Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

57results about How to "Reduce oil yield" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

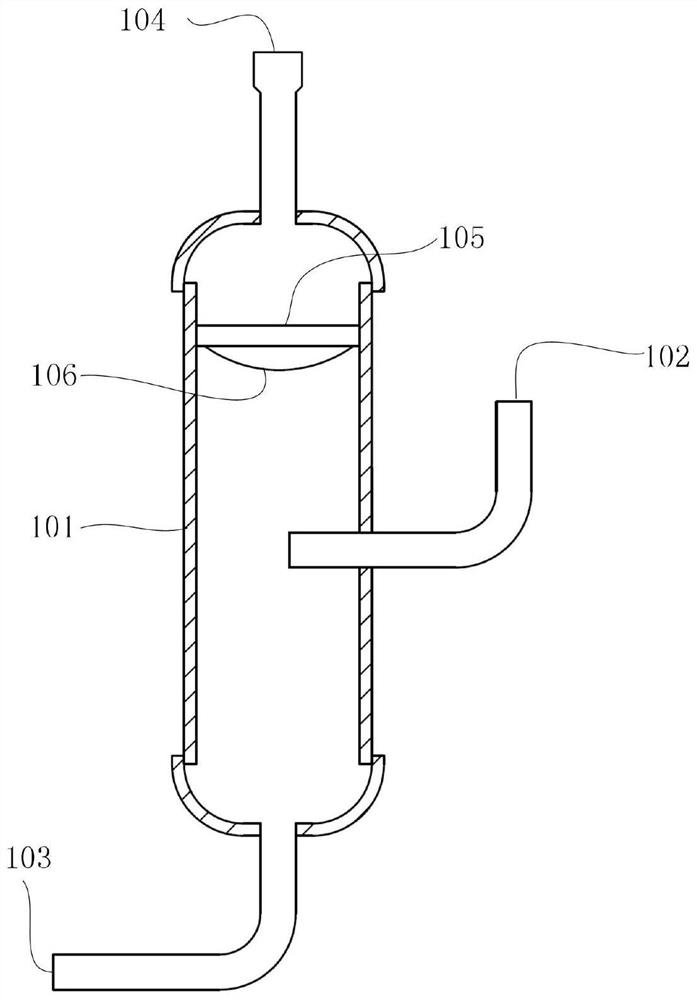

Plant volatile oil extractor and application thereof

ActiveCN101538510AQuick extractionEasy feedingEssential-oils/perfumesDistillation separationDistillationLaboratory facility

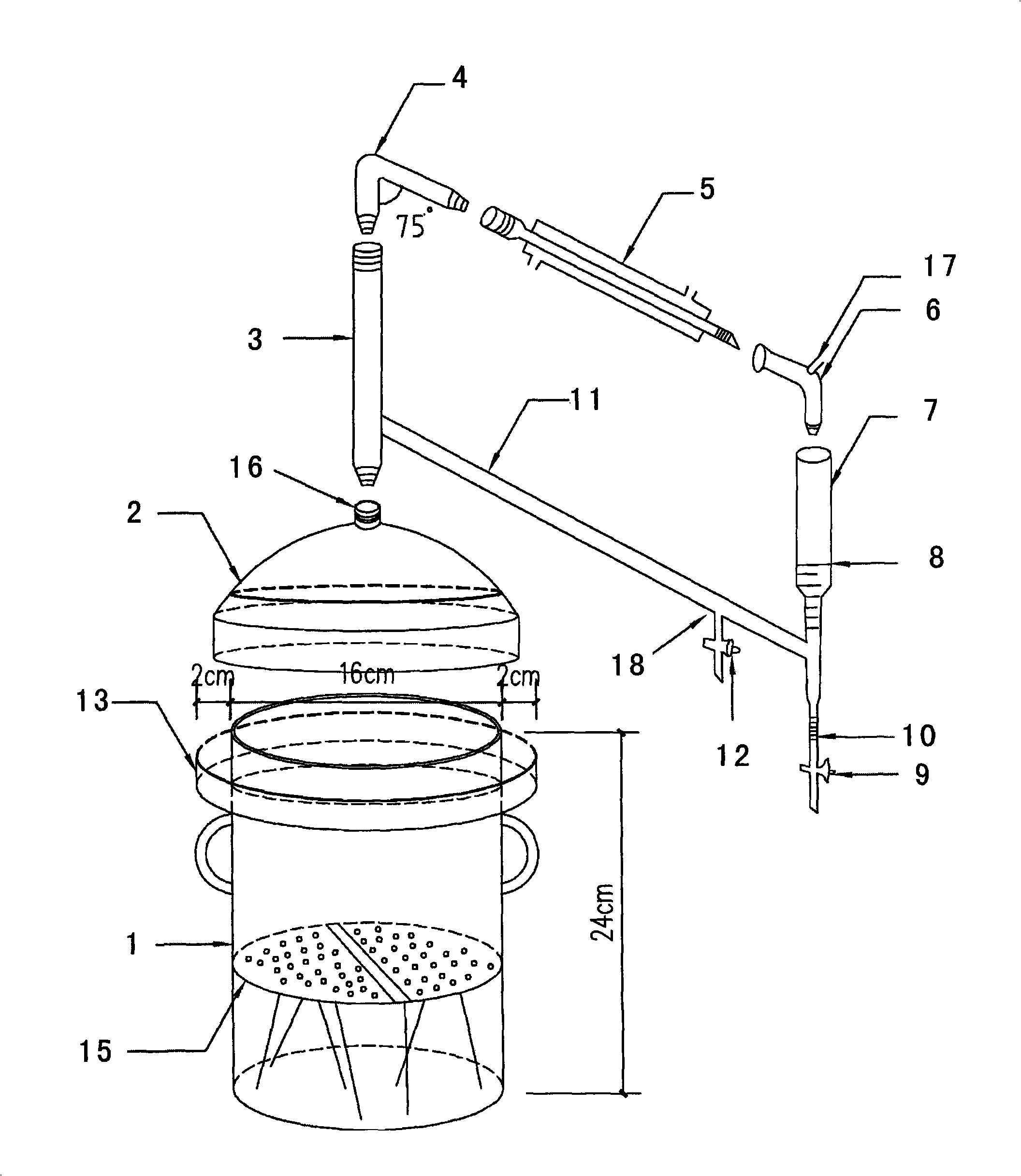

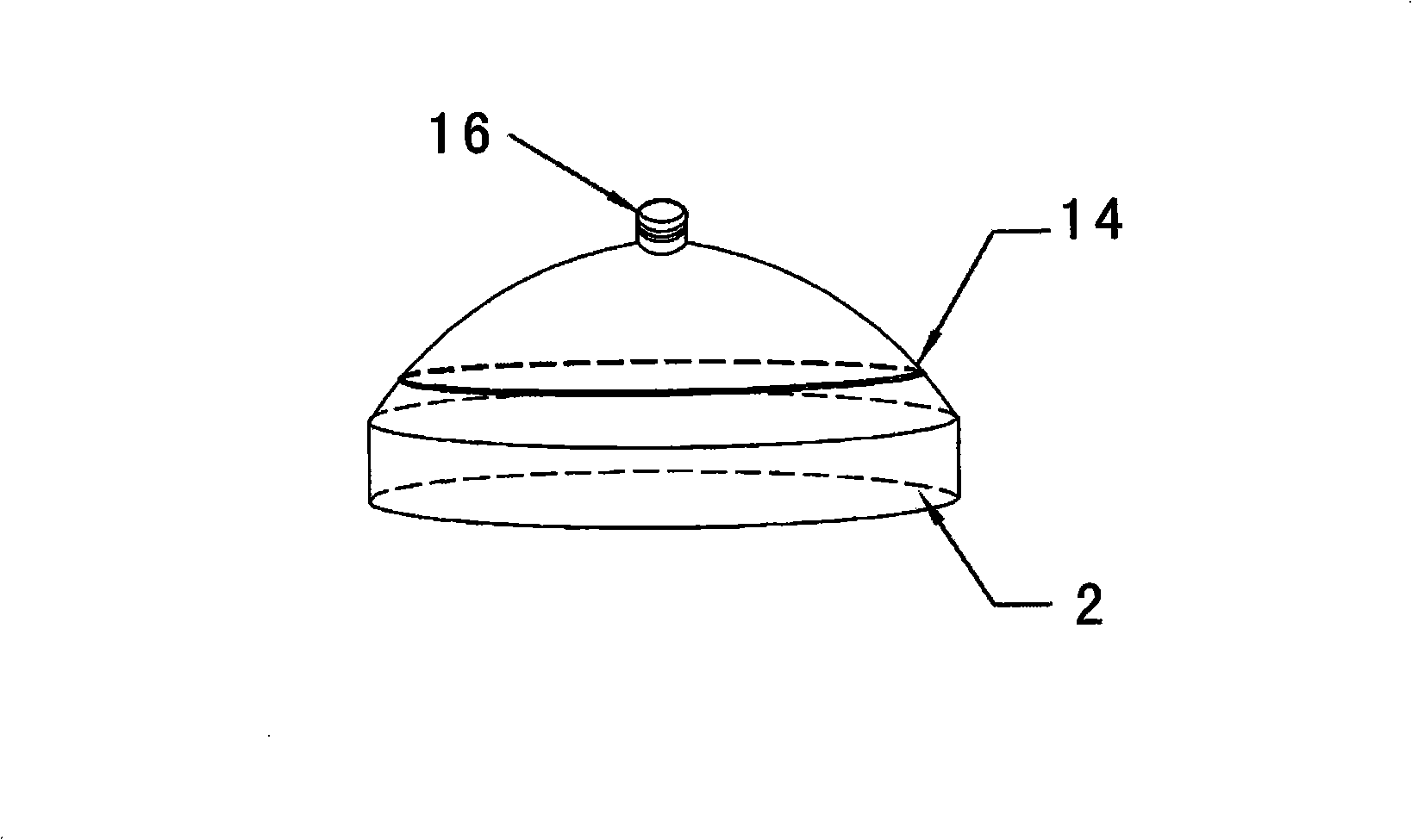

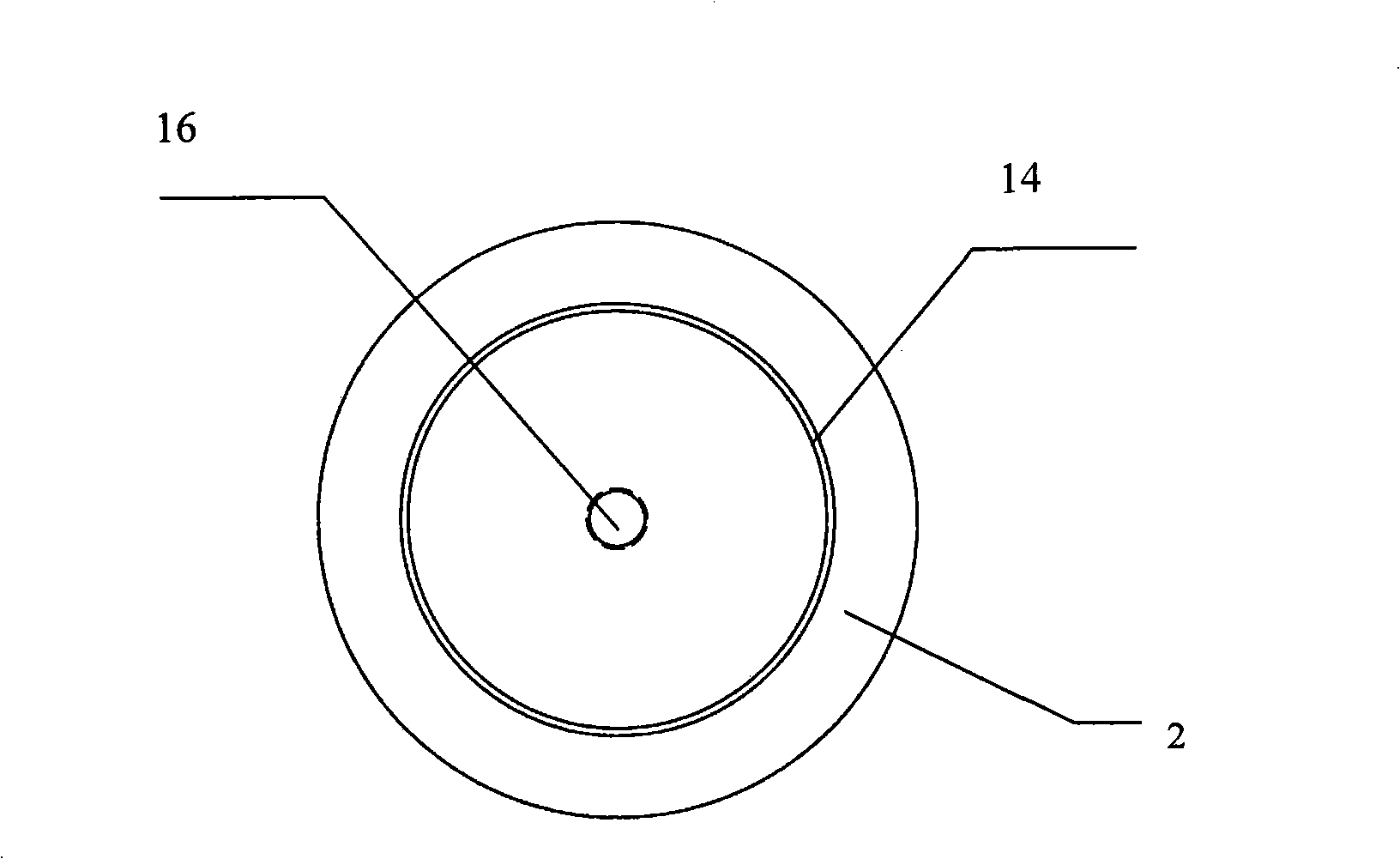

The invention discloses a plant volatile oil extractor and application thereof. The device comprises a distiller, a condenser and a collector. The distiller comprises a distilling container, a sealing cover matched with the distilling container and a water-resisting grate matched with the distilling container. The top of the sealing cover is provided with through holes. The condenser comprises a condenser pipe. The through holes at the top of the sealing cover are connected with the lower end of a vertical gas tube. The gas tube is connected with the inlet of the condenser pipe by a connecting bend. The outlet of the condenser pipe is connected with the inlet of the collector by the connecting bend. The plant volatile oil extractor in the invention can be used for fast extracting volatile oil with different specific weights in plants. The extractor has the characteristics that the extractor is convenient, easily disassembled and carried, simple to load and unload materials, and suitable for distillation requirements of water-resisting distillation, water distillation, backwater distillation and non-backwater distillation, and has high extraction rate. The extractor can be used for laboratory, in particular for field.

