Animal fat and production process thereof

A technology of animal fat and production process, applied in the direction of fat oil/fat production, fat oil/fat refining, fat production, etc., can solve the problem of high risk factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

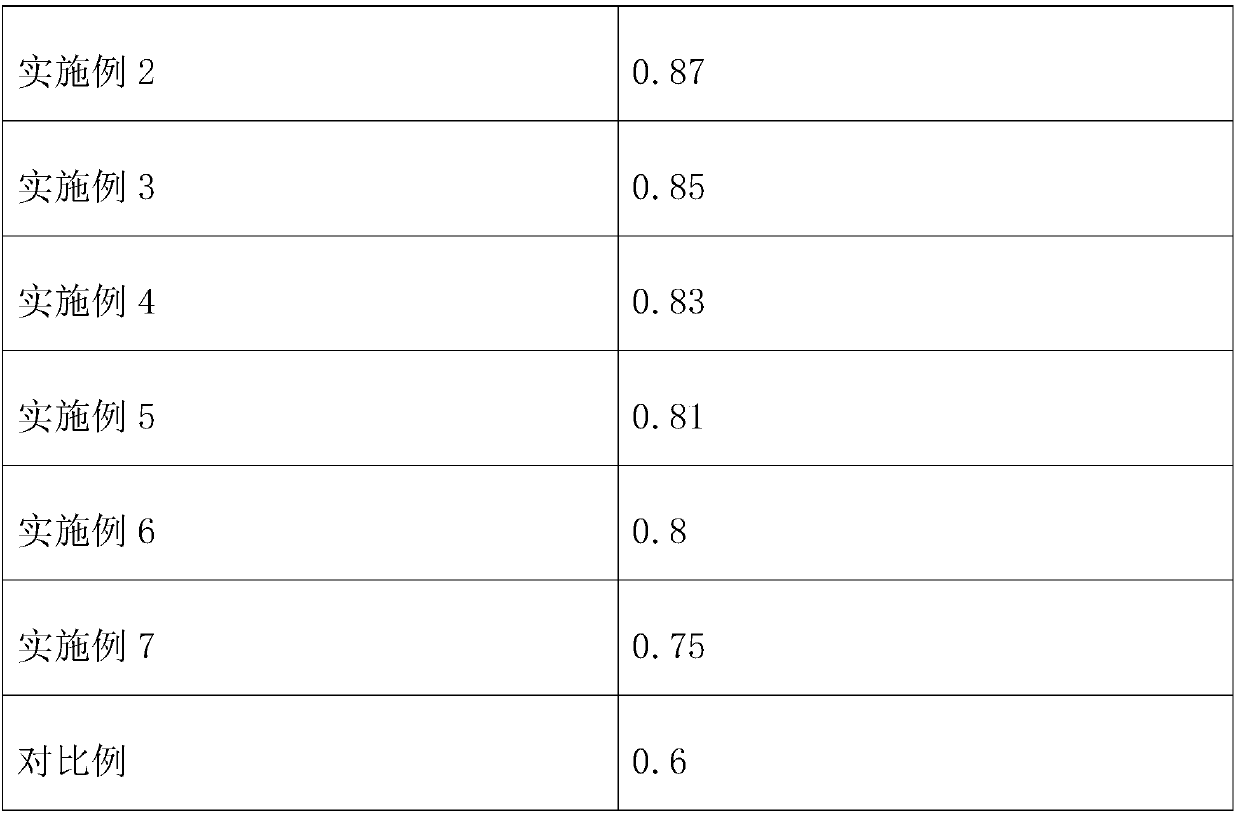

Embodiment 1

[0032] This embodiment provides a kind of animal fat, and it adopts following production process to make:

