Double-row silk thread oiling device

A technology of silk thread and oil tank, which is applied in the direction of processing textile material equipment configuration, liquid/gas/steam yarn/filament treatment, extruded liquid/gas/steam removal other than rollers, etc. Reduce, affect dyeing, weaving and other problems, to achieve the effects of not being easy to entangle and cross, improving the quality of silk threads, and ensuring the right amount of oiling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the examples, but not as a basis for limiting the present invention.

[0017] Example.

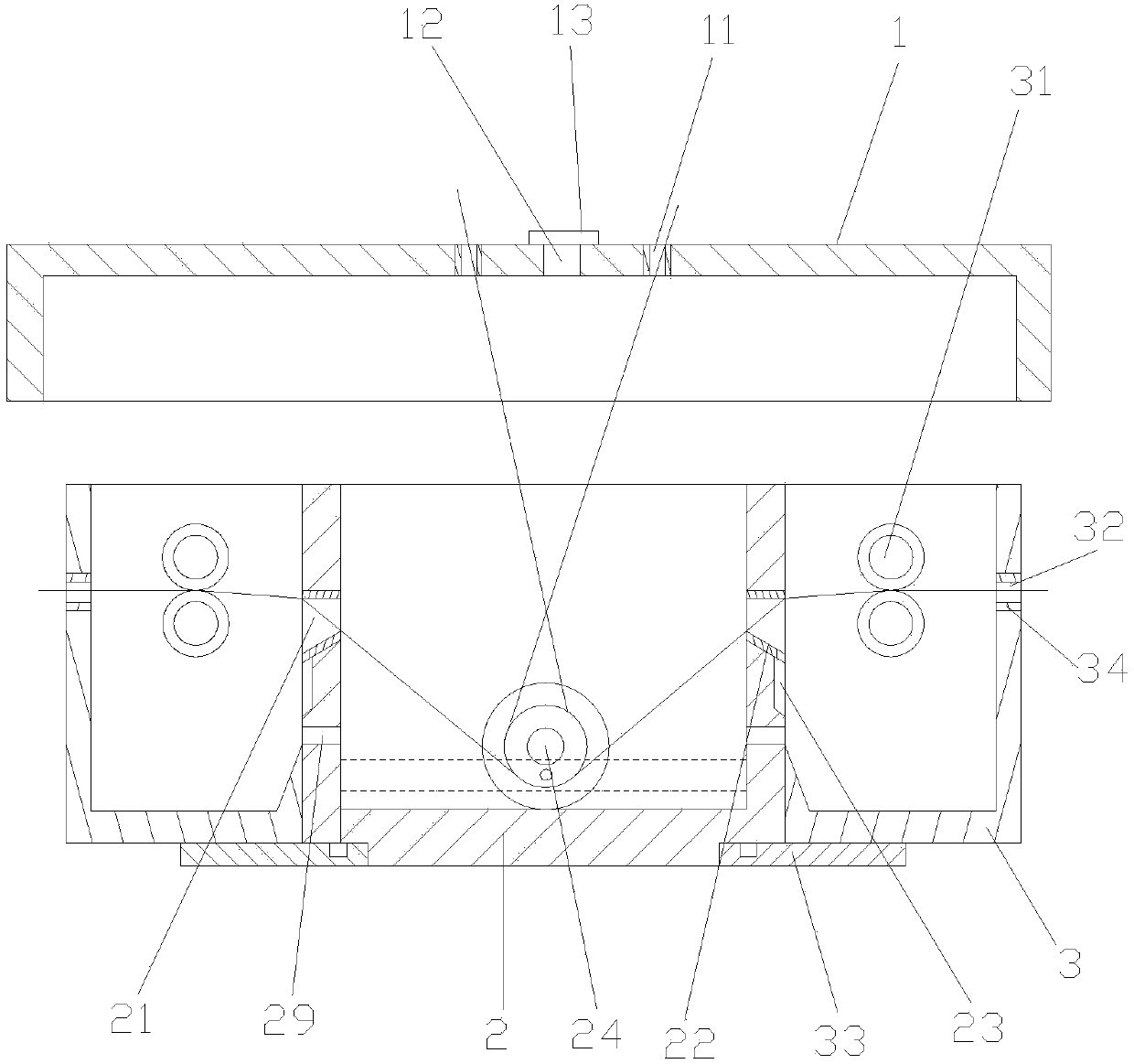

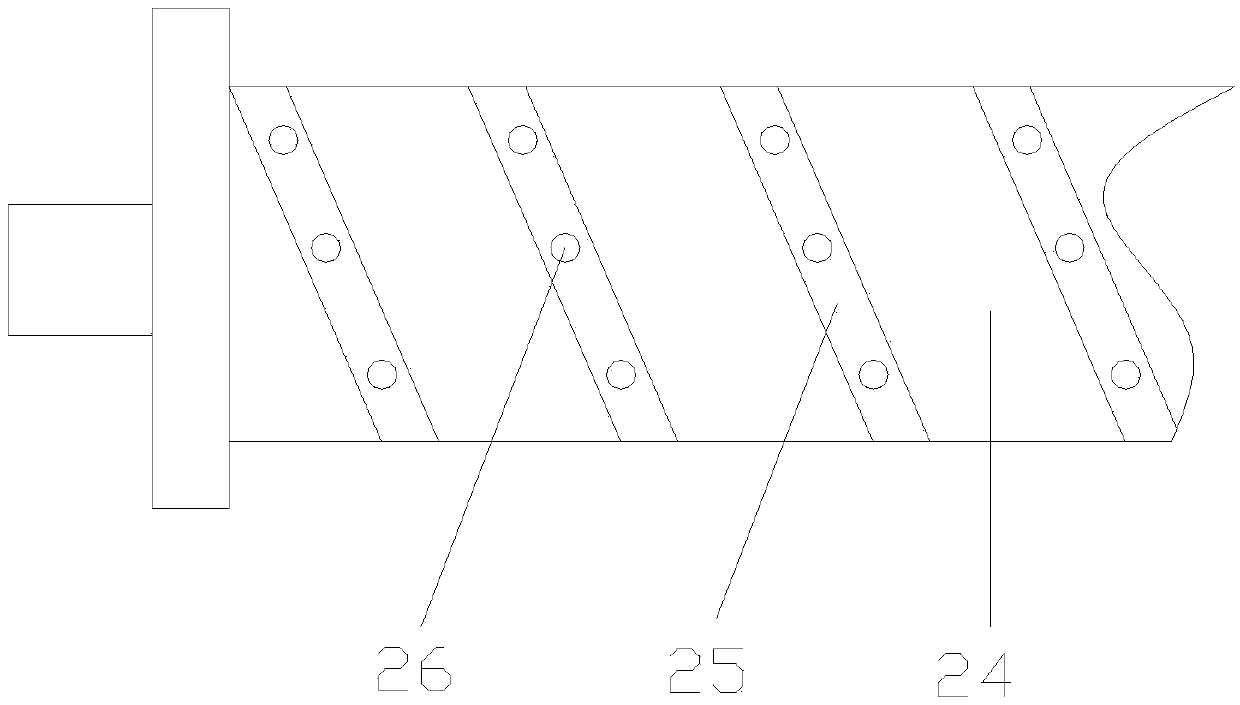

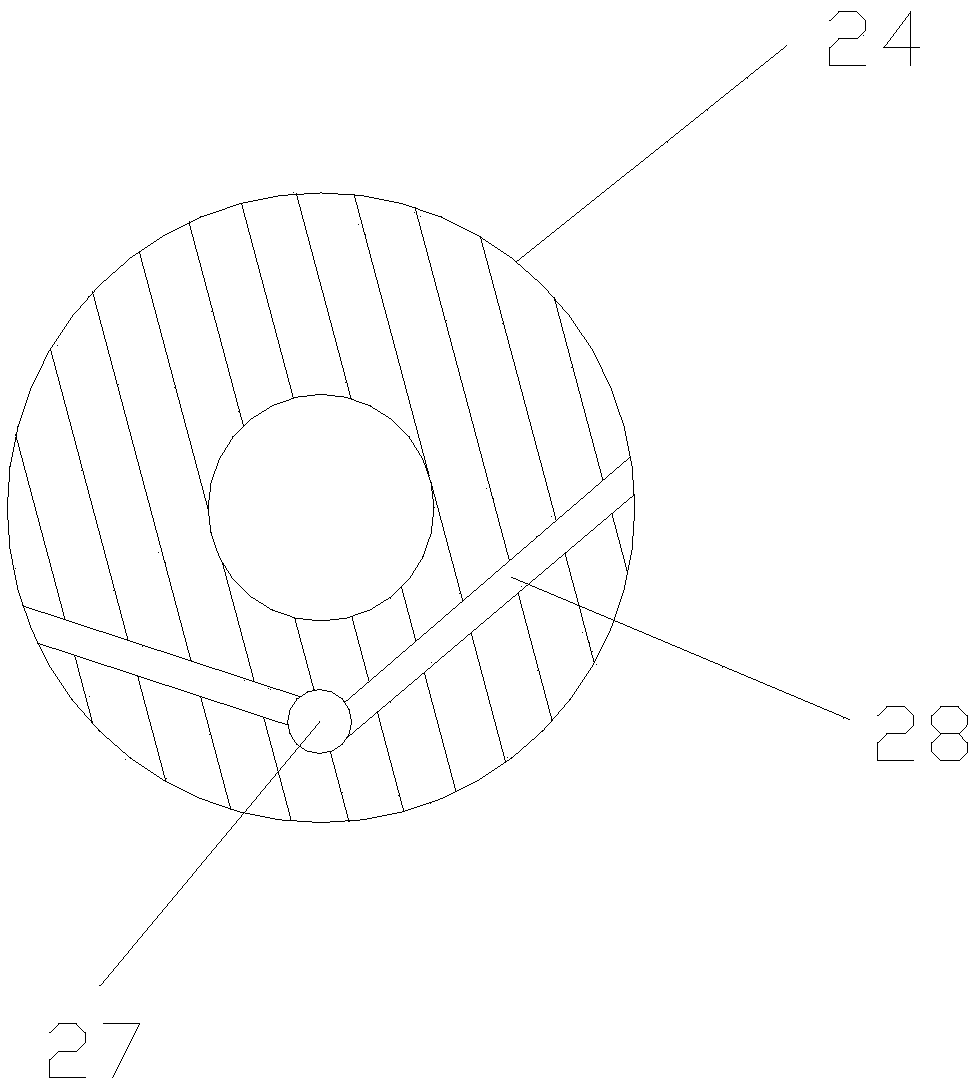

[0018] Such as Figure 1-4 As shown, a double-row wire oiling device includes an oil cover 1 and an upper oil tank 2. An oil overflow tank 3 is provided on both sides of the upper oil tank 2. The oil cover 1 is provided with two rows of staggered wire inlet holes 11. Both sides of the upper oil tank 2 are respectively provided with threading holes 21, the bottom surface of the threading holes 21 is an inclined surface 22, the lowest end of the inclined surface 22 faces the overflow tank 3, and the outer bottom end of the threading holes 21 is provided with a diversion groove 23; Oiling roller 24 is arranged in above-mentioned upper oil tank 2, and the surface of oiling roller 24 is provided with spiral winding groove 25, and the surface of winding groove 25 is provided with some oil outlet holes 26, and the e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com