Health product with efficacy of assisting in blood fat reduction and preparation method thereof

A technology that assists in lowering blood fat and health care products. It is applied in the direction of fat oil/fat refining, fat production, edible oil/fat, etc. It can solve the problems that the process parameters cannot be effectively adjusted and the proportion of active ingredients is not easy to control, so as to maintain activity and reduce occurrence. The effect of oxidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

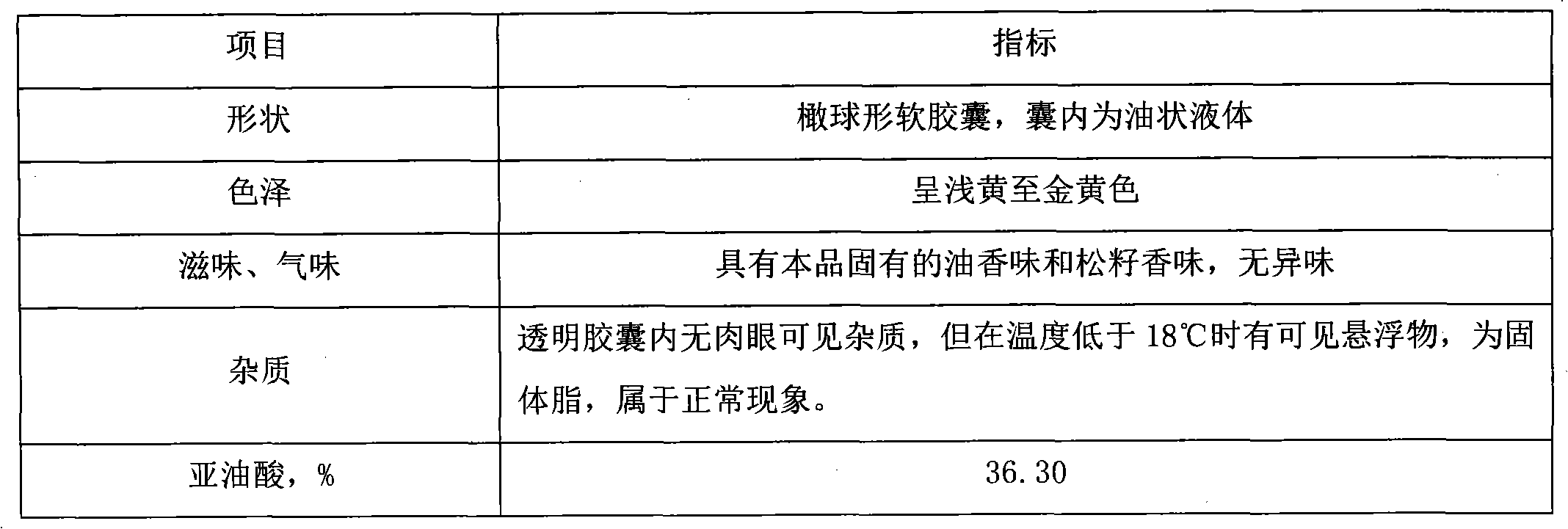

Embodiment 1

[0030] Select 70Kg of high-quality Yunnan pine nuts and 9.16Kg of high-quality perilla seeds that have been preliminarily screened and meet the requirements of moisture and impurities in Yunnan. After cleaning and drying, they are first pressed to initially extract part of the oil, and at the same time crush the raw materials for convenience. The first hydraulic cold pressing process; the crushed raw material is squeezed with a hydraulic cold press at a pressure of 30 Pa, and squeezed twice for about 20 minutes to obtain the crude oil initially extracted; the squeezed crude oil is filtered Filtrate twice with cloth or high-density filter paper in a vacuum state to remove impurities contained in the crude oil, and squeeze and filter with cotton to remove the colloid in the crude oil. The filtration time is 7 hours, and the filtered crude oil The oil is inspected and refined after passing the test; adding 80°C Na 2 CO 3 After the saturated solution and crude oil are stirred and...