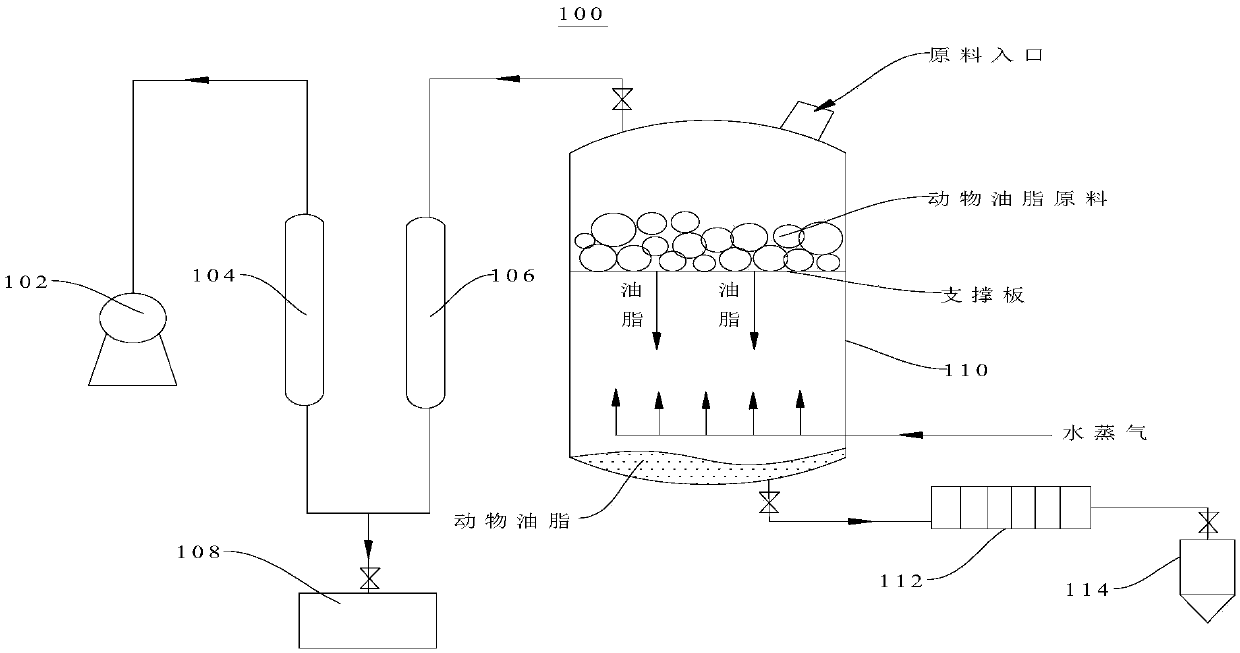

[0033] To provide a specific implementation, please refer to figure 1 , figure 1 Shown is a production process 100 of tallow. The equipment used in this process includes: a vacuum pump 102 , a first condenser 104 , a second condenser 106 , a first storage tank 108 , a stripping tank 110 , a filter 112 and a second storage tank 114 . Wherein, the vacuum pump 102 , the first condenser 104 , the second condenser 106 , the stripping tank 110 , the filter 112 and the second storage tank 114 are connected in sequence. The first storage tank 108 is connected to the pipeline between the first condenser 104 and the second condenser 106, so as to collect the condensed liquid condensed in the two condensers.

[0034] 1 ton of horse fat is washed and chopped, and then the horse fat is put into the support plate in the stripping tank 110 from the raw material inlet. The vacuum pu...

Embodiment 2

[0036] This embodiment provides a kind of animal fat, and its production process is roughly the same as that of Embodiment 1, the difference is:

[0037] The raw material is 1 ton of pig fat, which is purchased directly, cleaned and chopped.

[0038] Only one condenser is used between the vacuum pump 102 and the stripper tank 110 .

[0039] No support plates are used in the stripping tank 110 .

[0040] The medium steam directly adopts the heated air, and the air pressure is 0.2MPa.

Embodiment 3

[0042] This embodiment provides a kind of animal fat, and its production process is roughly the same as that of Embodiment 1, the difference is:

[0043] The raw material is 1 ton of beef fat.

[0044] No condenser is used between vacuum pump 102 and stripper tank 110 .

[0045] The medium steam adopts ethanol steam, and the pressure of ethanol steam is 0.3MPa.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com