Core-shell structure catalyst, and preparation method and application thereof

A technology of core-shell structure and catalyst, which is applied in the field of core-shell structure catalyst preparation, can solve the problems of industrial application of catalyst deactivation, agglomeration of active components, and carbon deposition of catalysts, so as to improve anti-coking performance, improve stability, The effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] A preparation method of a core-shell structure catalyst, comprising the following specific steps:

[0052] Weigh 0.991g of Ni(NO 3 ) 2 .6H 2 O, add 50ml deionized water to dissolve, weigh 0.205g urea and 0.5g sodium lauryl sulfate and add to the above solution, 250W ultrasonically treat the mixed solution for 80min and then transfer it to a 100ml polytetrafluoroethylene container In a lined high-pressure reactor, put the reactor in an oven at 150°C for hydrothermal reaction for 10 hours; after the reaction, filter and wash to obtain Ni(OH) 2 And redisperse it in 80ml deionized water, 250W ultrasonic treatment for 10min, then add 7.2g aluminum isopropoxide, 0.5g sodium lauryl sulfate and 3.2g urea, 250W ultrasonic treatment for 80min, transfer to the autoclave for 150 ℃ for 10 hours; after the reaction, filter, wash, dry at 120℃ for 2 hours and roast at 500℃ for 3 hours to obtain Ni / Al 2 o 3 catalyst.

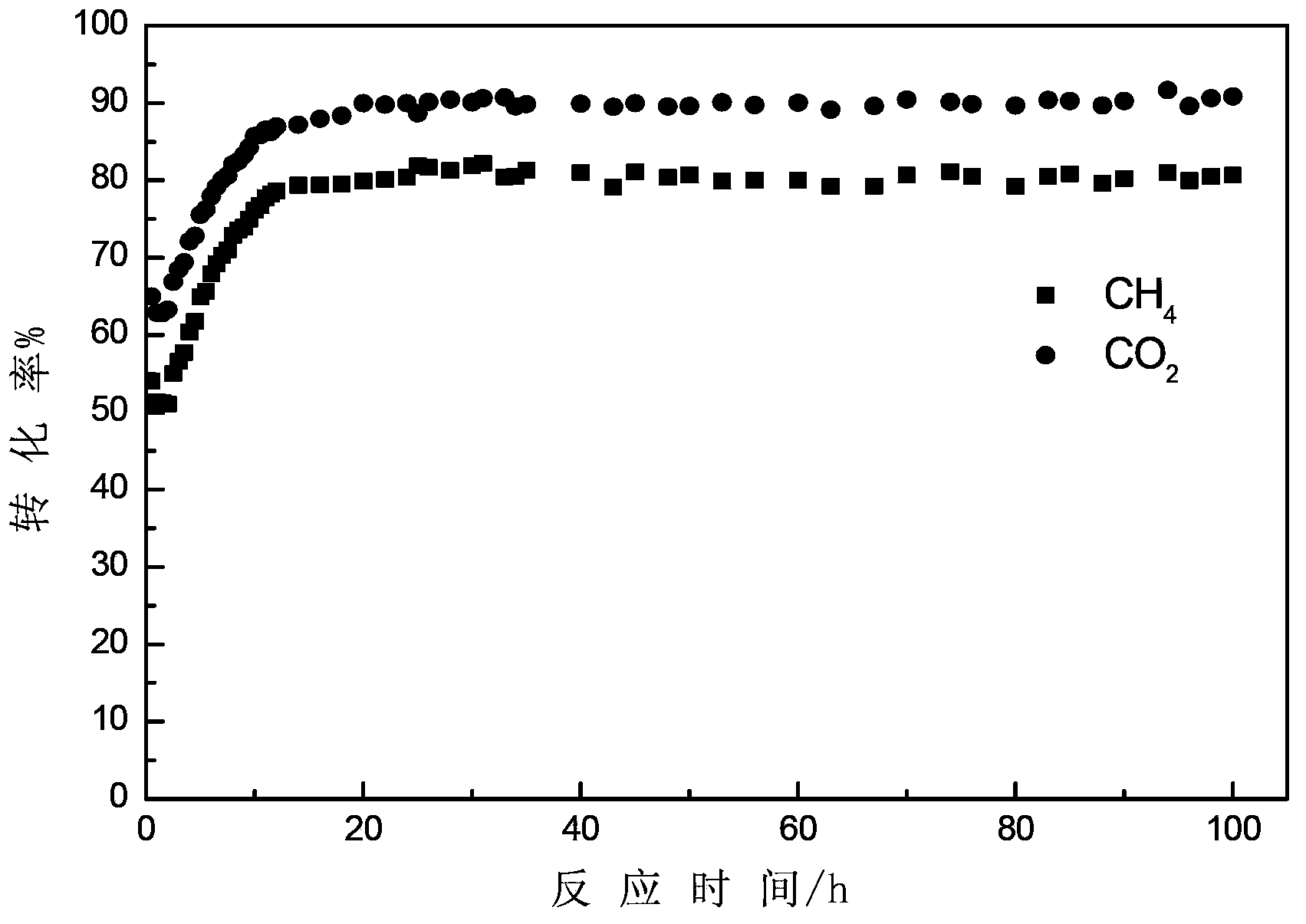

[0053] The resulting Ni / Al 2 o 3 The catalyst is based on Ni...

