Separation device for solid fermented fungus spore and separation method

A solid-state fermentation, fungal spore technology, applied in fungi, biochemical equipment and methods, bioreactor/fermenter combinations, etc., can solve the problems of high filtration resistance, high labor intensity, and dead ends of stirring, and achieve separation speed. Fast, labor-intensive, and small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

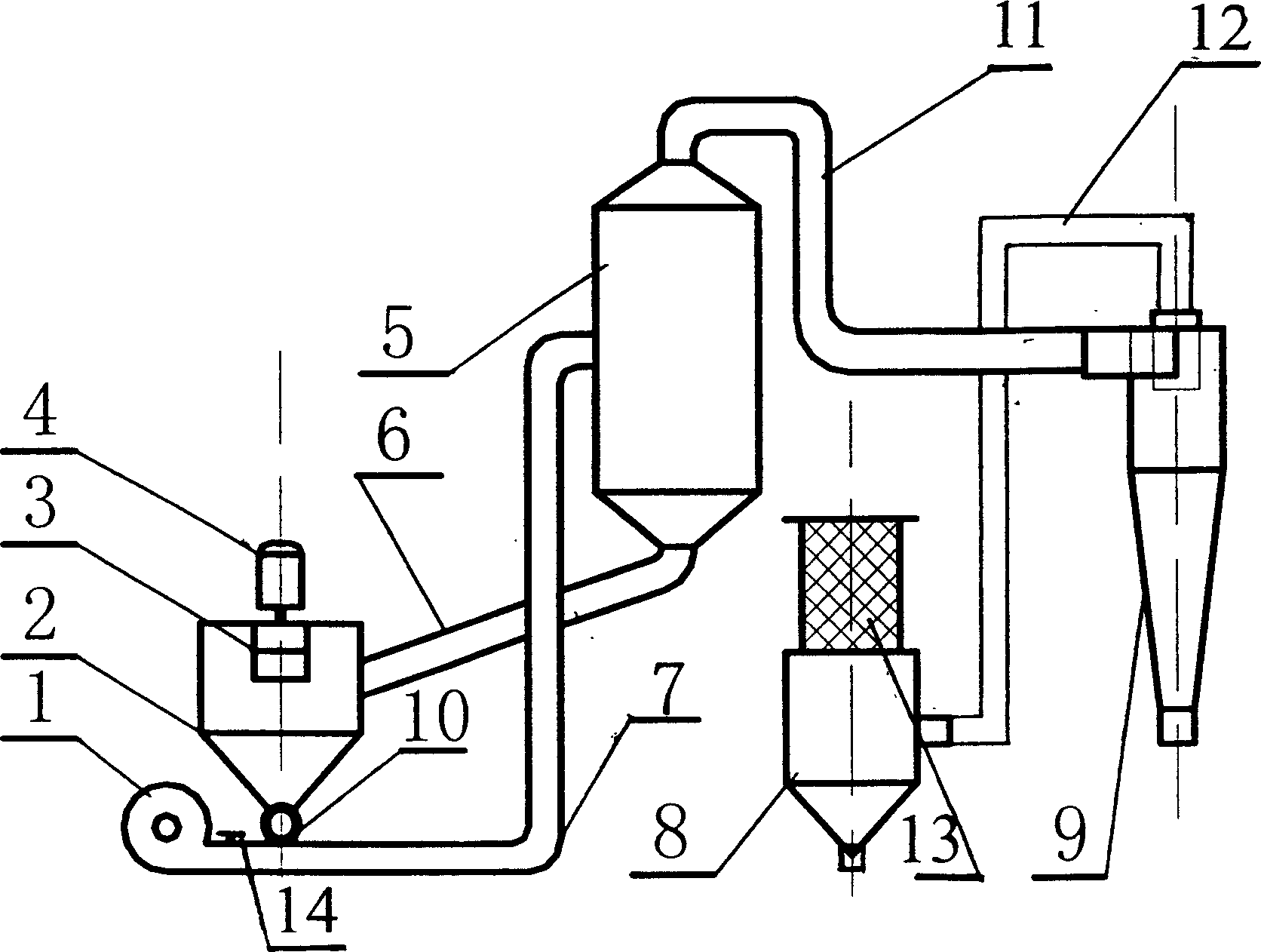

Method used

Image

Examples

Embodiment 1

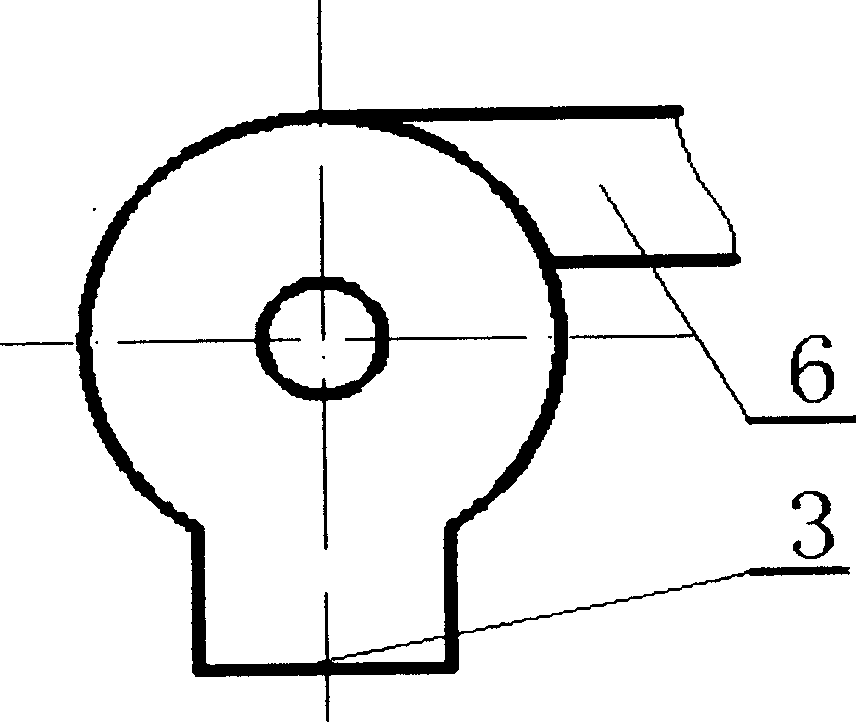

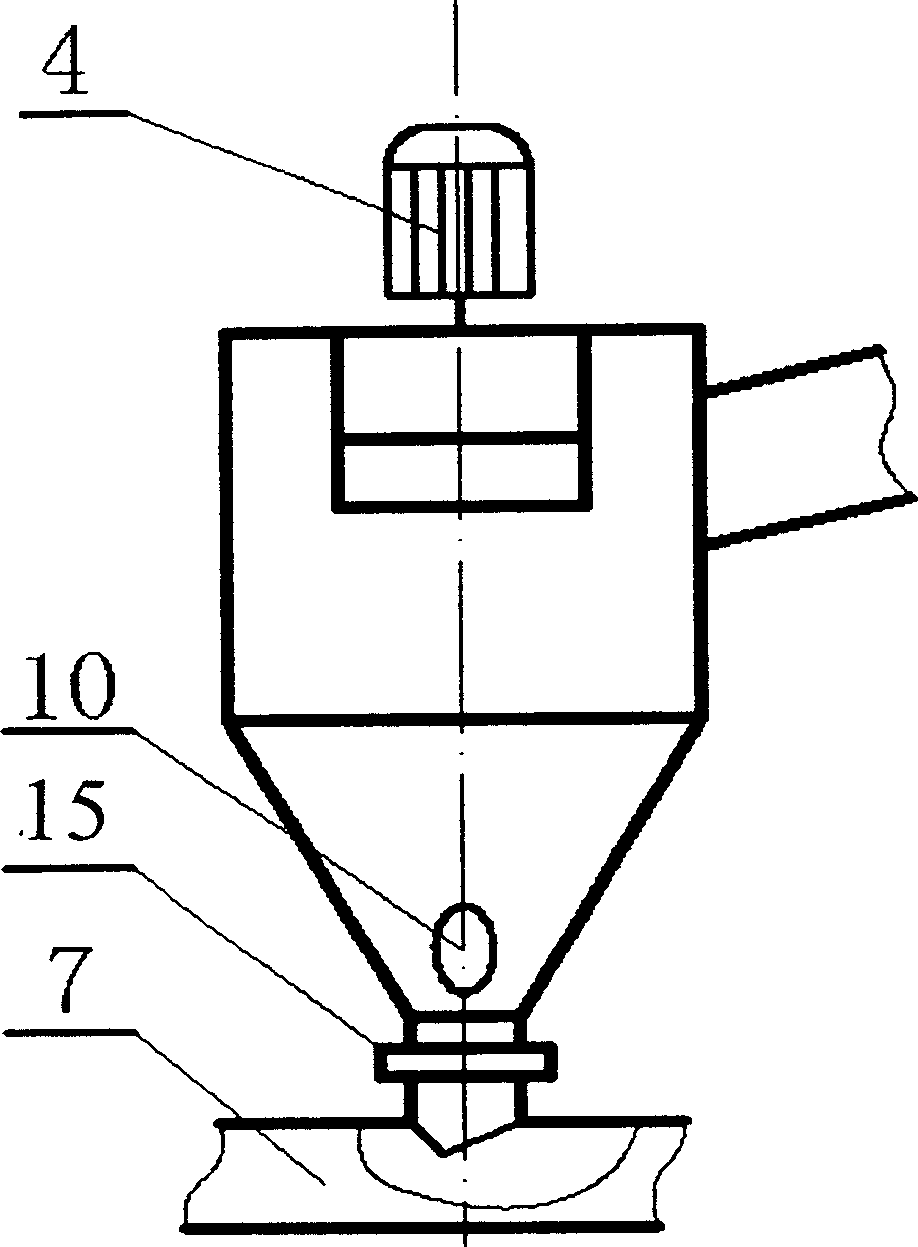

[0027] The Trichoderma viridans solid-state fermentation medium after weighing 1kg is dried, (moisture content 10%), drop in the feed hopper 2, close feed port 3, start agitator 4, stirring speed is 1500 rev / mins, starts centrifugation after 7 minutes Fan 1, turn on the fan, adjust the valve 14, and use the valve to adjust the air flow rate to 25 m / s. At this time, the solid particles enter the acceleration tube 7 with the air flow, and