Owner:INST OF BOTANY CHINESE ACAD OF SCI

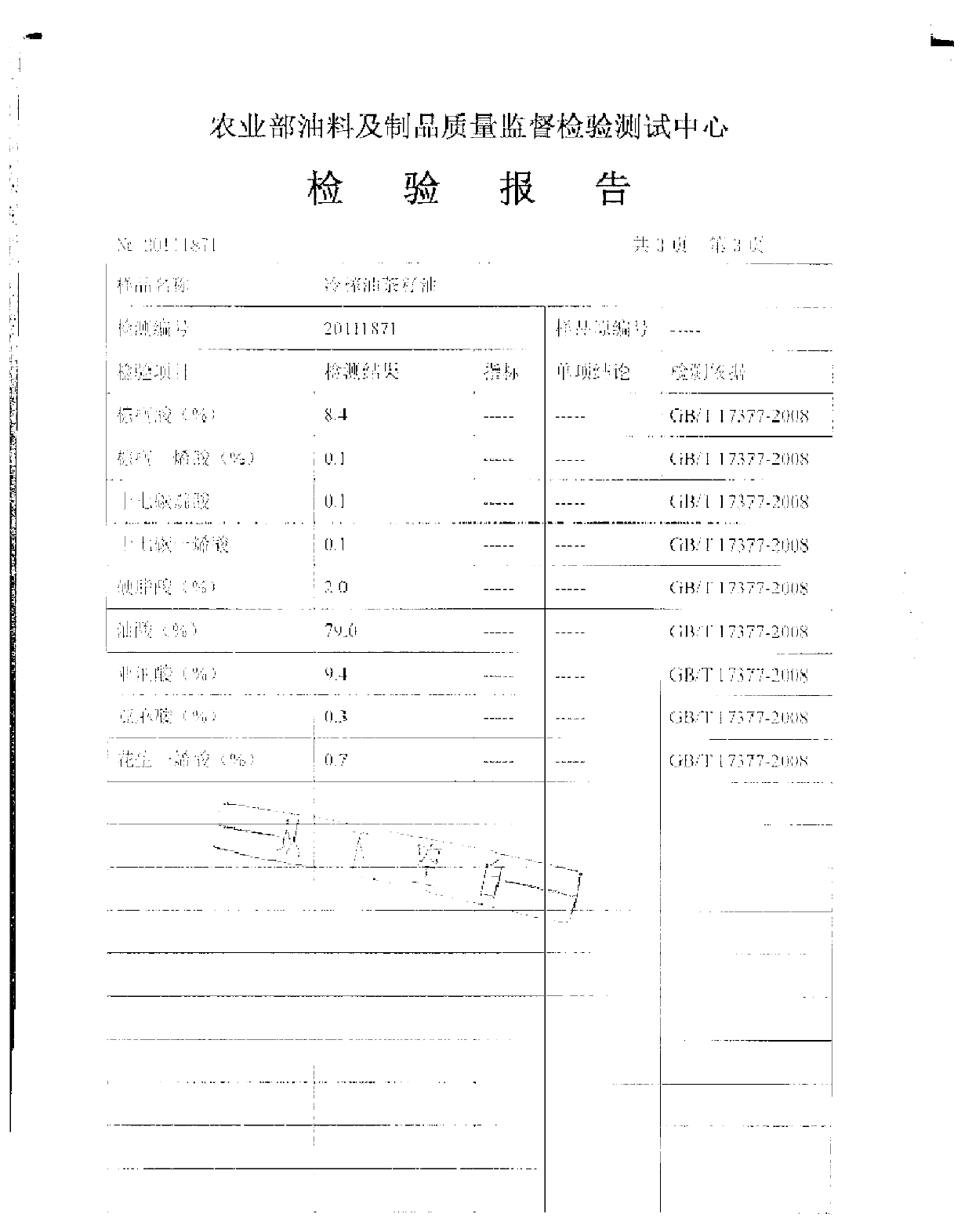

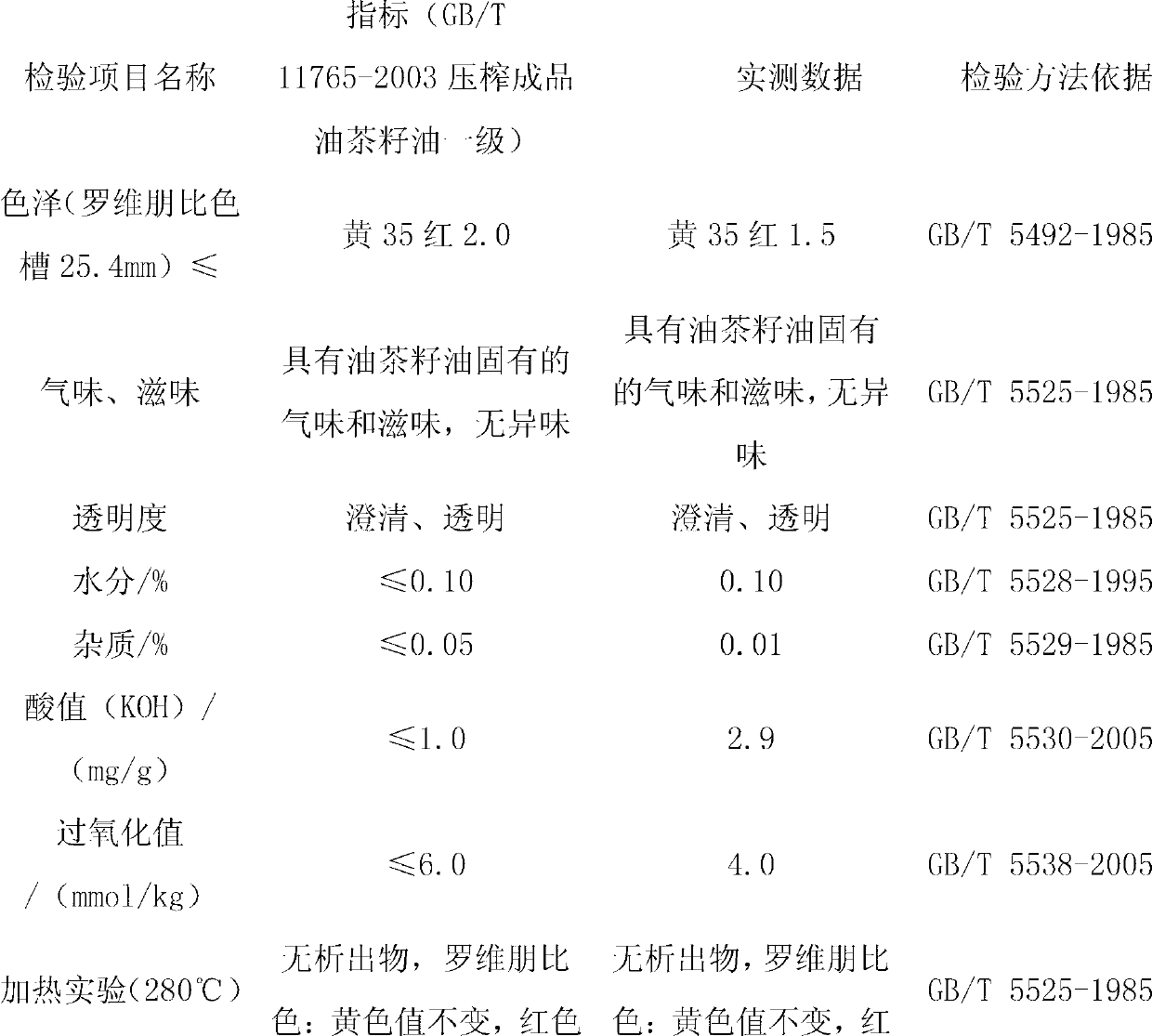

Method for preparing tea seed oil in low-temperature cold pressing manner

InactiveCN102965187AHigh mechanical wearReduce oil yieldFatty-oils/fats refiningFatty-oils/fats productionFlavorEngineering

The invention provides a method for preparing tea seed oil in a low-temperature cold pressing manner. The method comprises the following steps of cleaning tea seeds, removing shells and separating, milling oil at normal temperature, washing in water at low temperature, dehydrating under negative pressure, refining at low temperature, filtering for many times, winterizing and dewaxing. The method for preparing the tea seed oil in the low-temperature cold pressing manner, provided by the invention, has the advantages of simple process, low energy consumption and high oil yield; and the prepared tea seed oil has shallow color, high quality and comprehensive nutrition, and also keeps the original flavor of tea oil.

Owner:安徽新世界绿洲茶油有限公司

Main acid for oil well drilling and multi-hydrogen acid acidulating system with main acid

The invention relates to a main acid for oil well drilling and a multi-hydrogen acid acidulating system with the main acid. A multi-hydrogen acid is prepared by blending HCl, villiaumite, multi-hydrogen acid, an acidization corrosion inhibitor, a ferric ion stabilizer, a clay stabilizer, a demulsifier, a discharge aiding agent and water. Based on 100mg of water, the multi-hydrogen acid comprises 8 to 15g of HCl, 2 to 4g of villiaumite, 3 to 6g of multi-hydrogen acid, 1 to 3g of acidization corrosion inhibitor, 0.5 to 2g of ferric ion stabilizer, 1 to 2g of clay stabilizer, 0.5 to 1g of demulsifier, 0.5 to 1g of discharge aiding agent and 1 to 2g of mutual solvent, wherein the multi-hydrogen acid acidulating system comprises a front acid, the main acid and a back acid. The main acid and the multi-hydrogen acid acidulating system which contains the main acid is applicable for oil wells with the disadvantages of low oil well permeability, low oil recovery, no oil and the like and can effectively solve the problem of blockage caused by sedimentation.

Owner:北京奥凯立科技发展股份有限公司

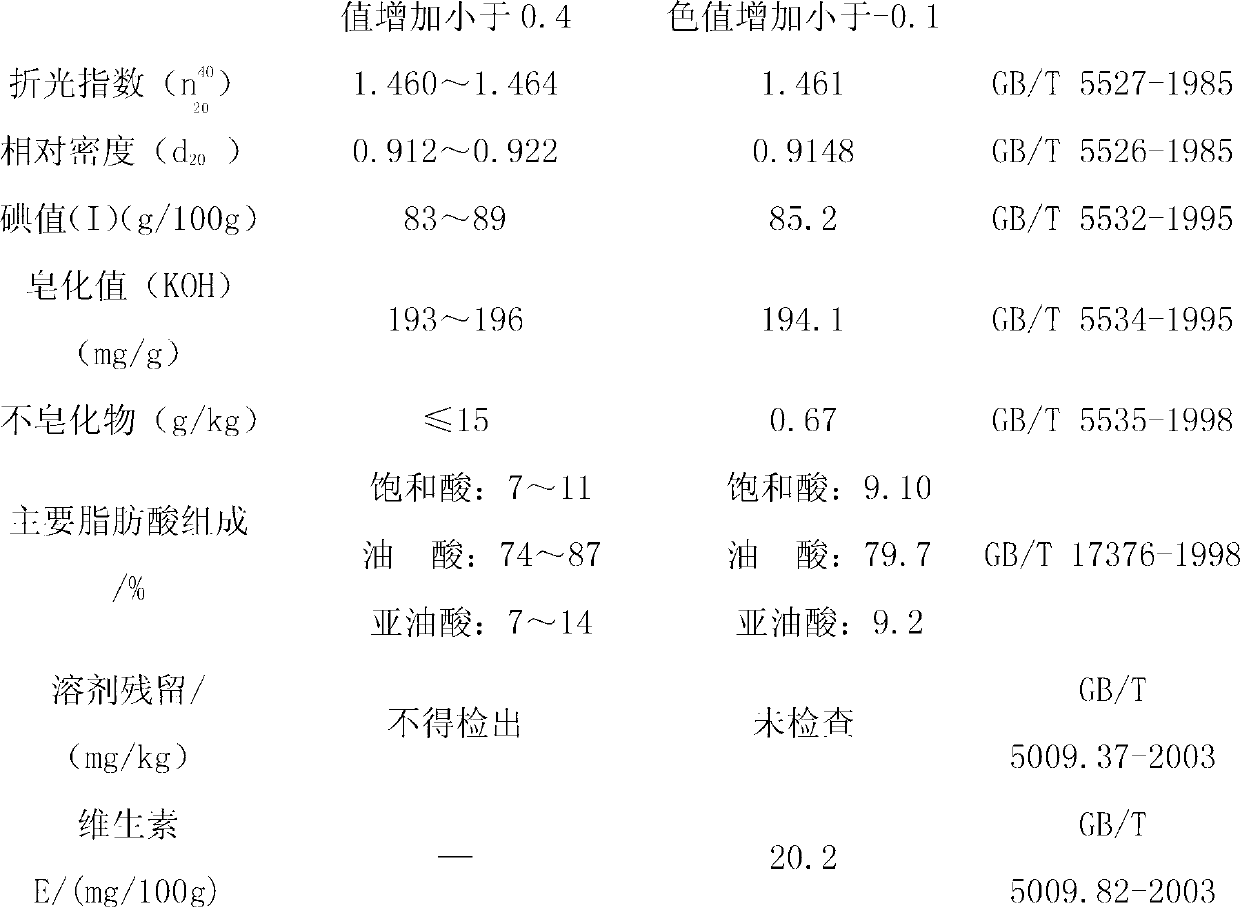

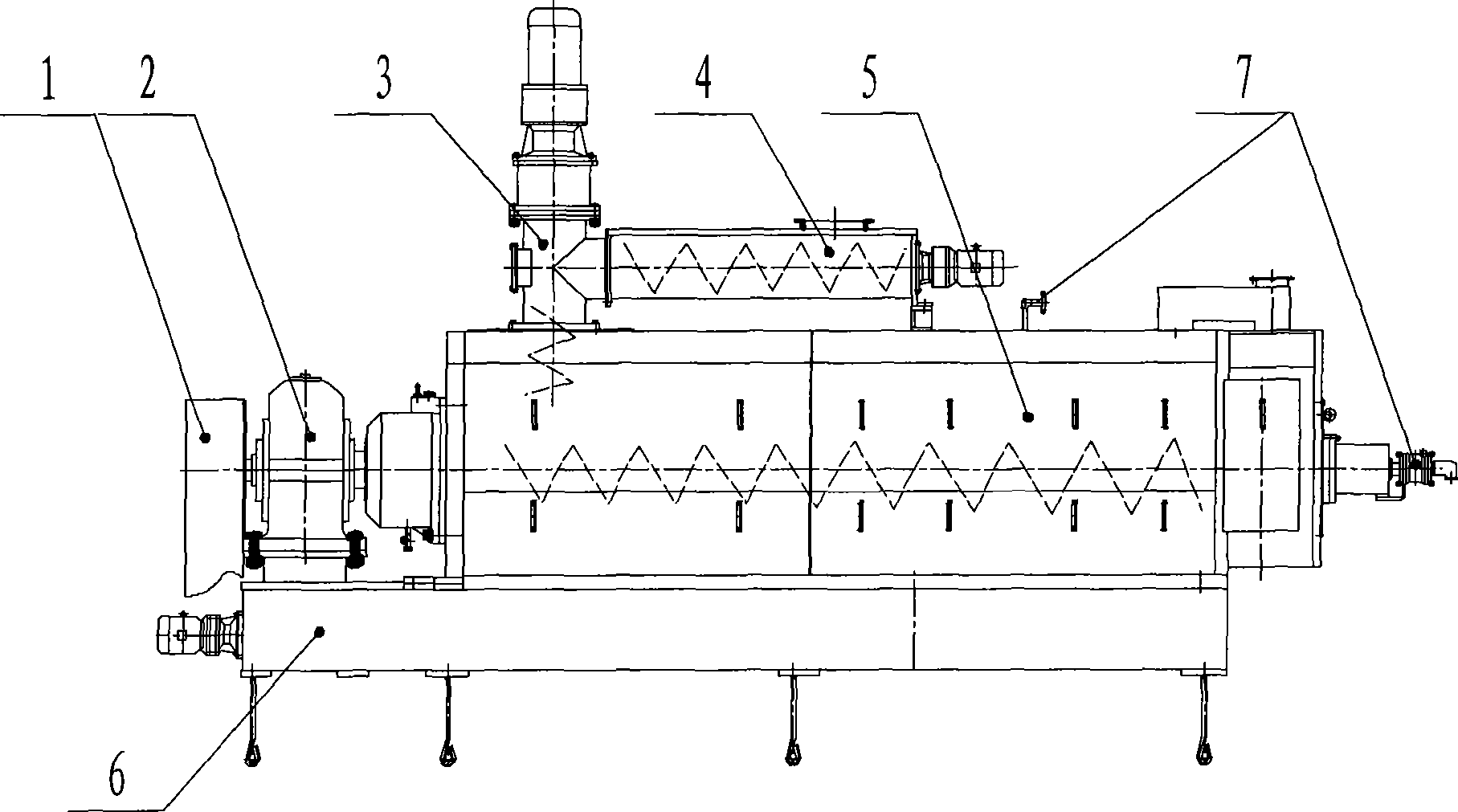

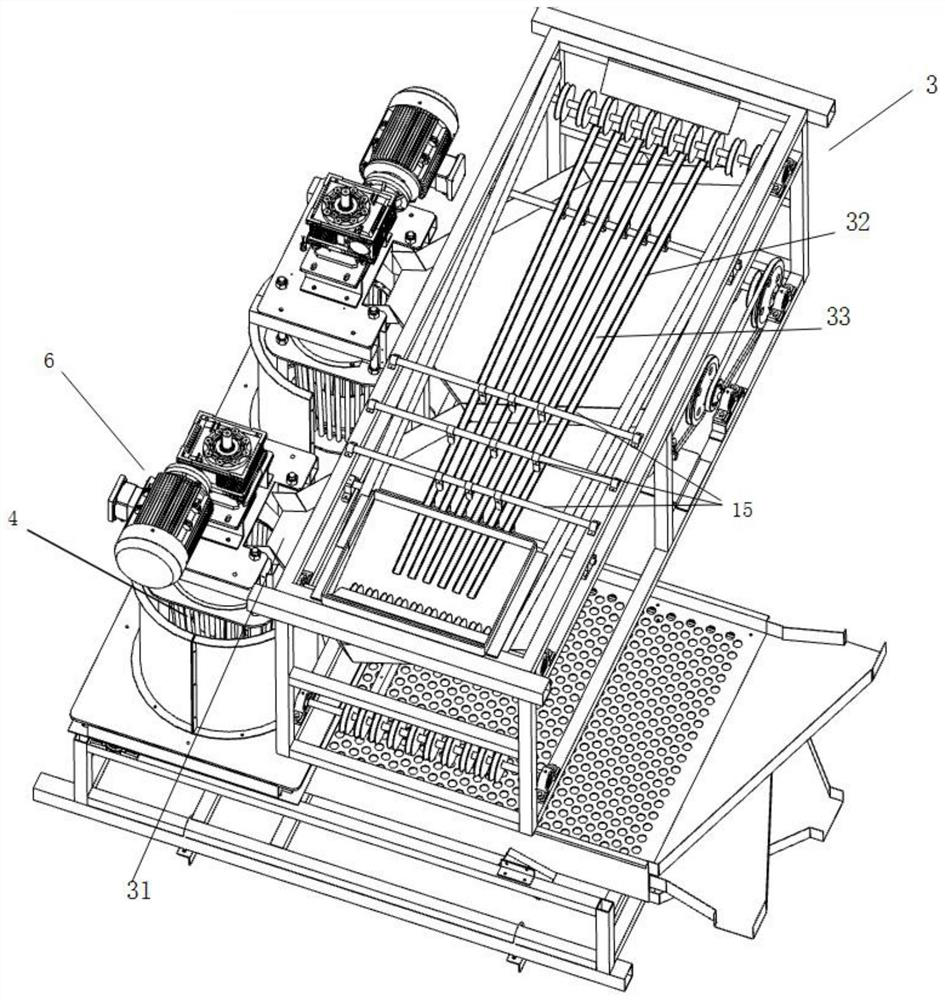

Single screw rod oilseed cold pressing expeller

The invention relates to a single-screw oil material cold squeezer which comprises a squeezing cage and shaft component, which consists of a squeezing cage part and squeezing shafts; and the squeezing shaft is positioned in the squeezing cage part. The cold squeezer is characterized in that the squeezing shaft comprises a squeezing screw mainshaft, a squeezing screw, a cake forming ring and a cake pulverization ring; and the squeezing screw, the caking forming ring and the cake pulverization ring are sleeved and fixed on the outside of the squeezing screw mainshaft. Spiral of the squeezing screw is broken. The squeezing cage part comprises a squeezing cage and a scraper; the scraper is arranged on the squeezing cage; and the scraper is centripetally inserted into a disconnection part of the spiral of the squeezing screw. The squeezing shaft comprises a first squeezing section, a second squeezing section and a third squeezing section. Under the condition of low temperature, the cold squeezer can squeeze an oil material, squeezes out most lipin of the oil material, ensures low denaturing performance of protein in the oil material, is suitable for single squeezing process and is also suitable for presqueezing and leaching process.

Owner:中机康元粮油装备(北京)有限公司 +2

Nutritious salt formulations of plant origin and process for the preparation thereof

InactiveUS20030185955A1High nutritional valueHigh in iodineClimate change adaptationFood preparationSalt Tolerant PlantsEdible oil

The invention describes the preparation of nutrient-rich salt from high salt-accumulating and edible oil-bearing salt tolerant plants in a way that allows simultaneous recovery of both salt and oil. The plants are routinely irrigated with seawater and occasionally with seawater enriched with salt bitterns and / or other types of wastes / by-products containing essential nutrients to raise the level of such nutrients in the plant.

