Highly efficient anti-phase emulsion breaker for thick oil pollution water processing

A technology of inverse demulsifier and heavy oil sewage, applied in chemical/physical processes, dissolution, chemical instruments and methods, etc., can solve the problems of difficult control of the production process, difficult to achieve synthesis conditions, high production costs, and achieve demulsification efficiency. The effect of high, low production cost and fast separation of oil and water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

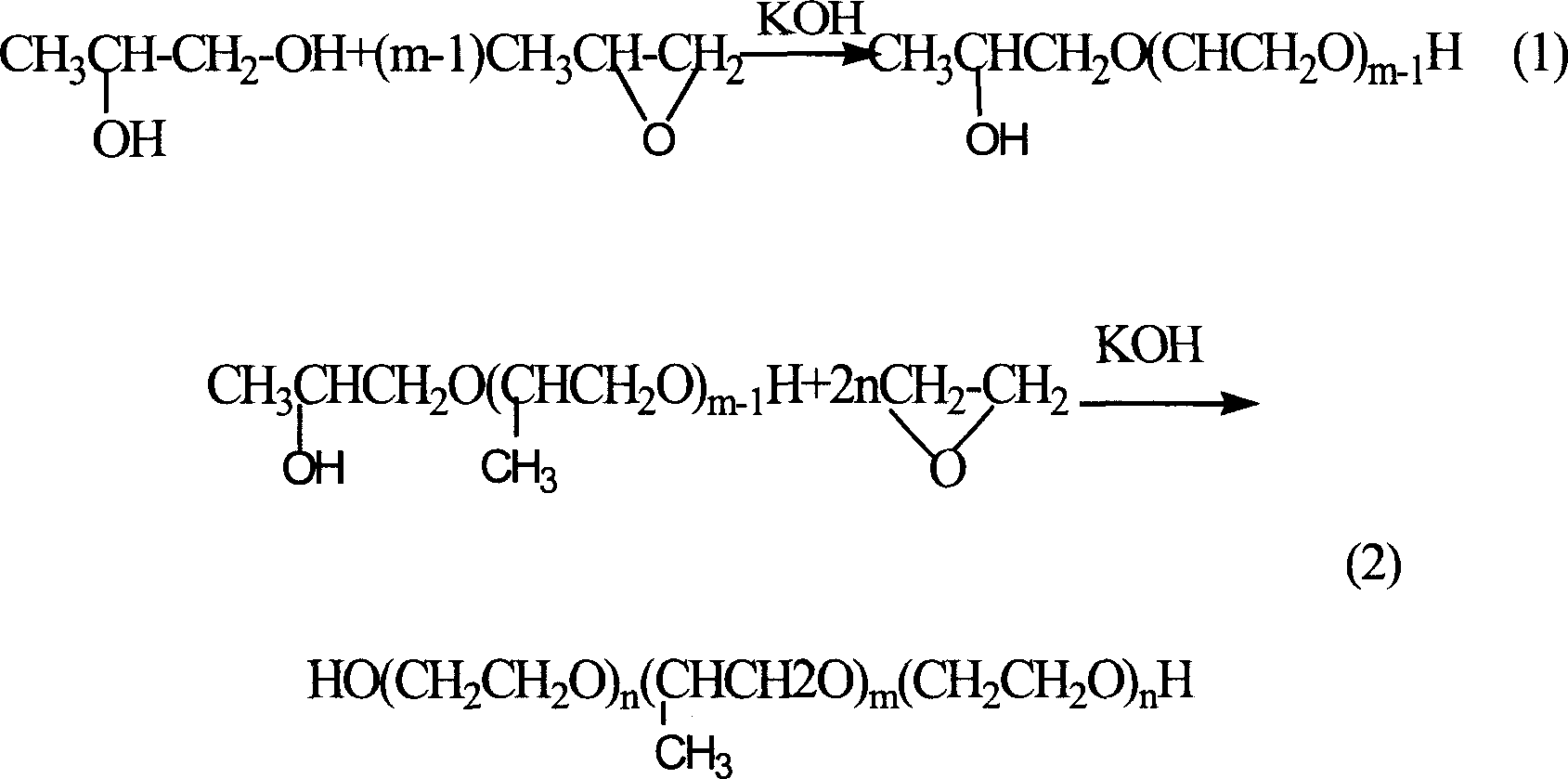

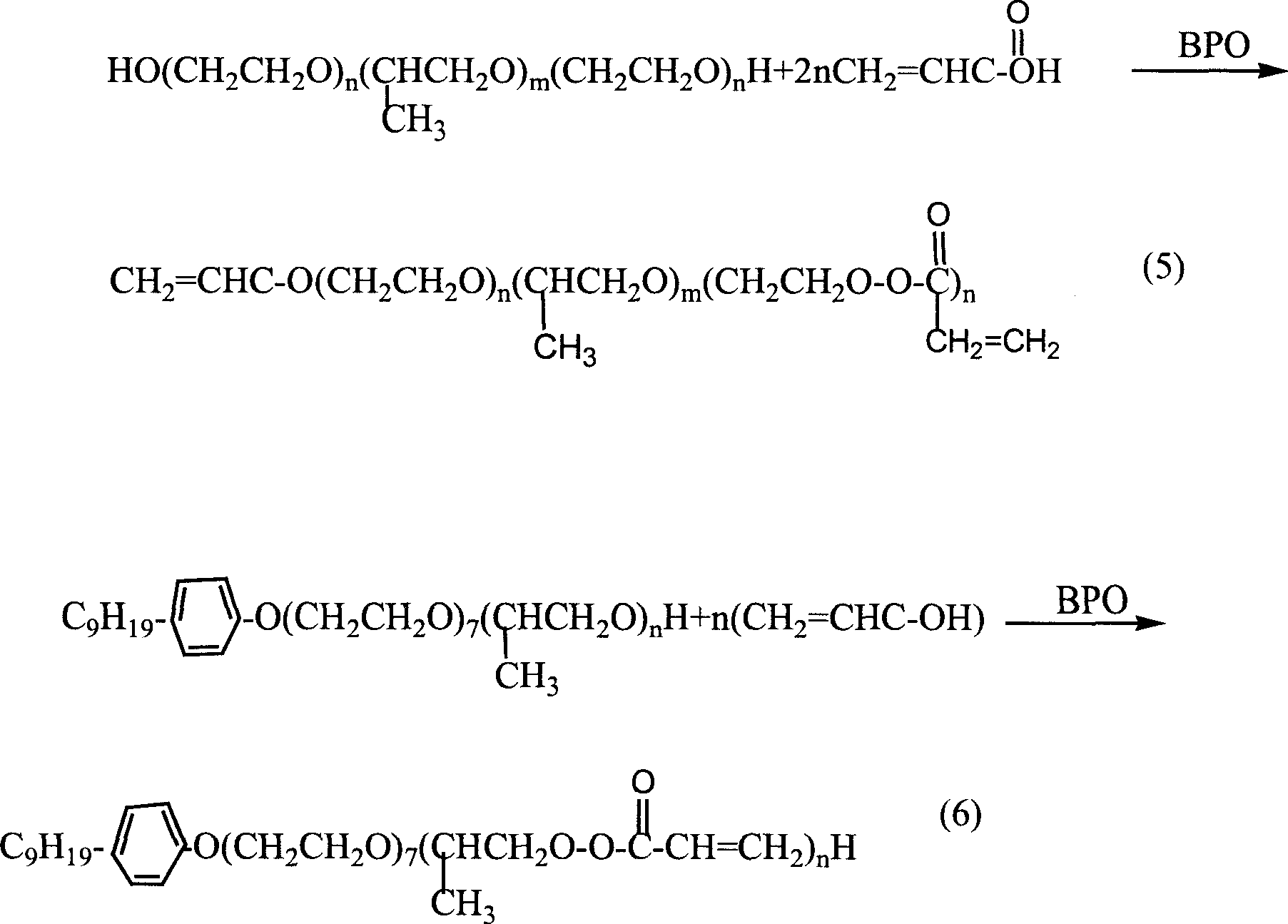

[0020] 1. Synthesis of Propylene Glycol Polyether

[0021] In a clean and dry three-necked flask, add 0.5mol of propylene glycol starter, then add 0.7g (about 2%) of catalyst KOH, replace with nitrogen 4 times, heat to 100°C under stirring, vacuumize and remove moisture, then Add 2.0mol propylene oxide and 2.0mol ethylene oxide to the three-necked flask successively, keep the temperature at 100°C, react for 6 hours, lower the temperature, clean the reaction with nitrogen, then discharge, wash with absolute ethanol 4 times, and then After drying at 120°C for 24 hours, the obtained white solid product is propylene glycol polyether.