Embodiment 2

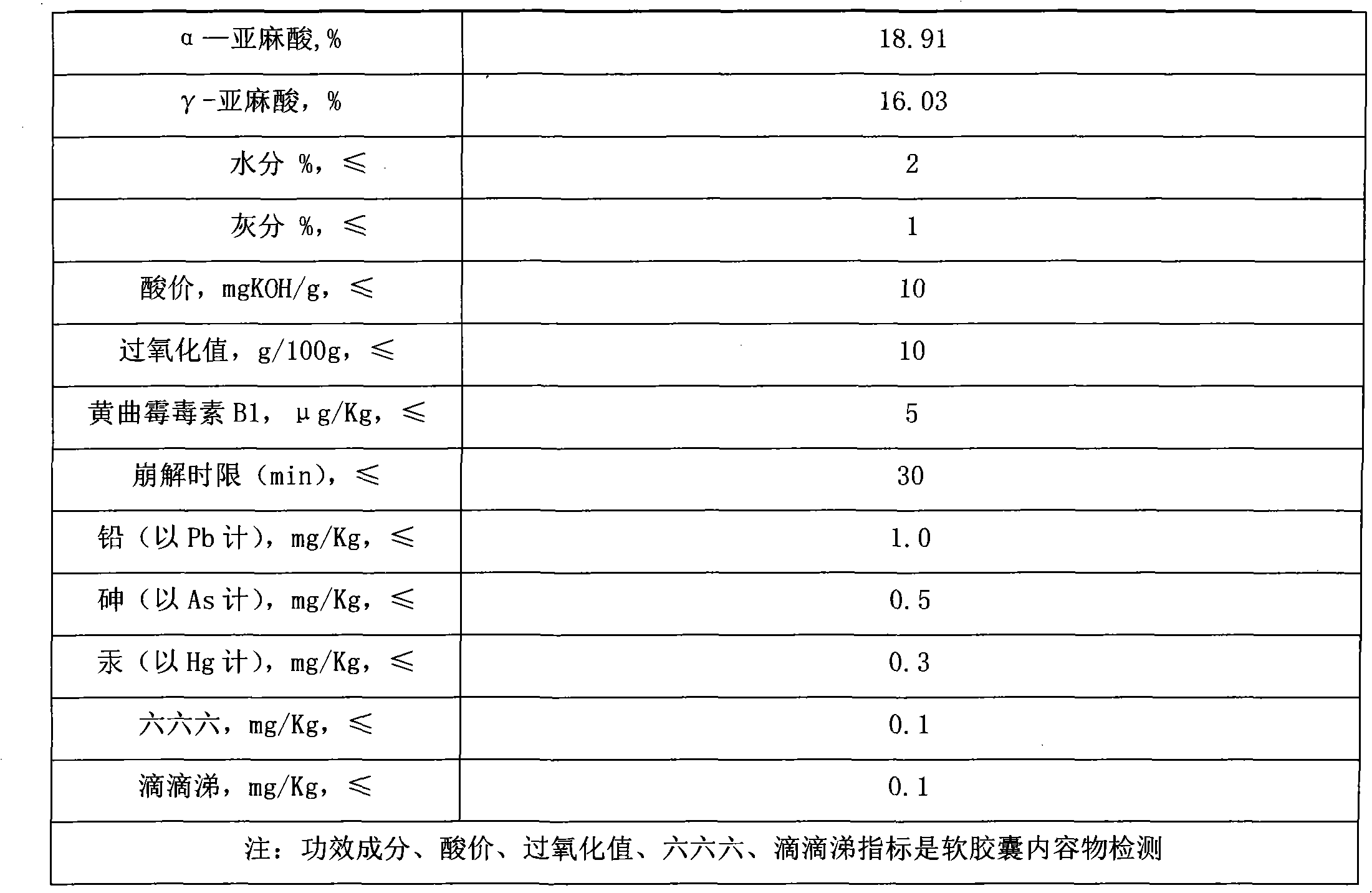

[0038] Select 112Kg of high-quality Yunnan pine nuts and 18.82Kg of high-quality perilla seeds that have been preliminarily screened and meet the requirements of moisture and impurities in Yunnan. After cleaning and drying, they are first pressed to initially extract part of the oil, and at the same time crush the raw materials for convenience. The first hydraulic cold pressing process; the crushed raw material is squeezed with a hydraulic cold press at a pressure of 45 Pa, squeezed 5 times, and the time is about 40 minutes to obtain the crude oil extracted initially; the squeezed crude oil is filtered Filter cloth or high-density filter paper 4 times under vacuum to remove impurities contained in the crude oil, and squeeze and filter with cotton to remove the colloid in the crude oil. The filtering time is 14 hours, and the filtered crude oil The oil is inspected and refined after passing the test; adding 85°C Na 2 CO 3 After the saturated solution and crude oil are stirred ...