Owner:COUNCIL OF SCI & IND RES

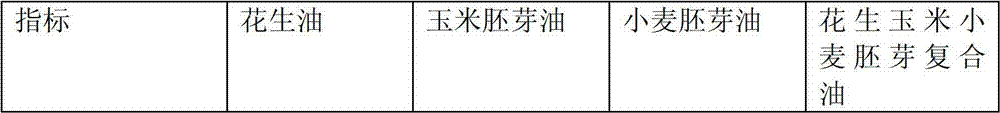

Production method for cold pressing compound oil of peanut, corn and wheat germs

InactiveCN102732377AReduce oil yieldImprove oil yieldFatty-oils/fats productionBiotechnologyWheat germ

The invention belongs to the technical field of producing and processing cold pressing edible oil and particularly relates to a production method for cold pressing compound oil of peanut, corn and wheat germs. The production method for the cold pressing compound oil of the peanut, corn and wheat germs comprises the following steps: (1) preprocessing of wheat bran, (2) preprocessing of corn germs, (3) preprocessing of peanut kernels, (4) modifying, (5) cold pressing, and (6) filtering, wherein the specific steps of (4) modifying are as follows: uniformly mixing the preprocessed wheat bran, corn germs and peanut kernels with the weight ratio of (1-3):(2-6):(7-23) to prepare a raw material, adding water with the weight of 2%-4% of the weight of the raw material and water temperature of 60-80 DEG C to the raw material and keeping 40-60 minutes for water absorption and softening. The compound edible oil abundant in unsaturated fatty acid and vitamin E is produced with the adoption of the method by utilizing the peanut kernels, corn germs and wheat bran as the raw materials and adopting the cold pressing process.

Owner:INST OF AGRO FOOD SCI & TECH SHANDONG ACAD OF AGRI SCI

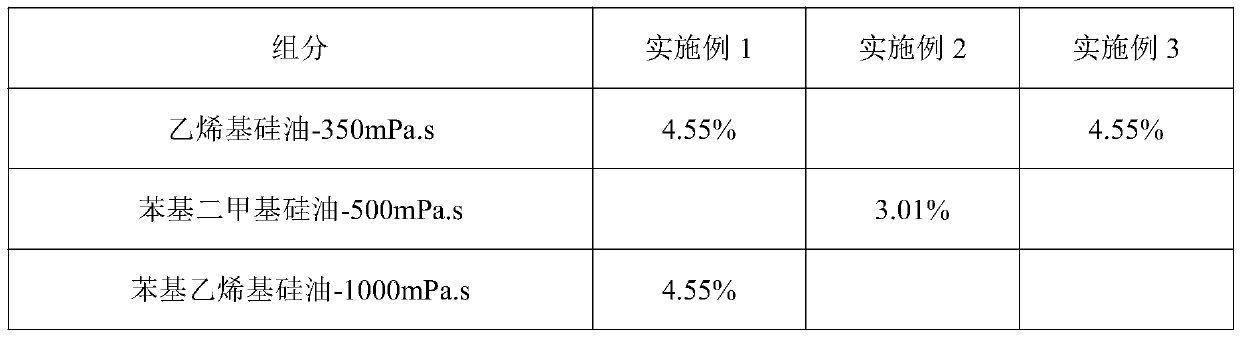

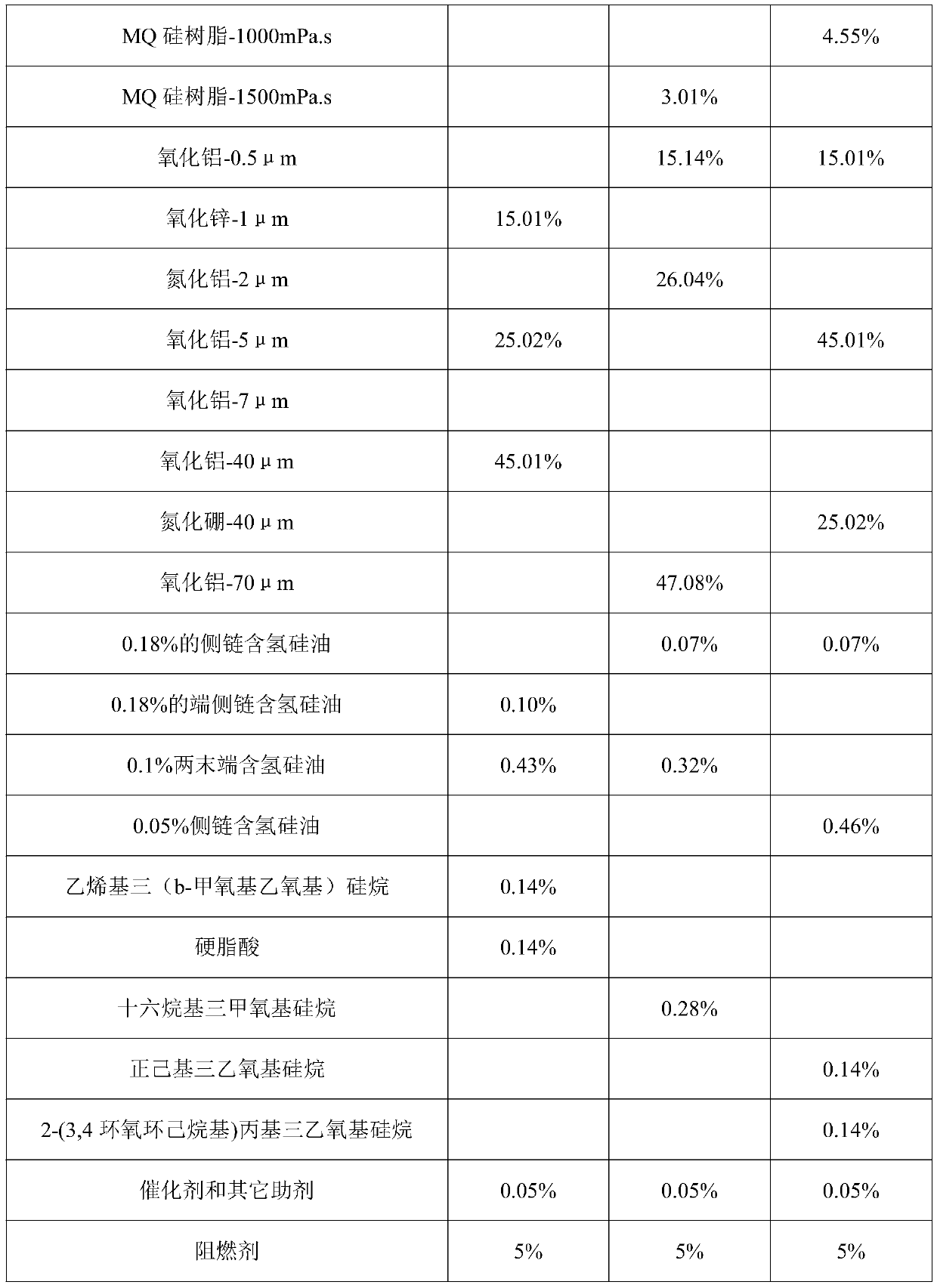

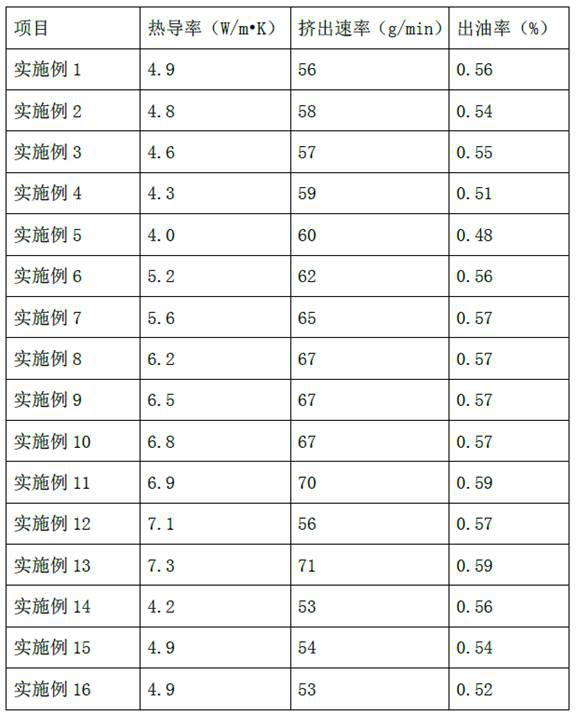

Mud-like high-temperature-resistant heat-conducting composite material and preparation method thereof

The invention discloses a mud-like heat-conducting composite material. The mud-like heat-conducting composite material comprises the following compositions according to a weight proportion: 3%-50% ofsilicone oil, 0.1%-5% of a cross-linking agent, 0.1%-5% of a surface modifier, 0-20% of a fire retardant, 50%-97% of heat-conducting filler, 0.05%-0.015% of a catalyst, and other auxiliaries. In addition, the invention further discloses a preparation method for the above mud-like high-temperature-resistant heat-conducting composite material. The mud-like heat-conducting composite material has theadvantages of excellent high temperature resistance, a high heat conductivity coefficient, good heat stability, a low oil yield, convenient extrusion, good storage stability and strong operability andthe like, and is capable of greatly improving efficiency, and very suitable for solving a heating problem of electronic components.

Owner:东莞市盛元新材料科技有限公司

High-temperature-resistant oil shale powder slag cold-pressing ball and preparation method thereof

InactiveCN102206499AHigh strengthHigh temperature resistanceSpecial form destructive distillationSodium BentoniteAdhesive

The invention discloses a high-temperature-resistant oil shale powder slag cold-pressing ball. The oil shale powder slag cold-pressing ball is characterized by being prepared from 2 to 5 weight percent of adhesive, 5 to 10 weight percent of coal slurry and the balance of oil shale raw ores, and has the diameter of between 30 and 60mm and the intensity of between 50 and 200kg / cm<2>, wherein the adhesive is cement or a self-made adhesive and is prepared from 20 to 40 mass percent of bentonite, 20 to 30 mass percent of viscose and the balance of water. Waste oil shale powder slag is successfully prepared into the oil shale powder slag cold-pressing ball which is subjected to dry distillation in a furnace and is used for extracting petroleum; and the oil shale powder slag cold-pressing ball has high intensity, greatly reduces mining cost without the reduction in oil yield, saves resources, reduces pollution, has high temperature resistance, effectively prolongs the furnace cleaning period of an oil smelter and improves working efficiency.