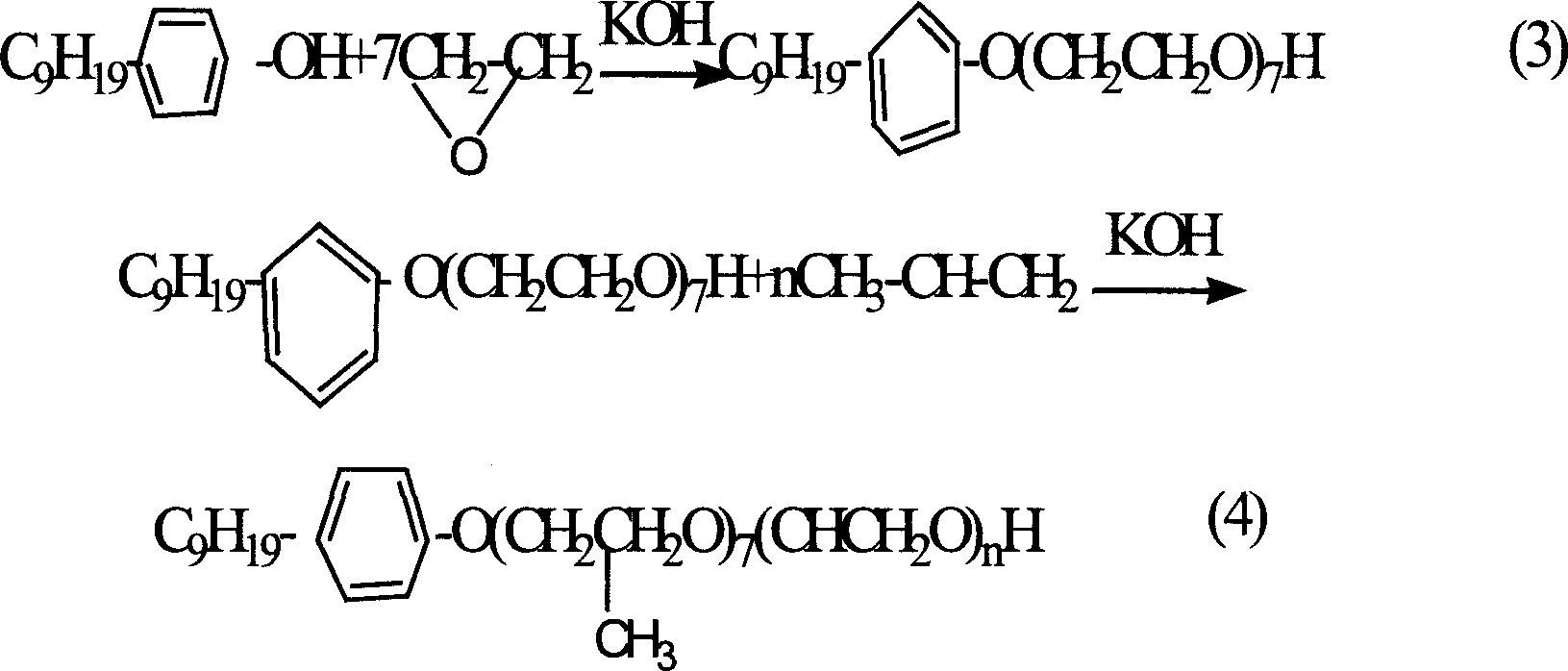

[0022] 2. Synthesis of alkylphenol polyoxyethylene ether

[0023] Add 0.5mol of nonylphenol initiator and 4.8g (about 2%) of catalyst KOH into a clean and dry autoclave, and after installing the autoclave, use nitrogen to purge the pipeline several times, and heat to 100°C- 110°C, vacuumize to remove moisture, then inject nitrogen into the autocla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com