Two-component heat-conducting gel as well as preparation method and application thereof

A two-component, gel technology, applied in the direction of modification by conduction heat transfer, cooling/ventilation/heating transformation, etc., can solve the problems of poor high temperature resistance and high hardness of thermally conductive gel, and achieve small thermal weight loss and good resistance. high temperature effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0086] This embodiment provides a two-component thermally conductive gel and a preparation method thereof, the two-component thermally conductive gel includes A component and B component;

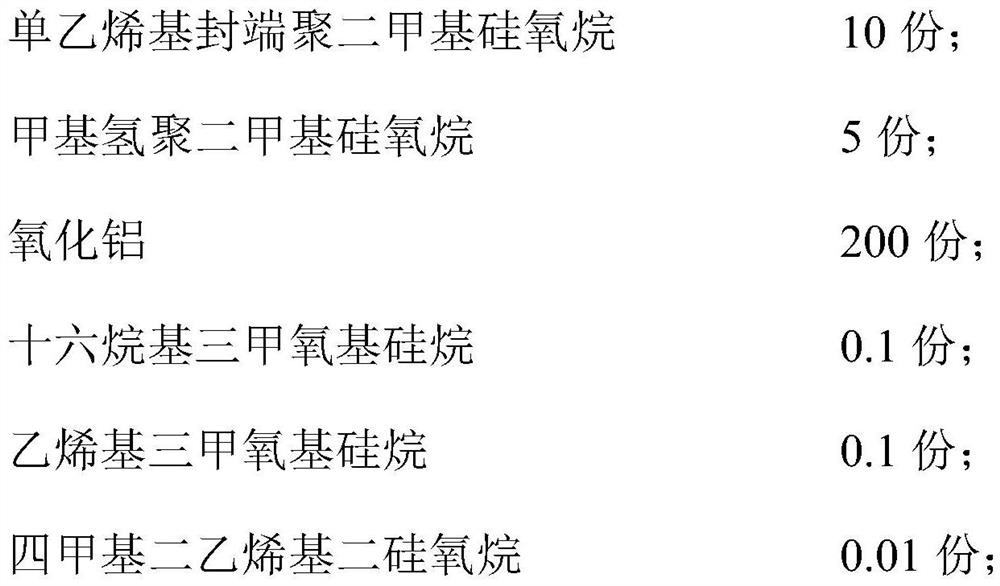

[0087] Described A component comprises the component of following parts by weight:

[0088]

[0089] Described B component comprises the component of following parts by weight:

[0090]

[0091] The viscosity of the monovinyl-terminated polydimethylsiloxane is 1000cps, and the simplified structure is (CH 3 ) 3 SiO[R 1 R 2 SiO 1 / 2 ] p [(R 1 ) 2 SiO 1 / 2 ] q Si(CH 3 ) 2 CH=CH 2 ; where R 1 for -CH 3 , R 2 is -H, p is 20, q is 20;

[0092] The viscosity of the methyl hydrogen polydimethylsiloxane is 100cps, and the simplified structure is H(CH 3 ) 2 Si[SiMeR 3 O] m [SiR 3 HO 3 / 2 ] n [SiO 2 ] s Si(R 4 ) 2 H; where, R 3 is methyl, R 4 is ethyl, m is 10, n is 18, s is 20;

[0093] The particle size of the first thermally conductive filler in the alumina is 40 μm...

Embodiment 2

[0101] This embodiment provides a two-component thermally conductive gel and a preparation method thereof, the two-component thermally conductive gel includes A component and B component;