Owner:张玉山

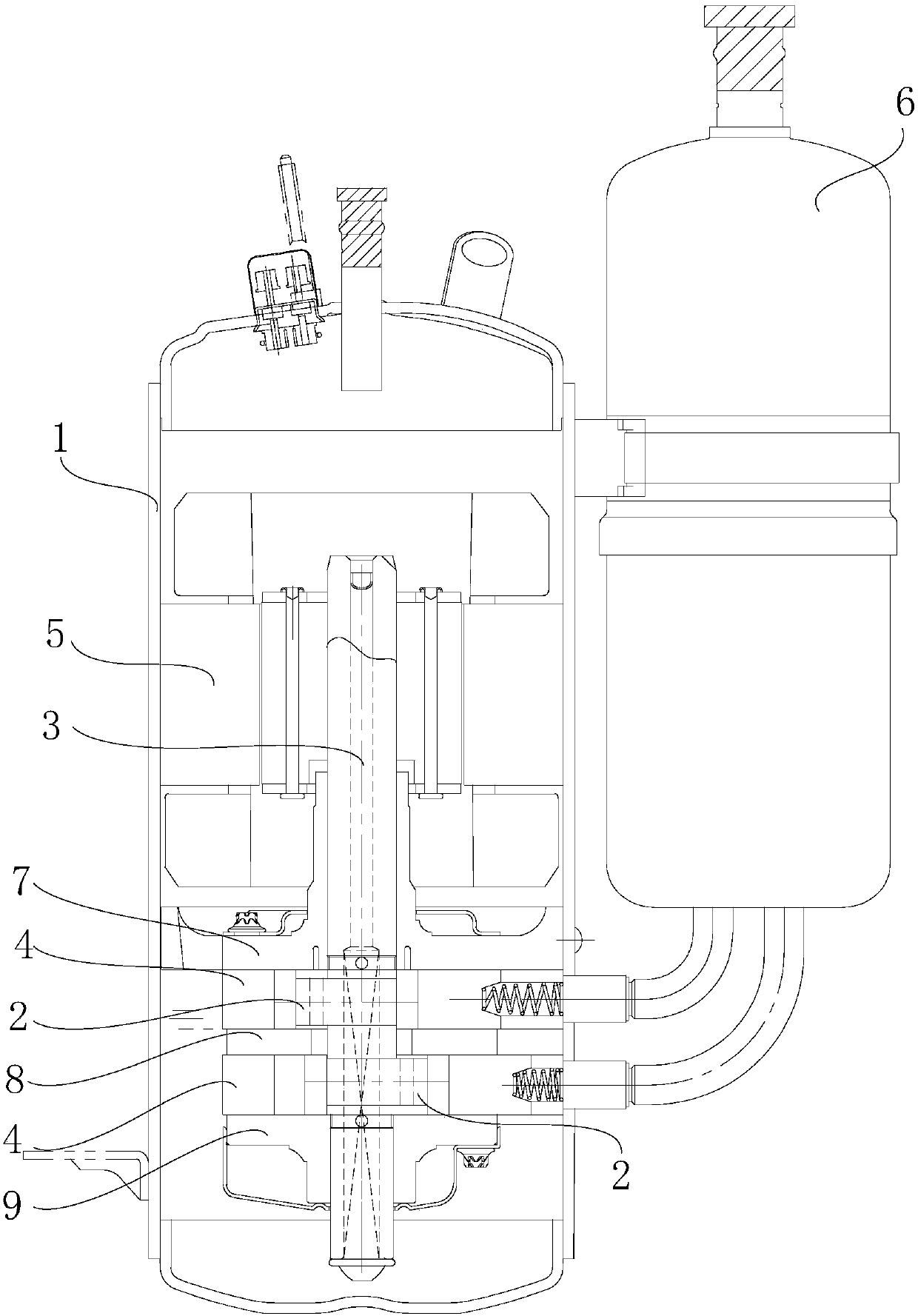

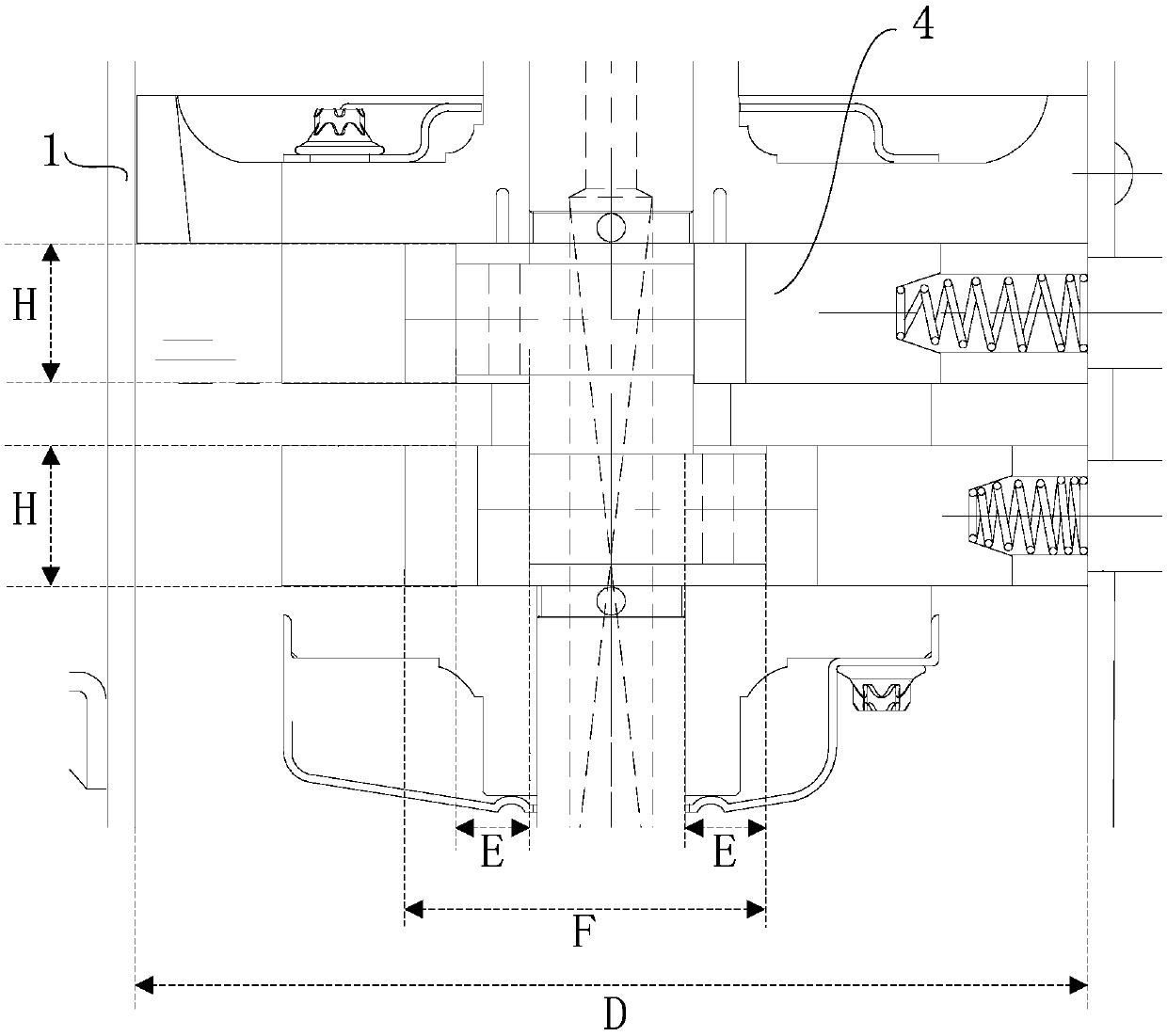

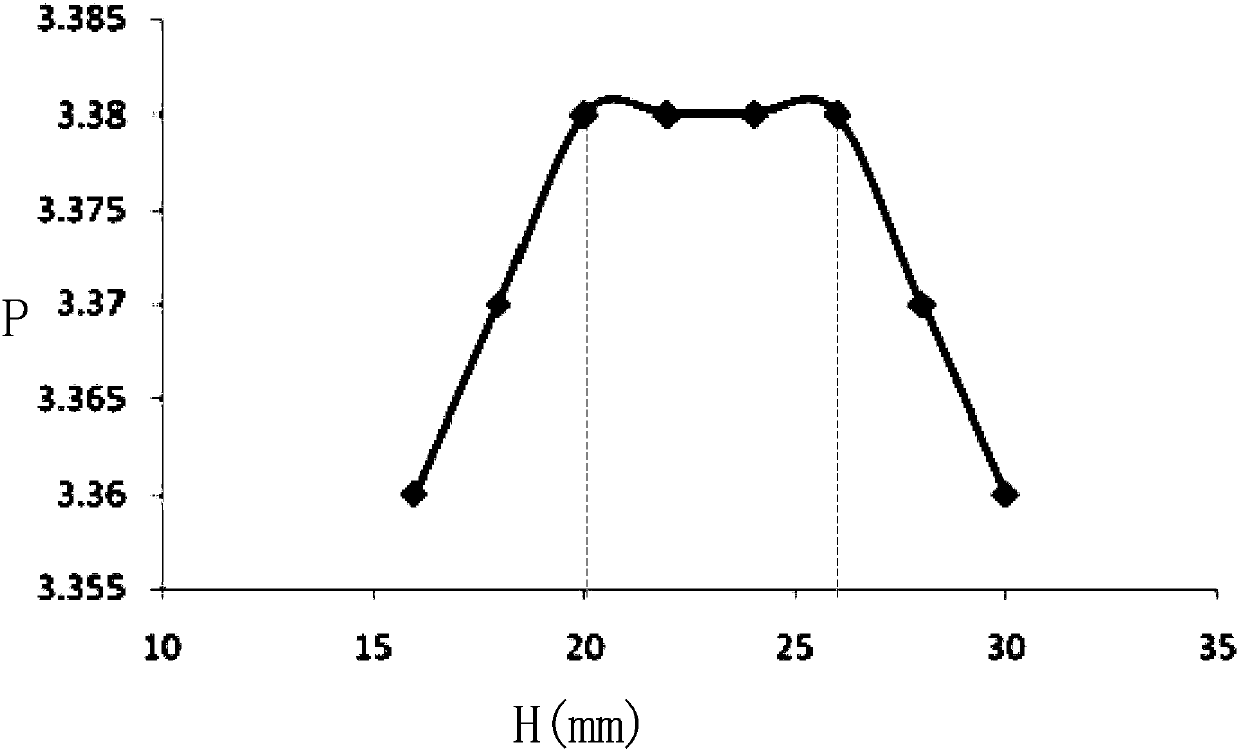

Double-cylinder compressor

PendingCN109958621ATaking performance into considerationImprove reliabilityRotary/oscillating piston combinations for elastic fluidsRotary/oscillating piston pump componentsLinear compressorEngineering

The invention provides a double-cylinder compressor. The double-cylinder compressor comprises a shell, a motor, two air cylinders, two pistons and a crankshaft, wherein the motor and the two air cylinders are contained in the shell, the two pistons can be arranged in the two air cylinders in a rotating mode correspondingly, the crankshaft is provided with two eccentric parts and transmits the rotating force of the motor to the two pistons, and the two eccentric parts correspondingly drive the two pistons to rotate in the corresponding air cylinders so as to compress a refrigerant. According tothe double-cylinder compressor, the height H of at least one air cylinder, the inner diameter F of each air cylinder and the inner diameter D of a compressor shell meet the condition that H is greater than 0.390F and is less than or equal to 0.215D, and therefore the double-cylinder compressor can give consideration to excellent performance, good reliability and low oil yield.

Owner:SHANGHAI HITACHI ELECTRICAL APPLIANCES CO LTD

Preparation method of high-quality pomegranate seed oil

InactiveCN105886100AReduce grease lossReduced grease lossFatty-oils/fats productionChemistryChemical substance

The invention discloses a preparation method of high-quality pomegranate seed oil. The preparation method comprises the following steps: (1) removing impurities; (2) soaking; (3) boiling with a warm fire; (4) carrying out pretreatment; (5) peeling; (6) screening; (7) carrying out cryogenic pulverization; (8) carrying out enzymolysis; (9) drying; (10) squeezing; and (11) purifying. The preparation method disclosed by the invention has the advantages that technology matching is scientific and reasonable, the whole energy consumption is low, cost is low, no chemical substance is introduced, safety of the pomegranate seed oil is guaranteed, content of harmful substances in oil is also reduced, and appearance quality and taste of the oil are improved; and finally oil extraction rate of pomegranate seeds is more than 20%, and good economic benefit and popularization value are obtained.

Owner:蚌埠市九华油脂有限公司

High-oil yield preparation method of grape seed oil

InactiveCN105969510AReduce lossGood removal effectFatty-oils/fats refiningFatty-oils/fats productionCollocationOil and grease

The invention discloses a high-oil yield preparation method of grape seed oil. The preparation method comprises the following steps: (1) impurity removal; (2) soaking; (3) warm boiling; (4) pretreatment; (5) peeling; (6) screening; (7) low-temperature grinding; (8) enzymolysis; (9) drying; (10) squeezing; and (11) purification. In the method disclosed by the invention, the collocation is scientific and reasonable, the overall energy consumption is low, and the cost is low; without introducing chemical substances, the safety of the grape seed oil is guaranteed, the content of harmful substances in the oil is reduced, and the condition and mouthfeel of the oil are improved; and moreover, the final oil yield of the grape seeds can be kept over 98%, thereby bringing great economic benefits and popularization values.

Owner:蚌埠市九华油脂有限公司

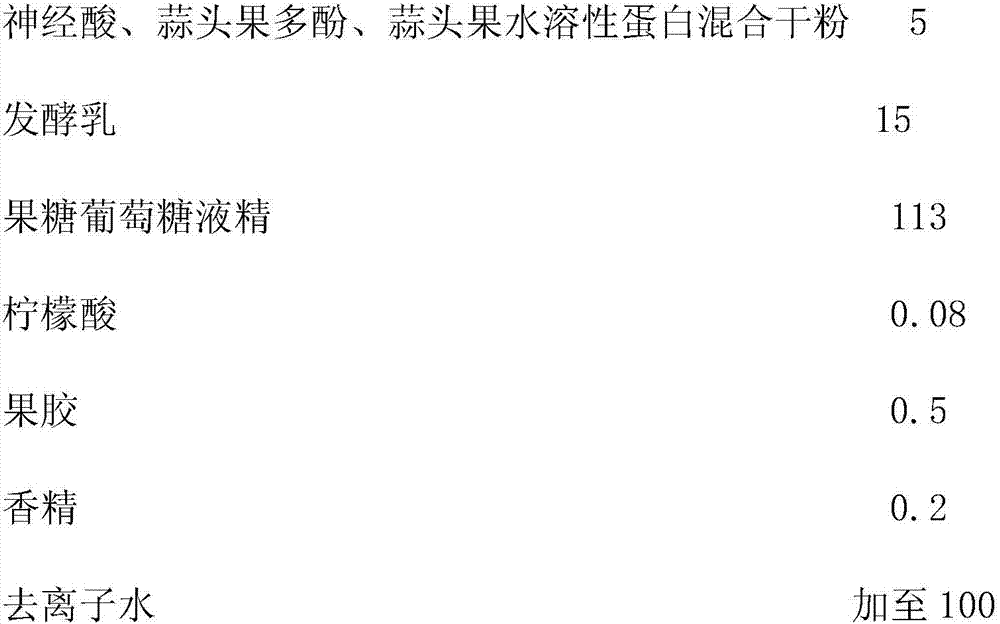

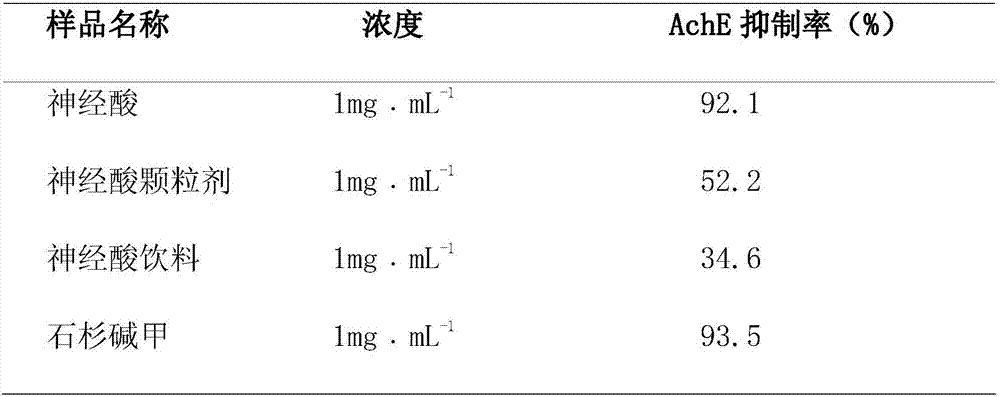

Alzheimer disease resistance composition containing active extract of semen malaniae oleifen and application thereof

InactiveCN107441130AReduce oil yieldNarrow distributionOrganic active ingredientsNervous disorderDiseaseNervonic acid

The invention relates to an alzheimer disease resistance composition containing an active extract of semen malaniae oleifen. The alzheimer disease resistance composition is prepared from the following components in parts by mass: 0 to 5 parts of nervonic acid, 0 to 10 parts of semen malaniae oleifen polyphenol, 0 to 10 parts of semen malaniae oleifen water-soluble protein and 1 to 80 parts of accessories, wherein the parts of the first to the third components cannot be equal to 0 simultaneously. Semen malaniae oleifen is used as a raw material; the plant nervonic acid, the semen malaniae oleifen polyphenol and the semen malaniae oleifen water-soluble protein are extracted from kernels of the malania oleifen by adopting a plant chemical separation purification means and form the alzheimer disease resistance medicinal composition. The alzheimer disease resistance composition is respectively prepared into health care foods, middle-aged and old-aged nutritious foods and brain-strengthening replenishers for application.

Owner:杨宇明

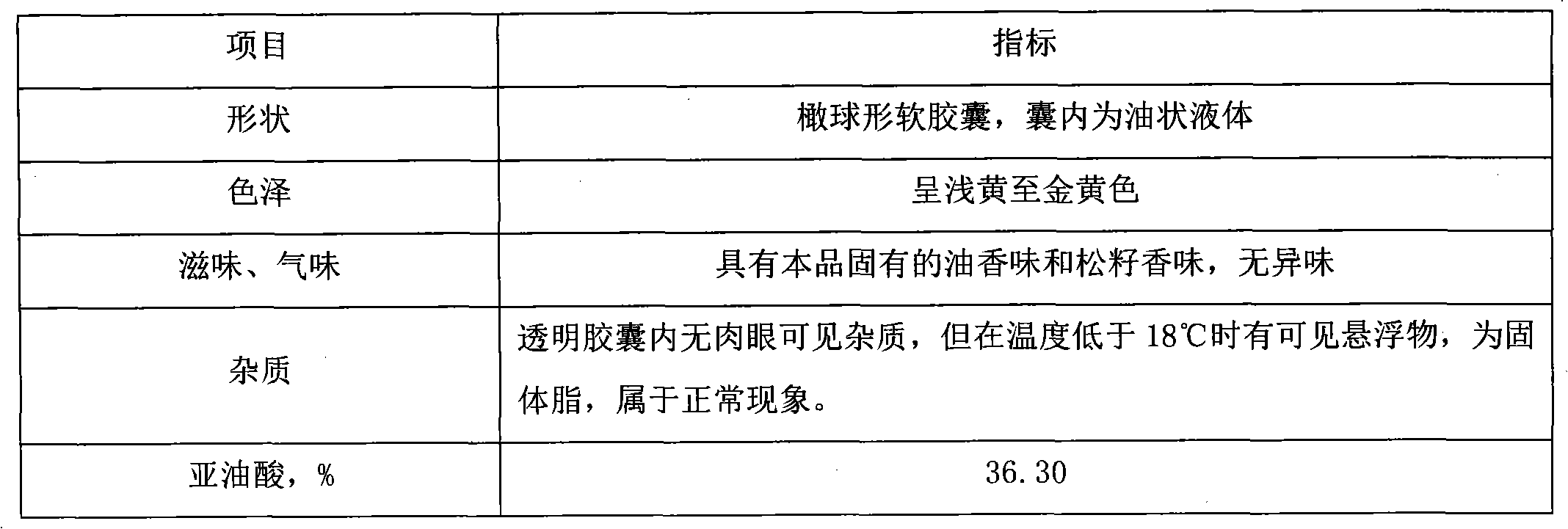

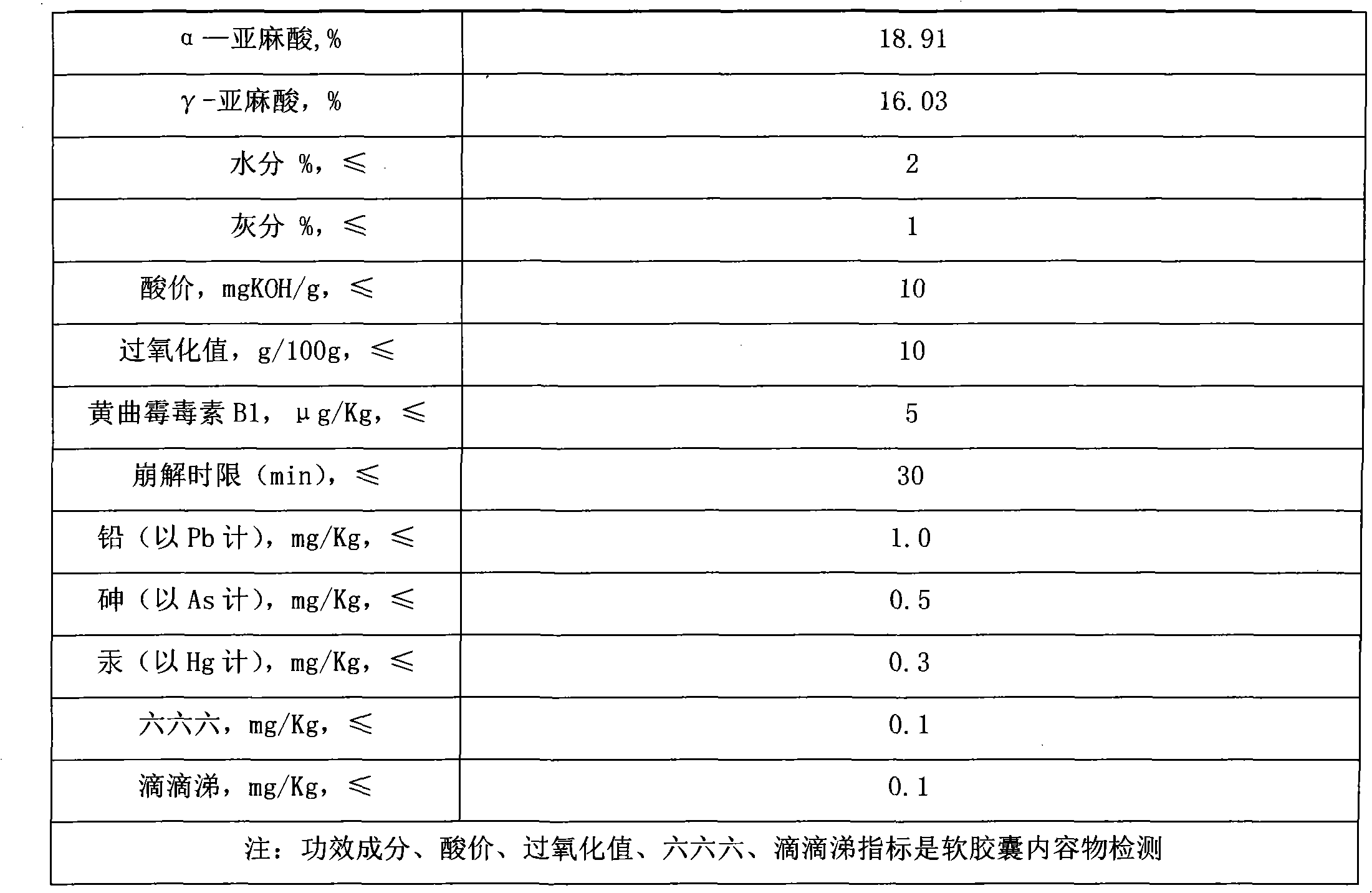

Health product with efficacy of assisting in blood fat reduction and preparation method thereof

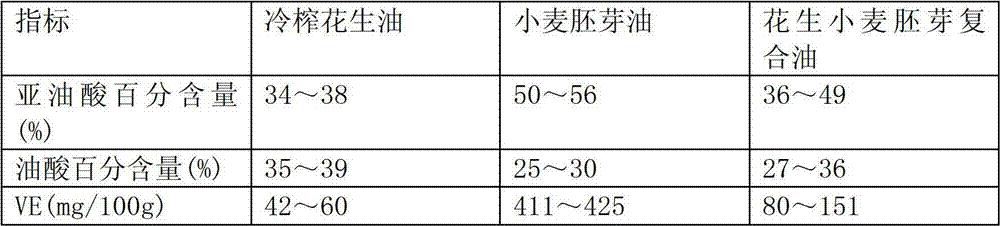

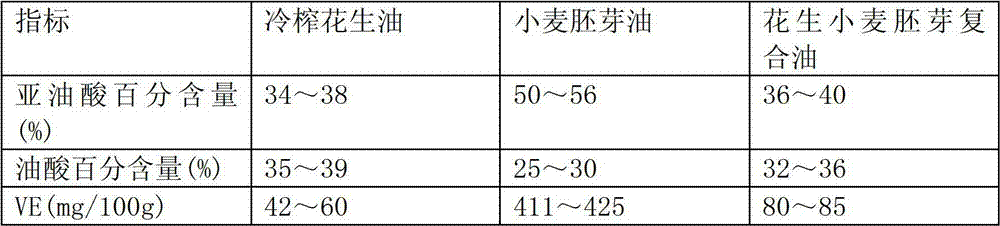

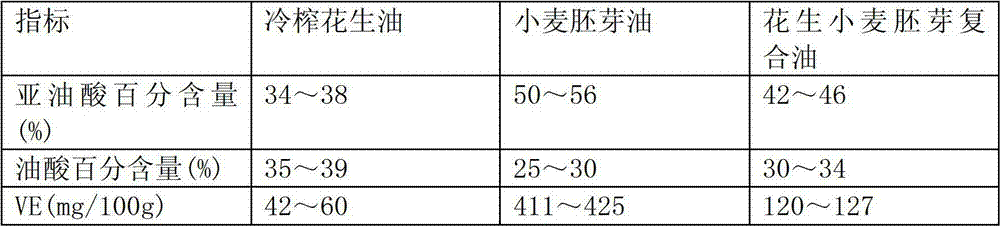

ActiveCN102150711AAppropriate proportionReduce oil yieldFatty-oils/fats refiningFatty-oils/fats productionMedicineGlycerol

The invention provides a health product with efficacy of assisting in blood fat reduction and a preparation method of the health product, which belong to the field of compound preparation and preparation. The invention adopts the technical scheme that the health product is composed of the following components: Yunnan pine nut oil and perilla herb oil; the ratio of Yunnan pine nut oil to perilla herb oil by weight portions is 7:1-4; a preferred ratio of Yunnan pine nut oil to perilla herb oil by weight portions is 7:2.5-3.5; the most preferred ratio of Yunnan pine nut oil to perilla herb oil by weight portions is 7:3. The preparation method comprises the following steps: firstly, preparing Yunnan pine nut oil; secondly, preparing perilla herb oil; thirdly, adding glycerol, gelatin and purified water as auxiliary materials to perform pelleting and drying, and finally, packaging.