Embodiment 2

[0056] A preparation method of a core-shell structure catalyst, comprising the following specific steps:

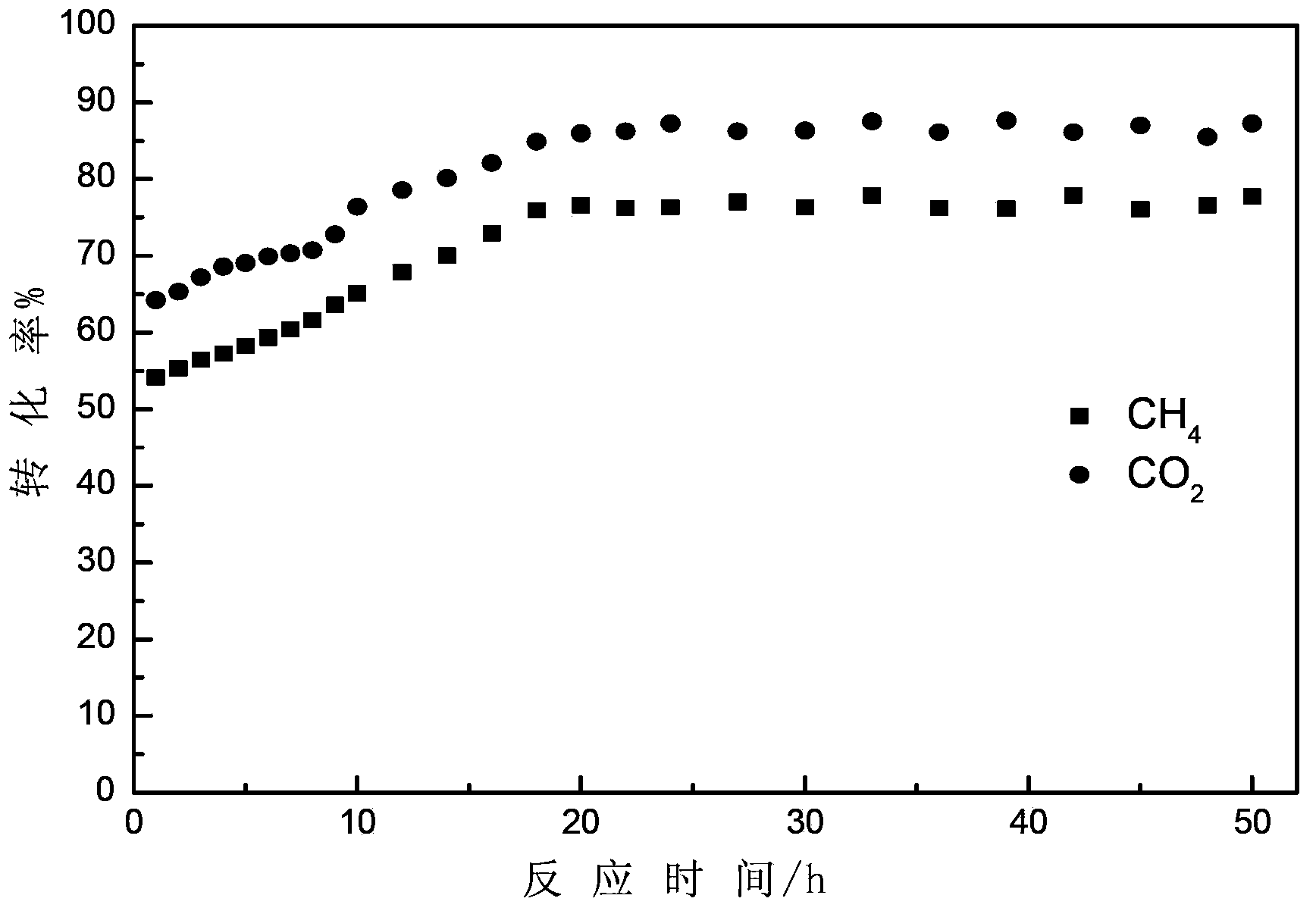

[0057] Weigh 1.98g of Ni(NO 3 ) 2 .6H 2 O, add 60ml of deionized water to dissolve, weigh 0.41g of urea and 0.5g of sodium lauryl sulfate and add to the above solution, 200W ultrasonically treat the mixed solution for 10min and then transfer it to a 100ml tank with a capacity of 100ml. In a lined high-pressure reactor, put the reactor in an oven at 150°C for hydrothermal reaction for 10 hours; after the reaction is completed, Ni(OH) 2 And redisperse it in 80ml deionized water, 200W ultrasonic treatment for 20min, then add 6.4g aluminum isopropoxide, 0.5g sodium lauryl sulfate and 2.84g urea, 200W ultrasonic treatment for 80min, then transfer to a high-pressure chamber with a capacity of 150ml Reaction in the reactor at 150°C for 10h. After the reaction was completed, Ni / Al was obtained after filtration, washing, drying at 150°C for 12 hours, and calcination at 400°C f...

