Implementation method based on 3D (Three Dimensional) printing data processing software platform

A data processing software, 3D printing technology, applied in electrical digital data processing, special data processing applications, instruments, etc., can solve problems such as inability to guarantee the quality of molding, long processing preparation time, increase costs, etc., to reduce memory costs and Waiting time, saving output time, improving the effect of layering efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0080] This embodiment illustrates the relevant theory of the present invention using ANSYS finite element thermal analysis tool and birth-death element technology to simulate the processing process of SLS and SLM.

[0081] (1) Finite element method

[0082] The basic principle of finite element analysis is to discretize the original continuous model body, that is, to decompose the continuous entity into a finite number of small unit blocks that are connected and regular in shape, and describe a certain physical characteristic through the hypothesis of each small unit block. Approximate functions are used to solve the functions of the entire model, thereby converting the original complex infinite degree of freedom problem into a limited degree of freedom problem, which simplifies the solution and is suitable for solving problems such as various complex models, complex boundary conditions, and complex material properties. The solution obtained by the finite element is not an ex...

no. 2 example

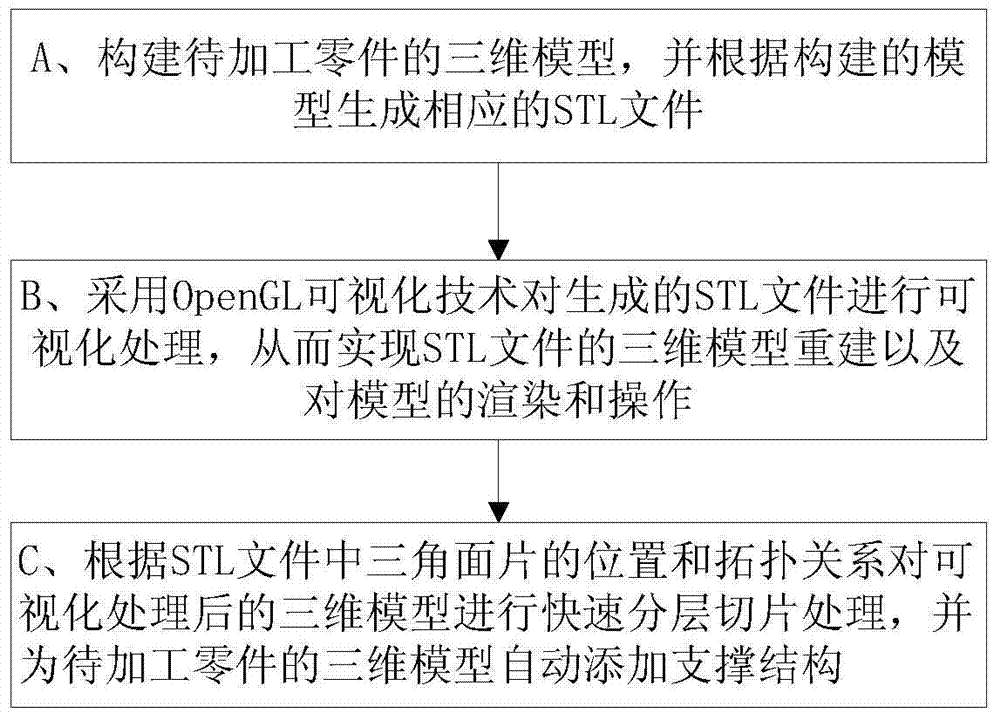

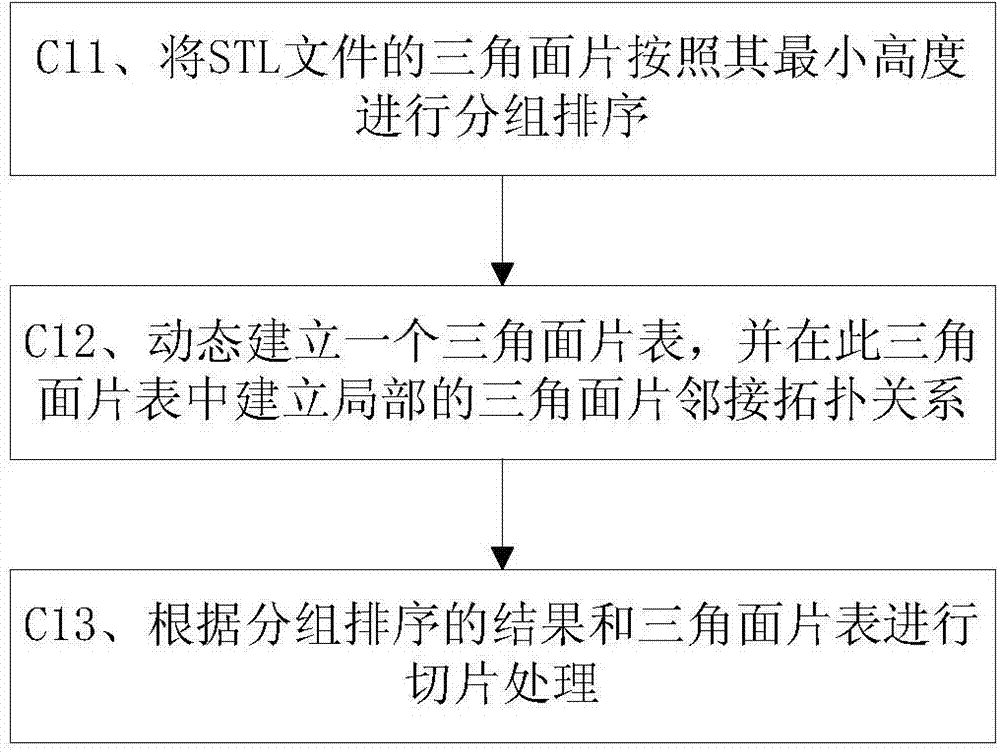

[0087] An implementation method based on the 3D printing data processing software platform of the present invention is divided into three parts: three-dimensional model reconstruction of STL files, rendering and operation of the model, layering of the three-dimensional model and automatic support addition, processing of SLS and SLM Process simulation and parameter selection and design model optimization based on the results. The three parts are described below one by one.

[0088] (1) 3D model reconstruction of STL file and rendering and operation of the model

[0089] The STL format is adopted by most 3D printing systems due to its characteristics of easy conversion, wide range of representation, and simple layering algorithm, and has become the de facto industrial standard in the 3D printing industry. There are two formats of STL files: ASCII format and binary format. Among them, the binary STL file is much smaller than the ASCII format file (generally 1 / 5), but the ASCI...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com