Owner:ENDIAN SCI & TECH DEV OF YUNNAN

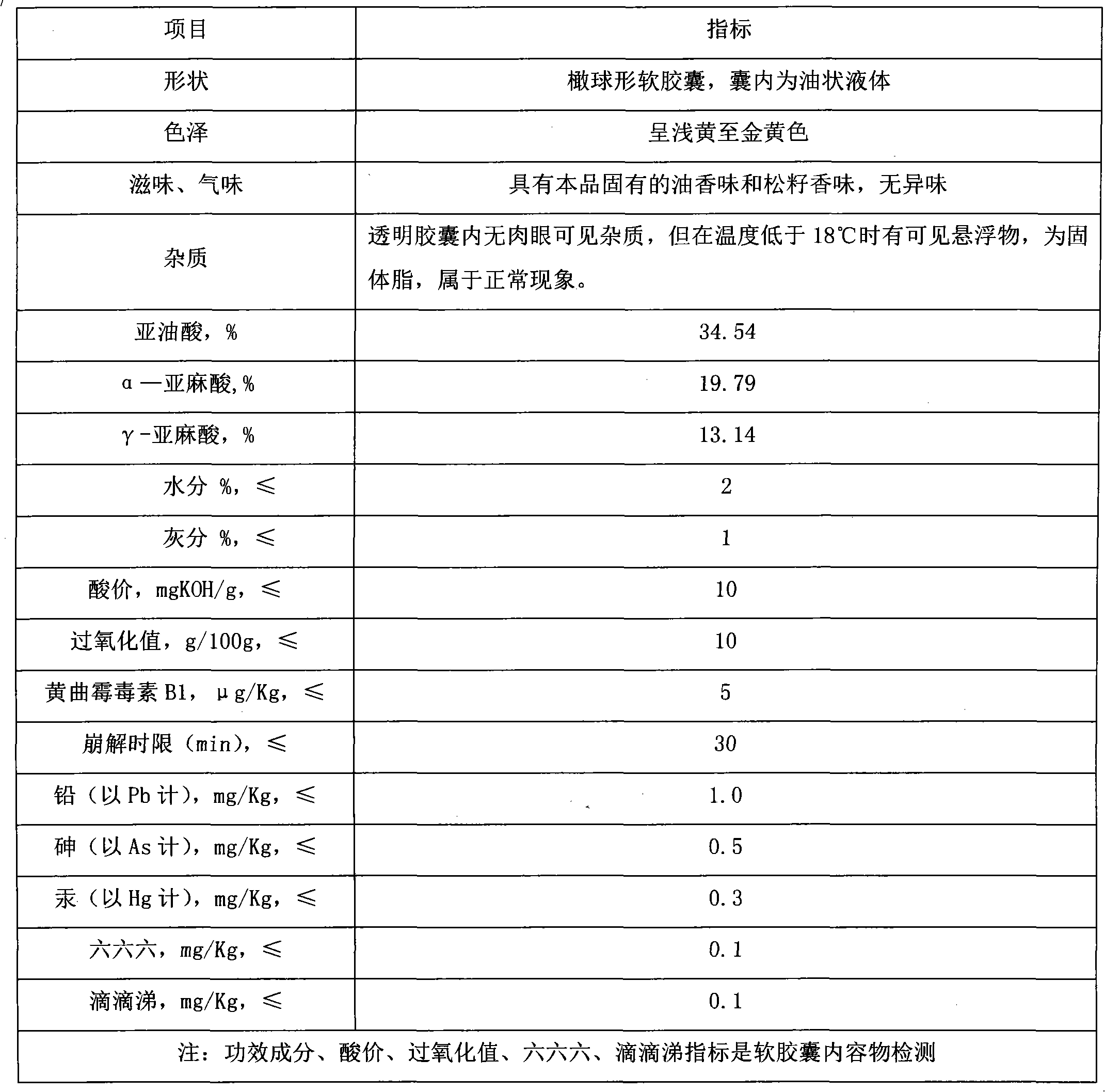

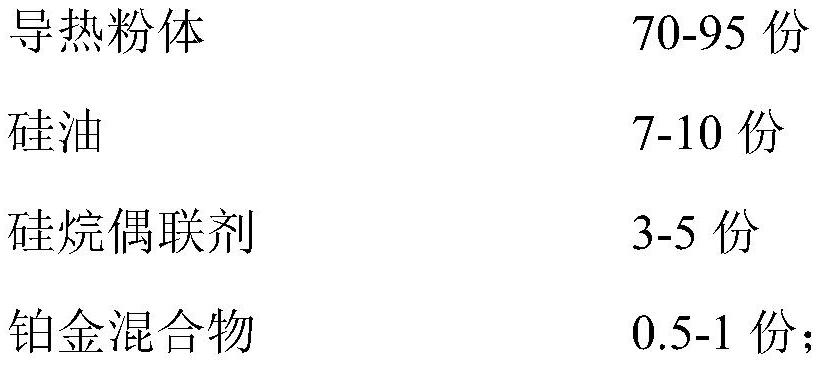

High-thermal-conductivity single-component thermal-conductive gel and preparation method thereof

PendingCN112322042AImprove liquidityReduce oil yieldHeat-exchange elementsPlatinumAluminium hydroxide

The invention provides high-thermal-conductivity single-component thermal conductive gel and a preparation method thereof. The high-thermal-conductivity single-component thermal conductive gel is prepared from 70-95 parts of thermal conductive powder, 7-10 parts of silicone oil, 3-5 parts of a silane coupling agent and 0.5-1 part of a platinum mixture. The heat conduction powder is prepared from 60-70 parts of stearic acid modified aluminum oxide, 10-20 parts of aluminum hydroxide and 15-30 parts of zinc oxide, the particle size of the stearic acid modified aluminum oxide is 30-80 microns, theparticle size of the aluminum hydroxide is 8-30 microns, and the particle size of the zinc oxide is 1-5 microns; the silane coupling agent is a mixture composed of octyl trimethoxy siloxane, diethoxymethyl phenyl silane and stearic acid according to the mass ratio of 1: 0.4-0.8: 2. The heat-conducting powder can form a uniform dispersion system in the single-component heat-conducting gel, so that the heat conductivity coefficient of the single-component heat-conducting gel is greatly improved, the contact heat resistance of the interface of the single-component heat-conducting gel is effectively reduced, and a better heat dissipation effect can be achieved.

Owner:GUANGDONG HERUN PRECISION METAL MATERIALS CO LTD

High-temperature demulsification method for waste emulsion

InactiveCN109607919AAchieve separationReduce oil yieldFatty/oily/floating substances removal devicesWater contaminantsEngineeringDemulsifier

The invention provides a high-temperature demulsification method for a waste emulsion. The high-temperature demulsification method for the waste emulsion comprises the following steps of (1) heating acertain amount of the waste emulsion at a certain temperature for heat preservation or boiling for a certain period of time, cooling the waste emulsion to the room temperature, and removing floatingoil, wherein the boundaries of separated layers are obvious after the waste emulsion is cooled to the room temperature; (2) heating and boiling the emulsion at the lower layer in step (1) again for acertain period of time, cooling the emulsion to the room temperature, and removing the floating oil; (3) heating and boiling the emulsion part at the lower layer in step (2) again for a certain periodof time, cooling the emulsion part to the room temperature, and removing floating oil; (4) repeating steps (2) and (3) until the oil yield is obviously reduced, wherein the emulsion part at the lowerlayer is obtained to be heated and boiled again during extraction each time. According to the high-temperature demulsification method for the waste emulsion, a demulsifier does not need to be additionally added, the disposal cost is low, and the separated oil can be recycled.

Owner:TIANJIN HIPURE MEMBRANE TECH CO LTD

Macromolecule heat conduction material

The invention relates to a macromolecule heat conduction material. The material is composed of raw materials comprising, by weight part ratio, 100-200 parts of ethylene organic silicon resin, 10-30 parts of curing agent, 5-10 parts of antifoaming agent, 6-15 parts of initiating agent, 2-5 parts of diluting agent and 1-5 parts of catalytic agent. The macromolecule heat conduction material is low in oil extraction rate, excellent in aging characteristic, stable in performance, good in heat resistance and difficult to decompose under high temperature, and has wide application value and market space.

Owner:QINGDAO YANBOO ELECTRONICS

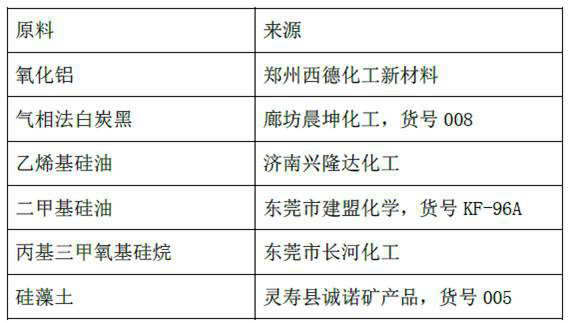

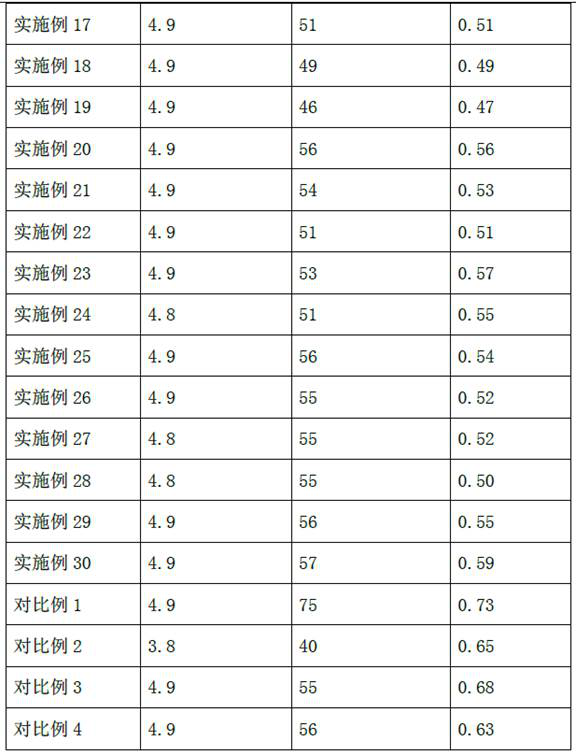

Low-oil-output heat-conducting gel and preparation method thereof

The invention relates to the field of heat-conducting gel, and particularly discloses low-oil-output heat-conducting gel and a preparation method thereof. The low-oil-output heat-conducting gel is prepared from the following raw materials in percentage by mass: 5-19% of silicone oil, 0.05-0.5% of white carbon black, 0.1-2% of a coupling agent, 0-1% of diatomite and the balance being heat-conducting powder. The preparation method comprises the steps: uniformly mixing the heat-conducting powder, the white carbon black, the silicone oil and the coupling agent according to the ratio, stirring for 30 minutes, and heating at the temperature of 120 DEG C for 2 hours to obtain the low-oil-output heat-conducting gel. The low-oil-yield heat-conducting gel provided by the invention has a relatively low oil yield and also has a certain extrusion rate.

Owner:苏州柯仕达电子材料有限公司

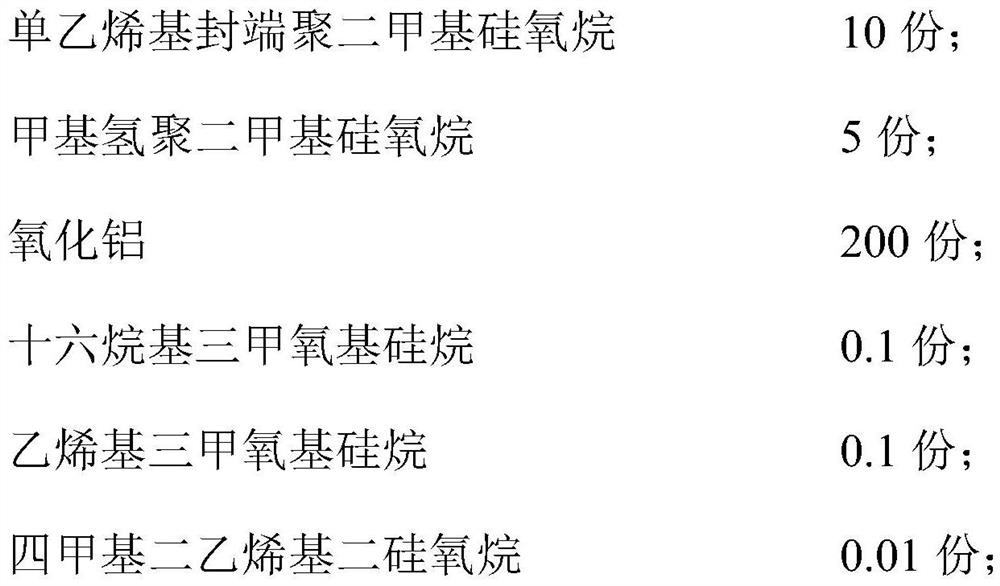

Two-component heat-conducting gel as well as preparation method and application thereof

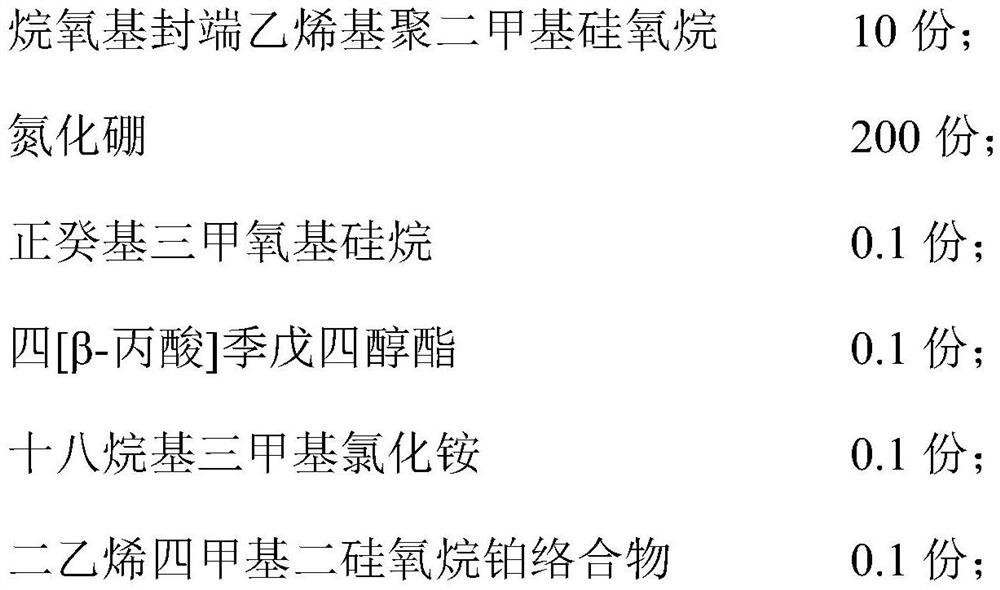

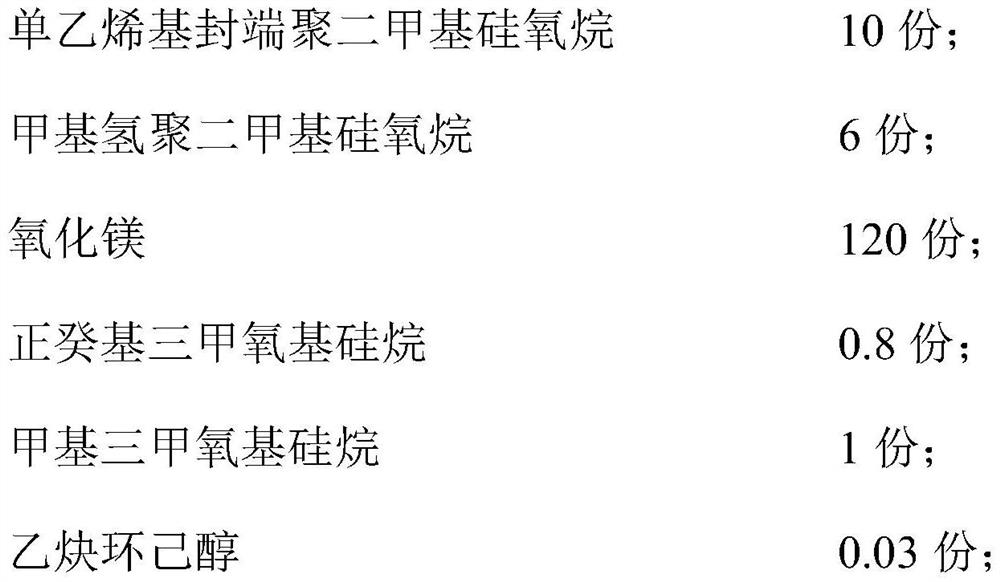

ActiveCN113736266AImprove the extrusion effectImprove high temperature resistanceModifications by conduction heat transferEndcappingPolymer science

The invention provides two-component heat-conducting gel as well as a preparation method and application thereof. The double-component heat-conducting gel comprises a component A and a component B, the component A is prepared from the following components in parts by weight: 10 to 40 parts of monovinyl terminated polydimethylsiloxane, 5 to 10 parts of methyl hydrogen polydimethylsiloxane and 100 to 200 parts of heat-conducting filler A; and the component B is prepared from the following components in parts by weight: 10 to 40 parts of alkoxy-terminated vinyl polydimethylsiloxane, 100 to 200 parts of heat-conducting filler B and 0.1 to 2 parts of catalyst. The preparation method comprises the following steps: firstly, mixing all the components in the component A to obtain a premix A; mixing all the components in the component B to obtain a premix B; and then mixing the premix A and the premix B to obtain the double-component heat-conducting gel. The double-component heat-conducting gel provided by the invention has a relatively high heat conductivity coefficient, relatively good high temperature resistance and relatively low oil yield.

