.5g of pseudo-boehmite; mix 2.31g of acetic acid, 189g of water and 2.31g of co-solvent methanol, and then add to nano-silica-hydroxide- In the mixture of aluminum hydroxide gel dry powder and binder, stir evenly, mix evenly on the mixer, and then shape it in the extruder, control the pressure at 30MPa. The molded product ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com