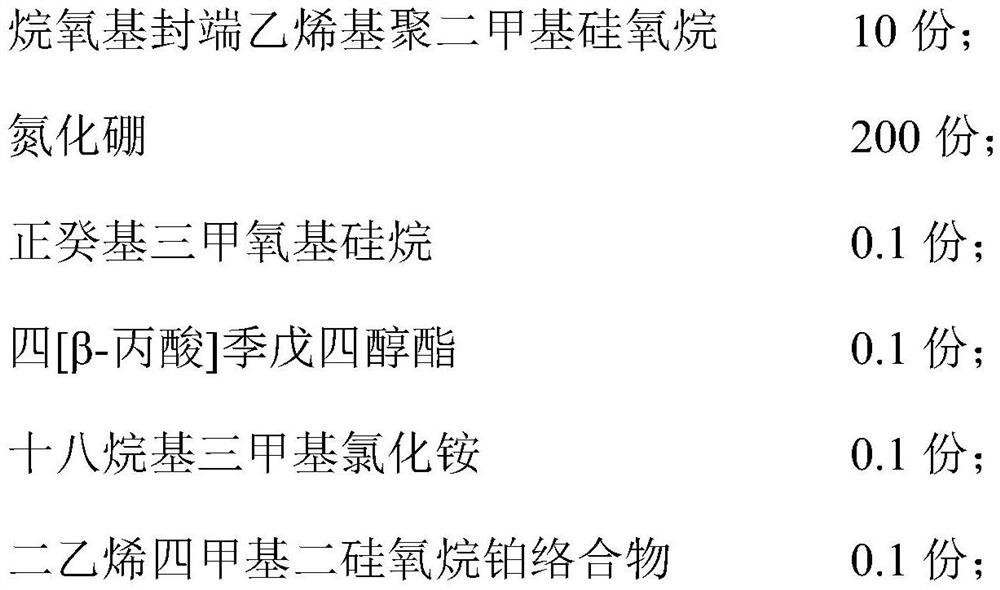

[0102] Described A component comprises the component of following parts by weight:

[0103]

[0104] Described B component comprises the component of following parts by weight:

[0105]

[0106] The viscosity of the monovinyl-terminated polydimethylsiloxane is 500cps, and the simplified structure is (CH 3 ) 3 SiO[R 1 R 2 SiO 1 / 2 ] p [(R 1 ) 2 SiO 1 / 2 ] q Si(CH 3 ) 2 CH=CH 2 ; where R 1 for -CH 2 CH 3 , R 2 for -CH 3 , p is 10, q is 32;

[0107] The viscosity of the methyl hydrogen polydimethylsiloxane is 150cps, and the simplified structure is H(CH 3 ) 2 Si[SiMeR 3 O] m [SiR 3 HO 3 / 2 ] n [SiO 2 ] s Si(R 4 ) 2 H; where, R 3 is ethyl, R 4 is n-propyl, m is 17, n is 19, s is 26;

[0108] The particle size of the first thermally conductive filler in the mag...

Embodiment 3

[0116] This embodiment provides a two-component thermally conductive gel and a preparation method thereof, the two-component thermally conductive gel includes A component and B component;

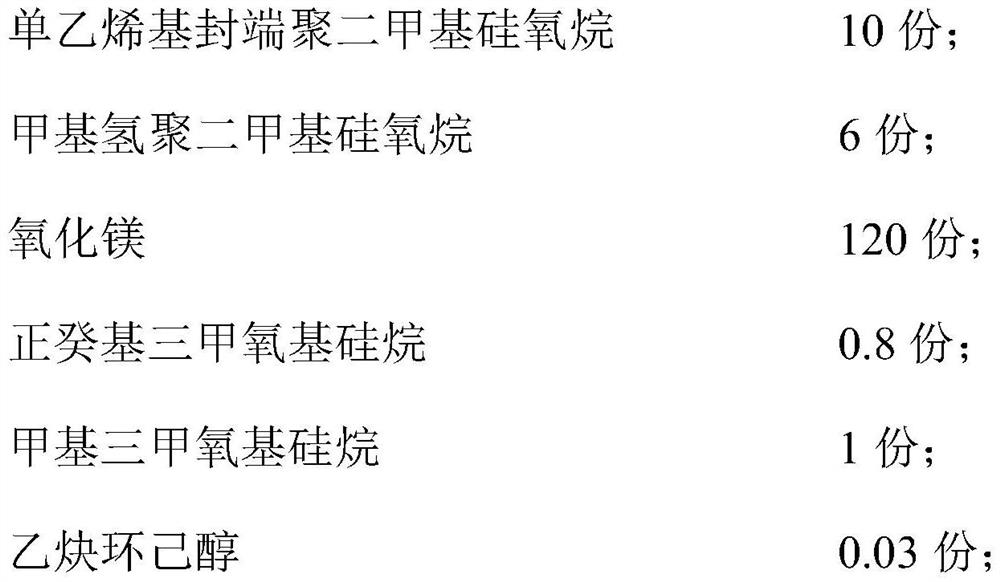

[0117] Described A component comprises the component of following parts by weight:

[0118]

[0119]

[0120]Described B component comprises the component of following parts by weight:

[0121]

[0122] The viscosity of the monovinyl-terminated polydimethylsiloxane is 5000cps, and the simplified structure is (CH 3 ) 3 SiO[R 1 R 2 SiO 1 / 2 ] p [(R 1 ) 2 SiO 1 / 2 ] q Si(CH 3 ) 2 CH=CH 2 ; where R 1 for-C 6 h 5 , R 2 is -H, p is 35, q is 40;

[0123] The viscosity of the methyl hydrogen polydimethylsiloxane is 1000cps, and the simplified structure is H(CH 3 ) 2 Si[SiMeR 3 O] m [SiR 3 HO 3 / 2 ] n [SiO 2 ] s Si(R 4 ) 2 H; where, R 3 is n-butyl, R 4 For n-propyl; m is 36, n is 42, s is 18;

[0124] The particle size of the first thermally conductive filler in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com