Owner:GUANGZHOU JOINTAS CHEM

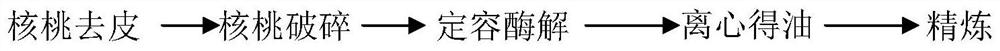

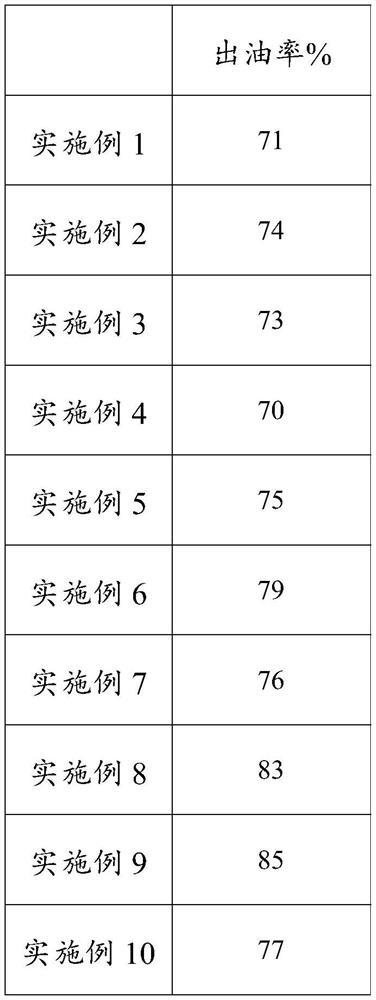

Method for preparing walnut oil by aqueous enzymatic method

PendingCN114874837AHigh degreasing rateReduce exposureFatty-oils/fats refiningFatty substance recoveryWalnut NutFood technology

The invention relates to the technical field of food, in particular to a method for preparing walnut oil by an aqueous enzymatic method, which comprises the following steps: under the condition of not adding water, crushing pretreated walnut kernels until the particle size of the crushed walnut kernels is less than or equal to 900 microns; adding water into the crushed walnut kernels to prepare walnut pulp; carrying out enzymolysis on the walnut pulp by using an aqueous enzymatic method; according to the method provided by the invention, the enzymolysis efficiency is greatly improved, and the final oil yield is up to 70% or above.

Owner:HEBEI YANGYUAN ZHIHUI BEVERAGE

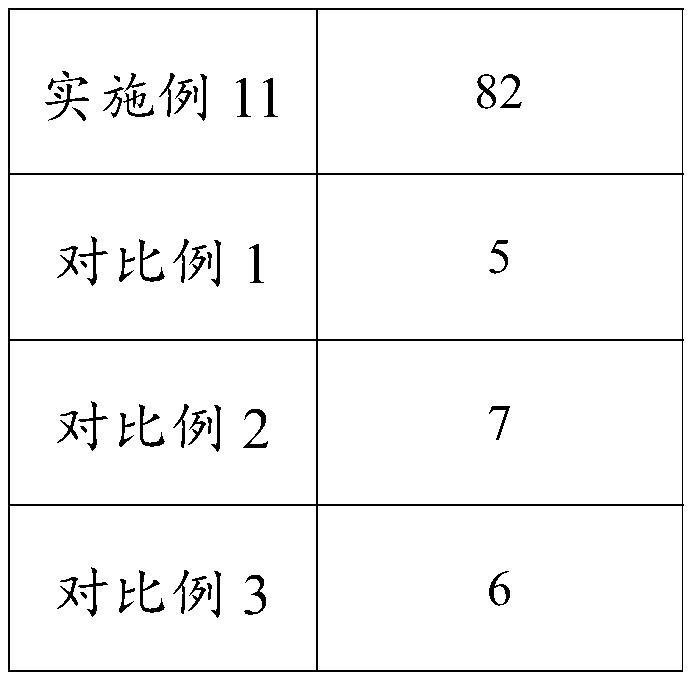

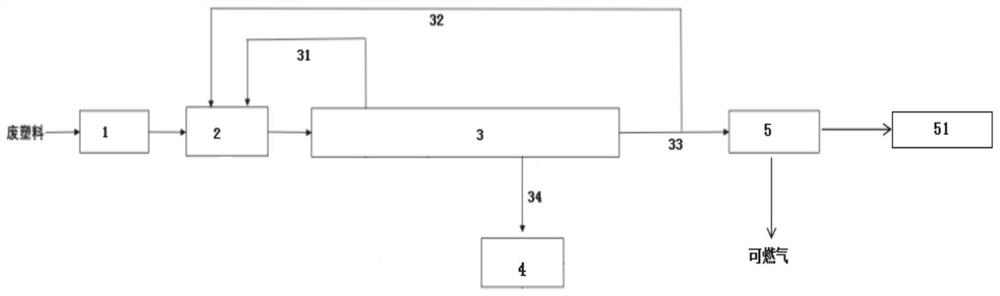

Waste plastic radiation thermal cracking process and system

PendingCN112760119ANo choiceImprove applicabilityLiquid hydrocarbon mixture productionHydrocarbon oils treatmentProcess engineeringEnvironmental geology

The invention relates to the technical field of plastic cracking, and particularly provides a waste plastic radiation thermal cracking process and system. The process comprises first-stage cracking and second-stage cracking, waste plastics are molten in the first-stage cracking and are cracked into light oil, cracking gas and slag charge in the second-stage cracking, and the slag charge enters the first-stage cracking to serve as a waste plastic melting medium to be cooperatively molten with the waste plastics; and cracked gas generated by second-stage cracking is stored as fuel for later use, and light oil is extracted and recycled. On the basis of the principle of cracking high-quality combustible gas, the cracking equipment mainly adopts radiation cracking, while the heating pipe performs radiation heating decomposition on waste plastics, high-molecular-weight organic matters are further decomposed into combustible gas with a high combustion value after passing through the 800 DEG C high-temperature pipe, and the gas production rate is high. The waste plastic radiation thermal cracking process and system solve a series of problems of overhigh cost, environmental pollution and the like caused by the fact that waste plastic treatment mainly adopts physical regeneration recovery, landfill and incineration power generation methods in the prior art.

Owner:李明泽

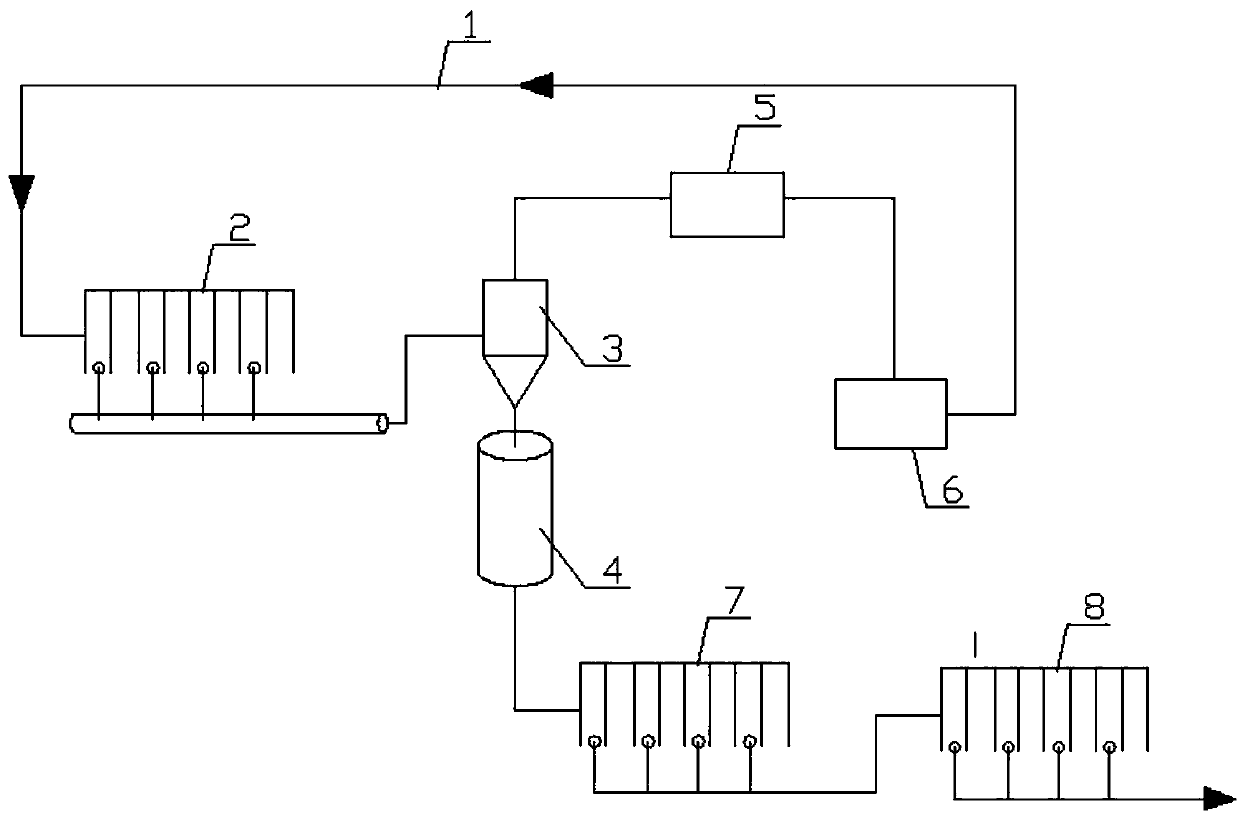

Edible vegetable oil filtering device and process

InactiveCN111575109AAvoid pollutionImprove oil yieldFatty-oils/fats refiningFatty-oils/fats productionBiotechnologyOil and grease

The invention provides an edible vegetable oil filtering device and process, belonging to the field of physical filtering of edible vegetable oil. According to the invention, a crushed peanut cake isused for assisting in filtering; a part of flavor substances and grease can be taken away by adding a food filter aid, so the flavor of a filtered oil product is reduced, and the oil yield is decreased; however, due to the fact that the peanut cake contains rich peanut oil flavor substances, the flavor of finished oil can be improved, oil yield is increased, and cost is reduced. A closed connecting pipeline is connected with a suspension separator, and separated oil enters an oil tank and enters subsequent filtration. Air collected at an upper layer is purified, and the purified air returns toan air compressor for recycling. After a process is improved, filtered oil enters a sealed environment, so pollution is avoided, environmental and air pollution caused by lampblack formation in a vehicle blowing process is avoided; and in addition, the oil yield of filtered oil is remarkably increased through cyclic utilization of air.