Embodiment 3

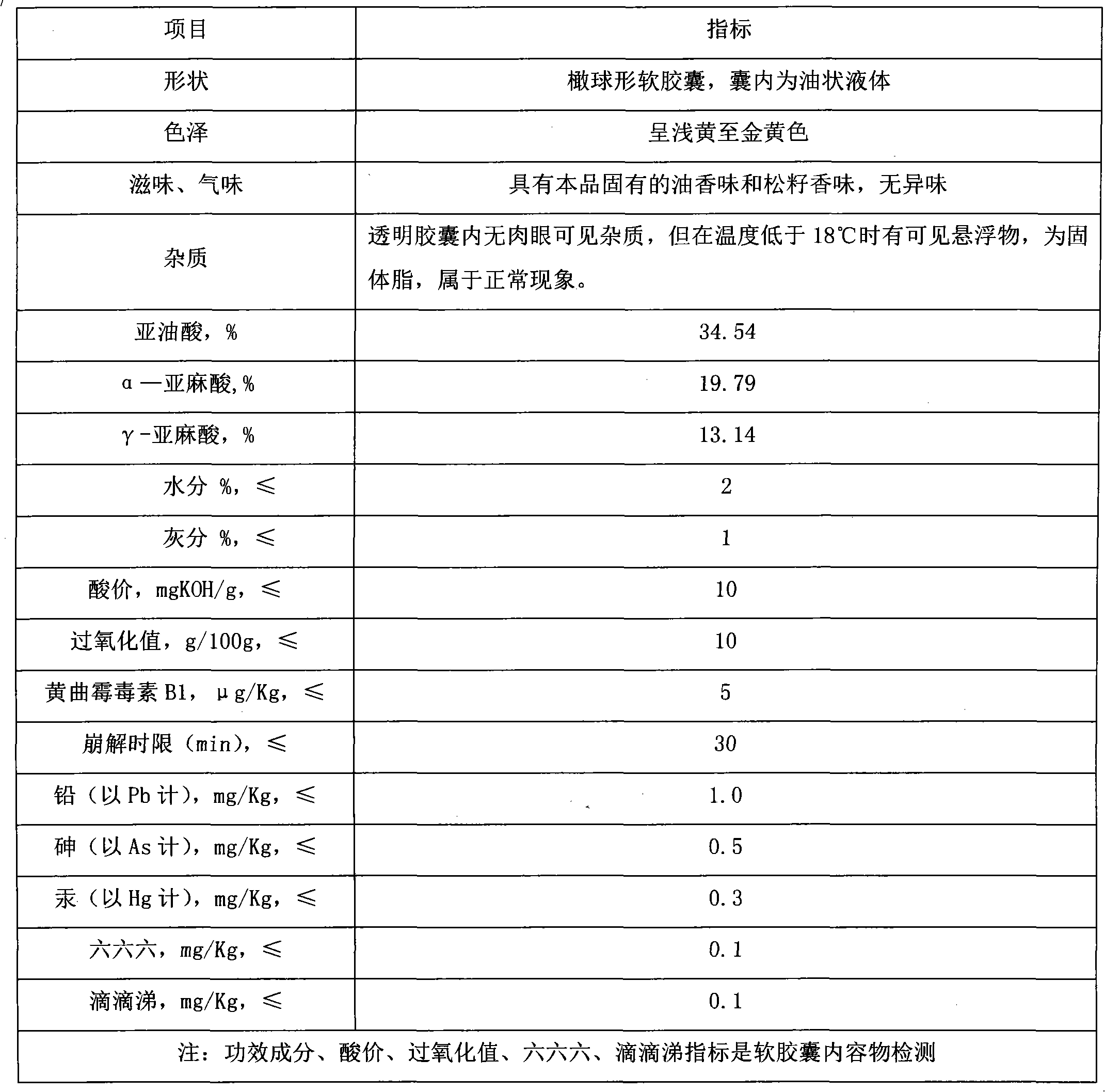

[0044] Select 147Kg of high-quality Yunnan pine nuts and 19.09Kg of high-quality perilla seeds that have been preliminarily screened and meet the requirements of moisture and impurities in Yunnan. After cleaning and drying, they are first pressed to initially extract part of the oil, and at the same time crush the raw materials for convenience. The first hydraulic cold pressing process; the crushed raw material is squeezed with a hydraulic cold press at a pressure of 40 Pa, and squeezed 4 times for about 30 minutes to obtain the crude oil initially extracted; the squeezed crude oil is filtered Filtrate three times with cloth or high-density filter paper in a vacuum state to remove impurities contained in the crude oil, and squeeze and filter with cotton to remove the colloid in the crude oil. The filtration time is 10 hours, and the filtered crude oil The oil is inspected and refined after passing the test; adding 80°C Na 2 CO 3After the saturated solution and crude oil are s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com