A hydraulic combined steam leaching type integrated edible oil press and a method for processing edible oil with the press

An oil press and leaching technology, which is applied in the field of hydraulic combined steam leaching integrated edible oil press, can solve the problems of affecting product quality, not being able to form industrialized production, and low oil yield, so as to reduce steam leaching and oil yield Resistance, solution to chemical additive residues, and the effect of saving labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

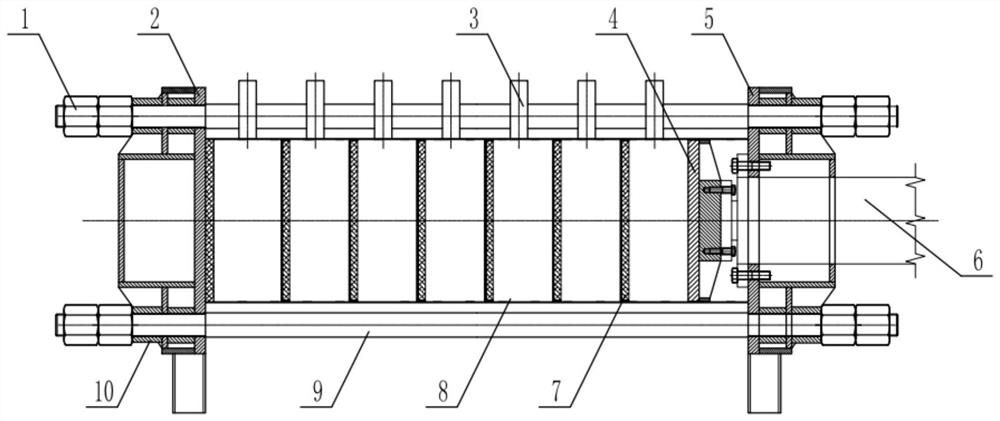

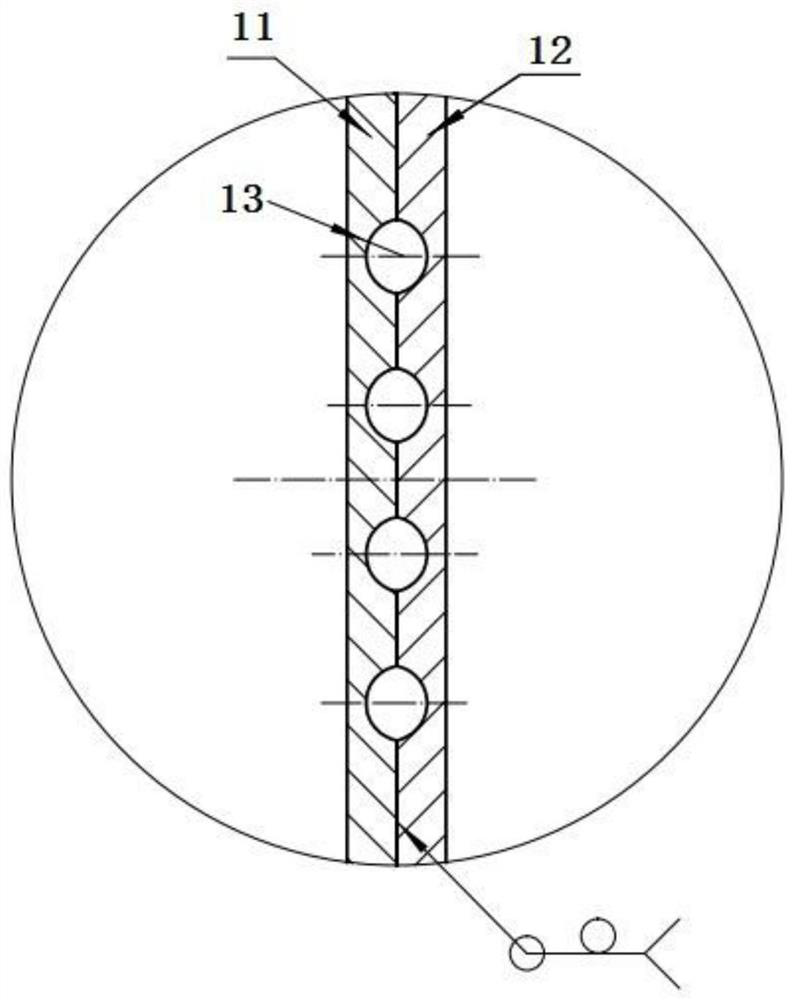

[0040] Specific implementation mode one: (in combination Figure 1-2 ) A hydraulic pressure combined with steam leaching type integrated edible oil press in this embodiment, which includes a press housing, a press cavity 8, a push plate 4 and a hydraulic cylinder 6, and the press cavity 8 is arranged on the press Inside the casing, a horizontal structure is formed. A push plate 4 is arranged in the press cavity 8, and the cylinder body of the hydraulic cylinder 6 is fixedly connected to one end of the press casing. The piston rod of the hydraulic cylinder 6 is connected to the push plate. The plate 4 is fixedly connected, and a plurality of oil-water-vapor separation spacers 7 are placed vertically at equal intervals along the horizontal direction in the press chamber 8, and each oil-water-vapor separation spacer 7 is provided with a plurality of water vapor holes 13 and a plurality of The oil hole, the water vapor hole 13 is connected to the water vapor pipeline, and the uppe...

specific Embodiment approach 2

[0049] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is that the oil plant described in step 1 is corn; the temperature described in step 2 is 85°C; the pressure of hydraulic cylinder 6 in step 3: 140 tons and the propulsion speed: 4cm / min Other steps and parameters are the same as those in Embodiment 1.

[0050] The method of this embodiment not only has no chemical addition, but also improves the oil yield, and the oil yield is 18.1%. Ensure that the color of oil and cake remains the original color, reduce the cost of subsequent processing, and has good economy and low power consumption. It only needs 6 kilowatt-hours of electricity to squeeze one ton of oil.

specific Embodiment approach 3

[0051] Specific embodiment three: the difference between this embodiment and specific embodiment one is: the oil plant described in step one is rice bran; the temperature described in step two is 95°C; the pressure of hydraulic cylinder 6 in step three: 160 tons and the propulsion speed: 6cm / min Other steps and parameters are the same as those in Embodiment 1.

[0052] The method of this embodiment not only has no chemical addition, but also improves the oil yield, and the oil yield is 18.1%. Ensure that the color of oil and cake remains the original color, reduce the cost of subsequent processing, and has good economy and low power consumption. It only needs 6 kilowatt-hours of electricity to squeeze one ton of oil.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com