Owner:青岛天祥食品集团有限公司

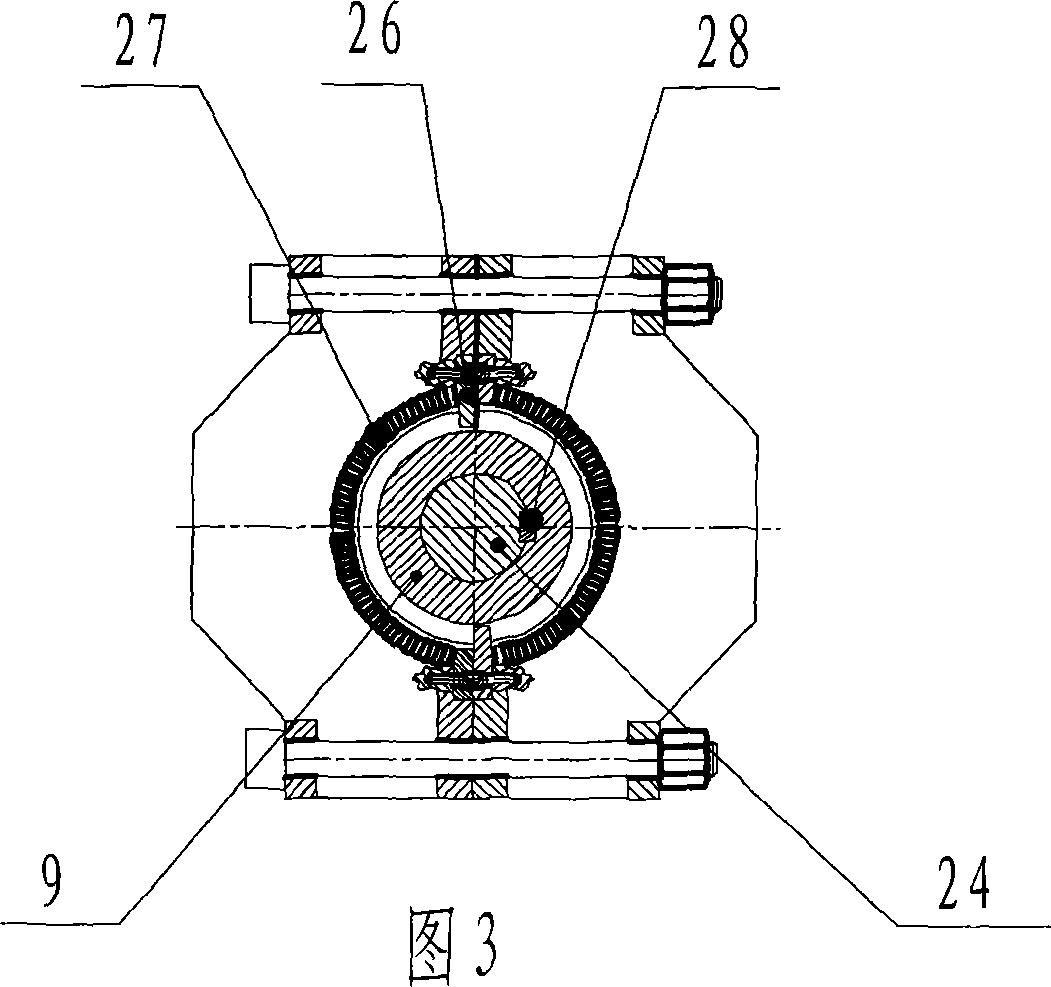

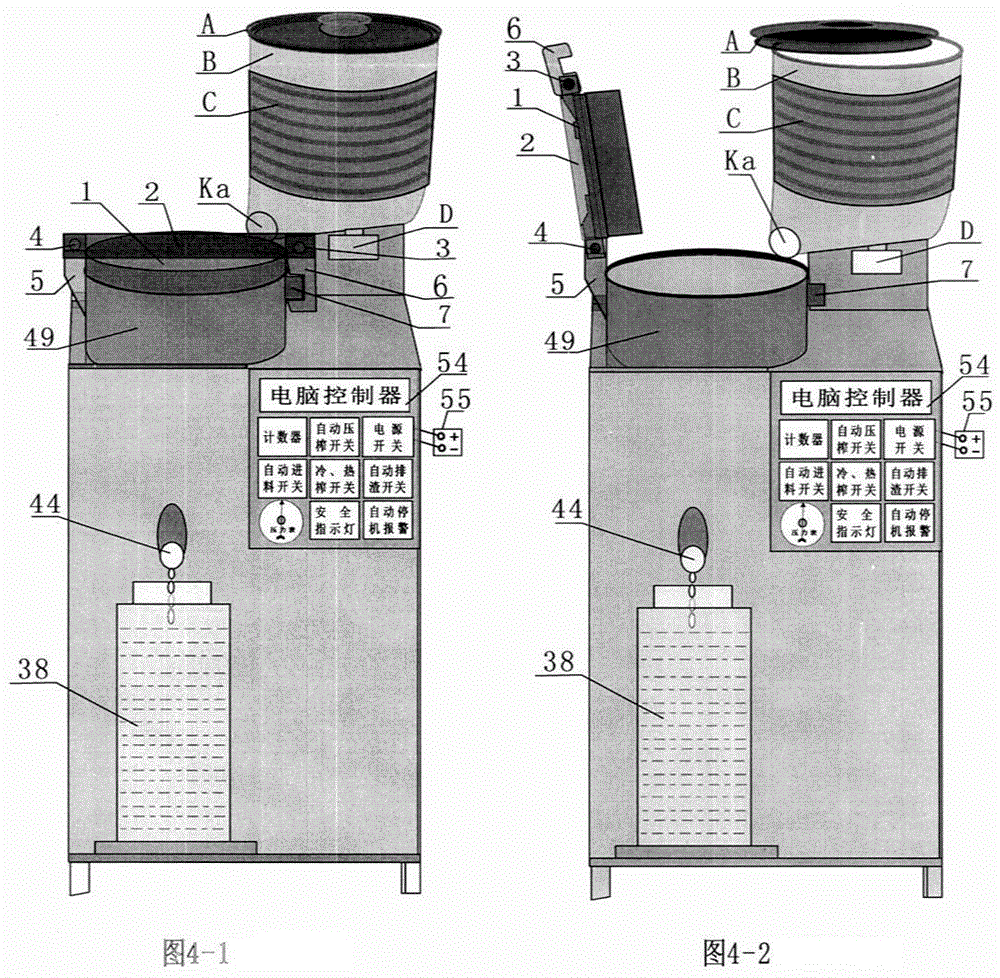

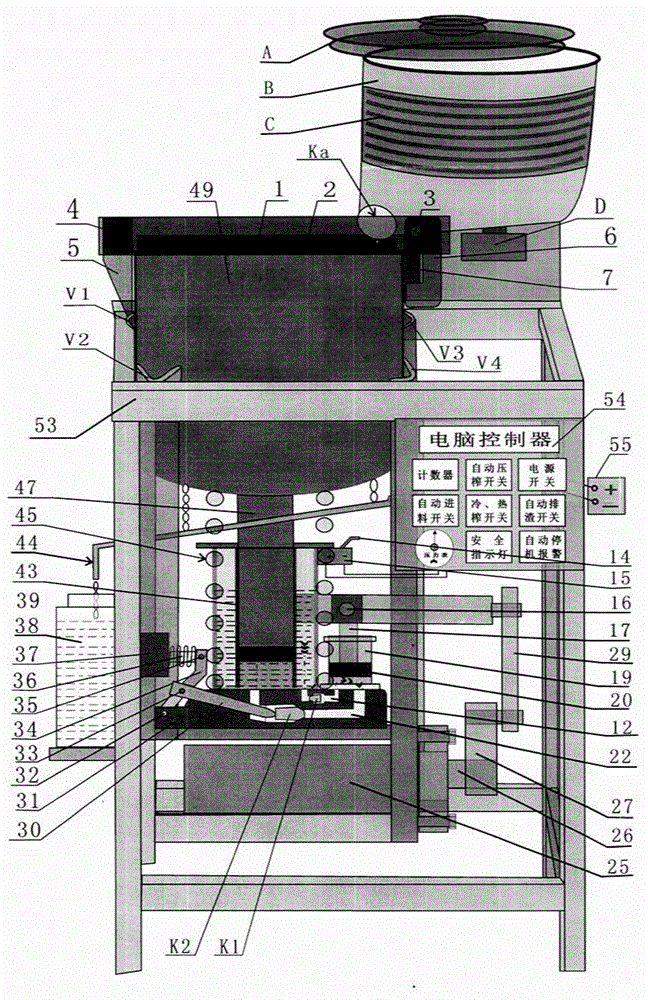

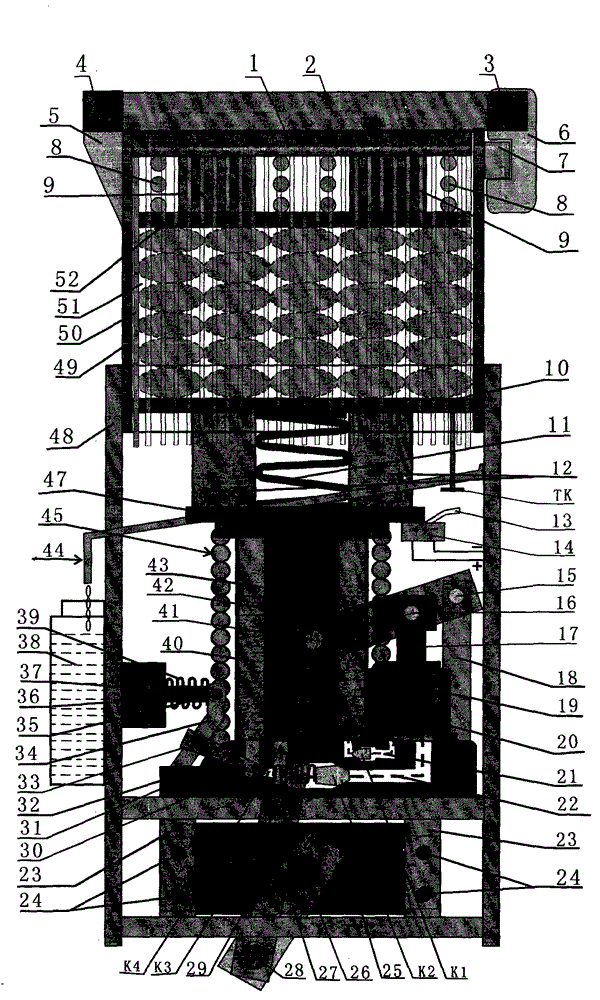

Safe and automatic-control oil press

The invention relates to a safe and automatic-control oil press which is mainly composed of a pressing cylinder (49), an oil and residue separator (50 in the graph 2 and the graph 3), an oil cylinder (40), a hydraulic pump (19), an electromagnetic valve (37), a motor (25), a hot material cylinder (B), an outer frame (53), a computer controller (54) and the like. The safe and automatic-control oil press is characterized in that the oil and residue separator (50), an upper pressing plate (52), springs (8 and 11), elastic force rubber (9 and 12), a piston (10) and a spring seat (47) are arranged in the pressing cylinder (49) in a sleeved mode, a top cover (1), a cross beam (2), a supporting force pillar (5) and a latch hook (6) are arranged on the upper surface of the pressing cylinder (49), the pressing cylinder (49) is integrally stuck to a tensile force frame (48), and the outer frame (53) is buckled and covered through an iron plate. According to the safe and automatic-control oil press, oil pressing can be automatically controlled, oil discharging is fast, the oil extraction rate is high, and the pressed oil can be eaten immediately without being filtered.

Owner:洪锡应

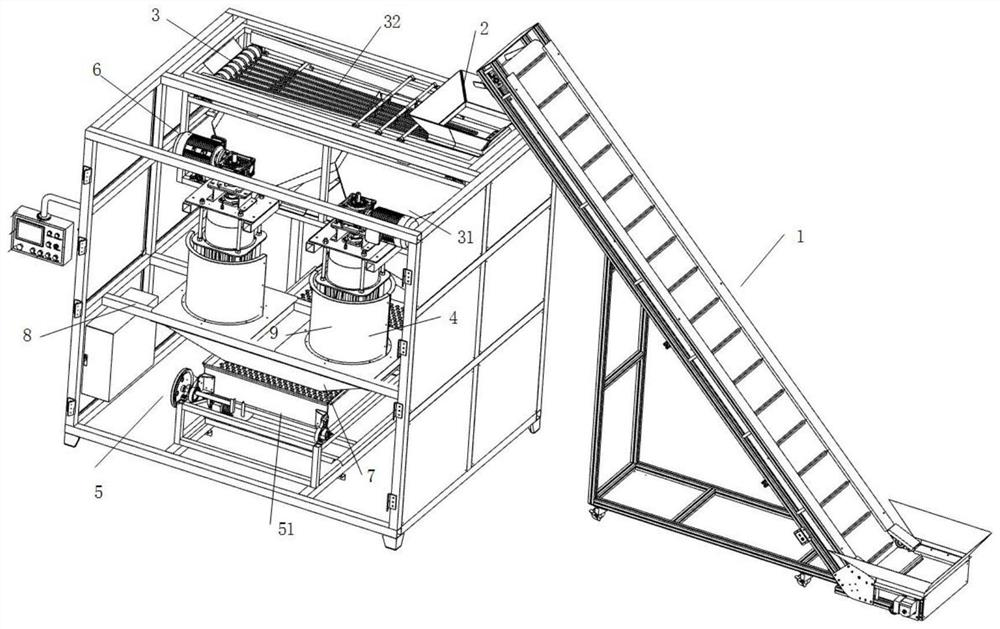

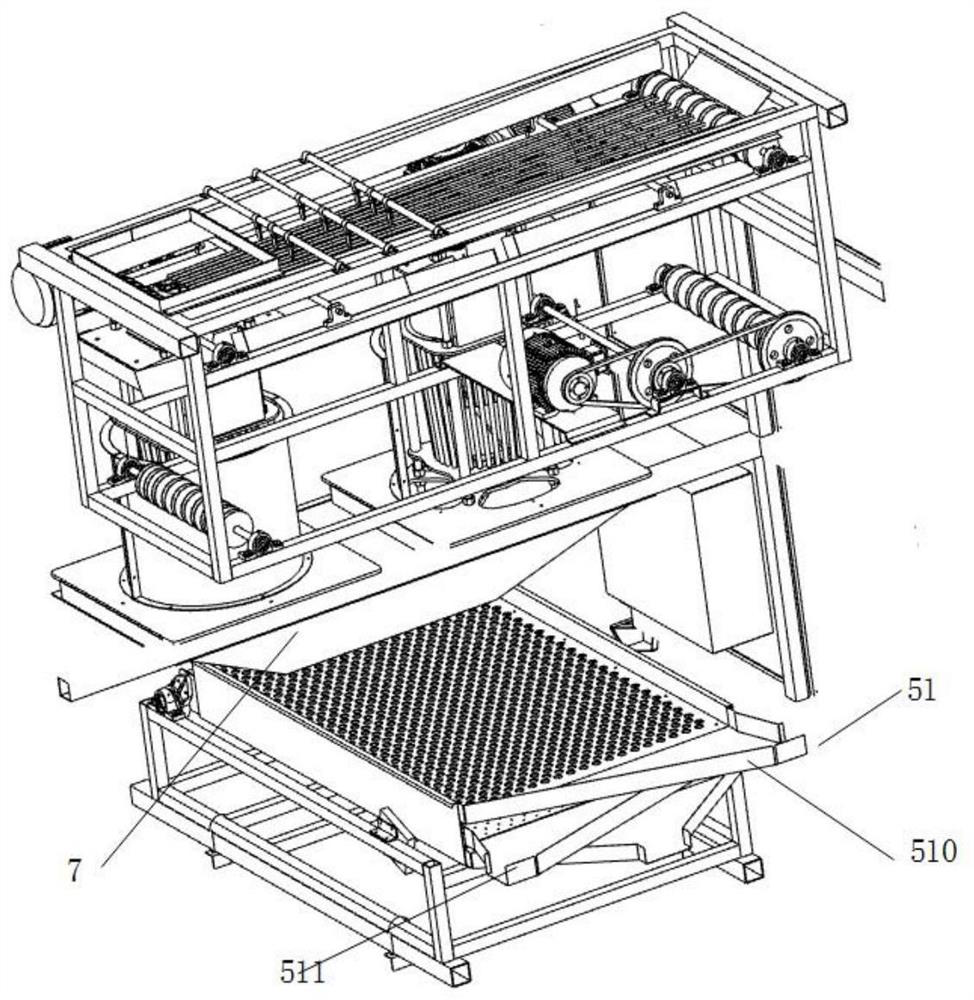

Camellia oleifera fruit husking equipment

The invention relates to camellia oleifera fruit husking equipment. The camellia oleifera fruit husking equipment comprises a receiving device, a conveying device, a primary sorting device, husking assemblies, a secondary sorting device and driving devices; the conveying device is used for conveying camellia oleifera fruits to the receiving device; the primary sorting device is positioned at the bottom of the material receiving device and is provided with at least two first discharge holes; the husking assemblies are connected with the primary sorting device, and the number of the husking assemblies is at least two; the secondary sorting device is arranged at the bottom of discharge ports of the husking assemblies and is used for sorting camellia seeds; and the driving devices rotate alonga vertical line and the number of the driving devices corresponds to the number of the husking devices. According to the camellia oleifera fruit husking equipment, the breakage rate of camellia oleifera seeds during husking is reduced, the camellia oleifera seeds can be classified, and the oil yield of the camellia oleifera seeds is increased.

Owner:HUNAN NONGYOU SHENGTAI AGRI TECH +1

Processing method for edible oil

InactiveCN106118859AReduce oil yieldMuch wasteFatty-oils/fats refiningFatty-oils/fats productionEngineeringEdible oil

The invention belongs to the technical field of squeezing methods and particularly relates to a processing method for edible oil. The processing method includes the steps of pre-squeezing, wherein dried raw materials are wrapped by gauze, then slight impact and extrusion are carried out, the impact force is kept within the range of 100-150 N, the frequency is 10-20 per min, and the time is 25-45 min. By means of the method, the raw materials can be firstly pre-squeezed, thus, nuts in the raw materials can be fully ground, oil molecules become more active, and time is short and the oil yield is high in the following squeezing process. Meanwhile, in the pre-squeezing process, the temperature in the raw materials cannot be greatly increased under the effect, the change of the oil molecular structure is not caused, the squeezing time is shortened, and the situation that the temperature of the raw materials is greatly increased in the squeezing process can be avoided.

Owner:HUANING CHANGSHENG IND & TRADE CO LTD

Method of extracting salvia hispanica seed grease

InactiveCN107325884AReduce oil yieldClear colorFatty-oils/fats productionEnzymatic hydrolysisEmulsion

A method of extracting salvia hispanica seed grease comprises the following steps: soaking salvia hispanica seeds into warm water for a period; then removing gel from the surface of salvia hispanica seeds by a spin-dry facility; carrying out cold pressing in a low temperature spiral oil press to obtain crude oil, precipitating and filtering the crude oil to obtain virgin oil; adding water into cold-pressing cakes according to a ratio of cold-pressing cakes to water of 1:5-1:8, soaking cold-pressing cakes for 2 hours, grinding cold-pressing cakes, filtering to remove residues, maintaining the temperature of the filtrate in a range of 45 to 55 DEG C, adding filtrate into food grade neutral proteins, shaking 5 to 10 hours, adding HCl to adjust the pH value to 5.5-6.0, adding food grade composite cellulase, shaking 5 to 10 hours, allowing the system to stand still for one hour, subjecting the upper layer emulsion to centrifugation, which lasts for 30 minutes, and mixing the virgin oil and the oil obtained through enzymatic hydrolysis and centrifugation to obtain the final finished oil. The provided method has the advantages that the equipment investment is low, the solvent is not polluted, the yield is increased, and the grease quality is improved.

Owner:HUNAN AGRICULTURAL UNIV

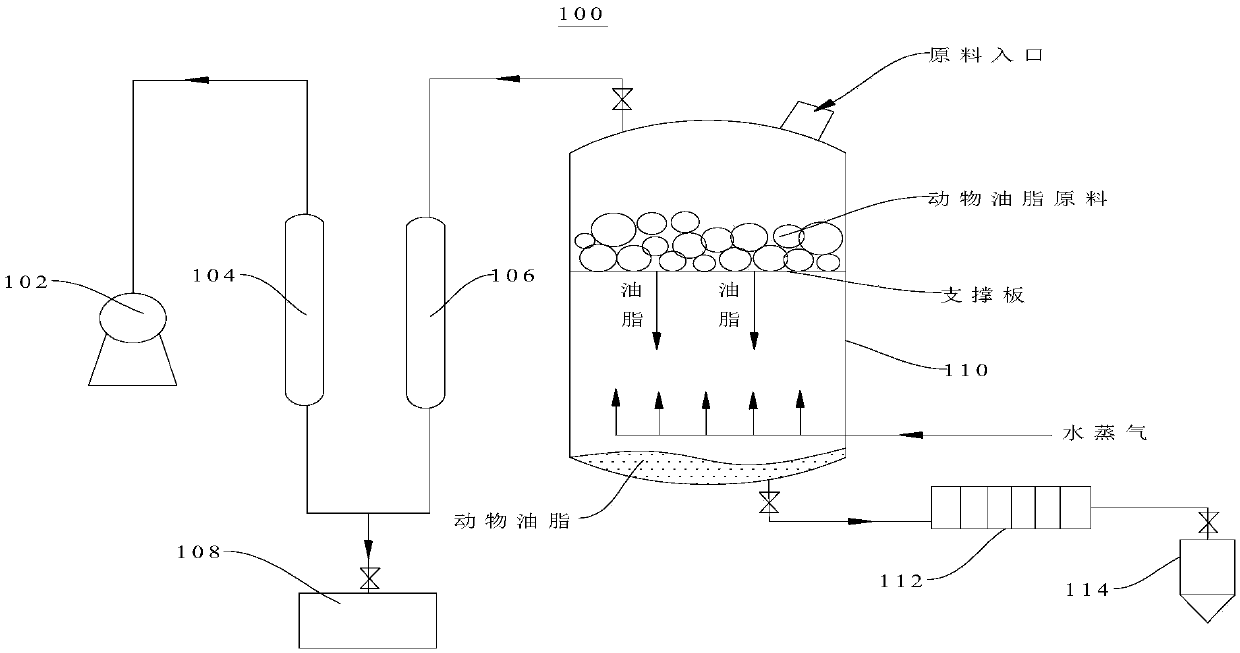

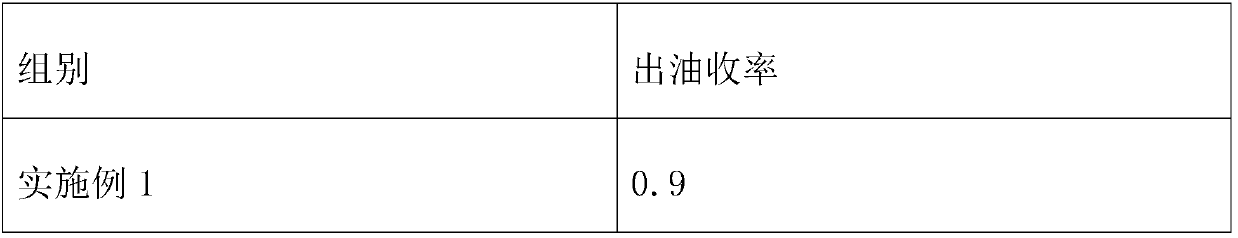

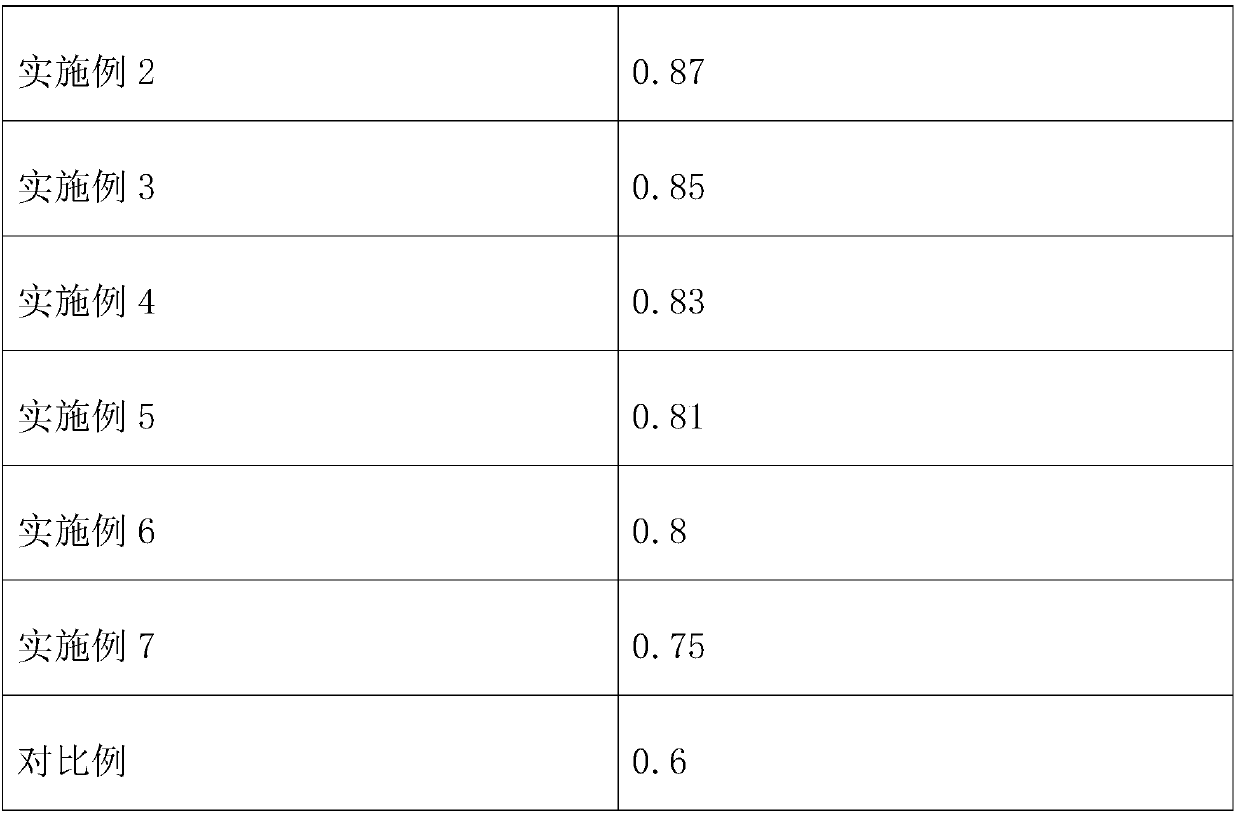

Animal fat and production process thereof

InactiveCN109554216AReduce qualityAvoid tar phenomenonFatty-oils/fats refiningFatty-oils/fats productionTarFire - disasters

