Super-hydrophilic and underwater super-oleophobic oil-water separation mesh membrane having, and its preparation method

An oil-water separation membrane and underwater super-oleophobic technology, applied in chemical instruments and methods, semi-permeable membrane separation, membrane technology, etc., can solve problems such as complex processes, achieve good separation effect, good stability, and oil-water separation good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Embodiment 1, prepare superhydrophilic and underwater superoleophobic oil-water separation omentum

[0028] (1) Soak the 400-mesh copper net in ethanol and acetone for 15 minutes, and then dry it;

[0029] (2) At room temperature, add 100ml of water, 4.0g of sodium hydroxide and 1.35g of potassium persulfate into a 250ml beaker, stir well to obtain a mixed solution, the molar concentration of sodium hydroxide in the mixed solution is 1.0mol / L, The molar concentration of potassium persulfate is 0.05mol / L;

[0030] (3) Immerse all the copper mesh obtained in step (1) into the mixed solution obtained in step (2);

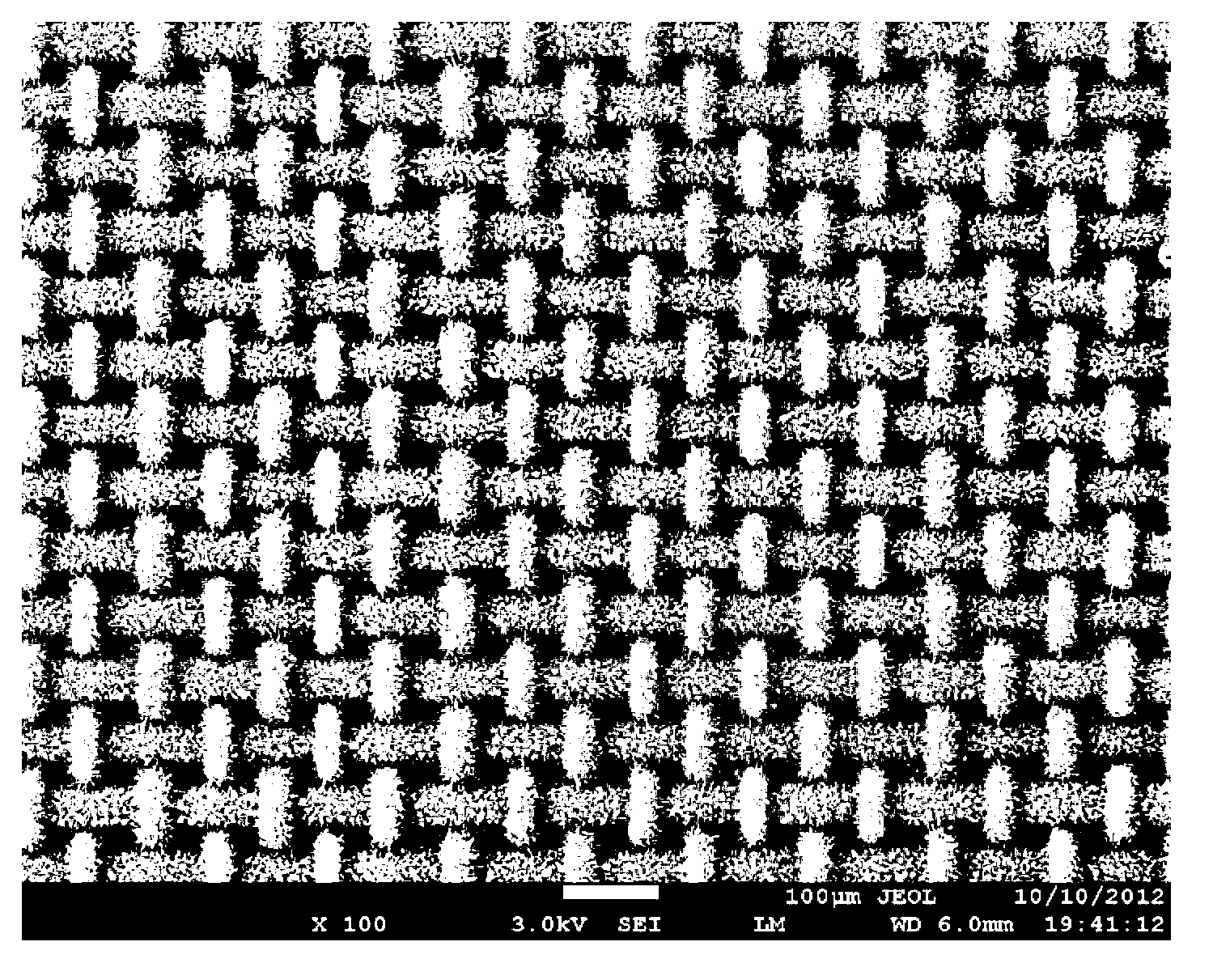

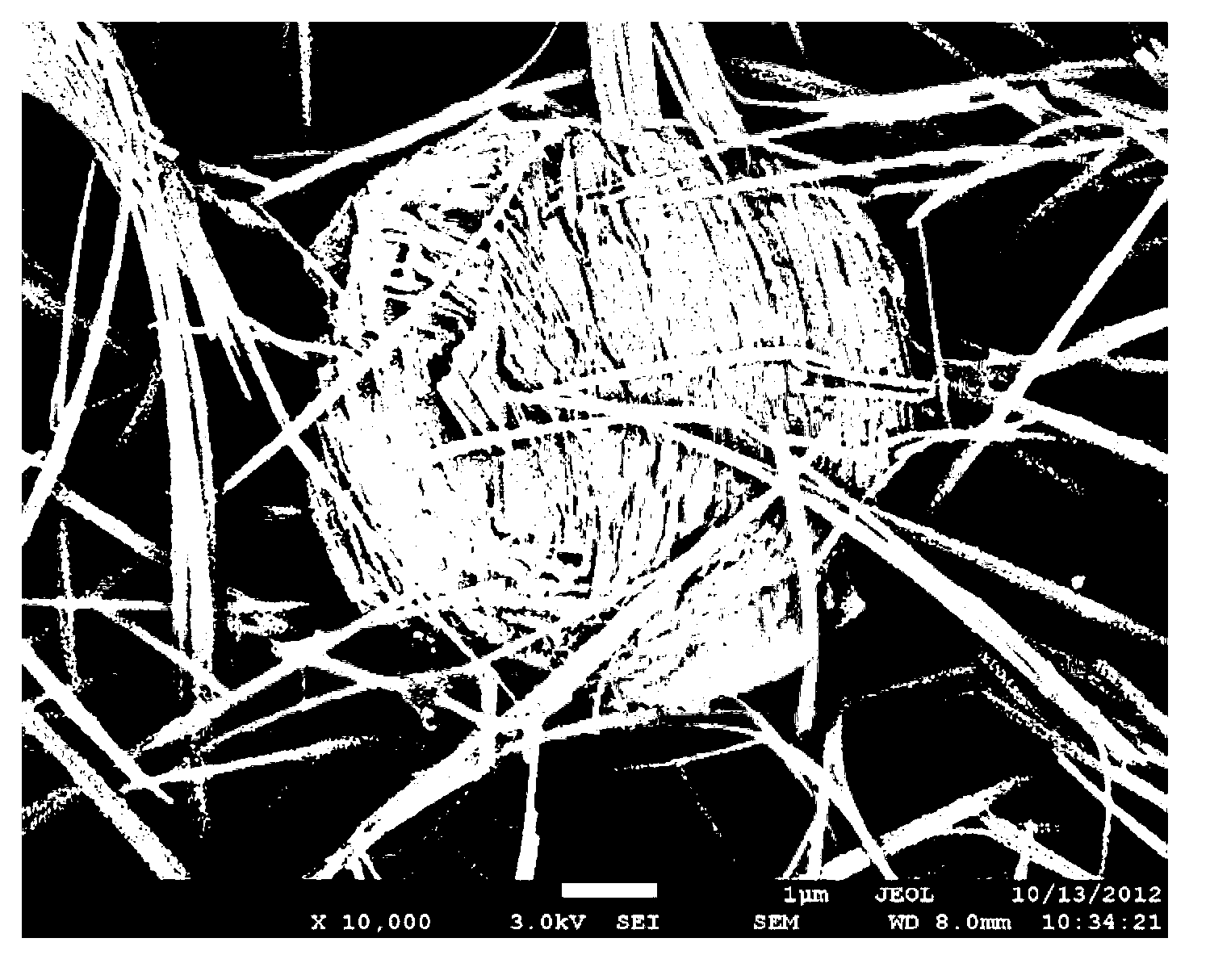

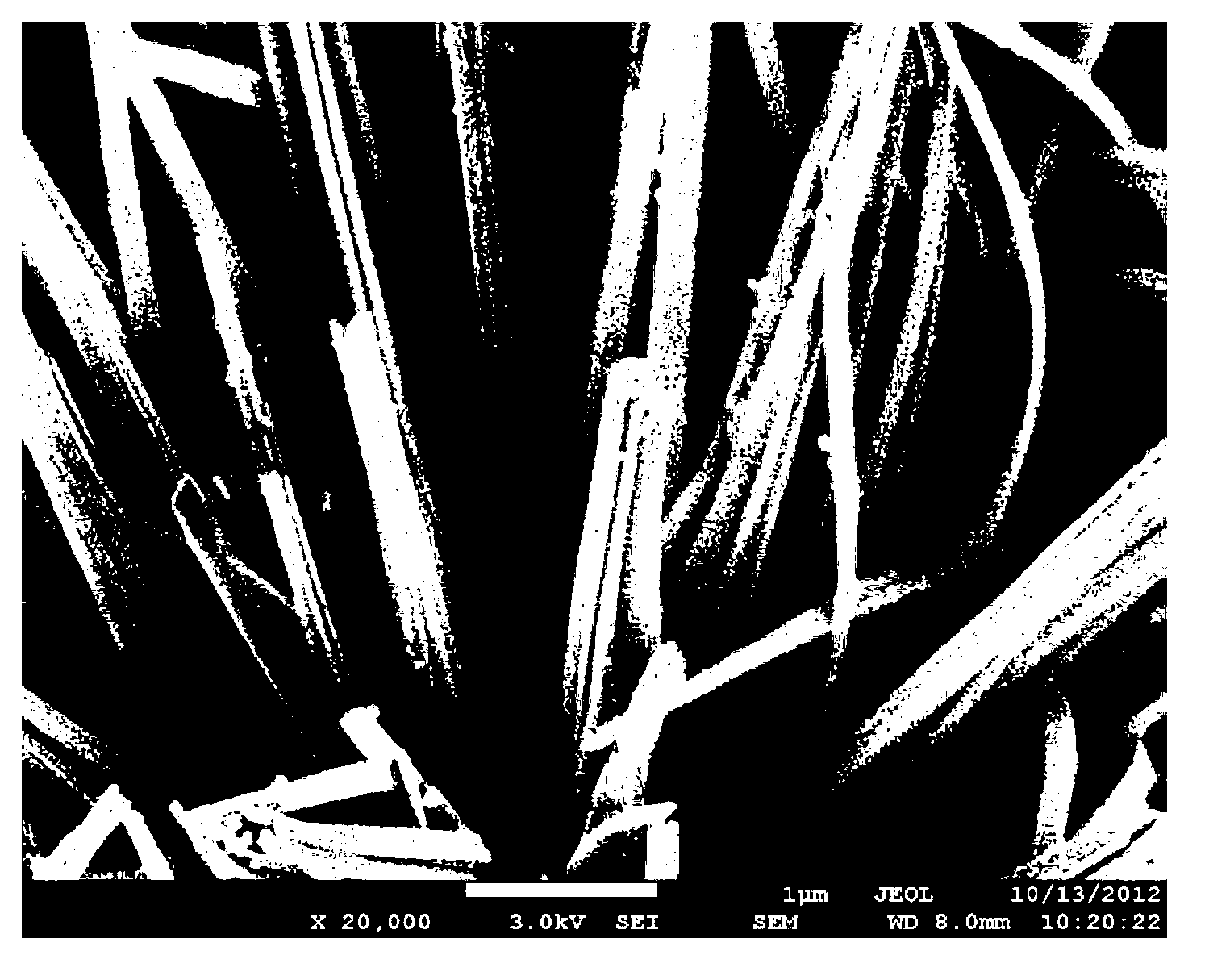