Embodiment 3

[0061] A preparation method of a core-shell structure catalyst, comprising the following specific steps:

[0062] Weigh 3.964g of Ni(NO 3 ) 2 .6H 2 O, add 50ml of deionized water to dissolve, weigh 0.82g of urea and 1.8g of oleylamine into the above solution, 300W ultrasonically treat the mixed solution for 20min, and then transfer it to a high-pressure reactor with a capacity of 100ml and lined with polytetrafluoroethylene. The reactor was placed in an oven at 180°C for hydrothermal reaction for 5 hours. After the reaction is finished, Ni(OH) is obtained after filtering and washing 2 And redisperse it in 80ml deionized water, 300W ultrasonic treatment for 30min, then add 4.8g aluminum isopropoxide, 2g oleylamine and 2.13g urea, 300W ultrasonic treatment for 30min, then transfer to a 150ml high-pressure reactor at 180℃ React for 50 hours; after the reaction is over, filter, wash, dry at 60°C for 15 hours, and roast at 700°C for 3 hours to obtain Ni / Al 2 o 3 catalyst.

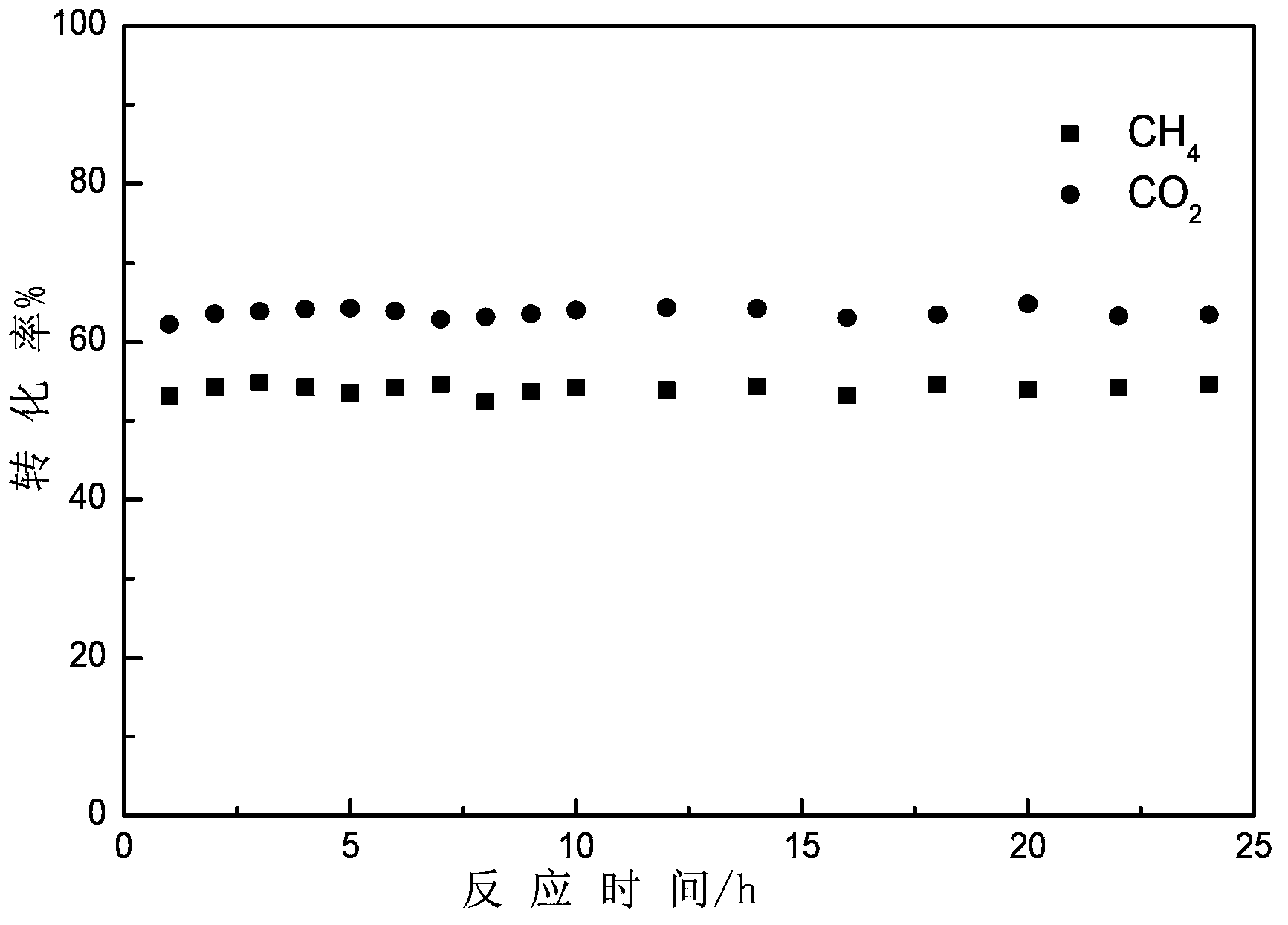

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com