The invention discloses a production process of animal fat. According to the production process, animal fat in an animal fat raw material is extracted by adopting medium steam. On one hand, direct contact between fat and open fire is avoided, and a fire disaster is avoided; and on the other hand, the medium steam can flow to be fully contacted with the animal fat raw material, so that the animal fat raw material is heated more uniformly, and an oil burning phenomenon is avoided. Through the advantages of small molecule flowing of the medium steam, the medium steam can enter into narrow spacesin the animal fat, so that a problem that the oil yield is reduced due to the fact that the heating degree in the animal fat is not enough is avoided. The medium steam can enter the animal fat raw material along with the flowing, the inside and outside of the raw material are heated at a same time, and the interior of the raw material can be heated for producing oil without external heat conduction, so that the oil burning phenomenon is avoided, and quality of the obtained animal fat is greatly improved. The invention further provides the animal fat which is prepared by adopting the productionprocess of the animal fat.

Owner:朱建华

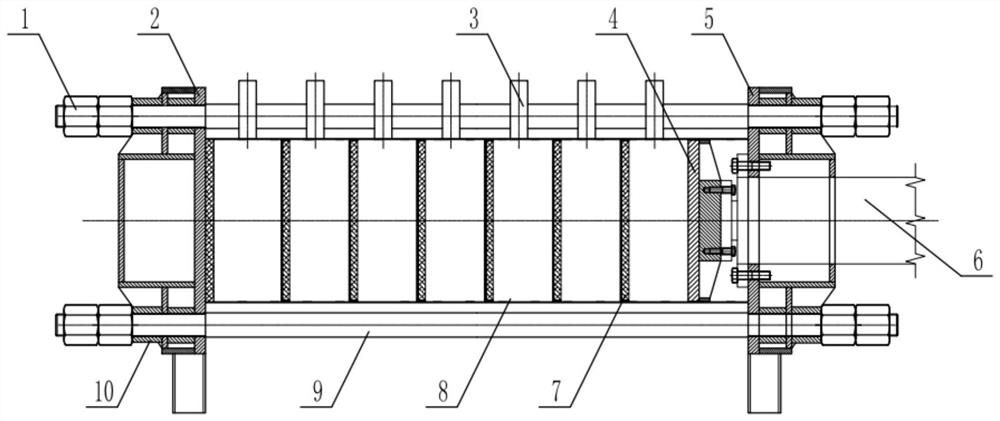

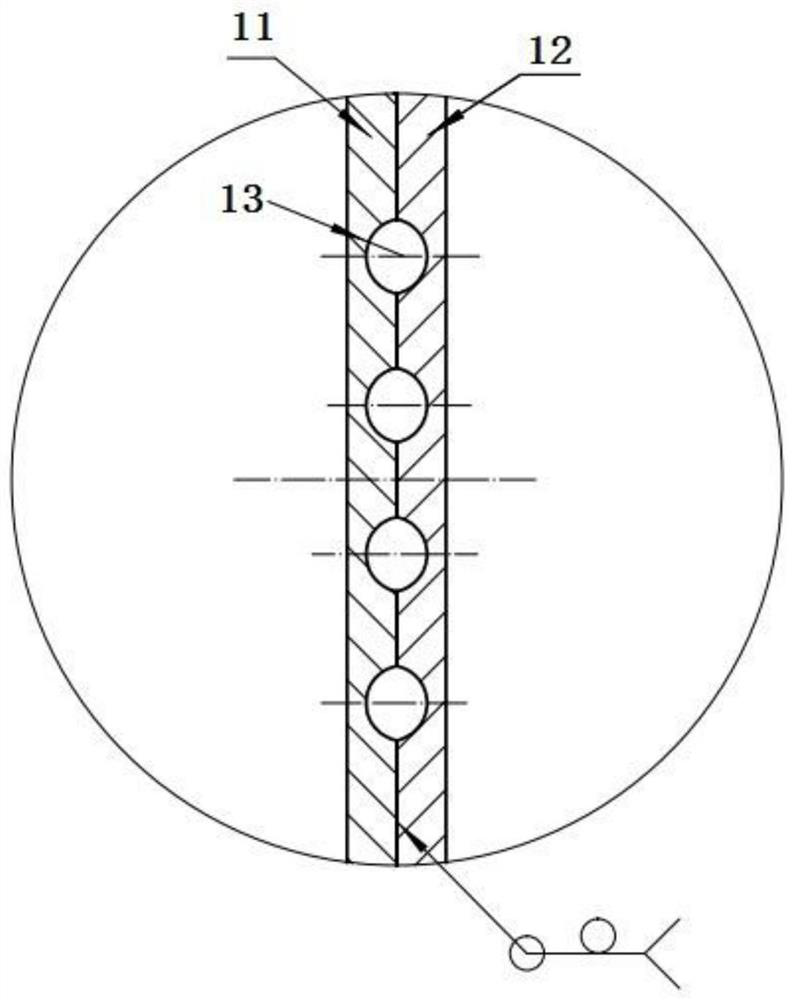

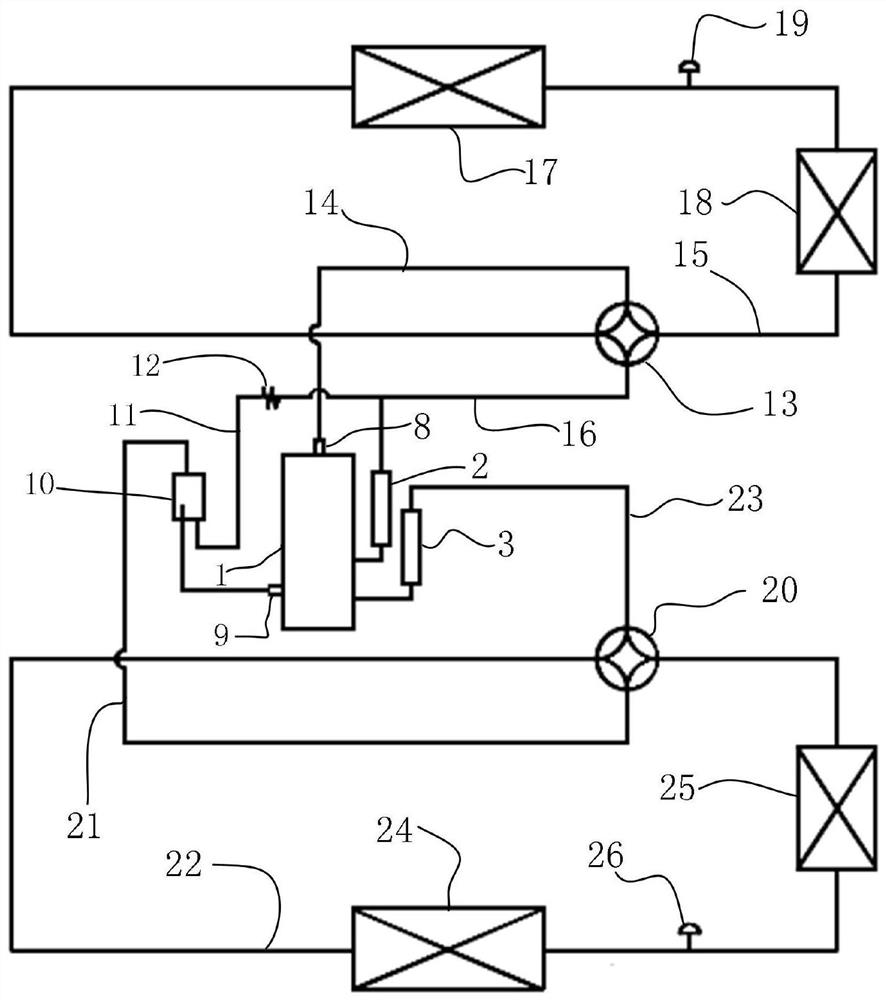

A hydraulic combined steam leaching type integrated edible oil press and a method for processing edible oil with the press

Owner:黑龙江天壤农业科技发展有限公司

Passion fruit seed oil and preparation method thereof

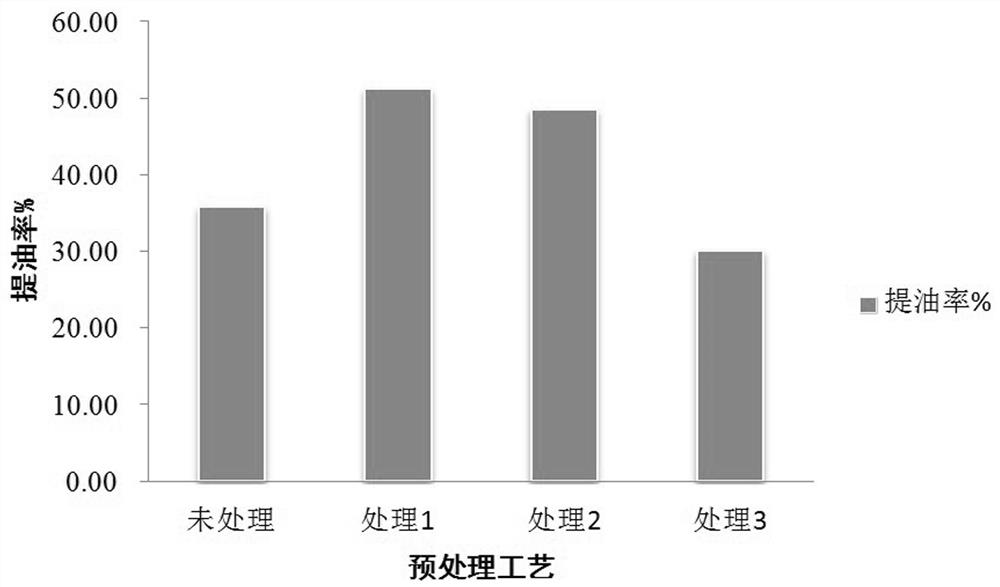

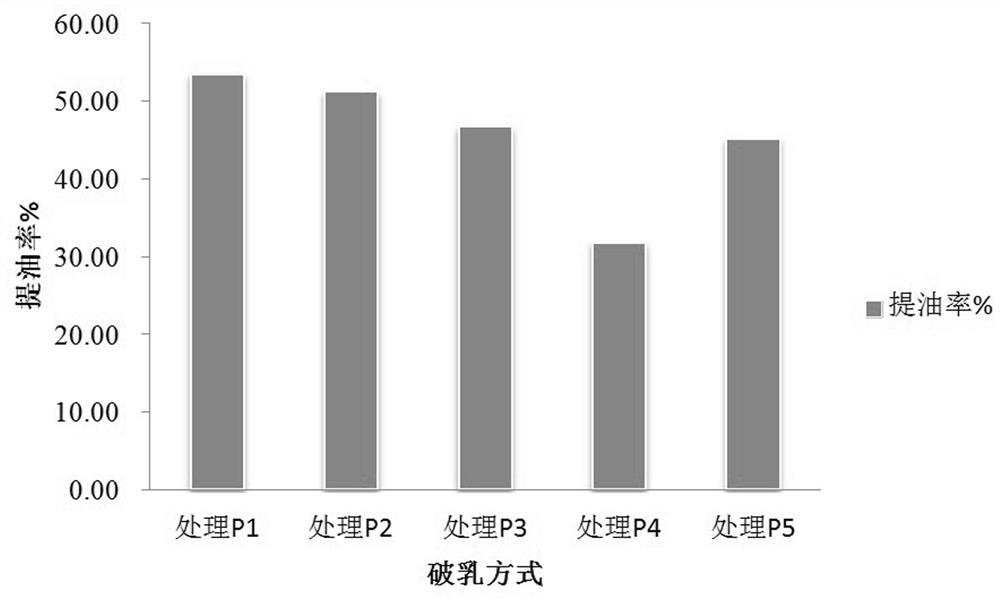

PendingCN113416599AImprove oil yieldReduce oil yieldFatty-oils/fats productionEdible oils/fatsBiotechnologyVegetable oil

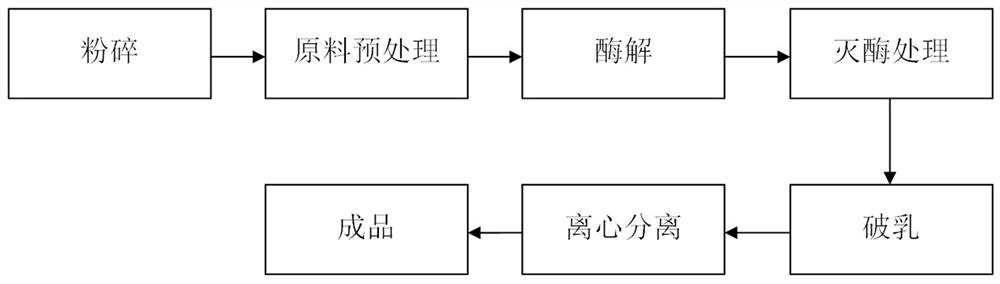

The invention belongs to the technical field of edible vegetable oil processing and extraction, and particularly relates to passion fruit seed oil and a preparation method thereof, wherein the preparation method comprises the following steps: (1) crushing; (2) pretreating raw materials; (3) performing enzymolysis; (4) performing enzyme deactivation treatment; (5) performing demulsification; (6) performing centrifugal separation; and (7) obtaining a finished product. According to the method, an aqueous enzymatic extraction process is adopted, no additives and solvent residues are left except for food enzymes, the treatment temperature and time are strictly controlled in the processing process, and it is guaranteed that natural effective components in the passion fruit seeds are reserved. Meanwhile, the raw materials are pretreated after being crushed, the oil extraction rate is increased to the maximum extent by means of demulsification after enzymolysis, and the problem that the oil extraction rate is low due to the fact that water-oil emulsions are difficult to separate is effectively solved. The passion fruit seed oil prepared by the method is clear, transparent and bright in color and luster, has sour and sweet fruit fragrance, is mild in texture, not greasy, free of irritation, good in quality, safe and stable, and nutrient substances such as linoleic acid, oleic acid and polyphenol are well reserved.

Owner:GUANGXI SUBTROPICAL CROPS RES INST GUANGXI SUBTROPICAL AGRI PROD PROCESSING RES INST

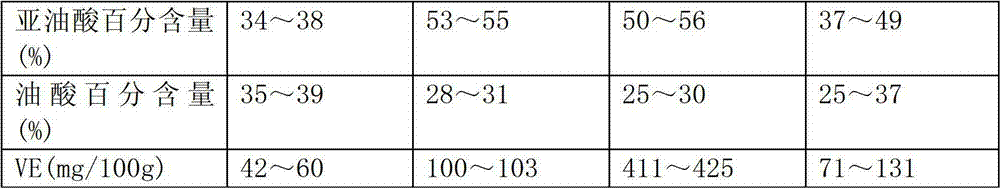

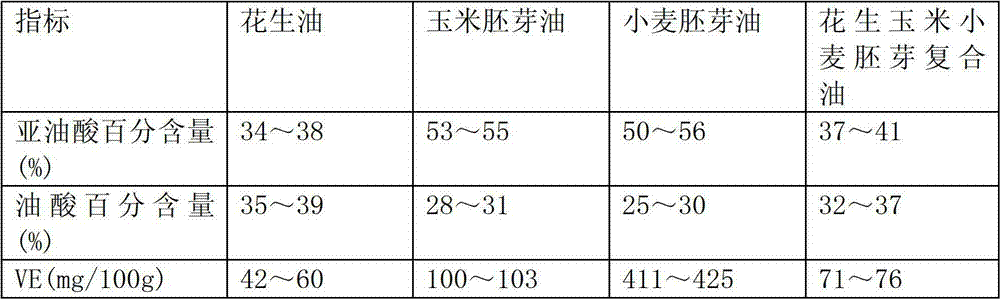

Production method of cold pressing peanut and wheat germ compound oil

ActiveCN102732376BReduce oil yieldImprove oil yieldFatty-oils/fats productionWheat germPre treatment

Owner:INST OF AGRO FOOD SCI & TECH SHANDONG ACAD OF AGRI SCI

Air conditioning system and control method thereof

ActiveCN112781128BImprove energy efficiencyImprove efficacyMechanical apparatusCompression machines with reversible cycleOil separationEngineering

Owner:SHANGHAI HITACHI ELECTRICAL APPLIANCES CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com