Production method of cold pressing peanut and wheat germ compound oil

A technology of wheat germ and production method, which is applied in the direction of fat oil/fat production, fat production, etc., can solve the problems of restricting the development of wheat germ oil market, difficulty in extracting wheat germ oil, adverse effects on nutritional quality, etc., and reduce the mixing process of finished oil , Improve the cell wall breaking rate, increase the effect of fiber content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

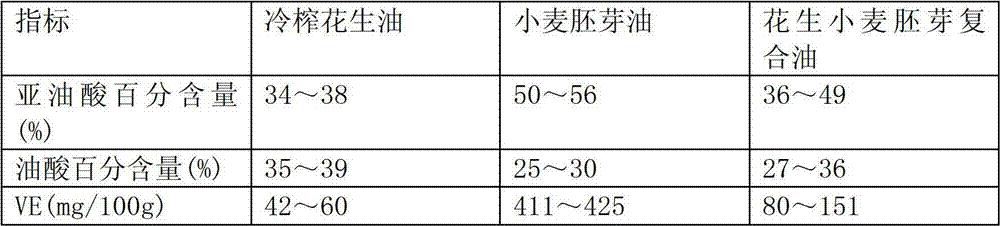

Embodiment 1

[0021] The production method of cold-pressed peanut and wheat germ compound oil comprises the following steps:

[0022] (1) Wheat bran pretreatment: first add wheat bran to a high-speed rotary blade grinder, pulverize for 1 to 3 minutes, and then steam treat the pulverized wheat bran under normal pressure for 20 to 30 minutes;

[0023] (2) Pretreatment of peanut kernels: firstly, put the peanut kernels into a low-temperature dryer for drying. The temperature of the hot air is 80-100°C, and the drying time is 20-30 minutes. Then, it is cooled to make the discharge temperature reach the normal room temperature; then The cooled peanut kernels are immediately sent to the undressing machine to remove the red coat, and then the kernel skin is separated, and the unreddened peanut kernels and the discolored peanut kernels are sorted out; finally, the selected ones that have taken off the red coat are The peanut kernels are added to the splitter for crushing, and the particle size is 4...

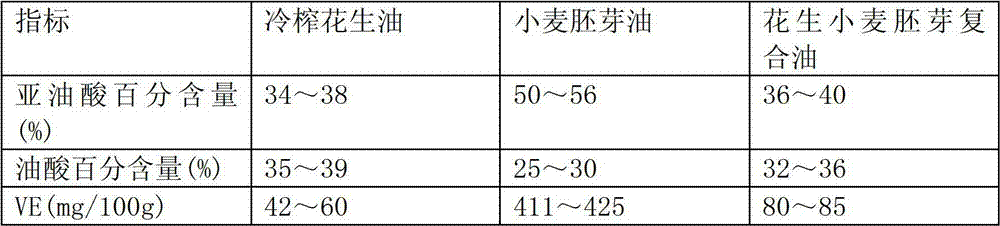

Embodiment 2

[0030] The production method of cold-pressed peanut and wheat germ compound oil comprises the following steps:

[0031] (1) Wheat bran pretreatment: first add wheat bran to a high-speed rotary blade grinder, pulverize for 1 to 3 minutes, and then steam treat the pulverized wheat bran under normal pressure for 20 to 30 minutes;

[0032] (2) Pretreatment of peanut kernels: firstly, put the peanut kernels into a low-temperature dryer for drying. The temperature of the hot air is 80-100°C, and the drying time is 20-30 minutes. Then, it is cooled to make the discharge temperature reach the normal room temperature; then The cooled peanut kernels are immediately sent to the undressing machine to remove the red coat, and then the kernel skin is separated, and the unreddened peanut kernels and the discolored peanut kernels are sorted out; finally, the selected ones that have taken off the red coat are The peanut kernels are added to the splitter for crushing, and the particle size is 4...

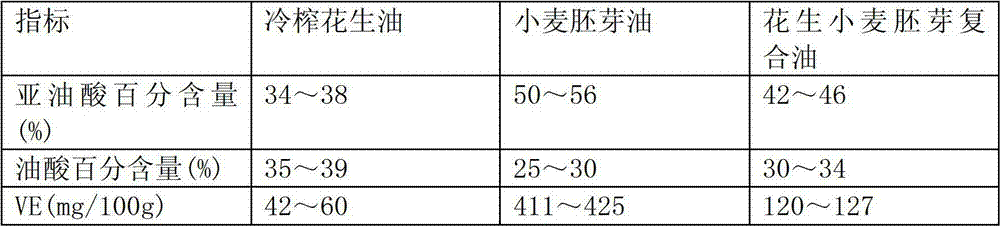

Embodiment 3

[0040] The production method of cold-pressed peanut and wheat germ compound oil comprises the following steps:

[0041] (1) Wheat bran pretreatment: first add wheat bran to a high-speed rotary blade grinder, pulverize for 1 to 3 minutes, and then steam treat the pulverized wheat bran under normal pressure for 20 to 30 minutes;

[0042] (2) Pretreatment of peanut kernels: firstly, put the peanut kernels into a low-temperature dryer for drying. The temperature of the hot air is 80-100°C, and the drying time is 20-30 minutes. Then, it is cooled to make the discharge temperature reach the normal room temperature; then The cooled peanut kernels are immediately sent to the undressing machine to remove the red coat, and then the kernel skin is separated, and the unreddened peanut kernels and the discolored peanut kernels are sorted out; finally, the selected ones that have taken off the red coat are The peanut kernels are added to the splitter for crushing, and the particle size is 4 t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com