[0031] (4) Wash it with water after 0.5 hours of oxidation reaction, and form a uniform micron and nanocomposite structure on the wire of the copper mesh (such as Figure 1a As shown), there are countless nanoneedles with a length of 6-10 microns and a diameter of 200-550 nm distributed on the mesh (such as Figure 1c shown) and crystals with a diameter of 5-1...

Embodiment 2

[0034] Embodiment 2, prepare superhydrophilic and underwater superoleophobic oil-water separation omentum

[0035] (1) Dip the 200-mesh brass mesh into ethanol and acetone and ultrasonically clean it for 15 minutes, then dry it;

[0036] (2) At room temperature, add 100ml of water, 8.0g of sodium hydroxide and 2.28g of ammonium persulfate into a 250ml beaker, stir well to obtain a mixed solution, the molar concentration of sodium hydroxide in the mixed solution is 2.0mol / L, The molar concentration of ammonium persulfate is 0.10mol / L;

[0037] (3) Immerse all the brass mesh obtained in step (1) into the mixed solution obtained in step (2);

[0038] (4) Wash it with water after 0.25 hours of oxidation reaction, and form a uniform micron and nanocomposite structure on the mesh of the brass mesh. Numerous nanometers with a length of 5 to 7 microns and a diameter of 100 to 400 nanometers are distributed on the mesh. Crystals with a diameter of 1-5 microns coated on the needles an...

Embodiment 3

[0041] Embodiment 3, prepare superhydrophilic and underwater superoleophobic oil-water separation omentum

[0042] (1) Soak the 300-mesh phosphor copper mesh in ethanol and acetone for 15 minutes, and then dry it;

[0043] (2) At room temperature, add 100ml of water, 16.8g of potassium hydroxide and 3.57g of sodium persulfate into a 250ml beaker, stir well to obtain a mixed solution, the molar concentration of potassium hydroxide in the mixed solution is 3.0mol / L, The molar concentration of sodium persulfate is 0.15mol / L;

[0044] (3) Immerse all the phosphor copper mesh obtained in step (1) into the mixed solution obtained in step (2);

[0045] (4) Wash it with water after 1.0 hours of oxidation reaction, and form a uniform micron and nanocomposite structure on the mesh of the phosphor copper mesh. Numerous nanometers with a length of 6 to 10 microns and a diameter of 100 to 500 nanometers are distributed on the mesh. Crystals with a diameter of 1-10 microns coated on the n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com