the accelerated solid particles hit the inertial separator at a speed of 18-20 m / s. 5. The conical disk 17 at the bottom, through high-speed impact, the spores attached to the surface of the solid particles break away and enter the cyclone separator 9 with the air flow, while the solid particles themselves slide down the conical disk 17 to the return pipe 6, and then return to the cyclone separator 9. In the hopper 2, after 10 minutes, all the solid medium particles in the hopper 2 circulate 6 times in the hopper 2, the acceleration tube 7, the ...

Embodiment 2

[0029] The Trichoderma viridans solid-state fermentation medium after weighing 2kg is dried, (moisture content 7%), drop into in the feed hopper 2, close feed inlet 3, start agitator 4, stirring speed is 2000 rev / mins, starts centrifugation after 5 minutes Fan 1, adjust the air flow rate to 25 m / s with valve 14, after 6 minutes, all the solid medium particles in the hopper 2 are in the hopper 2, the acceleration tube 7, the inertial separator 5, the return pipe 6, and the hopper 2 Middle circulation flows 5 times, close fan 1, agitator 4; Can collect the green Trichoderma spore powder of about 75g at the bottom of cyclone separator 9, open discharge port 10, can see that the culture medium of original green becomes khaki.

Embodiment 3

[0031] The Trichoderma viridans solid-state fermentation medium after weighing 1.5kg drying, (moisture content 5%), drop in the feed hopper 2, close feed port 3, start agitator 4, stirring speed is 3000 rev / mins, starts after 3 minutes Centrifugal fan 1, adjust the air flow rate to 25 m / s with a valve, after 5 minutes, all the solid medium particles in the feeding hopper 2 are in the feeding hopper 2, accelerating tube 7, inertial separator 5, return pipe 6, and feeding hopper 2 Middle circulation flows 5 times, close fan 1, mixer 4; Can collect the green trichoderma spore powder of about 40g at the bottom of cyclone separator 9, open discharge port 10, can see that the former green culture medium becomes khaki.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com